Ever wondered how silk fabric is made? In this video, we’ll take you through the fascinating process of creating this luxurious material.

You’ll learn about the history of silk fabric, the life cycle of silk worms, and the intricate steps involved in harvesting silk cocoons.

We’ll show you how silk filaments are extracted, spun into thread, dyed, printed, and finally woven into beautiful fabric.

So sit back, relax, and prepare to be amazed by the artistry behind silk production.

Table of Contents

The History of Silk Fabric

The history of silk fabric dates back thousands of years. Silk was first discovered in ancient China and quickly became a highly valued commodity. The importance of silk trade cannot be overstated, as it played a significant role in shaping the economies and cultures of many civilizations throughout history.

Silk was considered a luxury item and its production was a closely guarded secret in ancient China. The Chinese government tightly controlled the silk industry and anyone caught smuggling silkworm eggs or mulberry seeds outside of China faced severe punishment. The cultural significance of silk was immense, as it was associated with wealth, status, and royalty. Silk fabric was used to create elaborate garments, tapestries, and even armor.

The Silk Road, a vast network of trade routes connecting China to the Mediterranean, facilitated the exchange of goods and ideas between East and West. This trade route was not only responsible for the spread of silk fabric, but also for the exchange of knowledge, technology, and culture. The Silk Road played a crucial role in promoting cultural diversity and fostering economic growth.

Today, silk fabric continues to be highly valued for its softness, durability, and elegant appearance. It is used in a wide range of applications, from fashion and interior design to medical and industrial uses. The history of silk fabric is a testament to the ingenuity and creativity of ancient civilizations, and its impact on global trade and cultural exchange is still felt to this day.

The Silk Worm Life Cycle

In this discussion, you’ll explore the fascinating life cycle of silk worms and the intricate process of silk production.

You’ll learn about the metamorphosis of silk worms from eggs to larvae, pupae, and finally, adult moths.

Additionally, you’ll uncover the steps involved in silk production. This includes the cultivation of mulberry leaves, the harvesting of silk threads, and the spinning of these threads into luxurious fabric.

Silk Worm Metamorphosis

During metamorphosis, the silk worm spins a cocoon around itself. This remarkable process is both fascinating and awe-inspiring. As you witness the silk worm transforming into a pupa, emotions of wonder and curiosity undoubtedly arise.

Here are two sub-lists to evoke a deeper emotional response:

-

The beauty of transformation:

- The silk worm’s ability to change from a caterpillar to a pupa showcases the wonders of nature.

- Witnessing the silk worm encase itself in a delicate cocoon is a mesmerizing sight.

-

The challenges faced:

- The silk worm’s habitat, often located in mulberry trees, provides a peaceful environment for growth.

- However, lurking predators, such as birds and insects, pose a constant threat to the silk worm’s survival.

As you observe this incredible metamorphosis, you can’t help but appreciate the resilience and beauty of these tiny creatures.

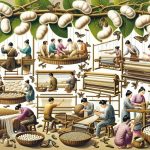

Silk Production Process

As you explore the world of silk production, you’ll discover the intricate steps involved in creating this luxurious material. Silk fabric is known for its softness, smoothness, and lustrous appearance. It is made from the natural fibers produced by silkworms. The process begins with the cultivation of mulberry trees, which provide the leaves that silkworms feed on. The silkworms then spin cocoons made of silk thread, which are carefully collected. The silk thread is then unraveled and spun into yarn. This yarn is then woven into fabric using specialized looms. The resulting silk fabric has a variety of uses, including in clothing, home furnishings, and accessories. Its properties include breathability, moisture-wicking, and hypoallergenic qualities, making it a sought-after material for many applications.

| Silk Fabric Uses | Silk Fabric Properties |

|---|---|

| Clothing | Softness |

| Home Furnishings | Smoothness |

| Accessories | Lustrous appearance |

| Breathability | |

| Moisture-wicking | |

| Hypoallergenic qualities |

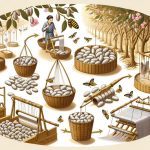

Harvesting Silk Cocoons

In this discussion, you’ll learn about the fascinating life cycle of a silk worm and how it contributes to the silk production process.

You’ll also explore the sustainability of silk and its impact on the environment.

Understanding these key points will give you a deeper appreciation for the intricate process of creating silk fabric.

Silk Worm Life Cycle

You can watch the silk worm life cycle unfold in this fascinating video.

Silk worm reproduction is a crucial part of silk production. Female silk worms release pheromones to attract male silk worms for mating. After mating, the female silk worm lays hundreds of eggs.

These eggs hatch into tiny silk worm larvae, also known as caterpillars. The caterpillars feed on mulberry leaves and grow rapidly, shedding their skin several times in the process. Once they reach their full size, the silk worms spin a silk cocoon around themselves using a single silk thread that can be up to 900 meters long.

Inside the cocoon, the silk worm undergoes metamorphosis and transforms into a moth. The moth then emerges from the cocoon, leaving behind a fine silk thread that can be harvested for silk production.

Silk Production Process

Take a moment to imagine how amazing it is that silk production involves the intricate process of transforming silk worm cocoons into beautiful fabric. The silk industry relies on silk farming, where silk worms are carefully nurtured and their cocoons harvested.

Here are five key steps in the silk production process:

- Silk worm rearing: Silk farmers provide the silk worms with a suitable environment to grow and spin their cocoons.

- Cocoon harvesting: Once the silk worms have spun their cocoons, they are carefully collected from the rearing trays.

- Cocoon boiling: The cocoons are then boiled to soften the silk fibers and remove any impurities.

- Silk thread extraction: The softened cocoons are unraveled to extract the thin silk threads.

- Weaving: The silk threads are spun into yarns, dyed, and then woven into beautiful silk fabric.

The silk production process involves a delicate balance of nurturing silk worms and transforming their cocoons into the luxurious silk fabric we all admire.

Sustainability of Silk

Imagine how sustainable silk production can be when you prioritize ethical practices and use eco-friendly methods in silk farming. By rearing silk worms in a responsible manner and adopting sustainable techniques to harvest cocoons, you can have a positive impact on the silk industry.

Ethical practices involve ensuring the well-being of the silk worms and minimizing harm during the cocoon harvesting process. Eco-friendly methods include using organic and natural materials for feeding the silk worms, as well as avoiding harmful chemicals in the production process.

These practices not only protect the environment but also contribute to the overall quality and value of the silk fabric. By prioritizing sustainability in silk farming, you can make a difference in the industry while enjoying the luxurious and versatile fabric that silk offers.

Silk Filament Extraction

To extract silk filaments, the silk moth spins its cocoon using a single thread that can be up to 900 meters long. Silk filaments are known for their remarkable properties. They are incredibly strong, elastic, and have a natural shine that gives silk its lustrous appearance. These properties make silk filaments highly desirable for a variety of uses.

Silk filaments are commonly used in the production of luxurious fabrics and textiles. The long, fine strands of silk are carefully extracted from the cocoons and then spun into thread. This thread is woven together to create silk fabric that is soft, smooth, and breathable. Silk fabric is highly valued for its comfort and elegance, making it a popular choice for clothing, bedding, and other high-end products.

In addition to its use in the textile industry, silk filaments also have various other applications. The strength and elasticity of silk make it suitable for surgical sutures, as it can withstand tension without breaking. Silk filaments are also used in the production of high-performance materials, such as bulletproof vests and parachutes, due to their exceptional strength-to-weight ratio.

Overall, silk filaments are prized for their unique properties and find wide-ranging uses in both traditional and modern industries.

Silk Spinning Process

The silk moth carefully spins its cocoon using a single thread that can reach up to 900 meters in length. This incredible feat of nature results in the production of silk fiber, which possesses unique properties that make it highly desirable for various fabric applications.

Silk fiber is known for its exceptional strength and durability. It is one of the strongest natural fibers, even surpassing steel in tensile strength. Additionally, silk is incredibly smooth, giving it a luxurious feel against the skin. It is also hypoallergenic, making it suitable for those with sensitive skin.

These exceptional properties make silk fabric highly sought after in the fashion industry. Silk garments are known for their elegance and timeless appeal. Silk dresses, blouses, and scarves are popular choices for special occasions and formal events. The smooth texture of silk also makes it ideal for bedding, providing a comfortable and luxurious sleeping experience.

Moreover, silk fabric is also used in the production of various home furnishings. Silk curtains, upholstery, and pillowcases add a touch of luxury and sophistication to any living space. The natural sheen of silk enhances the visual appeal of these items, making them highly desirable for interior design.

Dyeing and Printing Silk

You can achieve vibrant and colorful designs on silk by dyeing and printing it using various techniques. Silk dyeing techniques allow you to add color to the fabric, creating unique patterns and designs. Silk printing methods, on the other hand, involve transferring designs onto the silk using specialized equipment.

Here are five techniques commonly used in silk dyeing and printing:

-

Tie-Dye: This technique involves folding and tying the silk fabric in various patterns before dyeing. The tied areas resist the dye, creating beautiful and distinct patterns.

-

Shibori: Shibori is a Japanese technique that involves folding, pleating, and binding the silk fabric before dyeing. The bound areas resist the dye, resulting in intricate and organic patterns.

-

Block Printing: Block printing is a method where a carved block is used to apply dye or ink onto the silk fabric. The block is pressed onto the fabric, leaving behind a printed design.

-

Screen Printing: Screen printing involves using a screen with a stencil to apply dye or ink onto the silk fabric. The design is transferred onto the fabric by pushing the dye through the screen with a squeegee.

-

Digital Printing: Digital printing is a modern technique that involves printing designs directly onto the silk fabric using specialized printers. This method allows for highly detailed and complex designs.

Weaving Silk Fabric

Weaving silk fabric involves intertwining threads to create a strong and durable material. Silk is a luxurious fabric known for its smooth texture and lustrous appearance. The weaving process plays a crucial role in determining the quality and characteristics of the final silk fabric.

There are several weaving techniques used in the production of silk fabric, including plain weave, satin weave, and twill weave. Each technique creates a different texture and pattern on the fabric. The choice of weaving technique depends on the desired outcome and the properties of the silk fabric.

Silk fabric has several unique properties that make it highly sought after. It is lightweight, breathable, and has excellent draping qualities. Silk is also known for its natural sheen and ability to absorb moisture, keeping the wearer cool in hot climates. Additionally, silk fabric is hypoallergenic and resistant to wrinkles.

Weaving silk fabric requires skill and precision to achieve the desired results. The threads used in the weaving process can vary in thickness and color, allowing for endless possibilities in creating intricate patterns and designs. Whether it’s a delicate silk scarf or an elegant evening gown, the weaving techniques and properties of silk fabric make it a timeless and luxurious choice.

Finishing and Care for Silk Fabric

To maintain the quality and longevity of silk fabric, it’s important to follow proper care instructions. Silk fabric is known for its luxurious feel and delicate nature. It is made from the fibers produced by silkworms, which are then spun into silk threads. Silk fabric has unique properties that make it desirable, such as its natural sheen, smooth texture, and excellent draping ability.

When it comes to caring for silk fabric, there are a few important guidelines to keep in mind. First, always check the care label for specific instructions, as different types of silk may have different requirements. In general, silk should be hand washed or machine washed on a delicate cycle using cold water and a mild detergent. Avoid using bleach or harsh chemicals, as they can damage the fabric.

After washing, silk should be air dried by laying it flat on a clean towel. Avoid wringing or twisting the fabric, as this can cause it to lose its shape. Ironing silk should be done on a low heat setting, preferably with a pressing cloth to protect the fabric. Store silk fabric in a cool, dry place, away from direct sunlight and moisture.

Conclusion

Now you know how silk fabric is made.

From the history of silk to the life cycle of silk worms, harvesting cocoons, and extracting silk filaments, the process of making silk involves many steps.

After spinning and dyeing the silk, it is woven into beautiful fabric.

Remember to take proper care of your silk fabric to ensure its longevity and enjoy its luxurious feel for years to come.

- What We Commonly Call a Polyamide: Nylon Explained - July 1, 2025

- The Most Common Example of a Polyamide Is Nylon - July 1, 2025

- The Diameter of a Polyamide Fiber: A Technical Measurement - July 1, 2025