Silk is made from the protein secretions of silkworms. These amazing creatures spin cocoons that are unraveled to create silk fibers. The threads are then delicately spun into luxurious fabric, showcasing centuries-old craftsmanship. If you're curious to learn more about the fascinating process and properties of silk, keep exploring its intricate production and rich history.

Table of Contents

Key Takeaways

- Silkworms create silk fibers by spinning cocoons.

- Bombyx mori silkworms are mainly used for high-quality silk.

- Each cocoon yields a single filament for silk thread.

- Silk is crafted from protein secreted by silkworms.

- Boiling cocoons aids in unraveling silk fibers.

Silk Fabric: Properties and Characteristics

Exploring the properties and characteristics of silk fabric reveals its remarkable strength, softness, and alluring shimmer. Silk fabric, derived from the fibroin protein secreted by silkworms, boasts a unique triangular prism-like structure that contributes to its exceptional qualities. The strength of silk is unparalleled, making it one of the most durable natural fibers available. This strength is further complemented by the fabric's softness, which feels luxurious against the skin.

Additionally, silk fabric is renowned for its shimmering effect, giving it a lustrous appearance that catches the light beautifully. This shimmering quality is a result of the way the fibers reflect and refract light, creating an enchanting visual appeal. The combination of strength, softness, and shimmer makes silk fabric a coveted choice for various high-end garments and luxurious textiles. Understanding these distinctive properties and characteristics enhances appreciation for the craftsmanship and quality inherent in silk production.

Silk Fabric Production Process Explained

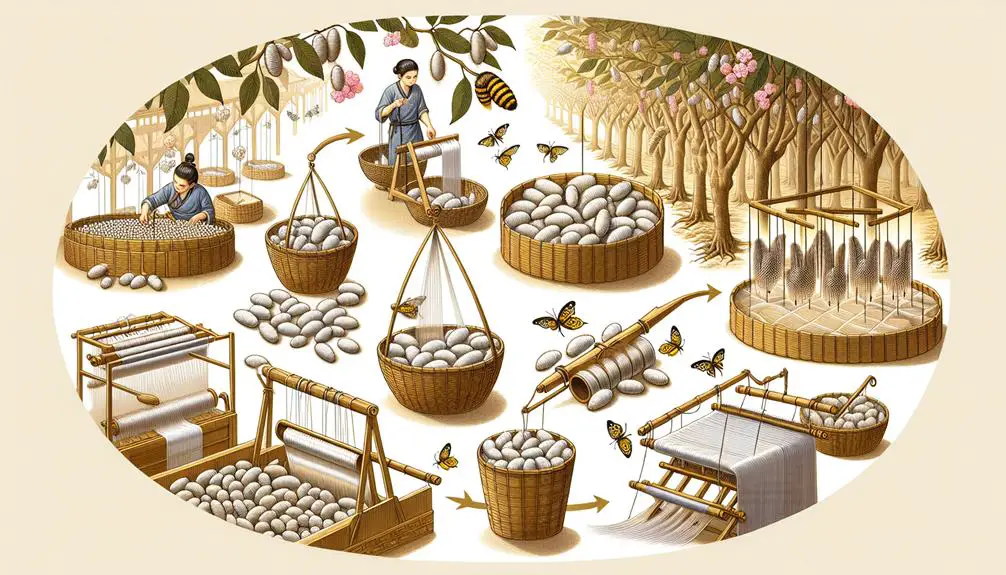

Curious about how silk fabric is made from start to finish? The silk production process involves several intricate steps that transform silkworm cocoons into luxurious fabric. Here's a breakdown:

- Silkworm Cultivation: The process begins with nurturing silkworms from larvae to maturity.

- Cocoon Weaving: Silkworms feed on mulberry leaves and spin cocoons made of silk fibers.

- Cocoon Harvesting: Cocoons are carefully collected before the moths emerge, ensuring the preservation of the long silk fibers inside.

- Fabric Production: The extracted silk fibers are unwound, twisted, dyed using various methods, and woven into stunning silk fabric.

This meticulous process highlights the craftsmanship involved in creating silk textiles. From the care of the silkworms to the dyeing process, each step contributes to the exceptional quality and beauty of silk fabrics.

Significance of Silkworms in Silk Production

Silkworms are essential to silk production as they produce the fibroin protein used to create silk fibers.

The Bombyx mori silkworms are favored for their high-quality silk output.

Each silkworm cocoon contains a single filament that can be unraveled to make silk thread.

Silkworm Life Cycle

Spinning their cocoons from delicate silk fibers, silkworms undergo a remarkable transformation essential to the production of silk.

- Silkworms are the larvae of the silkmoth Bombyx mori, important to silk production.

- They spin cocoons made of silk fibers to undergo metamorphosis into silkmoths.

- The silk fibers are harvested from the cocoons after the silkworms complete their transformation.

- Each silkworm cocoon can yield a significant amount of silk thread for fabric production.

Understanding the life cycle of silkworms is fundamental to appreciating the sustainable and traditional process behind silk making. It's fascinating how these tiny creatures play such a significant role in producing one of the most luxurious fabrics known to us.

Silk Fiber Production

Silk production depends greatly on the natural process of silkworms spinning themselves into cocoons for fiber extraction. Silkworms, specifically the larvae of the Bombyx mori moth, play an essential role in creating silk threads. Harvesting involves carefully extracting these threads from the cocoons the silkworms have spun.

It takes about 2,500 silkworms to produce just one pound of raw silk, highlighting the importance of these insects in silk production. This natural process of silkworms forming cocoons is crucial for obtaining the high-quality silk fibers used in various luxurious textiles. The meticulous care and attention given to silkworms during this stage guarantee the production of fine silk materials renowned for their sheen and durability.

Unraveling Silk: From Cocoon to Fiber

Carefully unwinding delicate silk threads from cocoons reveals the intricate process of transforming raw fibers into luxurious silk yarn. Unraveling silk involves delicately extracting the fibers from silkworm cocoons, ensuring the preservation of the silk's quality. This meticulous process is essential for creating high-quality silk yarn that serves as the foundation for exquisite silk textiles.

- Silkworm cocoons are carefully heated to preserve the silk fibers and prevent the worms from emerging prematurely.

- The extracted silk fibers are then twisted together to form silk yarn, a pivotal step in the production of silk textiles.

- Post-production processes such as dyeing, bleaching, and weaving are necessary to enhance the appearance and durability of the silk fabric.

- The transformation of silk fibers into yarn marks the beginning of the journey towards creating luxurious silk products that are highly valued for their softness and sheen.

Spinning Silk Threads: A Delicate Craft

Gentle hands craft intricate silk threads from the protein secreted by silkworms, embodying a delicate artistry that defines the essence of silk production. The spinning of silk threads is a meticulous process that demands skill and precision. Skilled artisans employ traditional techniques to carefully unravel and twist the fine fibers together, creating strands of silk that are both strong and lustrous. The quality of the silk threads is paramount as it directly impacts the final texture of the fabric. Every twist and turn in the spinning process contributes to the overall integrity of the silk thread, ensuring a smooth and consistent appearance.

Watching artisans spin silk threads is like witnessing a dance of expertise and tradition. Each movement is deliberate, each fiber handled with care. The final product is a tribute to the dedication and mastery of these artisans, resulting in silk threads that aren't just threads but a symbol of centuries-old craftsmanship.

Boiling Cocoon: Key Step in Silk Making

When boiling the cocoon, we soften it to separate the silk fibers needed for production. This technique plays an essential role in silk-making by dissolving sericin and allowing the extraction of long, continuous silk threads.

Boiling is a critical step in obtaining the raw silk material essential for weaving and fabric creation.

Cocoon Boiling Process

Boiling cocoons plays an important role in the silk production process. It softens them for easier extraction of the valuable silk fibers. During this process, boiling water is used to unravel the silk fibers easily for extraction. Heat is applied to dissolve the sericin, a sticky substance that binds the silk fibers together.

Boiling also serves the purpose of killing the pupae inside the cocoons, preventing them from emerging as moths. Subsequently, the softened cocoons are carefully unraveled to extract the long silk fibers for further processing.

Silk Production Technique

As the cocoons are heated during the silk production process, they undergo a transformation that facilitates the extraction of valuable silk fibers. Boiling water is used to soften the sericin, a natural gum coating the silk fibers, making it easier to extract the silk fibers intact.

This step is vital as it prevents the mature silkworms from emerging and damaging the fibers. Once the silk fibers are carefully extracted from the softened cocoons, they're twisted together to form yarn. This yarn is then used in the intricate process of weaving to create luxurious silk textiles.

The boiling process guarantees the quality and strength of the silk threads, preserving the integrity of the final product for various uses.

Importance of Boiling

During the intricate process of silk making, the pivotal step of boiling cocoons serves to soften the fibers, facilitating their unraveling to extract valuable silk threads.

- Boiling cocoons helps in separating the silk fibers from the sericin, a natural gum that holds the cocoon together.

- This process sterilizes the silk fibers and removes any impurities or debris present.

- Proper boiling guarantees the silk fibers remain intact and undamaged during the unraveling process.

- Boiling cocoons at specific temperatures and durations is essential for high-quality silk production.

Boiling is an essential stage in silk production, ensuring the fibers are prepared for the next steps in creating luxurious and durable silk products.

Luster and Texture of Silk Fabric

Radiating a luxurious luster and boasting a soft texture, silk fabric stands out as a highly coveted material in the textile industry. The natural sheen of silk comes from its distinctive triangular prism-like structure, allowing it to reflect light beautifully. This quality gives silk a premium quality that's unmatched by other fabrics.

The soft texture of silk is another key feature that sets it apart; it feels delicate and smooth against the skin, making it a top choice for high-end fashion and luxurious home decor.

The shimmering effect of silk fabric further enhances its appeal, making it a popular option for sophisticated clothing and accessories. Its luster and texture not only add to its aesthetic charm but also contribute to its durability and overall value. These characteristics make silk a preferred material for a wide range of luxury applications, where its premium quality truly shines.

Ethical Concerns in Silk Production

Silk production raises ethical concerns primarily due to the traditional practice of killing silkworms during the harvesting process. This practice has led to debates within the fashion industry regarding the treatment of animals in silk production.

As the demand for ethical practices increases, alternatives such as 'peace silk' or 'ahimsa silk' have emerged, offering ways to extract silk fibers without causing harm to the silkworms.

The controversial method of boiling silkworms alive to obtain silk has also sparked ethical discussions around the treatment of animals in the industry. Ethical silk production methods prioritize the well-being of animals and aim to promote sustainable practices, resonating with consumers who are seeking cruelty-free silk products that align with their values.

Silk Fiber Extraction Techniques

When exploring the process of silk production, understanding the techniques involved in extracting silk fibers is essential for appreciating the craftsmanship behind this luxurious fabric. Silk fiber extraction begins with boiling silkworm cocoons to soften them, making it easier to unravel and extract the long silk fibers. Skilled handling is vital during this process to prevent any damage to the delicate fibers. Once the fibers are extracted, techniques like reeling and spinning are employed to twist them into yarn for weaving. Finally, the extracted silk fibers are dyed, woven, and finished to create the luxurious silk fabric that we all admire. The table below summarizes the key steps involved in silk fiber extraction:

| Step | Description |

|---|---|

| Boiling Silkworm Cocoons | Softening the cocoons for unraveling |

| Reeling and Spinning | Extracting and twisting silk fibers into yarn |

| Dyed and Woven | Coloring, weaving, and finishing the silk fabric |

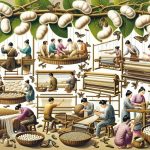

Crafting Silk: Traditional Methods

Crafting silk through traditional methods involves a meticulous process that has been honed over centuries for its exquisite results. Traditional silk production encompasses various steps that require skill and precision:

- Harvesting Silkworm Cocoons: Silkworm cocoons are carefully collected to preserve the delicate silk fibers within.

- Extracting Silk Fibers: Boiling the cocoons helps in extracting the silk fibers, which are then unraveled and prepared for spinning.

- Weaving: Skilled artisans weave the silk fibers into luxurious fabrics, showcasing intricate patterns and designs.

- Dyeing: The silk threads are dyed using natural or synthetic dyes to achieve a spectrum of vibrant colors for the final textiles.

These age-old techniques highlight the artistry and dedication involved in silk production. From the initial stages of nurturing silkworms to the final steps of weaving and dyeing, each phase contributes to the creation of the coveted silk fabric known for its softness, sheen, and timeless appeal.

Industrial Scale Silk Production

I'll kick off by shedding light on the industrial scale silk production methods and techniques used in countries like China, India, Uzbekistan, and Thailand.

This includes the intricate processes involved in silk manufacturing on a large scale, from rearing silkworms to harvesting silk threads.

Understanding these techniques is vital in grasping the sheer magnitude and complexity of the global silk industry.

Silk Manufacturing Process

Silk is manufactured on an industrial scale through a meticulous process that begins with the secretion of fibroin protein by silkworm larvae to create silk fibers in their cocoons. The process involves several key steps:

- Silkworm larvae secrete fibroin protein to create silk fibers in their cocoons.

- Heating cocoons prevents mature worms from emerging.

- Silk threads are unraveled, twisted together, dyed, and processed into yarn for weaving.

- Post-production processes are essential for enhancing silk yarn attributes.

This intricate process results in the production of high-quality silk that's utilized in various industries, such as parachute manufacturing and surgical sutures, due to its exceptional strength and antibacterial properties.

Silk Production Techniques

Efficiently managing the intricate process of industrial-scale silk production necessitates meticulous attention to detail and specialized expertise. When it comes to silk production, the journey from silkworms to the final fabric involves various steps.

| Process | Description |

|---|---|

| Raising Silkworms | Cultivating silkworms on a large scale to produce the necessary cocoons for extracting silk fibers. |

| Boiling Water | Softening the cocoons in boiling water to unravel the fibers efficiently for further processing. |

| Raw Silk | Extracting the silk threads from the cocoons, which are then processed to create raw silk material. |

These steps are vital in industrial-scale silk production, where handling large volumes of raw silk and maintaining quality are paramount.

Quality Assessment of Silk Fabric

When evaluating silk fabric quality, key factors such as smoothness, strength, and luster play an essential role in determining its premium standards. To assess the quality of silk fabric effectively, the following aspects are necessary:

- Evenness: The consistency of silk threads, absence of defects, and uniformity in texture are important indicators of high-quality silk.

- Color Consistency: Ensuring the color of the silk fabric is uniform throughout without any variations is critical for evaluating its quality.

- Proper Finishing: Inspecting for appropriate finishing touches, absence of snags or tears, and overall visual appearance is required in quality assessment.

- Durability Testing: Testing silk fabric for shrinkage, colorfastness, and overall durability helps in determining its longevity and quality standards.

Frequently Asked Questions

How Is 100% Silk Made?

To make 100% silk, silkworm cocoons are harvested before the worms emerge. The cocoons are then unraveled to obtain silk threads. These threads are twisted into yarn and woven into textiles, resulting in the luxurious fabric we are familiar with.

How Is Silk Made Today?

Today, we make silk by harvesting silkworm cocoons, heating them for fiber extraction, and carefully unraveling the threads to create yarn. Advanced machinery aids in these processes, allowing for efficient silk production and subsequent weaving of luxurious textiles.

How Do You Make Silk Without Killing Silkworms?

To make silk without killing silkworms, we allow them to emerge from the cocoons naturally. This method, known as Ahimsa silk or peace silk, prioritizes animal welfare. It results in slightly less uniform silk threads but is cruelty-free and ethical.

Where Do We Get Silk From?

I get silk from the cocoons of silkworms. The process involves harvesting the cocoons before the silkworms mature into moths. I carefully unwind the silk fibers from the cocoons, which are spun by the silkworms.

- How to Identify High-Quality Nonwoven Interfacing - July 12, 2025

- The Use of Nonwovens in Construction and Civil Engineering - July 12, 2025

- The Use of Nonwovens in Construction and Civil Engineering - July 11, 2025