I can tell you how silk is made! Silkworms eat mulberry leaves to produce silk threads. These threads form cocoons, collected before moths emerge. Heating softens a substance called sericin, then we extract silk threads. Skilled artisans in weaving towns play an important role in silk production. Silk is stored away from sunlight and moisture for preservation. Cleaning silk involves mild detergent and cold water. Silk's luxurious texture, sheen, and strength make it a top choice. Interested to learn more about the fascinating process behind silk production?

Table of Contents

Key Takeaways

- Silkworms are fed mulberry leaves to produce silk fibers in their salivary glands.

- Silk production involves spinning cocoons collected before moths emerge for quality fibers.

- Controlled heating softens sericin in cocoons for silk thread extraction.

- Extracted silk threads are spun together to create durable silk yarn.

- Skilled artisans in weaving towns contribute to the excellence of luxurious silk fabrics.

Silkworm Rearing and Feeding

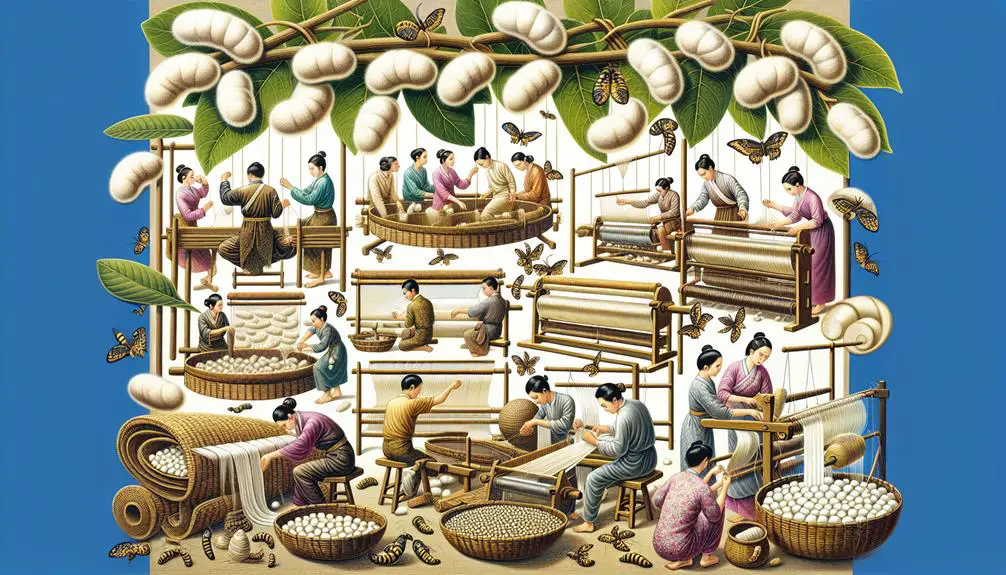

When I rear silkworms, I feed them mulberry leaves to produce silk fibers in their salivary glands. This natural process is essential in the production of silk fabric. Silkworms, with their voracious appetite for mulberry leaves, play a crucial role in creating this luxurious material. As the silkworms eat the leaves, they produce a protein-based fluid that hardens upon contact with the air, forming the silk threads used for making fabric.

The silk production process begins with these tiny creatures spinning cocoons to protect themselves during their metamorphosis. Each cocoon contains a single silk thread, which can stretch impressively long. The care and attention given to the silkworms every two hours ensure a healthy growth environment. Collecting the cocoons before the moths emerge is vital to maintain the quality of the silk fibers. This intricate yet fascinating interaction between silkworms and mulberry leaves results in the exquisite silk fabric that we use and admire in various forms.

Silk Fiber Production Process

In silk production, silkworms are carefully cultivated and fed mulberry leaves to facilitate the production of silk fibers in their salivary glands. Once the silkworms have spun their cocoons, these are harvested before the mature worms emerge to maintain the quality of the silk.

To extract the silk fibers, the cocoons are heated in boiling water to soften the sericin, a natural gum holding the cocoon together, allowing for easier unraveling. The softened cocoons are then unwound to reveal long silk threads.

These extracted silk threads are spun together to create a stronger, more durable thread suitable for making silk fabrics, garments, and textiles. The intricate process of extracting and processing the silk fibers ensures that the final products retain the luxurious qualities silk is known for.

The silk fiber production process is a vital step in the journey of transforming silkworm cocoons into exquisite silk goods.

Cocoon Collection and Preservation

I'll begin by explaining the vital process of cocoon harvesting. Silkworm cocoons are carefully collected to preserve the silk fibers' quality.

Then, I'll discuss the techniques used to extract silk from these cocoons. This process ensures that the long and continuous strands remain intact.

To wrap up, we'll touch on the importance of proper cocoon storage. This is crucial to maintain the strength and luster of the silk threads for further processing.

Cocoon Harvesting Process

Carefully collecting silk cocoons from silkworms is vital for high-quality silk production. Harvesting the silk cocoons before the mature silkworms emerge as moths is essential to preserve the integrity of the silk fibers.

Preservation methods, such as heating or storing the cocoons in a controlled environment, help maintain the quality of the silk. By ensuring proper cocoon harvesting and preservation techniques, the resulting silk fabric will be of superior quality.

This meticulous process of cocoon collection and preservation is a fundamental step in the silk production process, ensuring that the silk cocoons are handled with care and precision to yield the finest silk fibers for manufacturing high-quality silk products.

Silk Extraction Techniques

To extract silk from cocoons, the collected cocoons undergo a heating process to soften the sericin protein that binds the silk fibers together. This heating, often done in boiling water, not only eases the extraction of silk but also helps in preserving its quality.

The delicate extraction of silk threads from the softened cocoons is vital to maintain the strength and integrity of the silk thread. Once extracted, these silk threads are twisted together to form yarn, which can then be used for further processing into various silk products.

The careful handling of the cocoons during the heating and extraction processes guarantees that the silk retains its natural properties and is ready for subsequent manufacturing steps.

Proper Cocoon Storage

How can we guarantee the quality and integrity of silk fibers through proper cocoon storage techniques? To preserve the quality of silk fibers, cocoon storage is essential. It is vital to store cocoons in a cool and dry place to prevent mold growth and maintain their integrity. Using airtight containers or bags can help prevent moisture absorption, protecting the cocoons and ensuring ideal storage conditions. By maintaining these storage practices, we can safeguard the silk fibers within the cocoons, keeping them strong and suitable for processing.

| Cocoon Storage Tips |

|---|

| Store in cool, dry place |

| Prevent mold growth |

| Use airtight containers |

| Maintain integrity |

| Ensure ideal conditions |

Heating and Spinning of Cocoons

When processing silk, one of the essential steps involves heating and spinning silkworm cocoons to extract the valuable silk fibers efficiently. The process of heating and spinning cocoons is vital in silk making for obtaining high-quality silk threads.

Here are some key points to understand this step better:

- Silkworm cocoons are heated to prevent the mature worms from emerging, preserving the silk fibers.

- Heating the cocoons softens the sericin, a protein binding the silk fibers, facilitating silk extraction.

- The heating process also kills the pupae inside the cocoons, ensuring the integrity of the silk threads.

- Controlled heating of cocoons helps in unraveling silk fibers smoothly for further processing.

- Heating and spinning cocoons is a pivotal step in silk production to obtain high-quality and continuous silk threads.

This controlled heating process is fundamental in preparing the cocoons for the next stage of silk extraction.

Extraction of Silk Threads

Carefully extracting silk threads from cocoons involves boiling them in water to soften the sericin, enabling the unwinding of long silk fibers for yarn production. When the cocoons are boiled, the sericin, a natural gum-like substance that holds the silk filaments together, dissolves. This process allows the silk fibers to be unraveled smoothly.

Each cocoon can yield a continuous silk filament that ranges from 600 to 900 meters in length. The extracted fibers are then spun together to create silk yarn. The extracted silk threads require precision and skill to guarantee the quality of the fibers, as any damage during extraction can impact the strength and appearance of the final product.

Once the silk threads are twisted into yarn, they're ready to be used for weaving various textiles. This pivotal step sets the foundation for the creation of luxurious silk fabrics that are renowned for their softness, sheen, and durability in the world of textiles.

Processing in Weaving Towns

Silk threads produced from cocoons undergo further processing in weaving towns, where skilled artisans utilize traditional techniques to transform them into exquisite fabrics. This stage is essential in the journey of silk production, as weaving towns specialize in creating high-quality silk products. Here's a glimpse into the meticulous process in these towns:

- Skilled Artisans: Talented artisans in weaving towns bring years of experience to the table, ensuring the utmost quality in every piece they create.

- Traditional Techniques: These artisans employ traditional weaving techniques that have been passed down through generations, adding a touch of authenticity to the silk textiles.

- Time-Consuming Process: Crafting silk fabrics is a time-consuming endeavor, with each thread carefully woven to perfection, highlighting the dedication of these artisans.

- High-Quality: The attention to detail and precision in weaving towns result in silk products of unmatched quality, setting them apart in the market.

- Final Stages: Weaving towns play a crucial role in the final stages of silk production, where the raw silk threads are transformed into luxurious fabrics that captivate with their beauty and finesse.

Quality Preservation Techniques

I'll share some practical tips on how to preserve the quality of silk.

From proper storage in cool, dry places to avoiding direct sunlight exposure, there are simple steps to protect silk's color and fabric strength.

Additionally, keeping silk away from chemicals and moisture, using breathable covers, and airing out items regularly can all help maintain the freshness and longevity of silk products.

Storage Tips for Silk

When storing silk items, it's important to follow specific guidelines to uphold their quality and longevity. Here are some essential storage tips for silk:

- Store silk in a cool, dry place away from direct sunlight to prevent fading.

- Avoid hanging silk garments to prevent stretching; instead, fold and store flat.

- Keep silk away from sharp objects and rough surfaces to prevent snags and tears.

- Use padded hangers or garment bags to protect silk clothing from dust and moisture.

- Avoid storing silk near sources of heat or moisture, as they can damage the fabric over time.

Cleaning Silk Products

To maintain the quality of your silk products, it is essential to follow proper cleaning techniques that preserve the fabric's delicate nature. When cleaning silk items, it's best to use a mild detergent and cold water to avoid damaging the fibers. Hand washing is recommended over machine washing to prevent unnecessary wear and tear. After cleaning, air-dry your silk products away from direct sunlight to maintain their texture. When ironing silk, use a low heat setting and place a cloth barrier between the iron and the fabric to prevent any burns or shine marks. If you prefer, dry cleaning is also a suitable option for keeping your silk items in pristine condition.

| Cleaning Silk Products | |||

|---|---|---|---|

| Mild Detergent | Hand Washing | Air-Dried | Dry Cleaning |

| Cold Water | Low Heat Setting | Cloth Barrier |

Traditional Silk Fabric Characteristics

Traditional silk fabric exhibits a luxurious texture and aesthetic appeal that's highly regarded in the fashion industry.

Silk fabric is a natural protein fiber that offers a soft texture, making it comfortable to wear against the skin. Its natural sheen adds a touch of elegance to any garment, reflecting light in a beautiful way.

Despite its delicate appearance, silk is a durable fabric known for its strength and longevity. Silk's breathability allows it to help regulate body temperature, providing comfort in various climates.

Additionally, silk's hypoallergenic properties make it suitable for those with sensitive skin, offering a gentle touch. These characteristics have made silk a popular choice for designers and consumers alike, showcasing its versatility and timeless charm.

Frequently Asked Questions

How Do You Make Silk Without Killing Silkworms?

To make silk without killing silkworms, we allow cocoons to hatch naturally. The moths complete their life cycle, and then we harvest the spun silk threads after they leave. Ahimsa silk's cruelty-free production methods are gaining popularity.

How Is Silk Made Cruelty?

Making silk without cruelty involves methods like peace silk or wild silk production. These techniques aim to minimize harm to silkworms, allowing them to complete their life cycle without harm. Ethical concerns drive the shift towards cruelty-free silk production.

Do Silkworms Actually Make Silk?

Yes, silkworms actually make silk. They secrete fibroin protein from their salivary glands and solidify it into silk threads while spinning their cocoons. This process of silk production, called sericulture, yields luxurious silk fabric from the unraveled, twisted threads.

What Happens to the Worms After Silk Is Extracted?

After silk extraction, the silkworms are typically discarded or repurposed. The focus is on the silk fibers, not the worms. Unfortunately, they're viewed as a resource for silk rather than living creatures. Their sacrifice facilitates silk production.

- The Complete Guide to Nonwoven Polypropylene Tote Bags - July 11, 2025

- What Is Hydrophilic vs. Hydrophobic Nonwoven Fabric? - July 11, 2025

- Is Nonwoven Fabric Breathable? An Important Factor for Masks and Apparel - July 11, 2025