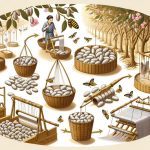

You start by growing healthy mulberry trees, since silkworms feed exclusively on their fresh leaves. After carefully nurturing the silkworms through their lifecycle, you harvest their cocoons before moths emerge. You then stifle and sort the cocoons to preserve silk quality. Next, you reel the fine silk threads, which are dyed and spun. Finally, weaving and finishing transform these threads into smooth, lustrous mulberry silk fabric. Keep exploring to understand each step in detail.

Table of Contents

Key Takeaways

- Mulberry trees are cultivated for their leaves, the exclusive food source for silkworms, ensuring high-quality silk production.

- Silkworms spin cocoons which are harvested before moth emergence to preserve the silk fibers’ integrity.

- Cocoons are softened in warm water to loosen sericin, enabling careful reeling of silk threads.

- Silk threads are dyed, woven into fabric, and finished with washing, softening, and calendering for texture and shine.

- Quality control throughout ensures durable, luxurious mulberry silk fabric ready for garment crafting and various applications.

The Cultivation of Mulberry Trees

To grow mulberry silk fabric, you first need healthy mulberry trees, since their leaves are the sole food source for silkworms.

You’ll want to select a site with well-drained soil and ample sunlight—mulberries thrive in warm, temperate climates.

Plant your saplings during early spring to give them plenty of time to establish roots before summer.

Regular watering is vital, especially in dry spells, but avoid waterlogging the soil.

Prune your trees annually to encourage fresh leaf growth and maintain manageable size for harvesting.

Keep an eye out for pests and diseases, treating issues promptly to protect your crop.

Silkworm Rearing and Feeding

Now that you’ve grown healthy mulberry trees, it’s time to focus on raising silkworms.

You’ll watch them progress through their lifecycle stages, feeding exclusively on fresh mulberry leaves.

This careful care guarantees they produce the finest silk fibers.

Silkworm Lifecycle Stages

Although you mightn’t realize it, understanding the silkworm lifecycle is essential for producing high-quality mulberry silk fabric. You start with eggs, which hatch into tiny larvae called silkworms.

These larvae go through several growth phases called instars, during which they shed their skin multiple times. As you care for them, they grow rapidly, preparing to spin their cocoons.

Once ready, the silkworms begin producing silk threads from specialized glands, wrapping themselves tightly in cocoons. After this stage, the pupae develop inside the cocoons, undergoing metamorphosis before emerging as moths.

Knowing each stage helps you manage the rearing process effectively, ensuring healthy silkworms and strong, continuous silk fibers for weaving. This lifecycle understanding directly impacts the quality of the silk fabric you’ll eventually create.

Mulberry Leaf Diet

A silkworm’s diet plays an essential role in producing premium mulberry silk fabric. You’ll need to feed silkworms fresh mulberry leaves exclusively, as this diet directly affects the quality and texture of the silk they spin. The leaves are rich in nutrients, which help the silkworms grow strong and healthy, enabling them to produce long, fine silk threads.

Here’s a quick look at what you should know about their feeding routine:

| Feeding Aspect | Details |

|---|---|

| Leaf Type | Fresh mulberry leaves only |

| Feeding Frequency | Every 2-3 hours during active stages |

| Quantity | Enough to keep silkworms full |

| Leaf Quality | Tender, pesticide-free leaves |

Feeding silkworms properly guarantees you get the best silk quality for weaving.

Harvesting the Cocoons

You’ll need to collect the cocoons at just the right time to guarantee the best silk quality.

Once harvested, sorting and grading the cocoons helps separate the finest ones from the rest.

After that, you’ll prepare the cocoons for the silk extraction process.

Timing of Cocoon Collection

When you harvest mulberry silk cocoons, timing matters greatly because collecting them too early or too late can affect silk quality. If you pick cocoons too soon, the silkworm inside may not have finished spinning its thread, resulting in weak or incomplete silk.

Wait too long, and the moth will emerge, breaking the continuous silk filament and lowering its value.

Here’s how you can time it right:

- Monitor the silkworms closely as they start spinning, which usually takes about 2-3 days.

- Collect the cocoons within 7-10 days after spinning begins, before moth emergence.

- Look for firm, intact cocoons that have turned a pale yellowish-white, signaling readiness for harvesting.

Proper timing guarantees the best quality silk for your fabric.

Sorting and Grading Cocoons

Since the quality of your silk depends heavily on the cocoons you select, sorting and grading them carefully is crucial.

Begin by examining each cocoon’s size, shape, and color. Look for uniform, intact cocoons without holes or stains, as these indicate healthy silkworms and high-quality silk fibers.

Separate damaged or discolored cocoons to avoid compromising the final fabric. You’ll also want to classify cocoons based on their weight and texture, as heavier, denser cocoons typically yield stronger silk threads.

This grading process helps guarantee consistency in fiber quality when you eventually unwind the silk. By sorting meticulously, you set the foundation for producing luxurious, smooth mulberry silk fabric that reflects the care you’ve taken from the very start.

Preparing for Silk Extraction

After carefully sorting and grading the cocoons, the next step is to prepare them for silk extraction. You’ll need to guarantee the cocoons are ready for the reeling process, which involves softening the sericin—the natural gum holding the silk fibers together.

Here’s what you do:

- Dry the cocoons: Lightly sun-dry them to reduce moisture without damaging the fibers.

- Stiffen the silk threads: Dip the dried cocoons in hot water to soften the sericin, making the silk threads easier to unwind.

- Remove pupae: Carefully extract or kill the pupae inside to prevent them from breaking the silk filament when emerging.

These steps set the stage for smooth silk reeling, preserving the long, continuous fibers essential for high-quality mulberry silk fabric.

Stifling and Sorting Cocoons

Before you can extract the silk threads, you need to stifle the cocoons to prevent the moths from emerging and damaging the silk fibers.

Stifling involves exposing the cocoons to heat, usually by steaming or drying them in hot air. This process kills the pupae inside without harming the silk threads.

Once stifled, you’ll sort the cocoons by size, quality, and color. Sorting guarantees that only the best cocoons are used for high-quality silk production, while damaged or irregular ones are set aside.

This step is essential because uniform cocoons produce smoother, stronger silk fibers.

Reeling Silk Threads

You start reeling silk threads by carefully unwinding the long, continuous fibers from each cocoon. This delicate process requires steady hands and patience to avoid breaking the fragile threads.

As you reel, the silk filament is guided onto a rotating reel, forming a single strand of raw silk. To create a stronger thread, you combine several filaments by twisting them together.

Here’s how the process unfolds:

- Soften the cocoon in warm water to loosen the sericin, the natural gum holding the fibers.

- Locate the filament’s end and gently pull it to start unwinding.

- Wind multiple filaments together onto a reel to form a uniform thread.

This careful reeling preserves the silk’s smoothness and strength for weaving.

Dyeing and Spinning Silk

Bring vibrant colors to life by dyeing the silk threads carefully to guarantee even absorption and rich hues. You’ll immerse the silk in natural or synthetic dyes, controlling temperature and timing to prevent uneven coloring or damage.

Once dyed, you spin the silk fibers to create strong, uniform threads. You twist the delicate fibers together, increasing their strength and smoothness. This spinning process makes certain the silk is ready for weaving, maintaining its luxurious texture and sheen.

Weaving and Finishing the Fabric

The weaving process transforms spun silk threads into fabric by interlacing them on a loom with care and precision.

You’ll set up the warp threads lengthwise, then weave the weft threads crosswise, creating the silk’s delicate texture.

After weaving, finishing touches enhance the fabric’s softness, sheen, and durability.

Here’s what you’ll experience during weaving and finishing:

- Warping and Weaving: Align warp threads tightly on the loom, then weave the weft threads to form a smooth, even surface.

- Washing and Softening: Gently wash the fabric to remove impurities and apply softeners for a luxurious feel.

- Calendering: Pass the fabric through heated rollers to enhance its shine and smoothness.

This process guarantees the mulberry silk fabric is ready for crafting exquisite garments.

Frequently Asked Questions

How Does Mulberry Silk Compare to Other Types of Silk?

You’ll find Mulberry silk smoother, stronger, and more uniform than other silks because it comes from silkworms fed exclusively on mulberry leaves, making it softer and more durable compared to wild or tussar silk varieties.

What Are the Environmental Impacts of Mulberry Silk Production?

Wondering about mulberry silk’s environmental footprint? You’ll find it’s more sustainable than many fabrics, but requires water and mulberry cultivation. You’ll want to contemplate farming practices and energy use to gauge its true impact.

How Should Mulberry Silk Fabrics Be Cared for and Cleaned?

You should hand wash mulberry silk fabrics gently in cold water with mild detergent, avoid wringing, and air dry away from direct sunlight. Iron on low heat while the fabric’s slightly damp to keep it smooth and soft.

Are There Any Common Allergens Associated With Mulberry Silk?

You might think mulberry silk causes allergies, but it’s actually hypoallergenic. Its natural protein structure resists dust mites and mold, making it ideal if you’re sensitive or prone to common fabric allergens.

What Are the Main Uses of Mulberry Silk in Fashion and Home Textiles?

You’ll find mulberry silk mainly in luxury fashion like scarves, dresses, and ties. At home, it’s popular for bedding, pillowcases, and curtains because it’s soft, breathable, and adds elegant comfort to your space.

- The Use of Nonwovens in Construction and Civil Engineering - July 11, 2025

- The Use of Nonwovens in Construction and Civil Engineering - July 11, 2025

- The Use of Nonwovens in Construction and Civil Engineering - July 11, 2025