Have you ever wondered how silk is made into fabric? Well, you’re in luck! In this article, we will take you through the fascinating process of transforming silk from cocoons into luxurious fabric.

From the life cycle of a silkworm to the intricate weaving and finishing techniques, you will gain a deeper understanding of the craftsmanship behind this ancient art.

So, get ready to unravel the secrets of silk production and discover the beauty that lies within each thread.

Table of Contents

The Life Cycle of a Silkworm

The life cycle of a silkworm begins when it hatches from an egg. Silkworm farming plays a crucial role in the silk production process. Once the silkworm hatches, it starts feeding on mulberry leaves. It goes through several molting stages, shedding its skin each time it grows bigger. After molting four to six times, the silkworm enters the pupa stage. During this stage, it spins a cocoon made of silk thread. The silkworm secretes a sticky substance called sericin, which hardens when exposed to air, forming the cocoon. The silkworm stays inside the cocoon for about two weeks, undergoing metamorphosis and transforming into a moth.

However, in order to obtain the silk, the cocoon is carefully harvested before the moth emerges. The cocoons are then soaked in hot water to soften the sericin. This allows the silk filaments to unwind and be easily extracted. The unwound silk filaments are then spun together to create silk threads. These threads are then woven into fabric using various techniques.

Silkworm farming is an intricate process that ensures the production of high-quality silk. From hatching to spinning cocoons, each stage is carefully managed to maximize silk production and maintain its superior quality.

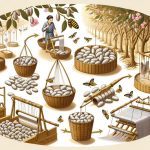

Harvesting Silk Cocoons

To harvest silk cocoons, you’ll need to carefully collect them from the mulberry trees. Here’s how you can do it:

-

Inspect the cocoons: Look for healthy, fully formed cocoons that are shimmering in color. These are the ones with the highest quality silk.

-

Use a gentle touch: Gently pluck the cocoons from the branches, making sure not to damage them. The cocoons are delicate and need to be handled with care.

-

Sort the cocoons: Separate the cocoons based on their color and quality. The best quality cocoons will have a uniform color and feel firm to the touch.

-

Store them correctly: Place the cocoons in a cool, dry place to protect them from moisture and pests. This will ensure that the silk remains in good condition until it is ready to be processed.

Silk production plays a significant role in the silk industry, and harvesting silk cocoons is an essential step in this process. By following these steps, you can ensure that you collect high-quality cocoons, which will result in superior silk fabric.

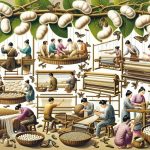

Silk Reeling and Spinning

After sorting the cocoons, you can begin reeling and spinning the silk fibers to create thread. Silk production involves various sericulture techniques, and this step is crucial in transforming the raw silk into a usable form.

To start the process, the cocoons are boiled in hot water to soften the sericin, a natural gum-like substance that holds the silk fibers together. Once softened, the loose ends of the silk fibers are located and carefully unwound. This delicate process is known as reeling.

The unwound silk fibers are then twisted together to create a single, continuous strand of silk thread. This process is called spinning. Traditionally, silk reeling and spinning were done by hand, but today, mechanized methods are also used to increase efficiency.

The quality of the silk thread depends on the skill of the reeler and spinner, as well as the quality of the cocoons. After the silk thread is spun, it can be dyed and woven into beautiful silk fabrics.

This intricate process highlights the artistry and precision required in silk production.

Weaving Silk Fabric

Once the silk thread is spun, it’s ready to be dyed and woven into beautiful fabrics. Silk weaving is the next step in the process of turning raw silk into luxurious textiles. This intricate craft requires skill and precision.

Silk production begins with the cultivation of silkworms and the harvesting of their cocoons. These cocoons are then boiled to remove the outer layer, revealing the silk fibers inside. The fibers are carefully reeled onto a spinning wheel to create a continuous thread.

To weave silk fabric, the silk thread is first dyed using natural or synthetic dyes to achieve the desired color. Then, the thread is stretched across a loom, which is a frame that holds the threads in place. The weaver carefully intertwines the threads in a specific pattern to create the fabric.

Silk weaving involves various techniques such as plain weave, satin weave, and twill weave, each producing a distinct texture and appearance. The weaver ensures the threads are evenly tensioned to create a smooth and uniform fabric.

Once the weaving is complete, the silk fabric is carefully inspected for any flaws or imperfections. It is then washed, dried, and ironed to enhance its lustrous shine and softness.

Silk weaving is a time-consuming and labor-intensive process, but the end result is a luxurious fabric known for its elegance and durability.

Finishing and Dyeing Silk

During the finishing and dyeing process, you carefully inspect the silk fabric for any flaws or imperfections. Once the weaving is complete, the fabric goes through a series of finishing techniques to enhance its appearance and texture. This includes processes like degumming, which removes the sericin, a natural gum that holds the silk fibers together.

After degumming, the fabric is washed to remove any remaining impurities or residues. Next, it undergoes a process called sizing, where a thin coating is applied to improve its strength and texture.

Once the fabric is finished, it is ready to be dyed. There are two main types of dyes used in the industry: natural and synthetic. Natural dyes are derived from plant, animal, or mineral sources. These dyes produce a range of beautiful, earthy colors but may be less colorfast than synthetic dyes. Synthetic dyes, on the other hand, are made from chemical compounds and offer a wider array of vibrant and long-lasting colors. They are often chosen for their durability and consistency.

After dyeing, the fabric is carefully dried and inspected once again to ensure the color is even and the fabric is flawless. The finishing and dyeing processes are crucial in transforming raw silk into a luxurious and vibrant fabric that is ready to be used in various applications.

Conclusion

So now you know how silk is made into fabric!

The process begins with the life cycle of a silkworm, followed by carefully harvesting the silk cocoons.

Then, the silk is reeled and spun to create the yarn needed for weaving.

Finally, the fabric is woven, finished, and dyed to achieve the desired texture and color.

It’s a fascinating journey from the silkworm to the beautiful silk fabric that we enjoy wearing and using in various ways.

- Tetron Fabric for Marine Applications: Durability and Use Cases - June 18, 2025

- Tetron Fabric for Outdoor Furniture: Weather Resistance and Care - June 18, 2025

- Tetron Fabric for Wall Coverings: Style and Application Tips - June 18, 2025