I'll share where wool comes from: Wool mainly comes from sheep. It's a versatile and sustainable material used in clothing, textiles, and insulation. If you want to know more about the sources, shearing process, yarn spinning, and characteristics of wool, keep discovering the fascinating journey behind this valuable resource.

Table of Contents

Key Takeaways

- Wool primarily comes from sheep.

- Merino sheep produce super soft wool.

- Cashmere goats provide luxurious cashmere wool.

- Shearing occurs before summer.

- Wool is sourced globally from countries like Australia, New Zealand, and the United States.

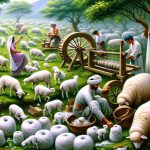

Wool Sources

When it comes to the sources of wool, sheep stand out as the primary providers, boasting a thick, cosy coat known as a fleece during winter. These fluffy creatures offer a diverse range of wool types. For instance, the Merino sheep, mainly from Spain and Australia, provide super soft and fine wool fibers highly valued for their quality. On the other hand, cashmere goats from China and Mongolia produce the luxurious and light cashmere wool, which comes from their undercoat.

Sheep undergo shearing before summer to harvest their wool, with each sheep's annual fleece weight averaging over 8 kilos. This process guarantees that the sheep stay comfortable during the warmer months while also providing a sustainable source of wool. While other animals like goats, rabbits, llamas, and alpacas also contribute to the wool industry, sheep remain the primary source due to the quality and quantity of wool they produce.

Shearing Process

When it comes to the shearing process, understanding the basics, the tools involved, and safety measures are essential.

Shearing involves removing the sheep's wool, a task that requires precision and care to guarantee the animal's well-being.

Learning about the techniques and tools used in shearing can help maintain the quality of the wool and the comfort of the sheep.

Wool Shearing Basics

To shear a sheep effectively, one must carefully remove its fleece or wool using specialized tools.

Trust me, sheep are much happier and more comfortable after a fresh shearing.

It's incredible to see how quickly and skillfully professional shearers can handle the process.

The transformation from a fluffy sheep to a lightweight one is both satisfying and mesmerizing.

Shearing Tools Used

I depend on a combination of shearing machines, hand shears, and combs and cutters to efficiently remove the wool from sheep during the shearing process. Shearing machines are essential for shearing large flocks of sheep quickly and precisely.

Hand shears come in handy for more detailed work, ideal for smaller operations where precision is key. Combs and cutters play an important role in the shearing process by effectively removing the wool from the sheep's body, ensuring a clean cut.

These tools are necessary for maintaining the welfare of the sheep and the quality of the wool throughout the shearing process. Proper use of shearing tools is crucial for a successful and humane shearing process.

Shearer Safety Measures

Ensuring shearers' safety during the shearing process involves donning appropriate personal protective equipment, receiving training in proper handling techniques, and maintaining equipment regularly.

When it comes to shearer safety measures, three key aspects stand out:

- Personal Protective Equipment (PPE): Equipping shearers with gloves, eye protection, and ear defenders guarantees their safety.

- Correct Handling Techniques: Training shearers in proper handling methods not only protects them but also minimizes stress for the sheep.

- Equipment Maintenance: Regular maintenance and blade sharpening are vital for efficient and safe shearing practices.

Wool Fiber Creation

When creating wool fiber, the fleece of sheep is sheared annually before summer to retain the wool, which is then processed through cleaning, washing, and drying to prepare it for spinning into yarn. The wool fibers undergo a pivotal step called carding, where they are combed into thin strands to facilitate the spinning process. Spinning the wool involves twisting the carded fibers together to form yarn, which can then be dyed into various colors for different applications. Special machines are utilized in this process to untangle and spin the raw wool fibers efficiently. Below is a table summarizing the key steps in wool fiber creation:

| Step | Description | Purpose |

|---|---|---|

| Shearing | Annual removal of wool from sheep | Retain wool for processing |

| Cleaning | Removing impurities and dirt from wool | Ensure cleanliness of the fibers |

| Carding | Combing fibers into thin strands | Prepare fibers for spinning |

| Spinning | Twisting fibers together to create usable yarn | Form yarn for knitting and crocheting |

| Dyeing | Adding color to the yarn | Create yarn in various colors |

Yarn Spinning

After preparing the wool fibers through carding, the next step in the wool creation process is yarn spinning. Yarn spinning is an essential process that transforms wool fibers into usable yarn for knitting and crochet. Different spinning methods create various yarn types and weights, catering to different project needs. Spinning wheels, commonly used in this process, help combine wool strands to create longer and stronger yarn pieces. Wool yarn can be purchased undyed or dyed into a wide range of colors due to wool's excellent water absorption properties.

Yarn spinning techniques can be a soothing and meditative practice, connecting us to the rich tradition of wool crafting.

The feeling of accomplishment when spinning wool into yarn that will later become a beautiful garment is truly rewarding.

Exploring the different yarn types that can be created through spinning opens up a world of creative possibilities for fiber artists.

Wool Products

Wool products encompass a wide array of items, ranging from clothing and blankets to horse rugs, carpeting, insulation, and upholstery. In the textile industry, wool holds a significant place due to its versatility and unique properties. Wool fabrics are highly valued for their durability, softness, and natural fire-resistant qualities.

Apparel wool, in particular, is favored for its use in garments worn by firefighters and soldiers, providing them with added protection. The importance of wool extends beyond clothing; it's also widely used in household items like carpets and upholstery due to its resilience and resistance to pilling.

Different grades of wool cater to various needs, with finer grades typically used for delicate garments and coarser grades for outerwear or rugs. Despite its many benefits, wool can trigger allergic reactions in some individuals due to its lanolin content. Understanding the diverse applications and characteristics of wool products highlights the lasting impact this natural fiber has in multiple industries.

Sheep Farming Importance

Sheep farming plays an essential role in the production of wool, serving as the primary source of wool fibers for various industries. Here are three reasons why sheep farming is vital for a sustainable future in wool production:

- Sheep Breeds Diversity: Different sheep breeds produce varying types of wool, each with unique qualities that influence the final product. This diversity adds richness and versatility to the textile industry.

- Sheep Welfare: Proper care of sheep, including good living conditions and regular shearing, not only guarantees the quality of wool but also reflects our responsibility towards animal welfare. It's crucial for sustainable and ethical wool production.

- Global Livelihoods: Sheep farming provides livelihoods for many people worldwide, especially in countries with a strong wool industry. Supporting sheep farming means supporting communities and traditions that have been intertwined with wool production for generations.

Major Wool Producers

I'll kick off by highlighting the top wool producers, where global wool sources come from, and the leading wool suppliers around the world.

This information sheds light on the key players in the wool industry, showcasing the significant contributors to the market.

Let's explore the major wool producers and their impact on the global wool supply chain.

Top Wool Producers

Australia, renowned for its vast sheep farming landscapes, stands out as the leading producer of Merino wool globally, highly sought after for its luxurious applications in the fashion industry.

Some interesting facts about the top wool producers include:

- Australia produces 80% of the world's Merino wool, setting the standard for quality.

- New Zealand Merino is also highly regarded for its softness and fineness.

- The United States, South Africa, and other countries contribute immensely to the global wool market, showcasing the widespread impact of this natural fiber.

These countries play a pivotal role in shaping the wool industry, providing the world with high-quality wool for various uses.

Global Wool Sources

Leading the global wool market are countries like Argentina, New Zealand, South Africa, the United States, and Uruguay, known for their production of fine wool. Australia stands out as the leading producer of Merino wool, making a substantial contribution to the luxury fashion industry. In 2021, approximately 1.2 billion sheep globally produced about 1,945 million kilograms of raw wool, with Australia alone accounting for 80% of the world's Merino wool. Despite this, wool only makes up 0.9% of the global fiber market, highlighting its niche position. Major wool-producing nations utilize different sheep breeds tailored to specific industries and products, ensuring a diverse range of high-quality wool for various purposes.

| Country | Leading Wool Type | Annual Production (kg) |

|---|---|---|

| Australia | Merino Wool | 1,556 million |

| Argentina | Fine Wool | 124 million |

| New Zealand | Fine Wool | 101 million |

| South Africa | Fine Wool | 87 million |

Leading Wool Suppliers

One notable country in the global wool market is Argentina, renowned for its production of fine wool. Australian Merino wool is highly sought after worldwide, with Australia being the leading producer of wool. The region of New South Wales in Australia is particularly known for its high-quality raw wool.

When I think about these major wool producers, I can't help but marvel at the dedication and skill required to produce such a versatile and valuable material. The intricate process of shearing, sorting, and processing wool highlights the craftsmanship involved in creating luxurious fabrics.

The knowledge and expertise of these wool producers truly shine through in the exceptional quality of their wool products.

Factors Affecting Wool Quality

When considering factors that influence wool quality, it becomes evident that genetics, nutrition, and shearing practices play pivotal roles in determining the overall quality of the wool fiber. Fiber diameter, staple length, and strength are vital aspects that contribute to the quality of wool. Contaminants, such as vegetable matter, can impact the processing and pricing of wool, highlighting the importance of proper care during production. Additionally, wool comfort and handle attributes are essential for ensuring consumer satisfaction with wool garments.

| Wool Quality Factors | Description |

|---|---|

| Fiber Diameter | Refers to the thickness of the wool fiber, influencing softness and warmth. |

| Staple Length | Length of the wool fiber, affecting the strength and durability of the yarn. |

| Strength | The ability of the wool fiber to withstand stretching and breaking. |

| Contaminants | Impurities like vegetable matter that can affect wool processing. |

Instruments such as the Wool ComfortMeter and Wool HandleMeter are used to measure fabric comfort and handle characteristics in wool products, ensuring high-quality standards are met.

Wool Characteristics

Wool has some unique characteristics that make it stand out. From its soft texture to its natural insulation properties, wool is a versatile fiber.

Additionally, being sustainable adds to the appeal of wool as a material.

Wool Texture

The diameter of wool fibers plays a significant role in determining the texture of wool, influencing how soft or coarse it feels to the touch. Factors like the crimp in fibers, scale structure, and sheep breeds also contribute to the varying textures of wool.

Here are some key points to ponder when exploring wool texture:

- Finer fibers generally feel softer and smoother, making them ideal for luxurious products.

- The elasticity and bounce of wool are influenced by the crimp in the fibers, providing comfort and flexibility.

- Different sheep breeds produce wool with unique textures, from the silky Superfine Merino wool to the robust Romney wool. Each type offers distinct qualities for a range of woolen products.

Natural Insulation

With its unique crimp structure, wool naturally provides excellent insulation by trapping air and retaining heat efficiently. Wool's specific thermal resistance is high, making it ideal for insulating clothing and home textiles. Additionally, wool's absorbent nature allows it to regulate moisture, keeping you dry and comfortable. Its natural insulating properties make wool a top choice for various applications, from cozy sweaters to warm blankets. The table below highlights some key features of wool as a natural insulator:

| Feature | Description |

|---|---|

| Crimp Structure | Traps air for insulation. |

| Specific Thermal Resistance | High thermal resistance for warmth. |

| Absorbent Nature | Regulates moisture for comfort. |

| Flame-Resistant | Provides protection in fire-risk situations. |

Sustainable Fiber

Sustainably sourced fibers like wool offer a range of eco-friendly benefits due to their natural and biodegradable properties.

- Renewable Resource: Wool is a renewable resource, as sheep grow a new fleece each year that can be shorn without harming the animal.

- Merino Wool: Merino wool, highly valued for its softness and quality, is a type of wool that comes from Merino sheep.

- Versatile Material: Wool is a versatile material used in various industries, from fashion and textiles to insulation and upholstery.

Wool's sustainable nature makes it a popular choice for those seeking environmentally friendly options. Its unique characteristics, such as moisture-wicking and flame resistance, further enhance its value as a sustainable fiber.

Wool Industry History

Embarking on a journey through the annals of history reveals the intriguing evolution of the wool industry. Sheep domestication marked the beginning of wool production around 9,000 to 11,000 years ago.

The wool trade gained prominence in the 13th century, highlighting the commercial significance of this natural fiber. English wool exports emerged as a powerhouse in the economy, rivalling Castile during the 15th century.

Remarkable innovations such as the putting-out system and the influence of banking houses like the Medici in Florence greatly influenced the trajectory of the wool industry.

However, it was the Industrial Revolution that truly transformed wool production through mass manufacturing techniques. This period saw a significant shift towards mechanization, revolutionizing how wool was processed and manufactured on a large scale.

The historical journey of the wool industry showcases a fascinating evolution, shaped by centuries of innovation and economic competition.

Wool Manufacturing Process

Delving into the intricate process of wool manufacturing reveals the meticulous steps involved in transforming sheep's fleece into versatile yarn. Shearing is the initial step in the process, where skilled professionals carefully remove the fleece from sheep, ensuring the animals' well-being while providing the raw material for yarn production.

Following shearing, carding plays an essential role in preparing the wool fibers for spinning by combing them into thin strands, aligning them for the next stage. Spinning, the final step, involves the art of twisting these fibers together to create strong, usable yarn. This process highlights the craftsmanship and dedication required to turn nature's gift, the sheep's fleece, into a valuable product like yarn.

- The gentle shearing process respects the sheep and their natural fibers, showcasing sustainability in action.

- Carding transforms the tangled fleece into organized strands, setting the foundation for quality yarn production.

- Spinning brings life to the wool fibers, weaving them together to form yarn with unique characteristics and strength.

Sustainable Wool Production

To guarantee minimal impact on the environment, sustainable wool production practices prioritize eco-friendly methods such as rotational grazing and water conservation. These environmentally friendly practices are essential in maintaining soil health, preserving biodiversity, and ensuring the welfare of the animals involved in wool production. Woolgrowers in sustainable systems adhere to ethical treatment standards for their sheep, minimizing the use of chemicals and focusing on natural alternatives.

Certification programs like the Responsible Wool Standard (RWS) play an important role in ensuring transparency and accountability within sustainable wool production. By following these standards, wool producers can demonstrate their commitment to ethical and sustainable practices, providing consumers with confidence in the products they purchase.

Frequently Asked Questions

Is Wool Only From Sheep?

Yes, wool is primarily sourced from sheep. It's a versatile fiber used in various textiles. Shearing sheep produces the wool, which then undergoes cleaning, washing, and spinning processes. The resulting yarn has different weights and textures.

What Animals Does Wool Come From?

Wool comes from various animals like sheep, goats, rabbits, llamas, and alpacas. Each animal produces unique types of wool, such as merino, cashmere, angora, and alpaca fiber. The diversity of sources results in a range of textures and qualities.

What Is the Source of Wool?

I gather wool from animals like sheep, goats, rabbits, llamas, and alpacas. It's sheared, then cleaned, washed, and spun into yarn. Merino sheep offer fine wool. The process is fascinating, resulting in cozy fabrics.

Where Is Wool Produced From the Most?

Australia leads global wool production, supplying about 80% of Merino wool. Other key producers include Argentina, New Zealand, South Africa, the United States, and Uruguay. Luxurious Merino and Rambouillet wool are highly coveted for fashion.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024