Wool fabric comes from animals like sheep, goats, and camels. Sheep are the primary source for this textile, offering warmth and durability. If you're curious about the shearing, cleaning, and dyeing processes, as well as the different types of wool fabrics available and their environmental impact, there's a lot more fascinating information waiting for you!

Table of Contents

Key Takeaways

- Wool fabric comes from animals like sheep, goats, and camels.

- Sheep domestication for wool began around 10,000 BCE.

- Different sheep breeds offer unique wool characteristics.

- Wool production involves shearing, cleaning, spinning, and processing.

- Merino sheep, known for fine wool, originated in Spain.

Origins of Wool Fabric

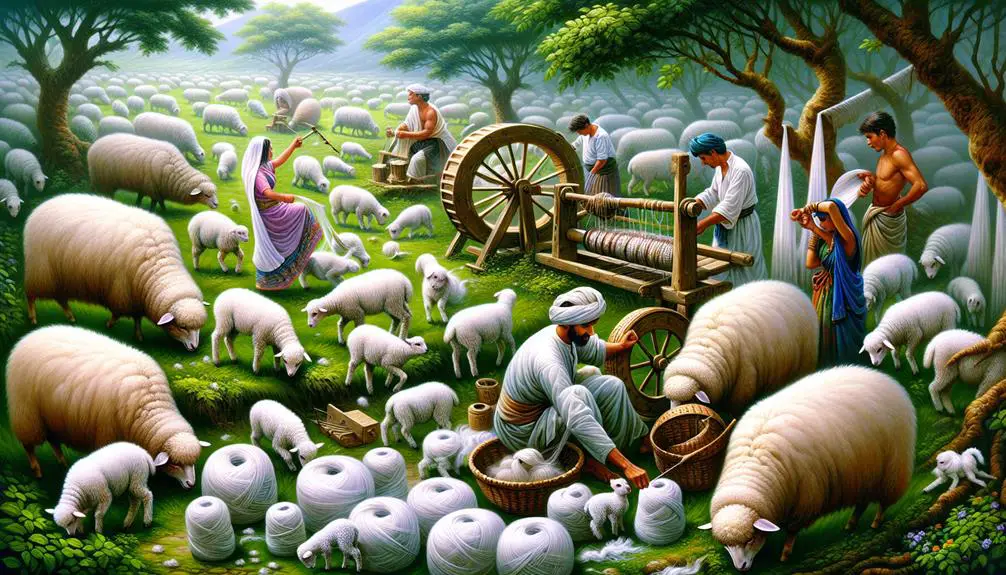

The history of wool fabric traces back to ancient civilizations where various animals like sheep, goats, and camels provided the raw materials for this versatile textile. Sheep domestication for wool production began around 10,000 BCE, marking a significant point in the development of wool as a fabric. Merino sheep, renowned for their fine wool, originated in Spain and played a pivotal role in the expansion of the wool industry, particularly in countries like Australia.

Different breeds of sheep are utilized for wool production, each offering unique characteristics. For instance, Merino and Rambouillet sheep are favored for their fine wool, ideal for apparel, while Romney and Scottish Blackface sheep provide thicker wools suitable for interior applications. The process of wool fabric production involves shearing the wool-bearing animals, cleaning, sorting, spinning the fibers into yarn, and further processing them into various types of wool fabrics, showcasing the intricate journey from sheep to stylish garments.

Sheep Shearing Process

I'll discuss the sheep shearing process, concentrating on the techniques for harvesting wool, the tools used for shearing, and the significance of this practice.

Let's delve into how shearing plays an essential role in maintaining sheep health and well-being, ensuring they're free from issues like heat stress and flystrike.

Additionally, we'll touch on how the wool obtained through this process is critical for creating a wide range of wool products.

Wool Harvesting Techniques

Sheep shearing, an important step in the wool harvesting process, involves removing wool from sheep's bodies using electric shears or manual clippers. This process is vital for obtaining high-quality wool from breeds like Merino sheep.

After shearing, the wool fibers are collected in large bags or bins. Professional shearers, with their expertise, can shear a sheep in about 2-3 minutes, ensuring the animal's well-being.

It's necessary to shear sheep once a year, typically before warm weather sets in. The collected wool is then sorted based on its quality and the type of fibers.

Proper shearing not only yields quality wool but also maintains the health of the sheep.

Shearing Tools Used

Using effective tools is essential during the sheep shearing process to guarantee the humane and precise removal of wool. Sheep shearing is commonly performed using electric clippers or hand shears. These tools have evolved to ensure efficiency and the well-being of the sheep.

Shearers, who are trained professionals, skillfully handle these tools to shear sheep safely. Specialized combs and cutters are integrated into the shearing tools to manage different types of wool effectively. It's important to maintain these tools properly to achieve clean and accurate shearing results.

The combination of electric clippers, hand shears, shearers, combs, and cutters plays a significant role in the successful and humane process of shearing sheep.

Importance of Shearing

Ensuring proper shearing of sheep is essential for their well-being and the quality of wool they produce. Skilled shearers play a pivotal role in this process, as they can efficiently remove the wool while minimizing stress on the animal.

By shearing the sheep, we not only maintain their health and prevent discomfort but also help maximize the wool yield. Regular shearing helps to keep the wool quality high by preventing matting and contamination.

Additionally, shearing is imperative for the animal welfare, as it prevents issues such as overheating. Hence, employing experienced and skilled shearers is key to ensuring a successful shearing process that benefits both the sheep and the quality of the wool they provide.

Wool Cleaning Methods

When caring for wool fabrics, it's crucial to select the appropriate cleaning method based on the specific care instructions provided. Different wool cleaning methods guarantee the longevity and quality of your wool garments. Here are some key methods to contemplate:

- Hand Washing: Gently wash in cold water with mild detergent to safeguard the fibers.

- Dry Cleaning: For delicate wool items or those labeled as dry clean only, professional dry cleaning is advisable.

- Spot Cleaning: Address stains promptly by spot cleaning with a mild detergent and water solution.

- Care Instructions: Always adhere to the care instructions on the garment's label to maintain the integrity and shape of the wool fabric.

Remember to avoid hot water, agitation, and harsh chemicals when cleaning wool to prevent harming the fibers. After cleaning, gently squeeze out excess water, reshape the garment, and dry it flat to maintain its shape. Following these methods will help keep your wool fabrics looking their best for years to come.

Dyeing Wool Fabric

To dye wool fabric effectively, one must carefully consider the choice between natural or synthetic dyes for achieving desired colors and patterns. Wool's protein-based fibers have a strong affinity for acid dyes, making them a significant choice for dyeing wool due to their ability to produce vibrant and long-lasting colors.

When dyeing wool, the fabric is immersed in a dye bath, where factors like temperature and time are controlled to ensure proper color absorption. Different dyeing techniques such as tie-dyeing, dip-dyeing, or ombre dyeing can be used to create unique patterns and effects on wool fabric.

Ensuring color fastness is vital in dyeing wool fabric. Proper dyeing techniques play an important role in preserving the color vibrancy and durability of the dyed wool. Whether aiming for solid colors or intricate patterns, mastering the art of dyeing wool involves understanding the intricacies of color absorption and employing techniques that guarantee lasting and vibrant results.

Quality Factors in Wool

Quality factors in wool are essential determinants of its desirability and performance in various applications. When considering the quality of wool, several key factors come into play:

- Fiber Diameter: The diameter of wool fibers greatly impacts its quality, with finer fibers often being softer and more luxurious.

- Crimp: The natural waviness or crimp in wool fibers contributes to its elasticity and resilience.

- Micron Count: Wool quality is often assessed by its micron count, with lower microns indicating finer and higher-quality wool.

- Genetics, Nutrition: Factors such as genetics, nutrition, and even climate can influence the quality of wool produced by sheep, impacting its characteristics like softness and strength.

Understanding these quality factors is vital for selecting the right wool for specific applications, whether it be for crafting durable outerwear or creating soft and cozy blankets. By considering fiber diameter, crimp, micron count, and the influence of genetics and nutrition, one can guarantee the wool meets their desired standards of quality.

Historical Significance of Wool

Wool's historical importance stretches back to ancient times, weaving itself into the fabric of human civilization since 10,000 BCE.

The diverse array of over 1,000 sheep breeds globally, such as the luxurious Merino and the sturdy Romney, have played pivotal roles in shaping the historical importance of wool.

Merino sheep, originally hailing from Spain, were introduced to Australia in 1789. This introduction marked a turning point for Australia, propelling it to the forefront of the global wool industry. Today, Australia stands as the leading producer of Merino wool, contributing significantly to luxury fashion and the overall wool market.

The historical journey of wool mirrors human progress, from its humble beginnings to becoming a cornerstone of global trade and fashion. Through the centuries, wool has remained a symbol of quality, durability, and sophistication, making it an enduring choice for a wide range of applications.

Evolution of Wool Weaving

Wool weaving has a rich history that spans millennia, evolving alongside human ingenuity and technological advancements. From early wool production techniques to the traditional methods of weaving intricate designs, wool fabric has seen a remarkable journey of innovation.

Today, modern wool innovations continue to push the boundaries of what's possible in the world of textile production.

Early Wool Production

Weaving techniques for wool fabric underwent significant advancements during the early stages of production, shaping the evolution of wool weaving practices.

- Early wool production involved sheep rearing specifically for their wool, ensuring high-quality fibers.

- Wool farming practices were refined to improve the yield and quality of wool used in weaving.

- Wool producers in regions like Australia played an important role in supplying premium quality wool for fabric production.

- The utilization of Australian wool in early weaving processes contributed to the reputation of wool fabrics for their durability and luxurious feel.

Traditional Weaving Techniques

During the evolution of wool weaving techniques, traditional methods shifted from vertical to horizontal looms over time.

The choice of weave plays an important role in wool fabrics, with plain-woven fabrics and twill weaves being prevalent. Twill weaves, such as herringbone and diamond patterns, offer unique designs and increased durability.

Wool satins, known for their smooth and shiny finish, are favored for high-quality fabric production. Understanding the characteristics of different wool weaves aids in selecting the appropriate fabric for specific historical contexts or purposes.

Mastery of traditional weaving techniques allows for the creation of intricate patterns and durable wool textiles, showcasing the rich heritage and craftsmanship of wool weaving throughout history.

Modern Wool Innovations

Exploring the advancements in wool weaving techniques has revealed a shift towards modern innovations in the industry. In the ever-changing textile industry, wool weaving has seen remarkable progress, paving the way for a sustainable future in the wool trade.

Here are some key modern innovations in wool weaving:

- Integration of technology like computerized looms for precise fabric construction.

- Development of eco-friendly dyeing processes to reduce environmental impact.

- Introduction of blended wool fabrics to enhance performance and comfort.

- Implementation of innovative finishing techniques for unique textures and appearances.

These advancements not only improve the quality and versatility of wool fabrics but also contribute to a more sustainable and dynamic future for wool weaving in the textile industry.

Types of Wool Fabrics

When exploring the world of wool fabrics, one encounters a diverse range of types, each with unique qualities and origins. Merino wool, known for its fineness and softness, is sourced from Merino sheep primarily in Australia. Cashmere wool, originating from the Kashmir region, is luxurious and prized for its warmth and softness.

Mohair wool, produced from Angora goats, stands out for its high luster and durability in woolen textiles. Alpaca wool, originating from South America, boasts fibers as small as 15 microns, making it exceptionally soft and warm.

Camel wool, although less common in apparel, is insulative and utilized in specific applications due to its unique properties. Each type of wool fabric brings its own set of characteristics and benefits, catering to various needs and preferences in the domain of textiles.

Environmental Impact of Wool

When contemplating the environmental impact of wool, it's crucial to address its relationship with land use and water consumption. Sustainable practices in sheep farming and wool production can help minimize the negative effects on the environment.

Wool and Land Use

Amidst the lush landscapes where sheep graze and wool is harvested, the environmental impact of wool production on land use can't be overlooked. When considering the implications of sheep breeding, soil degradation, and the pollution of waterways from chemicals like sheep dips, it becomes evident that wool production can have detrimental effects on the environment.

However, by implementing humane practices and seeking certifications such as the Responsible Wool Standard (RWS) and Woolmark, sustainable wool production is achievable. While the majority of global wool production currently contributes to environmental harm, ongoing efforts are being made to shift towards more eco-friendly practices.

It's essential to recognize that the way wool is produced plays a significant role in its environmental impact.

Wool and Water Usage

With its minimal water requirements and reliance on natural rainfall, wool production stands out as an environmentally friendly industry. Sheep, the source of wool, mainly fulfill their water needs from rainfall, reducing the reliance on additional water sources.

In regions such as Australia, where sheep graze on native pastures, the water footprint of wool production remains low due to minimal irrigation requirements. Sustainable practices within the wool industry focus on responsible land management and animal welfare, further minimizing water usage.

Additionally, wool's inherent properties, such as moisture-wicking and breathability, contribute to its eco-friendly profile by decreasing the necessity for energy-intensive processes. Overall, wool production showcases a commitment to sustainable practices and environmental stewardship through its efficient water usage.

Wool Fabric Certifications

Certifications like the Responsible Wool Standard (RWS) and Woolmark play an important role in guaranteeing the quality and sustainability of wool fabric production. These certifications are vital for ensuring ethical and environmentally friendly practices within the wool industry.

Here are key points to ponder:

- Quality Assurance: Certifications ensure that wool fabrics meet specific industry standards for production and processing.

- Ethical Sourcing: Certified wool fabrics are traceable from the source to the final product, promoting transparency in the supply chain.

- Consumer Confidence: By displaying these certifications, consumers can make informed decisions when purchasing wool products.

- Environmental Impact: Compliance with these certifications signifies a commitment to sustainable practices, benefiting both the environment and the community.

These certifications not only uphold high-quality standards but also reflect a dedication to responsible and sustainable wool production practices.

Global Wool Fabric Production

As we explore global wool fabric production, it's fascinating to note that Australia leads as the top producer, accounting for 25% of the world's wool output. Following Australia, China is a significant player in the wool industry, producing 18% of the world's wool. New Zealand, renowned for its crossbred wool, stands as the third-largest producer globally. Additionally, Turkey and the United Kingdom also make substantial contributions to the global wool market.

These top wool-producing countries play a pivotal role in meeting the world's wool demands and shaping the industry's landscape. Australia's dominance in wool production is well-established, with its high-quality wool being sought after worldwide. China's significant output underscores its importance in the market, while New Zealand's specialization adds diversity to the global wool offerings. Turkey and the United Kingdom, with their own unique contributions, further enrich the variety of wool fabrics available on the international stage. The collaboration and competition among these key players drive innovation and excellence in the wool industry, benefiting consumers and businesses alike.

Frequently Asked Questions

Where Does High Quality Wool Come From?

High-quality wool comes from Merino sheep, prized for their fine fibers. Australia is a key producer, delivering 90% of premium wool globally. Merino wool stands out for its softness and insulation qualities, favored by luxury brands.

Where Is Wool Produced From the Most?

Australia is the world's largest producer of wool, exporting around 98% of its 345 million kilograms annually. Merino wool, known for its quality, is a significant product. Australia supplies about 90% of premium wool apparel globally.

What Is the Source of Wool?

Wool, sourced mainly from sheep like Merino sheep, is a fine fiber made of keratin. It's known for warmth and durability. Australia leads in wool production, exporting most of it globally. Merino wool is considered top quality.

Where Is Wool Obtained?

I get wool from the fleece of sheep. It's a fantastic material with unique properties. Merino wool, especially, is soft and fine, coming from Merino sheep. This fabric is wonderful for high-end clothing.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024