Welcome to the ultimate guide on 5 carbon fiber fabric patterns.

Uncover the intricacies of twill, plain, satin, harness satin, and 2×2 twill weaves.

You'll explore the unique characteristics and applications of each pattern, equipping you with the knowledge to master the art of working with carbon fiber.

This concise yet comprehensive guide is tailored for those seeking a deep understanding of carbon fiber fabrics and their diverse uses.

Whether you're an enthusiast, engineer, or craftsman, this guide will empower you to make informed decisions and unleash your creativity with confidence.

Let's delve into the world of carbon fiber fabric patterns and elevate your expertise to new heights.

Key Takeaways

- Twill weave patterns, including the twill weave pattern and 2×2 twill weave pattern, are highly popular in carbon fiber fabrics due to their exceptional drapability for complex shapes and curves, as well as their high strength and durability.

- Plain weave patterns offer a balanced and uniform construction, high fiber straightness for stiffness and dimensional stability, and a cost-effective and efficient production process, making them suitable for applications requiring stability and strength.

- Satin weave patterns, including satin weave pattern and harness satin weave pattern, provide enhanced flexibility for molding around complex shapes, a smooth surface finish with a lustrous appearance, and a high strength-to-weight ratio for high-performance applications.

- Satin weave patterns are also versatile choices for aesthetics and performance, providing high pliability and drapability, smooth surface finish, excellent strength-to-weight ratio, and are used in high-performance sports equipment and luxury goods.

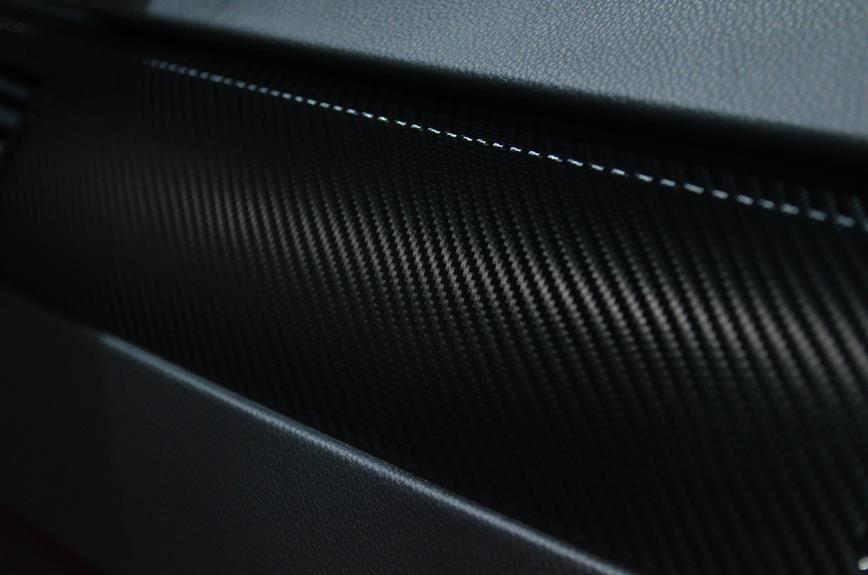

Twill Weave Pattern

You'll frequently encounter the twill weave pattern in carbon fiber fabrics. This pattern is highly popular due to its numerous benefits and wide range of carbon fiber applications.

One of the key advantages of the twill weave is its exceptional drapability, allowing it to conform to complex shapes and curves with ease. This makes it an ideal choice for applications where flexibility and conformity are essential, such as in the aerospace and automotive industries.

Another benefit of the twill weave pattern is its high level of strength and durability. The diagonal structure of the weave distributes the load evenly, providing excellent tensile strength and impact resistance. This makes twill weave carbon fiber fabrics suitable for demanding applications that require superior structural integrity and resilience.

In terms of carbon fiber applications, the twill weave pattern is commonly used in manufacturing lightweight yet robust components for aircraft, high-performance vehicles, sporting goods, and industrial equipment. Its versatility and strength make it a preferred choice for creating parts that require a combination of durability and low weight, making it an indispensable pattern in the world of carbon fiber fabrication.

Plain Weave Pattern

The Plain Weave pattern, unlike the twill weave, offers a different structure and set of advantages in carbon fiber fabrics. With its straightforward over-under pattern, it provides a balanced and uniform construction that lends itself well to certain applications. This pattern is characterized by a simple crisscross style, where each warp fiber passes alternately over and under each weft fiber. The result is a tightly woven fabric with excellent stability and strength.

In terms of fiber properties, the Plain Weave pattern allows for a high level of fiber straightness, maximizing the inherent strength of the carbon fibers. This makes it particularly suitable for applications that require stiffness and dimensional stability.

The manufacturing process for Plain Weave carbon fiber fabric involves the interlacing of fibers in a simple over-under pattern, which is generally less complex compared to other weave patterns. This simplicity not only makes it a cost-effective option but also allows for efficient, high-volume production.

Satin Weave Pattern

Explore the unique characteristics of satin weave pattern in carbon fiber fabric.

Satin weave is known for its distinct attributes that make it a popular choice in various applications. Here are some key points to consider:

- Satin Weave Benefits:

- Enhanced Flexibility: Satin weave pattern provides increased flexibility compared to other weave patterns, allowing for easier molding around complex shapes.

- Smooth Surface Finish: The weave's long floats create a smooth surface with a lustrous appearance, making it ideal for visible carbon fiber components.

- High Strength-to-Weight Ratio: Satin weave carbon fiber fabric offers exceptional strength while remaining lightweight, making it suitable for high-performance applications.

- Satin Weave Applications:

- Aerospace Industry: The flexibility and strength of satin weave make it valuable in aerospace for components like aircraft interiors and structural elements.

- Automotive Sector: Satin weave carbon fiber is used in luxury car interiors, exterior body panels, and performance parts due to its aesthetic appeal and strength.

- Sporting Goods: From tennis rackets to bicycles, satin weave carbon fiber is utilized in various sporting equipment for its strength and lightweight properties.

Satin weave pattern offers a balance of aesthetics and performance, making it a versatile choice for a wide range of applications.

Harness Satin Weave Pattern

Continuing from the previous subtopic on satin weave pattern, harness satin weave pattern also offers unique characteristics that make it a desirable choice for carbon fiber fabric applications.

The harness satin weave is known for its distinct diagonal pattern, which provides the fabric with a high level of pliability and drapability. This makes it an ideal choice for applications where the fabric needs to conform to complex shapes and contours, such as in automotive and aerospace industries.

Additionally, the harness satin weave offers the same advantages as traditional satin weaves, including a smooth surface finish, excellent strength-to-weight ratio, and reduced fraying of the fabric edges.

In terms of applications, harness satin weave carbon fiber fabric is commonly used in the production of high-performance sports equipment, luxury goods, and advanced structural components. Its ability to provide a balance of strength, flexibility, and surface quality makes it a preferred choice for applications where both aesthetics and performance are crucial.

When considering carbon fiber fabric patterns, the harness satin weave stands out as a versatile and effective option for a wide range of demanding applications.

2×2 Twill Weave Pattern

To understand the x2 twill weave pattern, begin by examining its unique characteristics and applications. This weave pattern is known for its distinct diagonal lines and is commonly used in high-performance applications due to its exceptional strength and flexibility.

x2 Twill Weave Pattern Characteristics:

- Diagonal Structure: The x2 twill weave pattern is characterized by its distinct diagonal structure, which provides excellent drapability and conforms well to curved surfaces.

- Balanced Strength: This pattern offers balanced strength and stability, making it ideal for applications requiring both durability and lightweight properties.

- Enhanced Aesthetics: The diagonal pattern of x2 twill weave creates a visually appealing surface, often chosen for its aesthetic appeal in addition to its performance benefits.

The x2 twill weave pattern finds extensive applications in industries such as aerospace, automotive, and sports equipment manufacturing. Its benefits include exceptional strength-to-weight ratio, improved impact resistance, and reduced material usage.

Whether used in high-performance car parts, aircraft components, or sporting goods, the x2 twill weave pattern is favored for its superior performance and versatility.

Frequently Asked Questions

How Does the Cost of Carbon Fiber Fabric Differ Between the Different Weave Patterns?

Cost variations between carbon fiber fabric weave patterns are influenced by market demand. Prices fluctuate based on the complexity of the weave and the amount of material required, impacting the overall cost for each pattern.

Are There Any Specific Industries or Applications That Favor One Weave Pattern Over the Others?

In specific industries like aerospace and automotive, certain weave patterns are preferred due to their strength and weight characteristics. For sports equipment, marine industry, and other applications, different weave patterns offer unique advantages.

Can the Different Weave Patterns Affect the Overall Strength and Durability of the Carbon Fiber Fabric?

Different weave patterns impact performance differently. For instance, twill weave provides a good balance of strength and aesthetics, while plain weave offers uniform strength. Understanding these differences is crucial for optimizing carbon fiber fabric durability.

Are There Any Specific Care or Maintenance Considerations for Each Weave Pattern?

When caring for different carbon fiber weave patterns, consider specific care considerations and maintenance tips. Each weave pattern may require unique cleaning methods or protective measures to maintain its integrity and appearance over time.

How Do the Different Weave Patterns Affect the Appearance and Texture of the Carbon Fiber Fabric?

Different weave patterns significantly impact the appearance and texture of carbon fiber fabric. The weave variations create distinct visual and tactile effects, ranging from a smooth, uniform surface to a textured, three-dimensional look.

- Tetron Fabric for Marine Applications: Durability and Use Cases - June 18, 2025

- Tetron Fabric for Outdoor Furniture: Weather Resistance and Care - June 18, 2025

- Tetron Fabric for Wall Coverings: Style and Application Tips - June 18, 2025