Just like the ripple effect in water, the choices you make in textile production can have far-reaching consequences. You might wonder how adopting sustainable practices can truly impact your business and the environment. By prioritizing eco-friendly materials, conserving water, and managing chemicals responsibly, you not only reduce your ecological footprint but also align with the growing consumer demand for ethical products. But what specific strategies can you implement to guarantee your textile production supports a more sustainable future?

Table of Contents

Key Takeaways

- Use natural fibers like organic cotton and hemp to reduce reliance on synthetic materials.

- Implement rainwater harvesting and advanced dyeing techniques to conserve water.

- Integrate renewable energy sources and energy-efficient machinery to lower operational energy use.

- Substitute hazardous chemicals with safer alternatives and ensure proper chemical management.

- Adopt upcycling initiatives and zero waste designs to minimize fabric waste.

Eco-Friendly Materials

When selecting eco-conscious materials for textile production, you prioritize not only the quality but also the environmental impact of the fabrics. Choosing natural fibers like organic cotton, hemp, or linen guarantees you're reducing dependence on synthetic materials that often lead to harmful waste. These plant-based materials not only provide durability and comfort but also align with sustainable farming practices, reducing chemical usage and promoting soil health.

Upcycled fabrics are another great option. By reusing materials such as post-consumer plastics and old textiles, you help divert waste from landfills and lessen the reliance on new resources. This approach promotes a circular economy, where materials are continuously repurposed, further decreasing the environmental impact of textile production.

Eco-friendly textiles, like those crafted from bamboo or Tencel, naturally decompose at the end of their lifecycle, preventing long-term pollution. These materials break down without releasing harmful substances, making them a wise choice for lessening environmental damage.

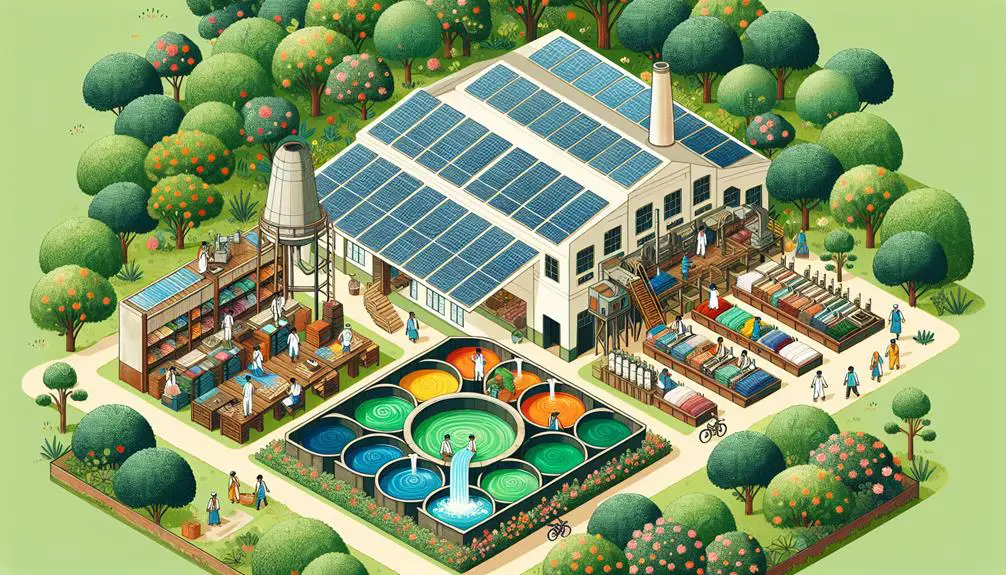

Water Conservation

Alongside selecting sustainable materials, conserving water in textile production is crucial for reducing the industry's environmental footprint. You can make a significant impact by adopting various water conservation strategies.

For instance, rainwater harvesting allows you to collect and use natural precipitation, reducing reliance on municipal water supplies. Additionally, implementing advanced dyeing techniques can drastically cut water usage and minimize the release of harmful chemicals into the environment.

Wastewater treatment is another vital component. By treating and recycling wastewater, you not only save water but also protect local ecosystems from contamination. Efficient irrigation systems in cotton production can also play a pivotal role by ensuring that water is used judiciously.

Here are some effective practices to keep in mind:

- Rainwater harvesting: Collect and store rainwater for use in various textile processes.

- Advanced dyeing techniques: Use low-water and no-water dyeing methods.

- Wastewater treatment: Invest in systems that treat and recycle water.

- Efficient irrigation systems: Implement drip irrigation to minimize water waste.

- Regular audits: Conduct water audits to identify and rectify inefficiencies.

Energy Efficiency

Maximizing energy efficiency in textile production reduces costs and minimizes environmental impact. By embracing renewable resources and leveraging technology advancements, you can greatly enhance your manufacturing process. Shifting to energy-efficient machinery and optimizing operational workflows are crucial steps.

Consider implementing a smart energy management system. This technology provides real-time data, enabling you to monitor and adjust energy consumption effectively. Additionally, integrating renewable resources like solar and wind energy can further decrease reliance on fossil fuels, aligning your production with sustainable practices.

Here's a snapshot to illustrate different strategies for energy efficiency:

| Strategy | Benefits | Implementation Time |

|---|---|---|

| Smart Energy Management System | Real-time data, optimized energy usage | Short-term |

| Renewable Energy Integration | Reduced fossil fuel dependency, eco-friendly | Medium to long-term |

| Energy-Efficient Machinery | Lower operational costs, higher efficiency | Medium-term |

Investing in energy-efficient machinery often results in substantial long-term savings. Machines with higher efficiency ratings consume less energy, reducing both your costs and carbon footprint. Furthermore, these advancements in technology enhance productivity, ensuring you achieve more with less. By focusing on energy efficiency, you're not just cutting costs but also promoting a sustainable future for the textile industry.

Chemical Management

Effective chemical management in textile production guarantees safety and minimizes environmental impact. By adopting meticulous practices, you can significantly diminish the reliance on hazardous substances and promote a healthier environment for both workers and consumers. Your approach should integrate green chemistry principles to foster sustainable innovation.

To streamline chemical management:

- Inventory Control: Maintain a precise inventory of all chemicals used to guarantee proper handling and disposal.

- Substitution: Identify and replace hazardous substances with safer alternatives whenever feasible.

- Training: Regularly educate your staff on the safe handling, storage, and disposal of chemicals.

- Monitoring: Implement continuous monitoring systems to detect and mitigate any potential chemical leaks or spills.

- Compliance: Ensure adherence to local and international regulations regarding chemical use and disposal.

Embracing green chemistry involves selecting chemicals that aren't only effective but also environmentally benign. For instance, opting for biodegradable dyes and solvents can markedly reduce the ecological footprint of your textile production process. By prioritizing the use of non-toxic, renewable materials, you'll align your operations with sustainability goals and regulatory standards.

Implementing these strategies won't only guarantee compliance and safety but will also enhance your reputation as a leader in sustainable textile production. Take control of your chemical management practices today to pave the way for a greener tomorrow.

Ethical Labor Practices

Securing ethical labor practices in your textile production not only protects workers' rights but also enhances your brand's integrity. By committing to fair wages, you demonstrate respect for your employees and their contributions. Fair wages guarantee that workers can live with dignity, which in turn fosters loyalty and reduces turnover. This stability is vital for maintaining high-quality production standards.

Prioritizing safe working conditions is equally important. A safe workplace minimizes the risk of accidents and health issues, guaranteeing that your workforce remains productive and motivated. Regular safety audits, proper training, and the implementation of safety measures create an environment where employees feel valued and secure. When workers know their well-being is a priority, they're more engaged and committed to producing superior products.

Moreover, transparency in labor practices builds trust with consumers who increasingly demand ethical standards from brands. Showcasing your commitment to fair wages and safe working conditions can distinguish your brand in a competitive market. Ethical labor practices aren't just a moral obligation but a strategic advantage. Adopting these practices can lead to long-term success, both ethically and economically, solidifying your position as a leader in sustainable textile production.

Waste Reduction

Reducing waste in textile production not only conserves resources but also greatly lowers operational costs. By implementing strategic waste reduction practices, you can make a significant impact on both the environment and your bottom line.

Start by focusing on upcycling initiatives, which transform leftover materials into new, valuable products. This approach not only reduces waste but also creates unique items that can appeal to eco-conscious consumers.

Zero waste designs are another powerful tool in your arsenal. These designs are meticulously planned to minimize or completely eliminate fabric waste during the cutting process. By adopting zero waste patterns, you can maximize material usage and reduce the need for additional raw materials.

Here are some practical steps to get you started:

- Implement upcycling initiatives: Convert scrap materials into new products.

- Adopt zero waste designs: Use patterns that eliminate fabric waste.

- Optimize cutting techniques: Improve cutting methods to reduce leftover material.

- Educate your team: Train employees on waste reduction practices.

- Monitor waste: Keep track of waste production to identify areas for improvement.

Circular Fashion

Circular fashion revolves around designing and producing clothing in a way that allows materials to be reused and recycled, minimizing waste and environmental impact.

To master circular fashion, you need to embrace the concept of upcycled garments. These are items that have been creatively reimagined from pre-existing materials, giving them new life and reducing the demand for raw resources. By incorporating upcycled garments into your wardrobe, you actively contribute to decreasing textile waste.

Another critical aspect of circular fashion is the implementation of closed-loop systems. In these systems, the end-of-life stage for one garment becomes the starting point for another, forming a continuous cycle. This involves processes like fiber reclamation and recycling, safeguarding that no material goes to waste. By supporting brands that utilize closed-loop systems, you help foster a more sustainable textile industry.

To achieve true mastery in circular fashion, you must also consider the longevity of your clothing. Invest in high-quality pieces and care for them properly to extend their lifespan. This reduces the frequency of replacement and further minimizes waste.

Adopting these practices will guarantee you're not just following a trend but leading a sustainable movement.

Frequently Asked Questions

How Do Sustainable Practices Impact the Cost of Textile Products?

You're curious about how sustainable practices impact costs. Sustainable methods often have higher initial costs due to eco-friendly materials and ethical labor. However, they reduce long-term environmental impact and can lead to cost savings over time.

What Certifications Should Consumers Look for in Sustainable Textiles?

Simply put, you should look for certifications like GOTS, OEKO-TEX, and Fair Trade. These global standards guarantee minimal environmental impact. It's like choosing the Holy Grail of textiles for a sustainable lifestyle!

How Can Small Textile Businesses Implement Sustainable Practices?

You can implement eco-friendly materials by sourcing organic fibers and natural dyes. Focus on waste reduction strategies like recycling scraps and optimizing production processes. Commit to these actions and you'll master sustainable practices in your small textile business.

What Are the Long-Term Benefits of Sustainable Textile Production for Consumers?

Imagine a world where your wardrobe is a finely tuned symphony. By embracing reduced waste and improved quality, you enjoy durable, high-quality clothes that last longer, saving money and contributing to a healthier planet.

How Can Consumers Contribute to Sustainability in the Textile Industry?

You can contribute to sustainability by supporting recycling initiatives, educating yourself on eco-friendly materials, and choosing products with ethical sourcing. Your informed choices drive positive change and promote a more sustainable textile industry.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024