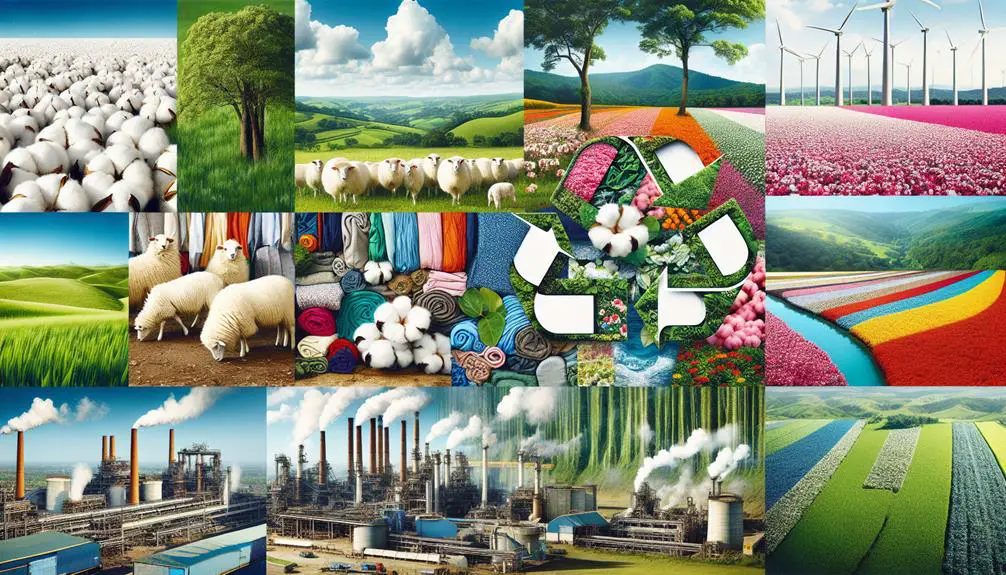

When you consider the clothes you wear daily, do you ever think about their environmental impact? Cotton, while soft and breathable, demands vast amounts of water and pesticides, leading to water scarcity and biodiversity loss. Polyester, made from petroleum, releases greenhouse gases and sheds microplastics into our oceans. Wool, though renewable, requires careful energy management. Silk's luxurious feel comes at the cost of high water and energy use. Nylon, another synthetic option, isn't much better. Yet, materials like hemp and bamboo offer eco-friendly alternatives. Curious how your wardrobe choices affect the planet? There's more to uncover.

Table of Contents

Key Takeaways

- Cotton production consumes vast amounts of water and pesticides, leading to water scarcity, pollution, and biodiversity loss.

- Polyester production is energy-intensive and contributes to greenhouse gas emissions and microplastic pollution.

- Wool is a renewable, biodegradable material with a low carbon footprint and minimal environmental impact.

- Silk production is resource-intensive but supports biodiversity and uses fewer pesticides than cotton.

- Hemp cultivation is environmentally friendly, requiring minimal water and pesticides, and improves soil health.

Cotton

Cotton is often praised as a natural and versatile textile, but its environmental impact is significant. When you explore the details, you'll find that cotton's water consumption is particularly concerning. A single cotton T-shirt can require up to 2,700 liters of water to produce. This extensive water use puts pressure on water-scarce regions, worsening local water shortages.

Furthermore, cotton farming is infamous for its heavy pesticide use. These chemicals not only damage local ecosystems but also present health hazards to farmers and nearby communities. You'll observe how the widespread use of pesticides leads to biodiversity loss, polluting water sources and soils.

Soil degradation is another crucial issue. Conventional cotton farming methods deplete the soil of nutrients, resulting in diminished agricultural productivity over time. However, organic farming methods offer a more sustainable option. By avoiding synthetic pesticides and fertilizers, organic cotton farming helps preserve soil health and promotes biodiversity. Crop rotation and composting—key components of organic practices—can revitalize the soil, making it more resilient and fertile.

Understanding these impacts empowers you to make more informed decisions. Choosing organic cotton can alleviate some of these environmental challenges, contributing to a more sustainable textile industry.

Polyester

How does polyester, a synthetic textile, fare regarding environmental impact compared to natural fibers?

Unlike cotton, polyester is derived from petroleum, a non-renewable resource. This means its production is inherently more energy-intensive and contributes significantly to greenhouse gas emissions.

However, polyester recycling offers a ray of hope. By reprocessing used polyester into new fibers, you can reduce the need for virgin materials and cut down on environmental harm.

Yet, the story doesn't end there. One of the most pressing issues with polyester is microplastic pollution. Every time you wash a polyester garment, tiny plastic fibers are released into the water system.

These microplastics aren't only hard to filter out but also pose a severe threat to marine life and, ultimately, human health.

In the domain of textile sustainability, polyester's durability and recyclability present advantages, but you must weigh these against its environmental drawbacks.

To master the complexities of textile impacts, consider both the lifecycle emissions and the broader ecological consequences, such as microplastic pollution. Taking a holistic view will guide you in making informed choices that balance functionality with environmental stewardship.

Wool

When you consider wool, think about its entire production process, from sheep farming to textile creation.

You should understand its carbon footprint and the environmental challenges it poses.

Wool Production Process

The wool production process starts with shearing sheep, which is typically done once a year. The shearing process is essential as it not only harvests wool but also ensures the health and comfort of the sheep. Skilled shearers use specialized tools to carefully remove the fleece without harming the animal. This sustainable practice highlights one of wool's key environmental benefits: it's a renewable resource. Each year, sheep grow a new fleece, reducing the need for synthetic materials that rely on finite resources.

After shearing, the wool undergoes cleaning, or scouring, to remove impurities like grease, dirt, and vegetable matter. This step is crucial to prepare the wool for further processing. The cleaned wool is then carded, which involves disentangling and aligning the fibers, making it ready for spinning. Spinning transforms the wool into yarn, which can be woven or knitted into various textile products.

Throughout this process, wool stands out for its minimal environmental footprint. Wool production requires less energy compared to synthetic fibers and is biodegradable, breaking down naturally without contributing to landfill waste.

Carbon Footprint Analysis

Wool boasts a surprisingly low carbon footprint compared to many other textile materials. When you explore the specifics, you'll find that wool's production process involves minimal energy consumption. This naturally reduces its carbon emissions.

Additionally, sheep grazing helps maintain grasslands, which act as carbon sinks, further offsetting the carbon footprint.

Water consumption in wool production is also relatively low. Unlike cotton, which requires extensive irrigation, wool depends primarily on natural rainfall. Plus, wool's durability means garments last longer, reducing the need for frequent replacements. Effective recycling practices further extend wool's lifecycle, making it an eco-friendly choice.

Chemical usage in wool processing is generally limited. While some chemicals are employed in dyeing and finishing, many producers opt for eco-friendly options. You can look for environmental certifications like OEKO-TEX and the Global Organic Textile Standard (GOTS) to guarantee sustainable practices.

Sustainable Wool Alternatives

Investigating sustainable wool alternatives can lead you to innovative materials that minimize environmental impact without compromising on quality. When you explore these options, you'll discover fibers that not only replicate the luxurious feel of wool but also adhere to principles of ethical sourcing and animal welfare.

Consider materials like organic cotton, which is grown without harmful pesticides and supports eco-friendly farming practices. It's a biodegradable option that can seamlessly replace traditional wool in many applications.

Another promising alternative is Tencel, derived from sustainably sourced wood pulp. This eco-friendly fiber boasts excellent moisture-wicking properties and biodegradability, making it a great choice for those prioritizing sustainability. Additionally, hemp is gaining traction as a versatile, durable, and biodegradable option. It's cultivated with minimal water and pesticides, and its fibers are incredibly strong, making it an ideal substitute for wool.

Bamboo fibers, too, offer an eco-friendly solution. Though processing methods vary, choosing bamboo linen ensures a lower environmental footprint.

Silk

Renowned for its luxurious feel and natural sheen, silk has a significant environmental footprint that warrants attention. Silk production involves raising silkworms, a process that's resource-intensive and has notable ecological implications. Yet, there are environmental benefits worth noting. For instance, sericulture, or silk farming, can support biodiversity by encouraging the growth of mulberry trees, which are vital for silkworms.

However, the energy and water consumption associated with silk production can't be overlooked. It's important to weigh these factors when evaluating silk's overall environmental impact. Here's a quick comparison to provide you with more insight:

| Aspect | Impact on Environment | Points to Note |

|---|---|---|

| Land Use | Moderate | Mulberry trees enhance biodiversity. |

| Water Consumption | High | Demands significant irrigation. |

| Energy Consumption | High | Involves boiling cocoons and processing silk. |

| Pesticide Use | Minimal | Generally lower compared to cotton. |

| Waste Management | Moderate | Biodegradable but slow to decompose. |

To fully understand the nuances of silk's environmental impact, it's crucial to acknowledge both the benefits and drawbacks. While silk offers some sustainability advantages, its production requires meticulous resource management. By grasping these complexities, you can make more informed decisions regarding textile materials.

Nylon

When you consider nylon, it's important to recognize the significant energy required for its production. This synthetic material also generates considerable waste and pollution, impacting the environment negatively.

You'll find that these factors make nylon a less sustainable choice compared to natural fibers.

Production and Energy Usage

Producing nylon requires a substantial amount of energy, making it one of the most resource-intensive synthetic textiles. When you're considering the environmental impact, it's important to recognize that nylon production involves significant water consumption and generates considerable chemical waste. The manufacturing process uses large quantities of water for cooling and washing, which not only depletes natural water resources but also often leads to contamination if the wastewater isn't properly treated.

In addition to water consumption, the energy-demanding nature of nylon production primarily stems from its reliance on fossil fuels. Unlike textiles derived from renewable resources, nylon's synthesis involves the polymerization of petrochemicals, which contributes significantly to greenhouse gas emissions. This process is far from eco-friendly, and it poses a challenge for those aiming to adopt sustainable practices.

To mitigate these impacts, you should advocate for advancements in eco-friendly practices. Innovations in recycling nylon and using alternative, renewable feedstocks can reduce the environmental footprint. By focusing on more sustainable methods, the textile industry can move towards a future where the high energy demands of nylon don't compromise the health of our planet.

Waste and Pollution

Nylon's waste and pollution issues arise mainly from its non-biodegradable nature and the release of harmful chemicals during production and disposal. When you discard nylon products, they end up as landfill waste, contributing to the growing problem of overflowing landfills. Unlike natural fibers, nylon doesn't decompose, persisting in the environment for decades. This non-biodegradability leads to long-term environmental damage.

The production process of nylon isn't innocent either. It releases toxic chemicals, leading to chemical runoff that contaminates water bodies. This pollution affects aquatic life and disrupts ecosystems. When you consider the textile dye pollution involved in coloring nylon, the problem only worsens. These dyes often contain harmful substances that can leach into the soil and waterways, poisoning both plant and animal life.

Microplastic contamination from nylon is another critical issue. When you wash nylon-based textiles, tiny fibers break off and enter water systems. These microplastics are ingested by marine organisms, entering the food chain and eventually making their way back to you.

The environmental impact of nylon is profound and multifaceted, necessitating a thoughtful approach to its use and disposal.

Hemp

Hemp stands out as an eco-friendly textile option due to its minimal need for pesticides and water. When you explore hemp cultivation, you'll find that this plant thrives with little intervention. Unlike cotton, which demands significant water and chemical inputs, hemp grows robustly with natural rainfall and minimal pesticide use. This makes it a stellar choice for eco friendly textiles, offering a sustainable alternative to more resource-intensive materials.

You should appreciate how hemp's rapid growth cycle enhances its environmental benefits. It matures within four months, allowing for multiple harvests in a single year. This efficiency maximizes land use and reduces the need for expansive agricultural space. Additionally, hemp roots stabilize soil and prevent erosion, further contributing to environmental health.

Hemp fibers aren't just sustainable but also durable and versatile. They produce strong, long-lasting fabrics that soften with use without losing integrity. As a result, hemp textiles often outlast those made from other materials, reducing the frequency of replacement and lowering overall consumption.

Bamboo

Bamboo offers a compelling case for sustainability in textiles due to its rapid growth and minimal resource requirements. Unlike other plants, bamboo can thrive without pesticides or fertilizers, making it an eco-friendly choice. It also uses far less water compared to cotton, and some species can grow up to 35 inches per day. This rapid growth cycle means you can harvest it more frequently without depleting the soil.

In terms of eco-friendly uses, bamboo is incredibly versatile. It can be transformed into soft, breathable fabrics that are naturally antibacterial and hypoallergenic. This makes bamboo textiles not only sustainable but also highly functional. You'll find it in everything from clothing to home linens, all while knowing you're making a conscientious choice for the environment.

Bamboo sustainability goes beyond just the plant; the entire production process can be environmentally friendly if done correctly. When processed mechanically rather than chemically, bamboo retains its green credentials. This method involves crushing the woody parts and using natural enzymes to break them down, reducing the environmental impact even further.

Frequently Asked Questions

How Do Dyes and Finishes Affect the Environmental Impact of Textiles?

Imagine vibrant colors swirling in water. Dyes and finishes can spike energy consumption and increase your carbon footprint. Opt for eco-friendly alternatives to boost sustainability, reducing environmental harm while maintaining the allure of your textiles.

What Are the Benefits of Recycling Textile Materials?

Recycling textile materials helps you conserve resources and supports a circular economy. By reusing fabrics, you reduce waste, minimize the need for raw materials, and promote sustainability, ultimately contributing to a more efficient and responsible industry.

How Does Water Consumption in Textile Production Vary by Region?

Imagine a desert oasis: in regions like India, textile production guzzles water, skyrocketing energy consumption and carbon emissions. Meanwhile, resource depletion in water-rich areas is less dire, but pollution levels still spike, harming ecosystems.

What Are the Alternatives to Chemical-Intensive Textile Processing?

You can consider sustainable sourcing and natural fibers as alternatives to chemical-intensive textile processing. Opt for organic cotton, hemp, or bamboo. These choices reduce environmental impact and support eco-friendly practices, ensuring mastery in ethical fashion.

How Do Textile Waste Management Practices Differ Globally?

Globally, 92 million tons of textile waste are generated annually. Waste management practices vary considerably due to cultural differences, with some countries prioritizing recycling while others focus on landfill or incineration methods.

- How to Cut Slippery Fabrics Like Crepe: A Step-by-Step Tutorial - June 23, 2025

- 15 Essential Tips for Sewing With Crepe Fabric (Without the Headache) - June 23, 2025

- What Is Viscose/Rayon Crepe? the Sustainable & Drapey Option - June 23, 2025