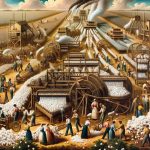

Are you interested in learning how to produce organic cotton fabric?

This step-by-step guide will walk you through the entire process.

From selecting the right organic cotton seeds to weaving the yarn into fabric, you’ll gain valuable insights on nurturing, harvesting, processing, and finishing the cotton fibers.

Get ready to embark on a journey of sustainable textile production.

Table of Contents

Choosing the Right Organic Cotton Seeds

To choose the right organic cotton seeds, you need to look for varieties that are specifically bred for organic farming and are certified by reputable organizations. When it comes to organic cotton farming techniques, using the right seeds is crucial for a successful and sustainable crop. Organic cotton seeds are specially developed to be resistant to pests and diseases without the use of synthetic pesticides and chemicals. These seeds are also bred to be adaptable to different climates and soil conditions, ensuring that they can thrive in organic farming systems.

One of the key benefits of using organic cotton seeds is their ability to promote soil health. Organic farming practices prioritize the use of natural fertilizers and crop rotations, which help to maintain the fertility of the soil. Organic cotton seeds are bred to be compatible with these practices, resulting in healthier soil and reduced environmental impact.

Additionally, organic cotton seeds contribute to the overall sustainability of the textile industry by reducing the reliance on synthetic inputs and supporting biodiversity in agricultural systems. By choosing certified organic cotton seeds, you aren’t only making a positive impact on the environment but also supporting the livelihoods of organic cotton farmers.

Nurturing the Cotton Crop for Optimal Growth

For optimal growth of the cotton crop, you need to nurture it with proper care and attention throughout its growth cycle. This involves implementing optimal watering techniques and natural pest control methods. Here’s a step-by-step guide to help you nurture your cotton crop for optimal growth:

-

Watering: Cotton plants require regular watering to thrive. However, overwatering can lead to root rot and other diseases. Use drip irrigation or soaker hoses to provide a slow, steady supply of water directly to the roots. This ensures that the plants receive adequate moisture without excessive waterlogging.

-

Mulching: Apply organic mulch, such as straw or compost, around the base of the cotton plants. Mulching helps to retain soil moisture, suppress weeds, and regulate soil temperature, creating an optimal environment for growth.

-

Natural Pest Control: Instead of relying on harmful chemical pesticides, opt for natural pest control methods. Introduce beneficial insects, like ladybugs and lacewings, to prey on pests such as aphids and caterpillars. Additionally, companion planting with marigolds and garlic can help repel pests.

-

Crop Rotation: Rotate your cotton crop with other crops to prevent the buildup of pests and diseases in the soil. This practice disrupts the life cycles of pests and helps maintain soil fertility.

Harvesting and Collecting Organic Cotton Bolls

Now let’s talk about harvesting and collecting organic cotton bolls.

When it comes to sustainable cotton farming, the process of harvesting is crucial.

You’ll also learn about the importance of organic cotton certification and how it ensures the integrity of the cotton’s organic status.

Sustainable Cotton Farming

When harvesting and collecting organic cotton bolls sustainably, you should ensure that you follow these steps carefully:

-

Practice water conservation: Use efficient irrigation systems and techniques to minimize water usage. This includes drip irrigation and rainwater harvesting methods.

-

Implement pest management strategies: Use natural and organic methods to control pests and diseases in your cotton fields. This can include crop rotation, beneficial insects, and botanical pesticides.

-

Promote biodiversity: Create a diverse ecosystem in your cotton farm by planting companion crops and native plants. This will attract beneficial insects and help maintain a balanced ecosystem.

-

Monitor soil health: Regularly test your soil for nutrient levels and make necessary amendments to maintain healthy soil. This will promote the growth of strong and productive cotton plants.

Organic Cotton Certification

To obtain organic cotton certification for your sustainably harvested and collected cotton bolls, you must adhere to specific guidelines and standards. Certification is crucial in the organic cotton market as it assures consumers that the cotton has been produced following environmentally friendly practices. The benefits of organic cotton certification are numerous. Firstly, it guarantees that the cotton has been grown without the use of synthetic fertilizers or pesticides, reducing the environmental impact. Secondly, it ensures that fair labor practices have been implemented, protecting the rights and well-being of workers. Lastly, organic cotton certification helps to establish trust and transparency between producers and consumers, driving the demand for sustainable and ethically produced cotton. See the table below for a summary of the certification process:

| Certification Process |

|---|

| 1. Organic Farming Practices |

| 2. Documentation and Auditing |

| 3. Certification Review |

| 4. Certification Decision |

| 5. Annual Inspection and Renewal |

Processing and Cleaning the Cotton Fibers

Now it’s time to tackle the important step of processing and cleaning the cotton fibers.

You’ll learn about the eco-friendly cleaning methods that are used in organic cotton production and how they contribute to preserving the environment.

Additionally, we’ll explore the impact of these cleaning methods on the overall quality of the textile, ensuring that you understand the benefits of choosing organic cotton.

Eco-Friendly Cleaning Methods

To achieve eco-friendly cleaning methods for processing and cleaning the cotton fibers in organic cotton fabric production, you can implement various sustainable practices. Here are four ways to ensure a more environmentally friendly approach:

-

Use eco-friendly detergents: Opt for detergents that are biodegradable and free from harsh chemicals. These detergents aren’t only better for the environment but also gentler on the cotton fibers.

-

Choose natural fabric softeners: Instead of using synthetic fabric softeners that contain harmful ingredients, consider natural alternatives like vinegar or baking soda. These options are safer for both the environment and your cotton fabric.

-

Reduce water consumption: Implement water-saving techniques such as using low-flow washing machines or reusing water for multiple cycles. This helps conserve water resources and minimizes the environmental impact.

-

Optimize energy usage: Use energy-efficient washing machines and dryers to minimize electricity consumption. Additionally, consider air-drying your cotton fabric whenever possible to reduce energy usage.

Impact on Textile Quality

Implementing eco-friendly cleaning methods in organic cotton fabric production has a significant impact on the quality of the textile by ensuring the preservation of the cotton fibers. By using sustainability practices in organic cotton fabric production, you can enhance the overall durability and strength of the fabric.

Traditional methods of cleaning cotton fibers often involve the use of harsh chemicals, which can weaken the fibers and compromise the textile’s quality. However, by opting for organic cleaning methods, you can avoid the use of harmful substances and maintain the integrity of the cotton fibers.

This, in turn, leads to a higher quality fabric that’s more resistant to wear and tear, making it ideal for textile manufacturing. By choosing organic cotton fabric, you can enjoy the benefits of a sustainable and durable textile that’s gentle on the environment.

Spinning the Cotton Fibers Into Yarn

After harvesting the cotton fibers, you’ll need to spin them into yarn. This step is crucial in the production of cotton fabric. Here is a step-by-step guide to help you understand the process:

-

Cleaning and Carding: The harvested cotton fibers are cleaned to remove impurities like dirt and seeds. Then, they go through the carding process where the fibers are straightened and aligned.

-

Drawing and Combing: In this step, the fibers are drawn through a series of rollers to further align them. Combing is often done to remove shorter fibers, leaving behind long and strong ones.

-

Roving: The drawn and combed fibers are then twisted into strands called rovings. The rovings are thin and continuous, ready for the next step.

-

Spinning: Finally, the rovings are spun into yarn by twisting them together. This process adds strength and cohesion to the cotton fibers, transforming them into a continuous thread that can be used to weave fabric.

Weaving the Yarn Into Organic Cotton Fabric

To weave the yarn into organic cotton fabric, you’ll need to utilize specialized machinery and a skilled operator. Weaving is a crucial step in the production process, as it transforms the yarn into a durable and versatile fabric. There are different weaving techniques that can be employed to create various types of organic cotton fabric, such as plain weave, twill weave, and satin weave.

The weaving process begins by setting up the loom, which is the machine used to interlace the yarn. The warp yarns are threaded vertically onto the loom, while the weft yarns are inserted horizontally. The skilled operator carefully guides the yarn through the loom, interlacing the warp and weft yarns to create the desired fabric structure.

Once the fabric has been woven, it goes through the dyeing process. Organic cotton fabric can be dyed using natural or synthetic dyes, depending on the desired color and environmental considerations. The dyeing process involves immersing the fabric in a dye bath and allowing it to absorb the color. After dyeing, the fabric is rinsed and dried to set the color.

Finishing and Quality Control of Organic Cotton Fabric

Begin by inspecting the organic cotton fabric for any flaws or imperfections. Quality control is a crucial step in the production of organic cotton fabric to ensure that the final product meets the desired standards.

Here are the steps involved in finishing and quality control of organic cotton fabric:

-

Washing: The fabric is washed to remove any dirt, impurities, or residual chemicals. This process helps to enhance the softness and absorbency of the fabric.

-

Dyeing and Printing: If color or patterns are desired, the fabric is dyed or printed using organic dyes and pigments. This step adds aesthetic value to the fabric.

-

Finishing Treatments: Various finishing treatments are applied to the fabric to improve its properties, such as shrinkage control, crease resistance, and wrinkle-free characteristics. These treatments enhance the durability and performance of the fabric.

-

Quality Control Checks: After the finishing treatments are applied, the fabric undergoes rigorous quality control checks. This involves inspecting the fabric for color consistency, fabric strength, dimensional stability, and other parameters. Any flaws or defects are identified and rectified before the fabric is deemed suitable for use.

Frequently Asked Questions

How Long Does It Take for Organic Cotton Seeds to Germinate and Start Growing?

It takes organic cotton seeds about 7-10 days to germinate and start growing. During this time, the seeds absorb water and nutrients, and the roots begin to sprout, allowing for further growth.

What Are the Common Pests and Diseases That Affect Organic Cotton Crops and How Can They Be Managed?

To effectively manage common pests and diseases in organic cotton crops, you need to employ some techniques. These include crop rotation, using beneficial insects, organic pesticides, and regular inspection to identify and treat any issues.

Are There Any Specific Certifications or Standards That Organic Cotton Fabric Producers Need to Adhere To?

To produce organic cotton fabric, you need to adhere to specific certifications and standards. These requirements ensure that the production process follows strict guidelines and regulations for organic practices.

What Are the Different Methods Used to Process and Clean Organic Cotton Fibers?

To process and clean organic cotton fibers, various methods are used. These include mechanical techniques like ginning and carding, as well as cleaning methods such as washing with natural detergents and using enzymes to remove impurities.

How Is the Quality of Organic Cotton Fabric Assessed During the Finishing and Quality Control Process?

During the finishing and quality control process, you assess the quality of organic cotton fabric by implementing quality control measures. This ensures that the fabric meets the required standards and is free from any defects or imperfections.

- Why Is Red Velvet Not Red? - April 25, 2024

- How Do You Describe Velvet Fabric? - April 25, 2024

- How Strong Is Velvet? - April 25, 2024