I start as mature cotton bolls picked in the fall, using machines or by hand. Efficient separation is crucial for quality. Next, the fibers get purified thoroughly using advanced tech like EVŌC. Carding aligns the fibers before spinning, guaranteeing excellent yarn. Spinning machines twist the fibers into various yarn styles. Weaving intertwines the yarns on a loom for fabric production. This is just the beginning of the journey from field to fabric, where a meticulous process guarantees the high-quality cotton we enjoy in our textiles.

Table of Contents

Key Takeaways

- Cotton is made through harvesting mature bolls.

- Mechanical or manual methods are used for picking.

- Purification processes like scouring and cleaning are vital.

- Carding aligns fibers for spinning into yarn.

- Spinning machines twist fibers into versatile yarn.

Cotton Harvesting Process

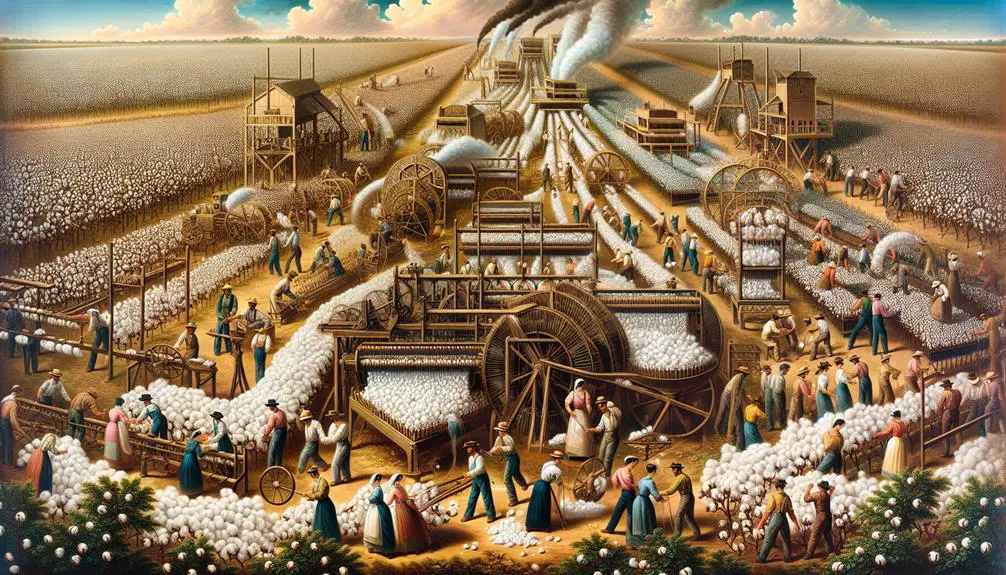

Harvesting cotton involves picking mature cotton bolls from the plants, an essential step in the production process. This task can be accomplished through mechanical pickers or manual labor, typically done in the fall when the bolls have fully developed. Once the cotton bolls are harvested, the next step is to separate the fibers from the seeds and other debris. This separation process is pivotal in ensuring high-quality cotton for further processing.

After the cotton is harvested and the fibers are separated, it goes through a processing machine to extract the fibers efficiently. These machines help in cleaning the cotton and removing any remaining impurities. The cotton fibers are then ready for the next stages of production, where they can be used to create a wide range of products such as clothing, textiles, and even medical supplies. The cotton harvesting process sets the foundation for the quality of the final cotton products we use in our daily lives.

Cotton Cleaning Methods

During the cotton cleaning process, advanced technologies ensure thorough purification of the fibers to eliminate plant matter and impurities effectively. Mechanical cleaning methods like EVŌC are utilized to remove unwanted debris from the cotton fibers, ensuring a clean and high-quality end product.

Scouring, a common step in cotton cleaning, involves treating the fibers with sodium hydroxide solutions to remove waxes and impurities, further enhancing the purity of the cotton. Additionally, the use of purifying agents such as hydrogen peroxide serves to whiten the fibers and eliminate any remaining coloring matter, resulting in a more pristine appearance.

These cleaning methods are essential in preparing the cotton fibers for further processing stages, ensuring that the fibers are free from contaminants that could impact the quality of the final cotton products. By incorporating these advanced cleaning techniques, the cotton fibers are primed for subsequent steps like carding and fiber alignment, where they'll be further refined to achieve the desired end product.

Carding and Fiber Alignment

So, let's discuss carding and fiber alignment in the cotton-making process.

Carding is a vital step that aligns cotton fibers before they're spun into yarn. This process helps remove tangles and guarantees a uniform strand, ultimately enhancing the quality and strength of the final cotton product.

Carding Process Overview

In the carding process for cotton production, fibers are meticulously aligned and straightened by carding machines to prepare them for spinning. Carding machines work by combing the fibers to remove impurities like dirt, seeds, and short fibers, creating a uniform strand of fibers.

This process is vital for improving yarn quality and strength, as well as ensuring a smoother and more consistent yarn for weaving into fabric. Fiber alignment during carding plays a pivotal role in enhancing spinning efficiency and overall fabric quality.

Importance of Alignment

As we explore the significance of alignment in cotton production, it's clear that the carding process plays a fundamental role in ensuring the quality and strength of the yarn that's spun for weaving.

Fiber alignment during carding is essential for producing high-quality cotton yarn suitable for weaving into fabric. By aligning the fibers, the carding process helps create a uniform strand, resulting in a smooth and even texture in the yarn. This alignment not only enhances the overall quality of the cotton yarn but also contributes to the strength, durability, and appearance of the final cotton fabric.

Through the carding process, short fibers, tangles, and impurities are removed, ensuring a consistent and uniform yarn, ready for the weaving process.

Fiber Quality Enhancement

When carding cotton fibers for yarn production, the process focuses on aligning the fibers to enhance their quality and strength. Carding machines play an important role in this process by combing the cotton fibers to remove impurities and guarantee uniformity.

Fiber alignment during carding is vital as it leads to improved strength, appearance, and consistency of the yarn. By separating and straightening the fibers, carding creates a smoother yarn suitable for weaving or knitting high-quality textiles and fabrics.

Proper carding of natural cotton fibers is essential in the overall process of making textiles, ensuring that the final product meets the desired standards for durability and performance.

Spinning Cotton Into Yarn

Using a spinning machine, we twist cotton fibers together to create durable yarn for weaving. This process involves aligning and twisting the cleaned and combed cotton fibers to form long, continuous threads.

By spinning the fibers, we enhance their significance and prepare them for the next stage of fabric production. Different spinning techniques can result in varying yarn thickness and textures, allowing for a wide range of fabric types to be created.

The importance of the yarn produced during spinning is pivotal, as it determines the final characteristics of the fabric. This step plays a vital role in converting raw cotton fibers into usable yarn for weaving into various textiles.

Through the spinning process, we're able to transform the natural fibers of cotton into versatile and resilient yarn that serves as the foundation for the creation of a wide array of fabrics.

Weaving Cotton Fabric

Weaving cotton fabric involves the intricate process of intertwining warp threads lengthwise with weft yarns crosswise on a loom. The warp threads are held taut while the weft yarn is inserted across them, creating the woven fabric. Looms employ different motions like shedding, picking, beating, and winding to weave the fabric seamlessly. It's important to make sure that the fiber length and quality of the cotton bales are suitable for the weaving process to yield a strong and durable fabric.

Once the weaving is complete, the fabric undergoes inspection to detect any flaws. If imperfections are found, they're corrected before the fabric is folded and graded based on quality standards. The weaving process plays a significant role in ensuring that the threads are securely interlaced, resulting in a finished product that's both resilient and visually appealing.

Role of the Cotton Gin

The invention of the cotton gin by Eli Whitney in 1794 revolutionized the process of separating cotton fibers from seeds, greatly boosting efficiency and productivity in cotton production.

Before the cotton gin, separating cotton fibers from seeds was a vital task that required significant time and effort. With the cotton gin, this process became automated, allowing for a much faster and more efficient separation of the fibers from the seeds.

This increase in efficiency had a significant impact on the cotton industry, leading to a notable expansion in cotton production.

The cotton gin played an essential role in the economic development of the Southern United States, particularly during the antebellum period. Its ability to increase efficiency and automate the process of separating cotton fibers from seeds made cotton production more profitable and accessible, ultimately shaping the course of the cotton industry and the economy at large.

Cotton Planting and Growth

Cotton planting and growth require specific environmental conditions such as warm temperatures, ample sunshine, and necessary water to thrive effectively. The cotton plant goes through various stages before the fibers are ready for harvesting. Initially, the plant produces flowers that eventually transform into cotton bolls containing the fibers we use to make textiles. It takes approximately 5 months for a cotton plant to reach maturity and be ready for harvesting, typically in the fall season when the cotton bolls are fully mature.

Once the cotton is harvested, the next step involves separating the valuable fibers from the seeds and other debris. This process is essential for further processing the cotton into various products. Understanding the growth cycle of cotton plants is fundamental for ensuring a successful harvest and high-quality fibers for processing. By providing the right conditions and care, we can cultivate healthy cotton plants that yield the fibers needed for a wide range of textiles.

Major Cotton Producing Countries

Among the top three cotton-producing nations globally, China, India, and the United States play an important role in shaping the cotton industry with their substantial annual production levels. China leads the pack, producing over 27 million bales of cotton each year, followed closely by India with around 22 million bales annually. The United States ranks third in cotton production, churning out approximately 18 million bales of cotton yearly.

These three countries collectively contribute a substantial portion of the world's cotton production. China's massive output cements its position as the world's largest cotton producer, while India's significant contribution solidifies its place as a key player in the cotton industry. The United States, although producing slightly less than China and India, remains an important player in the global cotton market.

The combined efforts of these nations significantly impact the supply and demand dynamics of the cotton industry worldwide.

Automation in Cotton Manufacturing

So, let's talk about the cool automated stuff happening in cotton manufacturing.

Robotic picking machines are out there picking cotton like pros, and integrated quality control systems are making sure all is excellent.

Plus, automated spinning processes are spinning cotton into threads quicker than you can say 'cotton candy.'

Robotic Picking Machines

Utilizing cutting-edge technology, robotic picking machines revolutionize the cotton harvesting process by efficiently and accurately collecting ripe cotton bolls at a rapid pace. These advanced machines greatly increase efficiency in the harvesting process by picking cotton at a much faster rate than manual labor.

Equipped with sensors and cameras, robotic pickers can precisely identify ripe cotton bolls, ensuring a high level of accuracy. The automation in cotton harvesting not only boosts productivity but also reduces the dependency on manual labor.

Designed to operate in various field conditions, these robotic machines enhance the overall cotton harvesting process, making it more streamlined and effective. Robotic picking machines represent a notable advancement in the automation of the natural fiber industry.

Integrated Quality Control

In the domain of cotton manufacturing, the integration of automated quality control systems plays a pivotal role in ensuring consistent fiber quality throughout the production process. Sensors are utilized to monitor crucial fiber characteristics such as length, strength, and cleanliness at various stages of processing. Automated sorting and grading systems categorize fibers based on predefined quality parameters, enhancing efficiency and precision. Data analytics and machine learning algorithms further optimize production processes, leading to improved quality control measures. The automation in cotton manufacturing not only reduces the likelihood of human error but also elevates the overall product quality, meeting the high standards expected in the industry.

| Automated Quality Control in Cotton Manufacturing |

|---|

| Sensors monitor fiber characteristics |

| Automated sorting and grading systems |

| Data analytics and machine learning algorithms |

| Enhances efficiency and precision |

| Reduces human error and improves product quality |

Automated Spinning Processes

Automated spinning processes revolutionize cotton manufacturing by efficiently and consistently twisting cotton fibers into yarn. These advanced machines can handle large volumes of cotton fibers, enhancing production efficiency.

Precise control over yarn thickness is achieved through innovative technology integrated into automated spinning machines. By reducing labor costs and ensuring a high level of production capacity, automated spinning processes have become essential in the cotton industry.

Modern automated spinning machines are equipped with sensors that monitor and adjust spinning parameters in real-time, guaranteeing excellent yarn quality. Embracing automation in spinning not only streamlines the manufacturing process but also maintains a high standard of yarn production, meeting the demands of the industry effectively.

Cotton Harvesting Techniques

Harvesting cotton involves the use of mechanical pickers or hand-picking, depending on the farm's size and available resources. For large-scale commercial cotton farming, mechanical pickers like spindle pickers are commonly used as they can efficiently harvest vast fields of cotton. These machines work by moving through the fields, grabbing the cotton plants, and then using rotating spindles to pull the fiber tufts from the bolls. This method is particularly efficient when dealing with crops like Gossypium hirsutum, the most widely cultivated type of cotton.

On the other hand, hand-picking remains a prevalent method in smaller farms or areas where machinery access is limited. This traditional method involves manually picking the cotton bolls from the plants. Once the cotton is harvested, the next step involves separating the fibers from the seeds and other debris to prepare it for further processing. Harvesting typically occurs in the fall when the cotton bolls are fully mature and ready for picking.

Efficiency in Cotton Processing

Utilizing modern technologies and precise techniques, cotton processing achieves maximum efficiency in transforming raw cotton fibers into high-quality products.

To enhance efficiency in cotton processing, advanced cleaning technologies such as EVŌC are employed to meticulously remove plant matter from cotton fibers. Scouring with a sodium hydroxide solution plays a vital role in making cotton fibers absorbent by effectively eliminating waxes.

Additionally, purifying cotton fibers with hydrogen peroxide guarantees the thorough removal of impurities and coloring bodies, resulting in a high-quality end product.

Fiber finishing is another essential step in the process, involving the addition of a lubricant to processed fibers. This lubricant aids in efficient processing on equipment, further optimizing the overall efficiency of the cotton processing workflow.

Frequently Asked Questions

How Is Cotton Turned Into Thread?

I clean, align, and spin cotton fibers into yarn. The spinning machines then twist the fibers into thread. This process transforms raw cotton into thread for further textile production, like weaving into fabric.

How Do You Make Cotton Step by Step?

Making cotton involves growing cotton plants, ginning to separate fibers from seeds, cleaning, combing, and spinning fibers into yarn. Steps like carding, spinning, and weaving are essential. The result is versatile cotton fabric used in clothing and furnishings.

How Is Cotton Made Today?

Today, cotton production involves steps like ginning, cleaning, carding, spinning, weaving, and finishing. Advanced machinery streamlines the process. Mechanical pickers or automated methods separate fibers from seeds. Purification steps like scouring guarantee top-quality cotton. Sustainably meeting customer needs is crucial.

How Do You Get Cotton From Cotton Plants?

To get cotton from cotton plants, we harvest mature cotton bolls and process them to separate fibers from seeds. Mechanical pickers or manual labor are used for harvesting. After cleaning and spinning, the fibers become usable yarn.

- Why Is Red Velvet Not Red? - April 25, 2024

- How Do You Describe Velvet Fabric? - April 25, 2024

- How Strong Is Velvet? - April 25, 2024