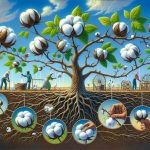

Are you curious about how cotton fabric is made? Look no further!

This complete guide will walk you through the entire production timeline, from planting and cultivating the cotton plants to the final finishing and quality control.

Discover the fascinating process of harvesting cotton bolls, separating seeds and fibers through ginning, and transforming cotton fibers into yarn through spinning.

Finally, witness the magical transformation of yarn into fabric through the art of weaving.

Let’s dive in!

Table of Contents

Planting and Cultivating Cotton

To successfully plant and cultivate cotton, you’ll need to prepare the soil, sow the seeds, and maintain the crop throughout its growth cycle.

Cotton cultivation techniques play a crucial role in improving cotton yield. Before planting, make sure the soil is well-drained and has a pH level between 5.8 and 6.5. Remove any weeds or debris from the field to prevent competition for nutrients and sunlight. Plow the soil to a depth of 6-8 inches to promote root penetration.

Next, sow the cotton seeds at the recommended depth, usually around 1 inch. Proper spacing between the rows and plants is essential for optimal growth and airflow.

Once the cotton plants start growing, it’s crucial to maintain them by providing adequate water, fertilizers, and pest control. Irrigation is necessary during dry periods to ensure the plants receive sufficient moisture. Apply fertilizers according to soil test results and crop requirements to provide essential nutrients for healthy growth.

Regularly monitor the crop for pests and diseases and take appropriate action to prevent damage.

Harvesting Cotton Bolls

Now let’s talk about harvesting cotton bolls.

There are two main methods used: picking cotton by hand and mechanized cotton harvesting.

Picking by hand involves manually plucking the cotton bolls from the plants, while mechanized harvesting uses specialized machines to harvest the cotton.

Picking Cotton by Hand

First, you’ll need to gather and collect the ripe cotton bolls by hand. Although the mechanization of cotton picking has increased efficiency in recent years, there are still areas where manual labor is necessary.

Picking cotton by hand has a significant impact on the laborers involved in the process. It requires a great deal of physical exertion and can be quite labor-intensive. The repetitive nature of the task can lead to fatigue and strain on the body. Additionally, the long hours spent in the fields can be mentally and emotionally challenging.

Despite these hardships, many laborers continue to pick cotton by hand, as it’s their livelihood and a vital part of the cotton fabric production timeline.

Mechanized Cotton Harvesting

Once the ripe cotton bolls have been gathered and collected by hand, it’s time to transition to mechanized cotton harvesting for the next step in the cotton fabric production timeline. Mechanized cotton picking has revolutionized the cotton industry, bringing about significant changes and advancements.

Here are four key points to understand about mechanized cotton harvesting:

-

Increased efficiency: Mechanized cotton picking allows for faster and more efficient harvesting compared to manual labor. It enables farmers to cover larger areas in less time, leading to higher productivity levels.

-

Cost-effectiveness: With the introduction of mechanization, the cost of labor has significantly decreased. This has made cotton production more economically viable for farmers, resulting in increased profitability.

-

Labor shortage solution: The mechanization of cotton harvesting has addressed the labor shortage issues faced by the industry. It has reduced the reliance on manual labor, which can be challenging to find and expensive to hire.

-

Quality improvement: Mechanized cotton picking has led to improved quality control. The machines are designed to gently remove the cotton bolls, reducing the risk of damage and preserving the fiber’s integrity.

The impact of mechanization on the cotton industry has been transformative, enhancing efficiency, reducing costs, addressing labor challenges, and improving the overall quality of cotton production.

Ginning: Separating Seeds and Fibers

Now that you’ve harvested the cotton bolls, it’s time to move on to the next crucial step in the cotton fabric production timeline: ginning.

During the ginning process, the seeds and fibers are separated, ensuring that only the valuable cotton fibers are used for further processing.

This step is of utmost importance as it allows for the production of high-quality cotton fabric without any impurities.

Ginning Process Explained

To understand the ginning process, begin by separating the seeds and fibers of the cotton plant. The ginning process is crucial in cotton fabric production, as it helps in obtaining pure cotton fibers that are free from seeds and other impurities. Here are four key points to understand the ginning process:

-

Ginning process benefits: Ginning removes the seeds and impurities from the cotton fibers, resulting in cleaner and higher-quality cotton. This improves the spinning process and ensures better yarn and fabric quality.

-

Ginning machinery advancements: Over the years, ginning machinery has undergone significant advancements. Modern ginning machines are more efficient, faster, and capable of handling larger quantities of cotton. This has greatly increased productivity in the ginning process.

-

Separating seeds from fibers: The ginning process involves separating the seeds from the cotton fibers using a combination of mechanical action and airflow. This separation ensures that only pure cotton fibers are used in fabric production.

-

Multiple ginning methods: There are different methods of ginning, including saw ginning, roller ginning, and knife roller ginning. Each method has its own advantages and is chosen based on factors such as fiber quality and production requirements.

Importance of Seed Separation

To fully understand the importance of seed separation in the ginning process, you must recognize its significant role in ensuring the purity and quality of cotton fibers for fabric production.

Seed separation, also known as ginning, is a crucial step in cotton processing. The benefits of seed separation are manifold. Firstly, it removes the seeds from the cotton fibers, allowing for a more refined and uniform end product. This enhances the quality and appearance of the fabric.

Secondly, seed separation eliminates impurities and foreign matter that may be present in the cotton, resulting in a purer and cleaner fiber. Techniques for seed separation include the use of machinery like cotton gins, which employ rotating brushes or saw-like teeth to separate the seeds from the fibers.

Carding: Aligning and Cleaning Fibers

You will need a large quantity of cotton fibers properly aligned and cleaned before moving on to the next step in the cotton fabric production timeline. This process is called carding, and it’s essential for creating high-quality cotton fabric.

Here are four key aspects to consider when it comes to fiber alignment techniques and cleaning methods:

-

Fiber alignment techniques: Carding involves passing the cotton fibers through a series of rollers with fine wire teeth. These rollers help to align the fibers in a parallel fashion, ensuring a more uniform and cohesive fabric.

-

Cleaning methods: Before carding, it’s crucial to remove any impurities from the cotton fibers. This can be done through various cleaning methods, such as air or mechanical filtration systems. Removing impurities ensures that the final fabric is clean and free from any unwanted substances.

-

Quality control: Throughout the carding process, it’s important to maintain strict quality control measures. This includes regular inspections of the fibers to ensure they’re properly aligned and free from any contaminants. Quality control helps to guarantee the production of high-quality cotton fabric.

-

Efficiency and productivity: Carding is a time-consuming process, but advancements in technology have helped improve efficiency and productivity. Automated carding machines can process large quantities of cotton fibers quickly and accurately, ensuring a smooth and streamlined production timeline.

Spinning: Creating Yarn From Cotton Fibers

How can you create yarn from cotton fibers during the spinning process?

The spinning process involves various techniques and machinery to transform cotton fibers into yarn. Traditionally, spinning was done manually using a spinning wheel or spindle. However, with advancements in technology, innovations in cotton spinning technology have revolutionized the industry.

Today, most spinning is done using machines called spinning frames or spinning mules. These machines automate the process, allowing for faster and more efficient production of yarn. The cotton fibers are first fed into the machine, where they’re drawn out and twisted together to form a continuous strand of yarn. The spinning process is carefully controlled to ensure that the yarn is of the desired thickness and strength.

In recent years, there have been significant advancements in cotton spinning technology. For example, open-end spinning machines have been developed, which can produce yarn at a much higher rate than traditional spinning frames. These machines use a rotor instead of a spindle, allowing for faster spinning and increased productivity.

Weaving: Transforming Yarn Into Fabric

During the weaving process, a large quantity of yarn is transformed into fabric. This crucial step in cotton fabric production involves the interlacing of warp and weft yarns to create a stable and durable fabric.

Here are four key aspects to consider when it comes to weaving:

-

Weaving Techniques: There are various weaving techniques used in cotton fabric production, each resulting in different fabric textures and patterns. Some common techniques include plain weave, twill weave, and satin weave. These techniques determine the way the yarns interlace and contribute to the overall appearance and characteristics of the fabric.

-

Types of Looms: Looms are the machines used to weave yarn into fabric. There are different types of looms, including hand looms, power looms, and modern computerized looms. Hand looms require manual operation, while power looms use mechanical power to weave fabric. Computerized looms, on the other hand, offer advanced features and precision control for intricate fabric designs.

-

Warp and Weft Yarns: The weaving process involves two types of yarns: warp and weft. The warp yarns run vertically on the loom, while the weft yarns run horizontally. The warp yarns provide the foundation and stability, while the weft yarns are interlaced to create the fabric’s structure.

-

Fabric Finishing: Once the weaving process is complete, the fabric goes through finishing treatments to enhance its appearance and performance. Finishing may involve processes such as bleaching, dyeing, printing, and applying special treatments like water repellency or flame resistance.

Finishing and Quality Control

After the weaving process, the fabric undergoes finishing treatments and quality control measures to ensure its final appearance and performance.

Finishing techniques are employed to enhance the fabric’s properties, such as its softness, durability, and resistance to wrinkling. These techniques include processes like bleaching, dyeing, and printing.

Bleaching removes any natural coloring from the fabric, resulting in a white or off-white base that can be easily dyed or printed on. Dyeing involves immersing the fabric in a dye bath to add color, while printing applies designs or patterns onto the fabric’s surface using various methods such as screen printing or digital printing.

Once the finishing techniques are completed, the fabric goes through rigorous quality control measures. These measures involve inspecting the fabric for any defects, such as uneven dyeing, printing errors, or fabric inconsistencies.

Quality control also includes testing the fabric’s performance characteristics, such as its strength, colorfastness, and shrinkage resistance. This ensures that the fabric meets the desired standards and is suitable for its intended use.

Frequently Asked Questions

What Are the Environmental Impacts of Cotton Cultivation and How Are They Managed?

Cotton cultivation has significant environmental impacts, but they can be managed through sustainable practices and environmental management. These practices aim to minimize water usage, reduce pesticide use, and promote soil health.

How Does the Process of Ginning Affect the Quality of the Cotton Fibers?

Ginning techniques greatly impact cotton fiber quality. The process involves separating the fibers from the seed, and improper techniques can cause damage. Understanding the effects of ginning is crucial for maintaining high-quality cotton fibers.

Are There Any Specific Techniques Used in Carding to Ensure the Alignment and Cleanliness of the Cotton Fibers?

In carding, specific techniques are used to ensure fiber alignment and cleanliness. By combing the cotton fibers, carding removes impurities and arranges the fibers in a parallel formation, resulting in a higher quality end product.

What Factors Determine the Thickness and Strength of the Yarn Created During the Spinning Process?

Factors such as the quality of the cotton fibers, the spinning method used, and the tension applied during the process determine the thickness and strength of the yarn created.

How Is the Quality of the Finished Cotton Fabric Assessed and Ensured During the Finishing and Quality Control Stage?

During the finishing and quality control stage of cotton fabric production, various assessment techniques are used to ensure consistency and assess the quality of the finished fabric.

- The Use of Nonwovens in Construction and Civil Engineering - July 11, 2025

- The Use of Nonwovens in Construction and Civil Engineering - July 11, 2025

- The Use of Nonwovens in Construction and Civil Engineering - July 11, 2025