You might think of cotton as simply a soft fabric, but the journey it takes from raw fiber to ring spun cotton is quite intricate. It starts with harvesting and cleaning the cotton fibers, which then undergo a process known as carding to align them. Once you've gotten to the ring spinning stage, the fibers get twisted into strong, cohesive yarn. Each step is crucial for maintaining quality and efficiency, but there's more to this process that affects the final product than meets the eye. What happens next might surprise you.

Table of Contents

Cotton Fiber Harvesting

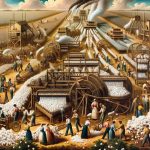

Cotton fiber harvesting begins when farmers carefully gather the fluffy bolls from cotton plants, ensuring minimal damage to the fibers. You'll witness the beauty of vast cotton fields, where ripe bolls burst open, revealing their soft, white treasures.

As a farmer, you need to choose the right time for harvesting. If you wait too long, the fibers can degrade, while harvesting too early might mean you miss out on the best quality.

When you're out in the field, you can use either manual or mechanical methods. If you're harvesting manually, your hands gently pluck the bolls, guaranteeing that the fibers remain intact. On the other hand, mechanical harvesters speed up the process by using specialized equipment that quickly picks the bolls while being mindful of fiber quality.

After harvesting, you'll pile the cotton bolls for transport. It's crucial to keep them clean and dry to avoid contamination and spoilage. With the gathered cotton, you're setting the stage for the next steps in the production process that transforms these fibers into the high-quality fabric you know and love.

The efficiency of your harvesting directly impacts the quality of the final product.

Cleaning and Separating Fibers

Once the bolls are harvested, you'll move on to cleaning and separating the fibers to remove any dirt, seeds, or plant debris. This step is crucial for preparing high-quality cotton for further processing. You'll typically use a machine known as a cotton gin, which is designed specifically for this purpose.

As the harvested cotton passes through the gin, it undergoes a mechanical process. Sharp teeth grab the cotton fibers, pulling them apart while simultaneously separating them from seeds and other impurities. You'll notice that this method ensures minimal fiber damage while efficiently removing unwanted materials.

Once the fibers are separated, you'll collect the clean, fluffy cotton lint, readying it for the next step in manufacturing. It's important to ensure that the cotton is thoroughly cleaned, as any residual debris can negatively affect the quality and texture of the final product.

Ultimately, the cleaning and separating stage gets your cotton ready to transform into ring spun yarn. With this important task completed, you'll set the stage for the next processes that further enhance the cotton fibers' quality and usability.

Carding and Drawing Process

During the carding process, the clean cotton fibers are further opened up and aligned, preparing them for spinning into ring spun yarn. This step ensures the fibers are untangled and organized, which is crucial for producing a high-quality yarn.

Once the fibers are carded, the next step is drawing. In this process, you'll take multiple carded slivers and draft them into a thinner, more uniform strand while simultaneously aligning the fibers even further. This not only enhances the strength of the yarn but also improves its consistency.

Here's a summary of the carding and drawing process:

| Process Stage | Description |

|---|---|

| Carding | Fibers are separated, opened, and aligned. |

| Drawing | Multiple slivers are combined and thinned out. |

| Purpose | Prepares fibers for consistent yarn production. |

| Result | A uniform strand ready for spinning. |

Ring Spinning Techniques

In ring spinning, a series of innovative techniques come into play to twist the drawn fibers into a strong, cohesive yarn.

You'll find that these techniques are essential in defining not just the strength but also the texture of the final product. Here are some key techniques to understand:

- Drafting: This occurs as the fibers are pulled apart and aligned, ensuring they're evenly distributed.

- Twisting: The spindle spins the fiber bundles, introducing the necessary twist that binds the fibers together securely.

- Cohesive Control: Adjustments are made to maintain the right twist per inch (TPI) to get the desired yarn thickness.

- Bobbin Winding: Once the yarn is spun, it's wound onto a bobbin, avoiding tangles and facilitating further processes.

Each of these techniques contributes significantly to the yarn's quality, making ring-spun cotton particularly sought after in the textile industry.

Final Processing and Quality Control

After the ring spinning process, the yarn undergoes final processing and quality control to ensure it meets industry standards and customer expectations. This stage involves several key procedures that enhance the yarn's quality and usability.

Initially, the yarn is subjected to a thorough inspection for any defects. You'll find that advanced technology, like vision systems, helps identify issues such as slubs or uneven thickness. Next, it's treated with appropriate finishes, which can improve its strength and appearance. You also don't want to overlook the dyeing process, where the yarn is color-treated to match specific requirements.

To give you a clear overview, here's a summary of the final processing steps:

| Step | Description | Result |

|---|---|---|

| Inspection | Detects defects using technology | Ensures uniform quality |

| Finishing | Applies treatments for enhancement | Improves strength and feel |

| Dyeing | Colors the yarn according to specs | Meets aesthetic requirements |

| Balancing | Adjusts for consistency in lots | Ensures uniformity by batch |

| Packaging | Properly packs for shipment | Maintains quality during transit |

These steps guarantee that the ring spun cotton yarn is ready for the market, meeting all necessary standards.

Frequently Asked Questions

What Are the Environmental Impacts of Ring Spun Cotton Production?

You'll find that ring spun cotton production can lead to resource depletion, water pollution, and greenhouse gas emissions. However, sustainable practices such as organic farming and efficient water use can help mitigate these environmental impacts significantly.

How Does Ring Spun Cotton Compare to Traditional Cotton Fabrics?

Ring spun cotton feels softer and more durable than traditional cotton. You'll notice it's smoother, less prone to pilling, and has improved tensile strength, making it ideal for comfortable, long-lasting clothing and textiles.

What Types of Products Use Ring Spun Cotton?

You'll find ring spun cotton in various products like t-shirts, bed linens, and towels. Its soft texture and durability make it popular for apparel and home textiles, enhancing comfort and quality in everyday items.

Are There Any Health Concerns With Ring Spun Cotton?

You shouldn't worry too much about health concerns with ring spun cotton. It's generally safe and hypoallergenic. However, always check labels for specific treatments or dyes that might cause sensitivities for some individuals.

How Is the Cost of Ring Spun Cotton Determined?

The cost of ring spun cotton's determined by various factors like raw material prices, production processes, labor costs, and market demand. You should consider these aspects when evaluating the price of different cotton products.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024