I once attempted to iron a patch onto a nylon jacket, and the results were not what I expected. The question of whether you can successfully iron a patch onto nylon is a common one among DIY enthusiasts.

The delicate nature of nylon fabric poses a challenge when it comes to using heat-based methods like iron-on patches. However, there are strategies and alternatives that can make this process feasible while ensuring the integrity of your nylon items.

Would you like to know how to navigate this tricky terrain effectively?

Key Takeaways

- Use low heat settings and pressing cloth to iron patches on nylon.

- Ensure patch material's heat tolerance matches nylon's sensitivity.

- Position patches accurately, apply even pressure for proper adhesion.

- Preserve nylon quality by following patch instructions and gentle care methods.

Nylon Fabric Characteristics

When it comes to nylon fabric characteristics, its durability and water-resistance make it a popular choice for outdoor gear. Nylon's robust nature makes it ideal for items like bags, jackets, and tents due to its ability to withstand rough outdoor conditions. Additionally, its high strength-to-weight ratio ensures that nylon gear is both strong and lightweight, a key advantage for hikers, campers, and adventurers.

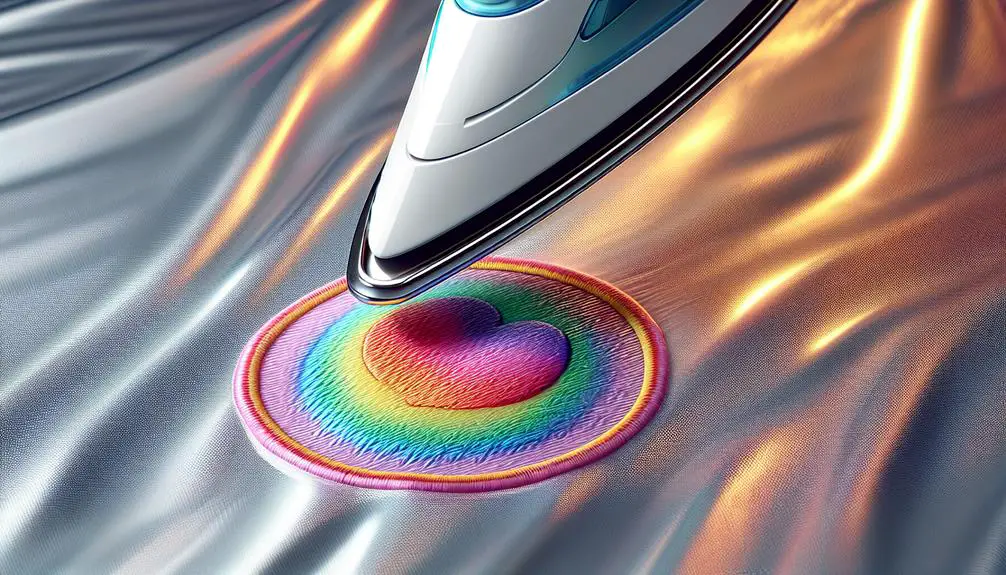

One common way to personalize nylon gear is by ironing on patches. While nylon is known for its heat sensitivity, making it prone to melting or distorting under high temperatures, it's still possible to attach patches carefully. To do so, one must use a low heat setting on the iron and place a thin cloth or a pressing cloth over the patch before ironing. This method helps protect the nylon fabric from direct heat exposure, ensuring that the patches adhere securely without damaging the gear.

Heat Tolerance of Nylon

Understanding the heat tolerance of nylon is crucial for ensuring the safe application of heat-based methods like ironing patches onto nylon fabric. Nylon has a melting point ranging from 400 to 500 degrees Fahrenheit, making it sensitive to high temperatures.

When ironing on nylon fabric, it's essential to use low heat settings to prevent damage. Direct heat from an iron can cause nylon fabric to melt or distort due to its heat sensitivity. To prevent mishaps, testing a small, inconspicuous area with low heat before ironing the entire patch can help determine how the nylon will react to the heat.

Ironing Patch Compatibility

When ironing patches onto nylon, understanding the compatibility between the patch material and heat settings is key to a successful outcome. Checking the patch material's heat tolerance before applying heat is crucial to avoid damage.

It's essential to follow recommendations for heat settings and test with a low temperature to ensure compatibility and prevent mishaps.

Patch Material Suitability

To ensure successful bonding when ironing patches on nylon, always check the patch material for heat suitability beforehand. It is crucial to test the patch's heat sensitivity by starting with a low heat setting and using a cloth cover. Once you determine the patch material can withstand heat, use the lowest temperature suitable for it on the nylon fabric. Positioning the patch accurately on the nylon surface before ironing is key to ensuring proper adhesion. Additionally, following the patch instructions is crucial for achieving successful bonding on nylon fabric. Below is a table summarizing key points to consider when assessing patch material suitability for ironing on nylon:

| Patch Material Suitability | |

|---|---|

| Check heat sensitivity | Test with low heat and cloth cover |

| Use lowest suitable temperature | Ensure proper adhesion |

| Position patch accurately | Follow patch instructions |

Heat Setting Recommendations

Before ironing patches on nylon, it's essential to consider the recommended heat settings for optimal patch compatibility. When using a heat press, always check the patch material for heat suitability.

To test heat sensitivity, start with a low setting and use a cloth cover on a small nylon area. It's crucial to use the lowest temperature suitable for the patch material to prevent nylon damage.

Properly position the patch on the nylon surface before applying heat to ensure accurate placement. Following patch instructions on heat settings and application techniques is key for successful results when ironing patches on nylon.

Patch Adhesive Options

When considering patch adhesive options for nylon, two primary methods come to mind: the iron-on patch method and the sew-on patch method. Each technique offers its own advantages and considerations, providing flexibility for individuals based on their preferences and the nature of the nylon fabric.

Exploring these two approaches can help tailor the patch application process to suit different needs and ensure a secure attachment without damaging the material.

Iron-On Patch Method

When ironing patches on nylon, selecting the appropriate adhesive option is crucial for a secure attachment without causing damage to the fabric. Common options for iron-on patches on nylon include velcro backing and fabric glue.

Velcro backing offers the flexibility of easily changing out patches on nylon items. On the other hand, fabric glue, heated with a heat gun, can securely attach patches to nylon without harming the fabric.

It's vital to choose the right adhesive for a successful iron-on patch application on nylon materials. By understanding the properties of the adhesive options available, you can ensure a durable and long-lasting bond between the patch and the nylon fabric, enhancing the overall look and functionality of your items.

Sew-On Patch Method

Let's smoothly shift our focus to the Sew-On Patch Method for attaching patches to nylon, exploring various adhesive options available for a lasting and personalized attachment.

Adhesive Options for Sew-On Patches:

- Fabric Glue: Offers a quick and easy way to attach patches securely.

- Heat-Activated Adhesives: Provides a strong bond when heat is applied, ensuring a durable attachment.

- Sewing: Traditional method for sew-on patches, offering a reliable and long-lasting solution.

Sew-on patches not only guarantee a secure attachment to nylon but also allow for customization and unique designs without the need for ironing. By choosing the right adhesive option, you can ensure your patches stay in place on nylon fabrics for a long time.

Preparation Steps Before Ironing

Before ironing patches on nylon, it's essential to verify the heat compatibility of the patch material with the nylon fabric. To ensure a successful ironing process, it's crucial to check the patch's heat sensitivity by starting with a low heat setting and placing a cloth cover over the patch. This test helps determine the appropriate temperature for ironing on nylon without damaging the fabric or the patch. When ironing, always use the lowest temperature suitable for the patch material to prevent any mishaps.

Positioning the patch correctly on the nylon fabric before applying heat is also vital. Make sure the patch is centered and aligned as desired to achieve the best results. Additionally, following the patch instructions carefully is key to achieving optimal adhesion and a neat appearance. By preparing adequately and paying attention to these steps, you can ensure a smooth and successful ironing process when applying patches on nylon.

Ironing Process for Nylon

To properly iron patches on nylon, ensure you select the appropriate temperature setting based on the patch material's heat sensitivity.

Ironing Process for Nylon:

- Temperature Selection: Test a small area of the nylon with a low heat setting and a cloth cover before applying the patch to avoid damage to the fabric.

- Positioning the Patch: Accurately position the patch on the nylon before ironing to ensure proper adhesion.

- Following Instructions: It's crucial to follow the patch instructions and test compatibility to guarantee successful application on nylon fabric.

Taking these steps will help you achieve a well-ironed patch on your nylon fabric without causing any damage. Remember, being cautious and attentive during the patch application process is key to preserving the integrity of the nylon material.

Avoiding Damage to Nylon

To safeguard your nylon fabric from potential damage when ironing patches, it's crucial to employ a gentle heat setting and utilize a pressing cloth as a protective barrier. Nylon is sensitive to high temperatures and can easily melt or become damaged if exposed to excessive heat. By using a low heat setting on your iron, you can prevent any unwanted alterations to the fabric.

Placing a pressing cloth between the iron and the patch acts as a buffer, ensuring that the nylon surface is shielded from direct contact with the heat. Additionally, applying even pressure while ironing helps the patch adhere properly without causing harm to the delicate nylon material.

It's important to avoid prolonged contact between the iron and the nylon to prevent overheating, which could lead to discoloration or other forms of damage. Following the patch instructions carefully is also key to achieving a successful application without compromising the integrity of the nylon fabric.

Patch Care on Nylon

When caring for patches on nylon, ensuring proper maintenance is essential to preserve the fabric's integrity and appearance. Here are three key practices to keep in mind:

- Use Gentle Cleaning Methods: When cleaning nylon with patches, opt for gentle methods like hand washing or using a mild detergent to prevent damage to the patches or the fabric.

- Avoid Harsh Chemicals: Refrain from using harsh chemicals or bleach when cleaning nylon with patches, as they can cause discoloration or deterioration of both the patches and the nylon material.

- Store Carefully: When storing nylon items with patches, ensure they're kept in a cool, dry place away from direct sunlight to prevent fading or damage to the patches.

Conclusion and Final Tips

After ensuring proper care for patches on nylon, mastering the art of ironing them on requires attention to detail and a gentle touch. Make sure to set your iron to the lowest heat setting suitable for the patch material to prevent any damage to the delicate nylon fabric.

Position the patch accurately before ironing to ensure proper adhesion, and always test a small area first to check compatibility and avoid potential melting or discoloration.

If you encounter difficulties or are concerned about the heat sensitivity of the nylon, consider using alternative methods like sewing or fabric glue for patch attachment. These methods can be equally effective without the risk of heat-related issues.

Frequently Asked Questions

How Do You Attach Patches to Nylon?

Attaching patches to nylon is best done cautiously. Check patch material compatibility and use low heat settings with a pressing cloth. Always test a small area first to prevent damage. Velcro patches are a safer choice for nylon items.

Do Iron-On Patches Stay on Nylon?

Iron-on patches can adhere to nylon effectively when applied correctly. Testing for heat compatibility, using low heat, and a pressing cloth are crucial. Following instructions and allowing for proper cooling time ensures a secure attachment.

Can You Iron Nylon Fabric?

Certainly! Yes, you can iron nylon fabric, but it requires caution. Testing a small area first with low heat and a pressing cloth is key. Positioning the patch correctly is crucial. Follow patch instructions for success.

What Materials Can Patches Be Ironed On?

Patches can be ironed on fabrics like cotton, denim, and polyester. It's essential to follow specific instructions for each material. Testing a small area first is wise. Adhesive-backed patches might work on nylon with caution.