When deciding between digital print and screen print for my company's latest merchandise line, I found myself intrigued by the distinct characteristics of each method.

The sharpness of digital prints and the durability of screen prints offer unique advantages that cater to different project requirements.

Understanding these differences can be pivotal in determining the best approach for your next printing endeavor.

Table of Contents

Key Takeaways

- Screen printing is durable, weather-resistant, and ideal for long-lasting designs.

- Digital printing is cost-efficient, fast for low quantities, and fades over time.

- Screen printing offers vibrant colors, while digital printing has a wider color gamut.

- Digital printing is eco-friendly, producing less waste, and suitable for various materials.

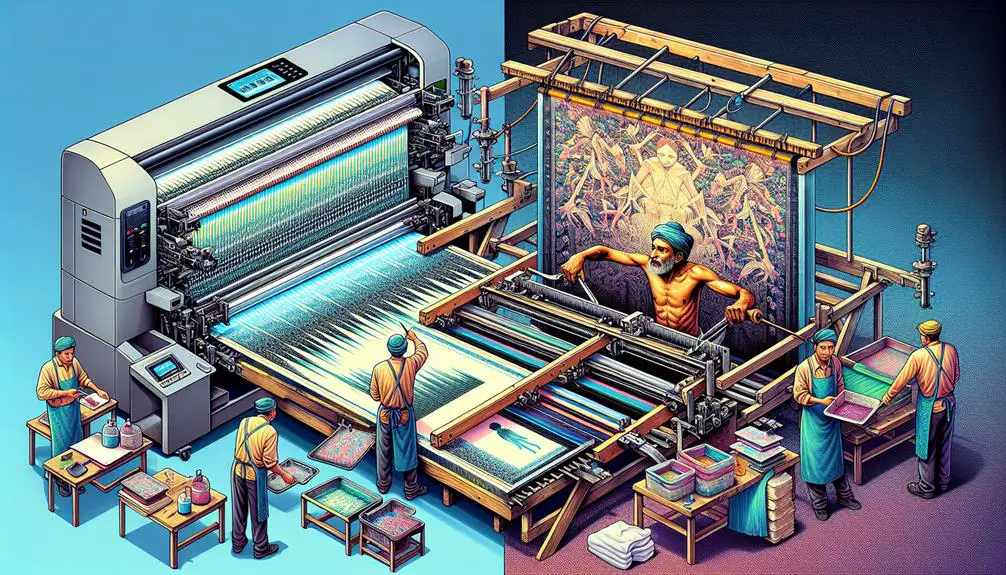

Overview of Digital Print and Screen Print

When comparing digital print and screen print, it's essential to understand the fundamental differences in their processes and applications. Screen printing, originating around 500 AD, involves using stencils on fine mesh screens to push ink onto surfaces. It's ideal for critical color needs, offering vibrant colors and high durability. However, screen printing incurs high set-up costs and is more suitable for simple images.

On the other hand, digital printing, which utilizes computer and digital files, is cost-effective for small runs with low or no set-up fees. It allows for mass customization, making it perfect for complex prints with intricate detail. Digital printing has improved adhesion and is more versatile for various surfaces.

While screen printing focuses on durability and weather resistance, digital printing offers high detail prints and is cheaper for low quantity jobs. In essence, screen printing excels in durability and color vibrancy, whereas digital printing shines in customization and cost-effectiveness for intricate designs.

Printing Process Variances

Exploring the differences between screen printing and digital printing reveals unique variances in their respective printing processes.

- Screen printing process: Involves creating stencils on fine mesh screens to apply ink directly onto the surface. It requires multiple screens for different designs/colors and UV curing.

- Digital printing process: Utilizes computer files for direct printing on surfaces. It can use solvent or inkjet printing with UV light for curing and doesn't require screens.

- Four-color process: Screen printing is ideal for vibrant colors and critical color needs, while digital printing uses the CMYK four-color process, making it suitable for mass customization and complex prints.

- Adhesion and cost considerations: Screen printing offers better adhesion to various surfaces and weather resistance but has high set-up costs. On the other hand, digital printing has improved adhesion, is more cost-effective for low quantity jobs, and has low or no set-up fees.

Cost and Efficiency Factors

Moving on to Cost and Efficiency Factors, it becomes evident that the choice between screen printing and digital printing significantly impacts the overall expenses and productivity of a printing project. When considering set-up costs, digital printing shines with its low or nonexistent fees, making it a cost-effective option for small print runs. On the other hand, screen printing involves high set-up expenses, but these costs are spread out over large quantities, making it the preferred choice for high-volume jobs. In terms of efficiency, digital printing allows for quick and efficient production of low quantities, while screen printing proves to be faster for large quantities due to the set-up costs being more economical over a large number of prints.

| Factors | Screen Printing | Digital Printing |

|---|---|---|

| Set-up Costs | High | Low/None |

| Quantity | Suitable for large quantities | Ideal for low quantities |

| Cost-Effectiveness | Better for high quantities | Better for low quantities |

| Efficiency | Slower for low quantities | Faster for high quantities |

Color and Design Considerations

Color and design play crucial roles in determining the most suitable printing method for a project. When considering screen printing and digital printing, several key factors come into play:

- Vibrant Colors and Precise Spot Color Matching: Screen printing excels in providing vibrant colors and precise spot color matching, making it ideal for projects with critical color requirements.

- Color Range: Digital printing, utilizing a four-color CMYK process, has a more limited color range compared to screen printing. This limitation may impact the color accuracy for some projects.

- Simple Designs vs. Complex Prints: Screen printing is better suited for simple designs with bold colors, while digital printing shines when intricate details and complex prints are involved.

- Mass Customization and Durability: Digital printing allows for mass customization and personalized designs, whereas screen printing is more cost-effective for large quantities. Additionally, screen printing yields more durable and weather-resistant prints, making it the preferred choice for outdoor and long-lasting applications.

Durability and Application Variances

When considering durability in print options, it's crucial to understand the wear resistance each method provides.

Additionally, the range of surfaces suitable for printing plays a significant role in choosing between digital and screen printing techniques.

These factors impact the longevity and versatility of the final product, dictating the best application for each method.

Wear Resistance

Screen printing ink outperforms digital ink in terms of durability and resistance to harsh weather conditions, making it a top choice for items exposed to challenging environments. When it comes to wear resistance, here's how the two methods compare:

- Durability: Screen printing ink is renowned for its robustness, lasting longer under tough conditions.

- Weather-Resistance: Screen printing ink exhibits superior resistance to weathering, ensuring longevity even in outdoor settings.

- Fading Resistance: The color vibrancy of screen printing ink remains intact for extended periods, showing minimal signs of fading.

- Wear Resistance: Screen printing excels in maintaining its quality and vibrancy over time, making it a preferred option for long-lasting prints.

Print Surface Options

With its durability and application variances, the choice of print surface options plays a crucial role in determining the longevity and versatility of the final product.

Screen printing offers superior durability and weather resistance, making it ideal for items exposed to harsh conditions. Screen printing ink is known for its resistance to weather elements, ensuring longevity. Screen printing shines when used on specialty products like water bottles or mugs, where durability is paramount.

On the other hand, digital printing excels in adhesion on various surfaces, providing a more versatile option for different materials. While digital printing may be pricier due to materials, it's preferred for its flexibility.

Understanding these differences in print surface options can help in selecting the most suitable method for specific projects.

Comparison of Quality and Use Cases

For a comprehensive understanding of the differences between digital print and screen print, let's delve into their distinct qualities and practical applications.

- Vibrant Colors and Detailed Designs:

- Screen printing offers vibrant and durable prints, making it ideal for consistent branding on textiles and plastic.

- Digital printing provides precise and detailed prints, perfect for modern finishes and personalized designs.

- Use Cases:

- Screen printing is best suited for large orders with simple designs on items like clothing, balloons, and wallpaper.

- Digital printing excels in intricate designs, small orders, and high-quality images due to its direct printing capabilities.

- Quality Benefits:

- Screen printing ensures durability and vibrancy, making it a preferred choice for long-lasting designs.

- Digital printing allows for customization and detailed work, catering to personalized print requirements.

Understanding these distinctions in quality and use cases can help determine the most suitable printing method for your specific needs.

Frequently Asked Questions

What's Better Screen Print or Digital?

For me, it depends on the project needs. Screen print is great for vibrant designs on dark shirts, while digital excels in intricate details. Screen works best for bulk jobs; digital is ideal for smaller orders.

What Lasts Longer Screen Printing or Digital Printing?

Screen printing typically outlasts digital printing. The durability of screen prints, with weather-resistant inks that adhere well, makes them a longer-lasting choice. For longevity, especially in high-wear or outdoor settings, screen printing stands the test of time.

Is Screen Printing More Expensive Than Digital Printing?

Yes, screen printing can be more expensive than digital printing initially due to set-up costs, especially for low quantities. However, for larger orders, screen printing's cost-effectiveness increases, making it a preferred choice despite the higher upfront expenses.

Does Digital Printing Last on Shirts?

Absolutely, digital printing on shirts can last a long time if done right. High-quality inks and proper curing methods ensure durability. With care, digital prints can handle repeated washings without fading, depending on fabric and washing instructions.

- Tetron Fabric for Marine Applications: Durability and Use Cases - June 18, 2025

- Tetron Fabric for Outdoor Furniture: Weather Resistance and Care - June 18, 2025

- Tetron Fabric for Wall Coverings: Style and Application Tips - June 18, 2025