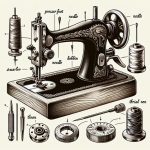

If you're like most Kenmore sewing machine owners, you're part of the 30% of American households that own a sewing machine. When your machine runs into issues, you want quick and effective solutions.

That's where '7 Quick Fixes for Your Kenmore Sewing Machine' comes in. In this guide, you'll learn essential tips and tricks to keep your Kenmore sewing machine running smoothly.

From adjusting thread tension to troubleshooting bobbin problems, you'll discover practical solutions to common issues. Whether you're a beginner or experienced seamstress, mastering these fixes will help you save time and frustration, allowing you to focus on creating beautiful, professional-quality garments and crafts.

Key Takeaways

- Adjust thread tension properly to improve stitch quality and prevent fabric puckering or uneven stitches.

- Choose the correct needle size for different sewing projects to avoid skipped stitches or broken threads.

- Troubleshoot bobbin thread tangling issues by checking threading, adjusting tension, and using high-quality thread.

- Regularly clean and oil your Kenmore sewing machine for optimal performance and refer to the manual for maintenance schedule.

Thread Tension Adjustment

Adjusting thread tension can improve the quality of your stitching on your Kenmore sewing machine. When the thread tension is too tight, it can cause the fabric to pucker, and when it's too loose, the stitches may appear sloppy or uneven. To achieve optimal stitch quality, it's crucial to have proper thread tension control.

Start by threading your machine properly and ensuring the presser foot is raised before threading, as this opens up the tension discs to allow the thread to seat properly.

Next, adjust the tension dial to regulate the thread tension. For most fabrics, the standard setting is usually sufficient, but for more delicate fabrics, you may need to decrease the tension, and for heavier fabrics, you might need to increase it. Test your settings on a scrap piece of fabric before starting your actual project to ensure the stitches are balanced and the tension is adjusted correctly.

Needle Replacement

It's important to choose the right needle size for your specific sewing project, as this can affect the quality of your stitches.

Make sure to insert the needle correctly, following your machine's manual for guidance.

Proper needle replacement is crucial for smooth and successful sewing, so let's explore these points in detail.

Proper Needle Size

To ensure smooth sewing on your Kenmore sewing machine, replace the needle with the proper size for your fabric and thread. Needle maintenance is crucial for stitch quality. Using the wrong needle size can lead to skipped stitches, puckered fabric, or broken threads.

When sewing lightweight fabrics, use a smaller needle size such as 9 or 11. For medium-weight fabrics, opt for a size 12 or 14 needle. Heavy fabrics like denim or upholstery require a larger size, typically 16 or 18.

Additionally, consider the thread thickness when selecting the needle size. A general rule is to match the needle size to the thread thickness.

Correct Needle Insertion

Replace the needle in your Kenmore sewing machine following the manufacturer's instructions for correct needle insertion. Proper needle maintenance is crucial for achieving optimal stitch quality.

To ensure the correct needle insertion, start by turning off the machine and unplugging it for safety. Use a screwdriver to loosen the needle clamp screw and remove the old needle.

Insert the new needle into the needle clamp with the flat side facing the back and push it up as far as it will go. Then, tighten the needle clamp screw securely.

Remember to use the right needle for the type of fabric you're sewing. By following these steps for correct needle insertion, you can maintain the integrity of your stitches and ensure smooth sewing operations.

Bobbin Troubleshooting

Having trouble with your Kenmore sewing machine's bobbin thread tangling or getting the tension just right? These common bobbin issues can cause frustration, but don't worry – we've got you covered.

Let's walk through the steps to troubleshoot and adjust the bobbin tension for smooth sewing and professional-looking stitches.

Bobbin Thread Tangling

Experiencing bobbin thread tangling in your Kenmore sewing machine can be frustrating and disruptive to your sewing projects. To troubleshoot this issue, consider the following:

- Check bobbin threading: Ensure the bobbin is wound smoothly and inserted correctly.

- Clean the bobbin case: Thread jamming can occur due to lint or debris, so clean the bobbin case regularly.

- Adjust tension: Improper tension settings can lead to thread tangling, so adjust the tension as needed.

- Use high-quality thread: Poor quality thread can contribute to tangling, so opt for good quality thread.

- Inspect needle and bobbin: A damaged or bent needle, as well as a rough or damaged bobbin, can cause thread tangling.

Regular maintenance and proper threading techniques can help prevent bobbin thread tangling issues, ensuring smooth sewing experiences.

Bobbin Tension Adjustment

To address bobbin tension adjustment on your Kenmore sewing machine, first, ensure that the bobbin is wound smoothly and inserted correctly. Proper bobbin winding is essential for achieving balanced tension. If the bobbin thread is too loose or too tight, it can cause stitching issues.

To adjust the tension, locate the small screw on the bobbin case that holds the tension spring in place. Use a small screwdriver to gently tighten or loosen the screw to achieve the desired tension. Make small adjustments and test the stitches on a scrap fabric until the tension is balanced.

Remember to clean the bobbin area regularly to prevent lint buildup, which can also affect tension.

With these steps, you can effectively troubleshoot and adjust the bobbin tension on your Kenmore sewing machine.

Cleaning and Oiling

First, ensure you clean and oil your Kenmore sewing machine regularly to maintain its optimal performance. Regular maintenance will prolong the life of your machine and ensure smooth, high-quality stitching.

- Maintenance Schedule: Refer to your machine's manual for a recommended maintenance schedule. Typically, it's advised to clean and oil your machine after every 8-10 hours of use.

- Cleaning Products: Use a small brush to remove lint and dust from the bobbin case, feed dogs, and other areas. For oiling, use high-quality sewing machine oil or lubricant specifically designed for sewing machines.

- Thorough Cleaning: Unplug your machine before cleaning. Remove the needle plate and bobbin case to access hard-to-reach areas. Clean the race hook and shuttle hook thoroughly.

- Oiling Points: Apply a drop of oil on the race hook, shuttle hook, and other designated oiling points as indicated in the manual. Use a lint-free cloth to wipe away any excess oil.

- Testing: After cleaning and oiling, run your machine at a slow speed to evenly distribute the oil and ensure everything is functioning smoothly.

Stitch Selection Tips

Selecting the appropriate stitch for your sewing project will greatly impact the quality of your finished product. When choosing a stitch on your Kenmore sewing machine, consider the fabric compatibility and stitch length to ensure the best results. Different fabrics require different stitches for optimal durability and appearance. Additionally, adjusting the stitch length can prevent puckering on delicate fabrics or ensure a strong hold on heavy materials.

Here's a quick reference table to help you select the right stitch and length for your project:

| Fabric Type | Recommended Stitch | Recommended Stitch Length |

|---|---|---|

| Light-weight | Straight Stitch | Short to Medium |

| Medium-weight | Zigzag or Overlock | Medium to Long |

| Heavy-weight | Triple Stitch or Bar | Short to Medium |

| Stretchy | Stretch Stitch | Short to Medium |

Foot Pedal Check

Check the foot pedal of your Kenmore sewing machine for proper functionality before starting your next sewing project. Proper maintenance and troubleshooting can ensure that your foot pedal operates smoothly, allowing you to sew with ease. Here are some tips to help you assess and address any issues with your foot pedal:

- Inspect the Connections: Ensure that the foot pedal is securely connected to the sewing machine. Loose connections can lead to erratic pedal sensitivity or non-responsiveness.

- Clean the Pedal: Dust and debris can accumulate inside the foot pedal, affecting its performance. Use a soft brush to gently clean the pedal and remove any buildup.

- Adjust Sensitivity: If you find that the pedal is overly sensitive or unresponsive, you may need to adjust its sensitivity settings. Refer to your machine's manual for specific instructions on sensitivity adjustments.

- Check for Wear and Tear: Examine the pedal for any signs of wear, such as frayed wires or damaged components. If you notice any issues, consider seeking professional repair techniques to address the problem.

- Test with Caution: Before resuming your sewing projects, test the foot pedal to ensure that any adjustments or maintenance have resolved the issues. Proceed with caution to avoid any potential mishaps during testing.

Belt Inspection

Before inspecting the belt of your Kenmore sewing machine, ensure that the machine is unplugged and that there is no power running to it. Inspecting the belts regularly is crucial for ensuring the smooth operation of your sewing machine. There are two main types of belts in a sewing machine, the motor belt and the timing belt. The motor belt is responsible for transferring power from the motor to the sewing machine's mechanisms, while the timing belt controls the movement of the needle and the bobbin. Here's a quick guide to help you inspect the belts of your Kenmore sewing machine:

| Belt Type | What to Look For |

|---|---|

| Motor Belt | Check for any cracks, fraying, or stretching. Ensure that it is properly aligned and not slipping. |

| Timing Belt | Look for signs of wear, such as missing teeth or stretching. Make sure it is correctly tensioned and aligned with the pulleys. |

Regularly inspecting and maintaining these belts will help prevent unexpected breakdowns and ensure that your Kenmore sewing machine operates smoothly. If you notice any issues with the belts, consider replacing them to keep your machine in top working condition.

Frequently Asked Questions

How Do I Troubleshoot a Jammed or Stuck Needle on My Kenmore Sewing Machine?

If your Kenmore sewing machine has a jammed or stuck needle, troubleshoot by first turning off the machine and gently trying to manually move the needle up and down. Check for any thread or debris causing the issue.

What Should I Do if My Kenmore Sewing Machine Is Making a Loud Grinding Noise While in Use?

If your Kenmore sewing machine is making a loud grinding noise, start by checking for proper lubrication maintenance. Then, adjust the thread tension to ensure smooth operation. Regular maintenance and adjustments can help prevent issues and keep your machine running smoothly.

How Can I Troubleshoot Issues With the Presser Foot Not Lowering or Staying in Place While Sewing?

If your presser foot isn't lowering or staying in place while sewing, check the presser foot height and tension. Ensure it's at the correct height and adjust the tension as needed. Also, clean and lubricate the presser foot mechanism for smooth operation.

What Are Some Common Reasons Why My Kenmore Sewing Machine's Motor Might Be Overheating During Use?

To prevent your Kenmore sewing machine's motor from overheating, ensure proper motor maintenance and troubleshooting. Regularly lubricate moving parts and check for ventilation blockages. Keep an eye on the motor's condition to prevent overheating during use.

Can I Use a Different Brand of Bobbins in My Kenmore Sewing Machine, or Do I Need to Use Specific Kenmore Bobbins?

Yes, you can use a different brand of bobbins in your Kenmore sewing machine, but it's important to ensure compatibility. Using the wrong bobbins can cause sewing machine maintenance issues and troubleshooting bobbin problems.