Learning how to wind a bobbin on a Brother sewing machine is like mastering the art of threading a needle—it seems simple yet requires precision.

As I carefully placed the thread on the spool pin, ensuring it's positioned just right, I realized the importance of each step in this process.

The satisfaction of seeing the perfectly wound bobbin waiting to be used is unparalleled, but there's more to discover about this essential sewing skill that can elevate your crafting game.

Table of Contents

Key Takeaways

- Brother machines offer efficient and convenient bobbin winding.

- Use compatible thread and tools for smooth winding.

- Adjust thread tension for balanced stitches.

- Verify proper bobbin insertion and stitch quality for optimal results.

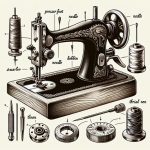

Brother Sewing Machine Overview

When using a Brother sewing machine, its efficient and user-friendly bobbin winding system is a standout feature that enhances the overall sewing experience. The bobbin winding process on Brother machines is designed for convenience and ease of use. With a fast bobbin winding system, time-saving benefits are a definite plus.

I found that the mechanism guarantees even and smooth winding, preventing any snags or tangles during sewing. The streamlined features provided by Brother machines make bobbin winding a breeze, allowing for a smooth changeover between winding bobbins and working on your projects. Understanding this critical aspect of the sewing machine is essential for mastering the art of sewing efficiently.

Brother machines have truly simplified the bobbin winding process, making it accessible for beginners while still catering to the needs of seasoned sewers. Mastering the bobbin winding on a Brother machine sets a solid foundation for a successful sewing journey.

Gathering Supplies Needed

As we prepare to wind a bobbin on a Brother sewing machine, the first step is gathering the necessary supplies.

You'll need a bobbin suitable for your specific Brother model to guarantee proper functionality. Additionally, make sure you have the correct type of thread that's compatible with your machine for winding the bobbin smoothly.

It's essential to have a pair of scissors or a thread cutter on hand to trim any excess thread after winding. Remember to consult your machine's manual to check for any specific tools or accessories required specifically for bobbin winding, making sure you have everything you need before you begin.

Preparing the Bobbin

When preparing the bobbin, it's important to correctly position the spool of thread on the spool pin and pass it around the pre-tension disk. This helps guarantee smooth bobbin winding.

Additionally, threading the end through the bobbin's hole and securing it on the winder shaft are key steps in the process.

Bobbin Loading Process

To prepare the bobbin for winding, make sure it's empty and clean before securing it onto the bobbin winder shaft.

When loading the bobbin onto the bobbin winder, follow these steps:

- Place the bobbin onto the bobbin winder shaft securely.

- Hold the end of the thread and guide it through the bobbin winding path.

- Engage the bobbin winding mechanism according to the machine's instructions.

- Monitor the bobbin winding process to guarantee even distribution of thread.

Thread Tension Adjustment

Adjusting the tension on the bobbin is essential for ensuring smooth and even stitches while sewing. To adjust the tension, locate the small screw on the bobbin case and turn it to regulate the thread tension.

Make sure the bobbin thread is wound evenly on the bobbin winder shaft to avoid thread bunching or looping during sewing. Test the bobbin tension by gently pulling the thread from the bobbin case to feel the resistance.

For specific guidelines on adjusting bobbin thread tension, refer to the sewing machine manual. Remember, proper bobbin tension is vital for achieving balanced stitches and ensuring high-quality sewing results.

Threading the Machine

Alright, let's get into the essentials of threading the machine to guarantee successful bobbin winding.

Understanding the basics of bobbin winding and following the machine's threading steps are essential for the best results.

Bobbin Winding Basics

When preparing to wind a bobbin on a Brother machine, make sure the spool of thread is correctly positioned on the spool pin before proceeding with threading the bobbin. Here are some key steps to follow for successful bobbin winding:

- Pass the thread around the pre-tension disk.

- Thread the end through the hole in the bobbin for winding.

- Place the bobbin on the winder shaft and slide it to the right.

- Turn the bobbin clockwise by hand until it locks.

- Start the winding process by following the machine's instructions carefully.

Following these steps will make sure that your bobbin is wound correctly and ready for use in your sewing projects.

Machine Threading Steps

To thread the machine properly, start by placing the spool of thread on the spool pin and guiding it through the thread guide. Make sure the machine is turned off before threading.

Pass the thread through the tension disk and direct it towards the bobbin winding mechanism. Follow the specific instructions to thread the bobbin correctly. Once the bobbin is in place, activate the bobbin winder function on the machine to start winding.

Confirm the bobbin is securely set up before beginning the winding process. Remember to refer to the machine's manual for any specific guidelines on threading to guarantee smooth operation.

Securing the Thread

Make sure the thread is securely placed on the spool pin to prevent slipping during winding. To guarantee proper thread securing, consider the following steps:

- Utilize a Spool Cap: Using a spool cap helps keep the thread in place and maintains tension while winding the bobbin.

- Guide the Thread Correctly: Direct the thread towards the bobbin winder and wrap it around the bobbin in a clockwise direction for best winding.

- Pass Through the Guide Slit: Make sure to pass the thread through the guide slit on the bobbin winder seat to properly secure it before starting the winding process.

- Check for Smooth Feeding: Verify that the thread is smoothly feeding onto the bobbin to guarantee an evenly wound and functional bobbin.

- Ensure Consistent Tension: Monitor the tension of the thread to prevent tangling or uneven winding, resulting in a well-prepared bobbin for your sewing projects.

Adjusting Tension Settings

After securing the thread on the bobbin, adjusting the tension settings is essential for achieving the best stitch quality on your Brother sewing machine. Proper tension adjustment guarantees that the upper and lower threads interlock correctly within the fabric, creating neat and balanced stitches. To assist you in mastering this critical step, refer to the table below for guidance on adjusting tension settings based on different scenarios:

| Thread Type | Tension Setting | Stitch Quality |

|---|---|---|

| Cotton | 4-5 | Even and secure |

| Polyester | 3-4 | Smooth and balanced |

| Silk | 2-3 | Delicate and fine |

Remember to consult your sewing machine manual for recommended tension settings specific to the thread you are using. It's advisable to test the tension by sewing a sample on scrap fabric before starting your project to make any necessary adjustments. Regularly checking and fine-tuning the tension settings will help maintain consistent stitch quality on your Brother sewing machine.

Winding the Bobbin

Position the spool of thread correctly on the spool pin before starting the bobbin winding process.

To wind the bobbin efficiently on a Brother machine, follow these steps using the bobbin winder:

- Pass the thread around the pre-tension disk to prepare it for winding.

- Turn the bobbin clockwise by hand until it locks in place for efficient winding.

- Hold the thread and press the foot controller to control the winding speed of the bobbin.

- Trim excess thread above the bobbin for a neat and organized winding process.

Checking Bobbin Thread

When checking the bobbin thread, it's important to confirm it's evenly wound and free of tangles. Verify that the bobbin is securely inserted and the thread matches the fabric being used.

Properly feeding bobbin thread is essential for smooth machine operation.

Thread Tension Check

To guarantee perfect sewing results, it's essential to check the tension of the bobbin thread by pulling it out of the bobbin case. Proper tension ensures smooth unwinding and prevents issues like breakage or looping. Here are some key points to bear in mind when checking the bobbin thread tension:

- Make sure the bobbin thread unwinds smoothly with minimal resistance.

- Adjust the tension screw on the bobbin case if needed.

- Balanced tension is crucial for high-quality stitching.

- Regularly inspect and adjust tension for consistent results.

- Ideal tension prevents thread-related sewing problems.

Maintaining the correct bobbin thread tension is crucial for achieving professional and flawless sewing outcomes.

Bobbin Insertion Verification

After ensuring the proper tension of the bobbin thread, the next step is to verify the correct insertion of the bobbin and check the thread for smooth unwinding. When using a bobbin winder, it's crucial to confirm that the bobbin thread unwinds evenly and without any snags or tangles. By suspending the bobbin with the thread, you can easily check if the unwinding process is smooth, indicating correct insertion. Make sure to inspect the bobbin thread for loose loops or knots that might impact your stitching quality. Additionally, ensure that the bobbin thread is securely positioned in the bobbin case for seamless sewing. Here's a table to summarize the key points:

| Bobbin Insertion Verification |

|---|

| 1. Check for smooth unwinding |

| 2. Verify even winding |

| 3. Ensure secure insertion |

Inserting the Bobbin

Insert the wound bobbin carefully into the bobbin case, making sure the thread comes off counterclockwise. It's crucial to follow this step correctly to avoid any issues during sewing. Here are some key points to keep in mind when inserting the bobbin:

- Make certain the bobbin is wound evenly and securely to prevent thread jams.

- Confirm the bobbin is properly seated and the thread is pulled through the bobbin case slot.

- Check the bobbin tension by gently tugging the thread; it should unwind slightly.

- Close the bobbin cover securely before resuming sewing.

- Double-check that the bobbin is securely placed and the thread is correctly threaded to maintain stitch quality.

Following these steps will help ensure that the bobbin is inserted correctly and the sewing process goes smoothly. Taking the time to insert the bobbin properly can save you from potential issues later on.

Testing the Stitch Quality

When checking the stitch quality after winding the bobbin, sew a sample fabric piece to guarantee consistent tension and smooth stitches. It's important to make sure that the thread around the bobbin is feeding properly to achieve best results. Inspect both sides of the fabric to verify that the stitches are secure and evenly formed. Additionally, test the stitch formation on various fabric types to assess the machine's versatility.

To assist in evaluating the stitch quality effectively, refer to the table below:

| Stitch Quality Criteria | Assessment |

|---|---|

| Consistent Tension | Check for even thread formation on both sides of the fabric. |

| Smooth Stitches | Ensure there are no loose threads or skipped stitches. |

| Secure Stitch Formation | Verify that the stitches hold firmly when gently tugged. |

| Versatility | Test the machine on different fabric types for consistent results. |

Frequently Asked Questions

How Do You Wind the Thread Around the Bobbin?

To wind the thread around the bobbin, I pull the thread from the spool, wrap it clockwise, secure it in the guide slit, start the winding process with the button or pedal, fill evenly, and slide the shaft left when done.

How Do You Wind the Bobbin on a Brother Sewing Machine?

To wind the bobbin on a Brother sewing machine, place the thread on the spool pin, pass it around the pre-tension disk, position the bobbin on the winder shaft, power on the machine, press the foot controller, and wind evenly for best performance.

How Do You Get the Bobbin Thread to Catch the Upper Thread?

To get the bobbin thread to catch the upper thread, hold the needle thread lightly, turn the handwheel towards me to bring the needle down, pick up the bobbin thread, then gently pull it through the needle plate slot to connect with the upper thread.

How Do You Put Cotton on a Bobbin Brother?

To put cotton on a bobbin Brother, place a spool on the spool pin, thread the cotton through the pre-tension disk, thread it through the bobbin, wind it evenly by turning it clockwise on the winder shaft.

- Chemistry's Role in Fabric Production - July 25, 2024

- Moisture Management in Modern Fabrics - July 25, 2024

- Engineering Fabrics for Optimal Performance - July 25, 2024