I've always been impressed by nylon's toughness, and here's why it's so durable: Nylon is made of long chains of polyamide molecules linked by strong hydrogen bonds. This structure allows the fibers to be extremely resilient and resistant to wear and tear. Nylon can snap back to its original shape after stretching and withstands abrasion like a champ. Plus, it's resistant to many chemicals and changes in temperature, all of which contribute to its long life in our bags, clothes, and more. There's a lot more to learn about how these properties are used in everyday items and harsh environments!

Key Takeaways

- Nylon's molecular structure features long chains linked by strong amide bonds, enhancing its toughness.

- The presence of hydrogen bonds between polyamide chains in nylon increases its durability.

- Nylon possesses high abrasion resistance, allowing it to withstand excessive rubbing and stress.

- It offers excellent resistance to wear and tear, maintaining integrity under repeated stress.

- Nylon is chemically stable against organic solvents and alkalis, contributing to its longevity in harsh environments.

Nylon's Molecular Structure

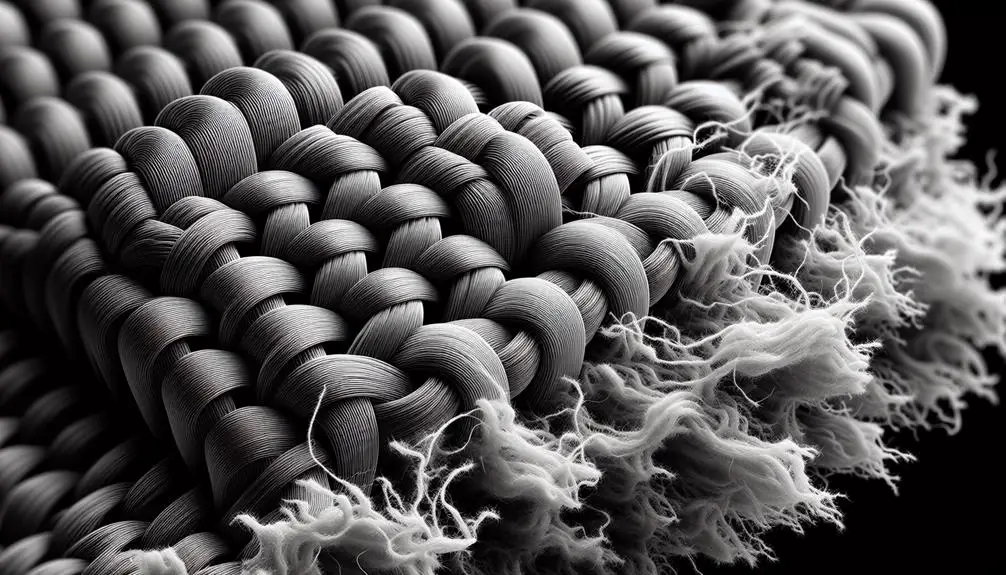

Nylon's incredible durability comes from its unique molecular structure, where long chains of repeating units are tightly linked by amide bonds. The hydrogen bonds between these chains aren't just a minor detail—they're crucial. They give nylon its remarkable strength and resilience, which is why it's such a go-to material for products that need to endure without giving way.

When we talk about the properties of nylon, we're diving into why it can handle so much stress without stretching or breaking. This strength isn't just about lasting a long time; it also means nylon can withstand a lot of wear and tear. It resists abrasion like a champ. Whether it's a backpack, a pair of tights, or even components in cars, nylon holds up incredibly well under pressure.

The environment throws a lot at materials, but nylon's setup allows it to resist harsh conditions. This isn't by chance but by design. The specific monomers chosen during production play a big part in this. They tailor the molecular structure in such a way that it maximizes strength and durability. This attention to detail at the molecular level is what sets nylon apart as a super durable material.

Polyamide Chains Explained

Building on how the molecular structure contributes to nylon's strength, let's focus on how the polyamide chains themselves work. These chains are the real MVPs when it comes to nylon's durability. Imagine them as super-strong links in an invisible chainmail, each link tightly bonded to the next.

The secret sauce behind these polyamide chains is their ability to form strong hydrogen bonds with each other. Think of these bonds as tiny, invisible hands holding each chain tightly together. This isn't just a light handshake either; it's a firm, unbreakable grip that significantly boosts the toughness and resilience of the material.

What's more, the arrangement of these chains isn't random. They're structured in a way that maximizes strength. Each chain aligns and packs together tightly, which not only enhances durability but also contributes to the longevity of the material. This tight packing means that nylon doesn't just give up under stress—it's built to withstand a lot without breaking down.

Resistance to Wear and Tear

Let's talk about why nylon can take a beating and still hold up.

Its high tensile strength means it doesn't easily break or stretch out of shape, even under a lot of pressure.

Plus, its ability to resist abrasion keeps it from wearing down quickly, even in rough conditions.

High Tensile Strength

Due to its molecular structure, nylon boasts high tensile strength, making it resistant to wear and tear. This resilience is primarily because of the strong hydrogen bonds between the polymer chains, which really amp up its toughness.

The amide bonds arranged within the material play a huge role too. They're like the unsung heroes maintaining the integrity of the fabric under stress.

What's more, nylon's ability to snap back to its original shape after being stretched is a game-changer. It means that even when you're putting it through the wringer, it holds up pretty well.

Abrasion Resistant Properties

Nylon's knack for resisting abrasion makes it incredibly durable against wear and tear. This resilience stems chiefly from its molecular structure, which is tough enough to handle constant friction or contact without breaking down.

The fibers in nylon are particularly good at fending off rubbing and repetitive stress, extending their life significantly. This quality isn't just a nice-to-have but critical in many applications where materials continually face rough conditions.

Whether it's clothing, ropes, or conveyor belts, nylon's abrasion-resistant nature ensures that these items last longer and maintain their integrity through extensive use. It's no wonder that nylon is often the go-to for products where durability is key.

High Abrasion Resistance

I've noticed that one of the reasons nylon is so tough is its high abrasion resistance. This characteristic is pivotal because it means nylon can handle a lot of rough treatment without showing much wear and tear. The molecular structure of nylon plays a huge part in this. Let's break it down a bit: nylon's molecules are arranged in a way that they provide robustness against friction and surface damage. This structure doesn't just help nylon put up a good fight against rubbing and scraping; it keeps it looking good as new for a lot longer than you might expect.

Here's a quick table to show how this plays out:

| Feature | Benefit | Application Example |

|---|---|---|

| Molecular Strength | Withstands intense friction | Hiking gear |

| Tough Structure | Resistant to surface damage | Industrial belts |

| Long-Lasting | Maintains integrity over time | Outdoor furniture |

| Aesthetic Durability | Keeps appearance longer | Fashion accessories |

Impact on Longevity

Let's look at what makes nylon last so long.

It's not just tough against wear and tear; its ability to shrug off moisture and chemicals plays a big part too.

These factors mean you can count on nylon to hold up well over time in various conditions.

Resistant to Wear, Tear

Due to its strong molecular structure, nylon stands up well to wear and tear, significantly extending its lifespan. I've come to appreciate how these features make nylon fabrics not just practical but also incredibly reliable over time. Here's why durable nylon is a top choice for anyone looking for longevity in their materials:

- Abrasion Resistance: Nylon's ability to resist surface wear from rubbing ensures it remains in great shape.

- Chemical and Oil Resistance: It withstands various chemicals and oils, which prevents degradation.

- Temperature Tolerance: Nylon maintains its properties across a broad temperature range, offering versatility.

- Resistance to Mold and Insects: Its ability to resist mold and pests further enhances its durability.

These characteristics collectively contribute to nylon's robustness and long-term usability.

Moisture Absorption Properties

Nylon's low moisture absorption rate significantly boosts its durability, as it prevents the material from breaking down due to water exposure. This quality is a big plus. Considering how water can wreak havoc on many materials, causing them to weaken or grow mold, nylon's resistance to soaking up moisture is a key player in its long-term game.

It keeps its shape and strength, which is crucial for items that need to last under stress or weather conditions. This hydrophobic nature means less risk of water damage, and that's a win for anyone looking for reliability. With minimal moisture absorption, nylon ensures products maintain their integrity and function longer, really stretching out their lifespan. That's why it's a top choice for many applications.

Chemical Resistance Factor

Moving on, another reason nylon holds up so well is its impressive chemical resistance. This trait significantly boosts its durability, making it a top choice for various demanding applications. Let me break down how this chemical resistance contributes to its long-lasting nature:

- Inert to Alkalis: Nylon's non-reactivity with alkaline substances means it won't degrade easily.

- Resists Organic Solvents: It stands strong against solvents, maintaining its structure and function.

- Unaffected by Most Bleaches: Ideal for use in environments where cleaning and sterilization are frequent.

- Withstands Exposure to Mineral Acids: Even harsh acids don't break it down easily.

These characteristics ensure that nylon can survive tough conditions without losing its integrity.

Comparing Nylon With Other Fibers

Let's compare nylon to other fibers to see why it's so tough. As a synthetic material, nylon boasts a concoction of properties that make it a heavyweight in the durability department. Its strength largely stems from hydrogen bonding between polymer chains. These bonds are like tiny, invisible superglues holding everything tightly together, which isn't something you see in many natural fibers like cotton.

Speaking of cotton, while comfy and breathable, it just can't match nylon when it comes to resisting wear and tear. Cotton tends to break down faster under stress and doesn't fare well with frequent stretching and washing. Nylon, on the other hand, keeps bouncing back, like a champ, maintaining its shape and structure incredibly well.

Moreover, nylon's resistance to moisture is another plus. Ever noticed how some materials start to sag or degrade after you've gotten them wet a bunch of times? Not nylon. It effectively repels water, preventing the kind of moisture-induced damage that can send other fibers to an early retirement. This makes nylon an outstanding choice for everything from outdoor gear to durable fashion.

Chemical Resistance Properties

Beyond its physical durability, I find nylon's resistance to various chemicals a key aspect of its robustness. This chemical resistance isn't just a minor feature; it's a major part of why nylon is so incredibly durable and favored in many high-demand environments. Whether it's being used in automotive parts, clothing, or industrial equipment, nylon's ability to shrug off chemical attacks helps it last longer and perform better.

Here's a quick rundown of the chemical resistance properties that boost nylon's durability:

- Organic Solvents: Nylon's structure makes it resistant to many organic solvents, which means it doesn't degrade easily when exposed to chemicals that would wear down less sturdy materials.

- Alkalis: Its inert nature towards alkalis ensures that nylon remains stable and retains its integrity even in environments where chemical exposure is frequent.

- Bleaches: Most bleaches don't harm nylon, enhancing its suitability in the textile industry where frequent washing and bleaching could be necessary.

- Hydrocarbons, Oils, and Cleaning Solutions: Excellent resistance to these substances contributes significantly to nylon's overall durability, making it a go-to material for various applications.

The combination of these chemical resistance properties ensures that nylon isn't just tough; it's also incredibly versatile and dependable.

Heat Resistance Capabilities

Nylon's ability to withstand high temperatures without losing its strength or structure makes it incredibly durable. This resilience is largely due to its unique molecular structure, which is designed to handle the heat. When I consider how this material manages to maintain its properties despite being exposed to high temperatures, it's clear why it's chosen for so many high-demand applications.

The heat resistance of nylon isn't just about surviving temperature spikes; it's about excelling in prolonged hot environments. In industrial settings, where machinery can generate immense heat, nylon components are crucial. They don't just survive; they thrive, ensuring that everything from automotive parts to heavy-duty machinery operates smoothly without frequent replacements.

This capability to resist heat contributes massively to nylon's overall durability. It doesn't degrade or melt away as some materials might. Instead, it stands firm, maintaining its integrity and functionality. This isn't just impressive; it's essential. In environments where thermal stability is a must, nylon's ability to remain stable and functional under such conditions is a game-changer.

Understanding this, it's easy to see why nylon is a go-to material for anyone looking for durability in high-heat scenarios. Its performance isn't just about handling a momentary temperature rise; it's about consistent reliability in the face of thermal challenges.

Benefits in Everyday Products

Every day, we rely on products made from nylon because of its ability to resist stretching, wear, and environmental damage. It's incredible how this material integrates into our daily lives, providing durability where we most need it. The strength and resilience of nylon make it an ideal choice for a multitude of everyday items. I've come to appreciate how these features translate into real-world benefits.

Here's a quick look at some everyday products where nylon's durability is a game changer:

- Bags and backpacks: Nylon's resistant to stretching and its abrasion-resistant nature mean these items can handle the rough and tumble of daily commutes and travels without falling apart.

- Sportswear: Highly valued in athletic gear, nylon withstands repetitive stress and strain, keeping sportswear intact and functional.

- Automotive components: In cars, nylon parts endure vibration and wear, proving essential for long-lasting performance.

- Home furnishings: From upholstery to curtains, nylon's durability extends the life of these products, resisting daily wear and tear effectively.

Nylon's role in these products showcases its unbeatable durability, making our investments last longer and perform better. It's fascinating to see how much we depend on this resilient material.

Nylon in Harsh Environments

While we've seen how nylon stands up in daily use, it's equally impressive in more demanding conditions. Let's dive into why nylon is so trusted in harsh environments.

First off, its chemical resistance is a big deal. Nylon doesn't just shrug off a bit of rain; it holds its own against aggressive oils, harsh chemicals, and even rigorous cleaning solutions. This makes it a go-to material for industries where such exposures are common.

Moreover, nylon's ability to handle extreme heat without weakening is remarkable. Imagine materials that need to withstand the blazing sun or high-engine temperatures; nylon can handle that without a sweat. Its high-temperature resistance ensures that it doesn't lose strength, even when things get hot.

The material is also tough against physical wear. Thanks to its excellent abrasion resistance, it's used in scenarios where you expect a lot of contact and friction. From heavy-duty work gear to adventure sports equipment, nylon keeps up without showing much wear.

Lastly, don't overlook its resilience against UV rays and water. These properties ensure that nylon remains strong and durable, whether it's used on a sunny beach or in a damp rainforest. That's why it's so widely used in outdoor and marine applications.

Maintenance and Care Tips

Caring for nylon properly boosts its longevity and ensures it remains tough against daily wear and tear. As a durable material, it's surprisingly easy to clean, but you've got to do it right to keep it in top shape. Here's how I ensure my nylon gear stays pristine and robust:

- Regular Cleaning: Gentle washing is key. I always avoid harsh detergents and stick to mild soap to prevent damage and maintain the fabric's strength.

- Avoid Harsh Chemicals: Never use bleach on nylon. It can seriously weaken the fibers. Instead, I opt for specialized cleaners or just plain old soap and water.

- Proper Storage: I make sure to store all my nylon items in a cool, dry place away from direct sunlight. This prevents the material from degrading over time and keeps it strong.

- Prompt Stain Treatment: If there's a spill, I tackle it immediately. Quick action with the right cleaning agents ensures the stain doesn't set and the fabric stays durable.

Following the manufacturer's care instructions also helps me avoid common pitfalls. It's all about respecting the material and handling it with care. Nylon's durability really shines when you treat it right!

Future of Durable Materials

Looking ahead, the future of durable materials is pretty exciting. Innovations in material science are popping up everywhere, and we're even seeing advances in biodegradable materials that promise a greener footprint.

Plus, technology like 3D printing is totally changing how these materials are produced.

Innovations in Material Science

Recent advancements in material science are revolutionizing how we enhance the durability of materials like nylon. It's fascinating to see how these innovations are shaping the future of materials we use daily. Here's what's happening:

- Nanotechnology Integration: By reinforcing nylon with nanoparticles, we're seeing a significant increase in its strength and wear resistance.

- Nanofibers and Nanocomposites: These are being developed to further boost nylon's mechanical properties and overall durability.

- Surface Modifications: Techniques like plasma treatment are enhancing nylon's adhesion and performance in various applications.

- Smart Materials: Incorporating self-healing technologies in nylon production could lead to materials that aren't only durable but also incredibly resilient.

It's clear that the future holds exciting possibilities for nylon and similar materials!

Biodegradable Durables Emerging

As we move forward, it's clear that biodegradable durables are the next big step in creating sustainable, eco-friendly materials. These innovative materials are designed to offer the same durability we've come to expect from traditional options like nylon, but with a crucial difference—they can break down naturally over time.

This shift is largely driven by the increasing concern over plastic waste and the environmental impact of non-biodegradable goods. Companies are now pouring resources into developing materials that not only meet the demands of everyday use but also ensure that they don't linger in the environment for centuries.

The challenge is real, but the commitment to balancing durability with biodegradability is paving the way for a more sustainable future in material science.

Technology Impacting Production

While biodegradable durables promise a more sustainable future, ongoing technological innovations continue to enhance the production and durability of materials like nylon. Let's dive into how technology is impacting production and the advantages that make nylon even more impressive.

- Nanotechnology: Researchers are developing nanocomposite nylon, which offers unmatched strength and resilience.

- Electrospinning: This method produces ultra-strong nylon fibers, significantly boosting their durability.

- Additives: Incorporating materials like carbon nanotubes and graphene enhances the performance and lifespan of nylon products.

- Polymer Engineering: Constant improvements in polymer chemistry are making nylon more versatile and durable for various applications.

These advancements highlight how nylon is evolving to meet modern demands, ensuring it remains a top choice for durable materials.

Frequently Asked Questions

Why Is Nylon Durable?

Nylon's durability comes from its high tensile strength, resistance to abrasion, and ability to withstand chemicals. Its molecular structure, featuring strong hydrogen bonds, also plays a crucial role in maintaining its resilience.

Why Is Nylon the Strongest?

Nylon's exceptional strength stems from its tightly bonded polymer chains and robust hydrogen bonding. These molecular traits significantly enhance its tensile strength, making it incredibly tough and suitable for demanding applications.

Does Nylon Break Easily?

Nylon doesn't break easily; it's got a high tensile strength and excellent resistance to wear and tear. That's why it's often used in tough environments, like outdoor gear and heavy-duty fabrics.

What Are Advantages of Nylon?

I've found that nylon's advantages include its incredible durability, resistance to chemicals, and versatility in various applications, from clothing to industrial products. Its strength and easy maintenance also make it supremely practical.