Nylon's fame comes from its sheer versatility and pivotal role in transforming industries. Imagine a material born out of DuPont in 1938 that not only changes fashion but also impacts automotive and medical fields. Its durability, resistance to wear, and low friction make it ideal for everything from rugged outdoor gear to high fashion. Plus, its ability to withstand high temperatures and resist moisture opens doors to numerous applications. As a lightweight, strong, and recyclable material, nylon continues shaping technological and design innovations. Stick around, and you'll see just how this material keeps innovating and adapting to meet modern needs.

Table of Contents

Key Takeaways

- Nylon is renowned for its exceptional durability and flexibility, making it ideal for various applications.

- It revolutionized fashion by replacing materials like silk with more affordable, versatile options.

- Nylon's high tensile strength and chemical resistance enhance its use in industrial and medical fields.

- The material's ability to be recycled aligns with growing environmental sustainability efforts.

- Its versatility extends to uses in textiles, automotive parts, and even advanced technologies like 3D printing.

Invention and History

Nylon's journey to fame began in 1938 when DuPont revolutionized the textile industry with its invention. Spearheaded by the brilliant chemist Wallace Carothers, this breakthrough wasn't just another step but a giant leap for synthetic fibers. As a material, nylon was unlike anything the industry had seen before, combining durability and flexibility in ways that natural fibers couldn't match.

I've always been fascinated by how DuPont's prior experience with rayon paved the way for nylon. It's like they took what they learned from earlier synthetic endeavors and kicked it up a notch. By focusing on the polymerization process, Carothers and his team managed to create a thermoplastic that could be easily melted and transformed. This adaptability opened doors to a range of products beyond mere fabrics.

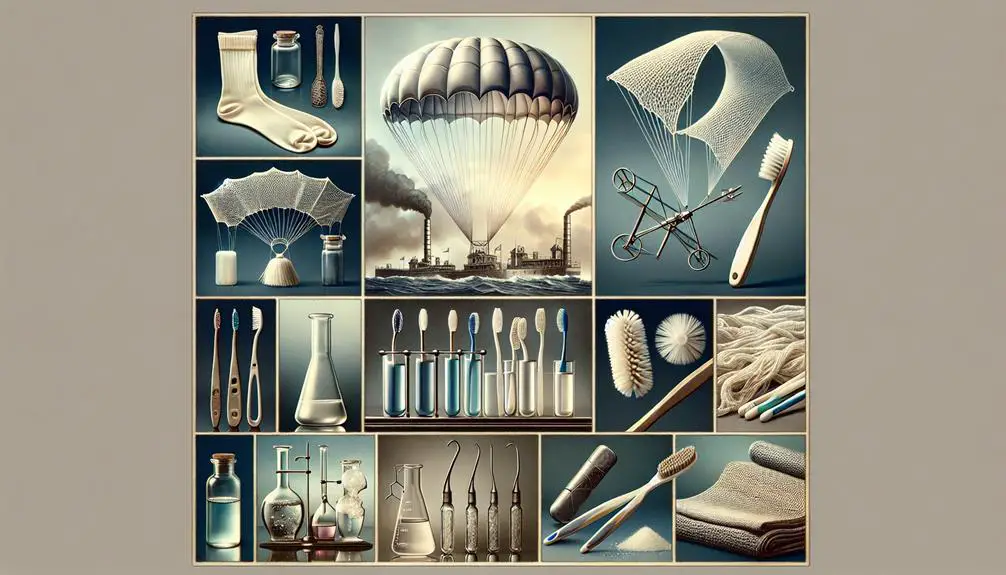

What's more, the ability of nylon to be molded into various shapes led to its use in numerous applications, from stockings to toothbrush bristles. It's pretty amazing to think about how one invention sparked such a diverse array of uses. This versatility certainly played a key role in cementing nylon's place in both the textile industry and the broader market for molded parts.

Unique Properties

Building on its historical significance, let's explore the unique properties that make nylon such a standout material. First off, this fabric isn't just tough; its high tensile strength means it can take a lot of stretch and stress before it gives way. That's a big deal if you're looking for durability and resilience in your materials.

Nylon's wear resistance is another key factor. It resists abrasion like a champ, which is why it's a go-to for items that need to withstand a lot of rubbing or wear. Plus, the low friction coefficient helps it slide and move without snagging or tearing. This makes it ideal for parts that need to glide smoothly over each other.

Don't even get me started on the melting point. Nylon's high melting point means it can handle some serious heat before it starts to deform. This is crucial in applications where high temperatures are a norm. Also, its moisture resistance is a lifesaver for outdoor or water-exposed products. It keeps moisture at bay, ensuring things stay dry and intact.

And, it's not just about handling the rough stuff—nylon's also lightweight and resists acid, widening its use even more.

Versatile Applications

From car parts to kitchen tools, I've seen nylon used in an astonishing range of products. This thermoplastic marvel isn't just versatile; it's a powerhouse in both performance and adaptability. As a fabric, nylon's strength and flexibility make it a go-to for everything from rugged outdoor gear to sleek, fashionable attire. Its ability to be dyed easily adds to its popularity in the textile industry.

In the realm of fibers, nylon shines due to its exceptional durability. Think about those tough carpet floors and sturdy ropes, all owing their resilience to nylon fibers. Even more impressive are the molded parts made from nylon, especially in the automotive sector—everything from intricate dashboard components to durable door handles.

Nylon's thermoplastic nature means it can be melted and remolded without losing its chemical structure, which allows for endless recycling possibilities. Types like nylon-6,6 offer enhanced resistance to heat and wear, making them ideal for high-demand applications. Whether it's in films for food packaging or as reinforcement in rubber, the adaptability of nylon is unmatched, ensuring it plays a critical role across various domains.

Impact on Industries

Let's talk about how nylon has truly changed the game in several industries.

For starters, it's taken fashion apparel to new heights by providing designers with durable, flexible materials.

It's also made significant strides in medical devices, enhancing both innovation and functionality.

Revolutionizing Fashion Apparel

Nylon completely transformed the fashion industry when it hit the scene with its introduction of nylon stockings in 1939. DuPont's innovative synthetic not only became a staple in everyday wear but also captivated the high fashion scene. By replacing traditional materials like silk and cotton, nylon reshaped the apparel industry, offering durability and ease of care that silk and cotton couldn't match.

| Impact on Material | Description |

|---|---|

| Silk & Cotton | Decreased use in mass market due to nylon's advantages |

| High Fashion | Increased use of nylon, endorsed by top designers |

| Everyday Apparel | Shift to more synthetic fibers for durability and ease of care |

This shift wasn't just a trend; it was a total game changer in how we dress today.

Advancements in Medical Devices

The use of nylon in medical devices has significantly boosted the efficiency and safety of modern medical procedures. Thanks to its strength, flexibility, and resistance to chemicals, nylon is a standout in the medical field. It's fascinating how it plays a vital role in various applications, from basic to complex devices.

Here's a quick rundown of its uses:

- Medical tubing: Essential for fluid transfer with great durability.

- Catheters: Offers biocompatibility that's crucial for patient safety.

- Surgical instruments: Nylon's strength supports the creation of reliable tools.

- Sterilization capability: Easily sterilized, maintaining hygiene standards.

- Implants: Used in devices due to its adaptability and safety.

Nylon's versatility is truly revolutionizing medical device technology, enhancing patient care remarkably.

Environmental Considerations

Considering the environmental impact, nylon production is notably harmful due to its emissions of nitrous oxide, a potent greenhouse gas. Let's not forget that this isn't the only issue. Nylon's non-biodegradable nature means it sticks around in landfills and oceans for centuries, adding to the ever-growing problem of plastic pollution. It's a stubborn material, to say the least.

Moreover, making nylon isn't exactly gentle on our resources—it gobbles up a significant amount of energy and water. This heavy consumption contributes further to environmental degradation, a price we're paying for a material found in everything from clothing to carpets. Now, you might wonder, can't we just recycle it and ease its environmental footprint? Well, while recycling nylon is possible, it's complicated and not as widespread as we'd hope. The process itself is energy-intensive and still underused, which is a bummer.

Thankfully, some smart folks are working on sustainable alternatives. These include recycled nylon and bio-based materials aimed at minimizing environmental concerns. These innovations are crucial because they offer a glimmer of hope for reducing our environmental impact while still enjoying the benefits of this versatile material.

Technological Advancements

With its debut in 1938 by DuPont, nylon revolutionized the textile industry through its remarkable strength and durability. This synthetic marvel didn't just stop at being a robust material; its thermoplastic nature opened up a world of possibilities in fabric production and beyond. I can't help but marvel at how DuPont fibers transformed not only fashion but also various industrial applications.

Here's why nylon's technological advancements are such a big deal:

- Versatility: Nylon can be molded into countless shapes, making it ideal for both everyday items and specialized uses.

- Durability: Its high tensile strength means products last longer, even under tough conditions.

- Material Innovation: Nylon was a groundbreaking substitute for natural fibers, offering benefits like resistance to mildew.

- Design Flexibility: The thermoplastic nature allows for innovative designs that were previously impossible.

- Industrial Utility: From automotive to aerospace, nylon's applications are extensive because of its unique properties.

These factors collectively underscore nylon's pivotal role in material innovation and highlight its significance in advancing not just the textile industry but many others. It's clear that DuPont's development of nylon fibers wasn't just about creating something new; it was about setting the foundation for future innovations.

Global Popularity

So, let's talk about why nylon's become such a big deal everywhere.

It's not just about clothes; this stuff is used in everything from car parts to industrial machinery because it's so adaptable and tough.

Plus, its attributes like being light yet super strong mean it's spread across industries and countries like wildfire.

Versatile Material Uses

Nylon's versatility shines through its myriad uses, from fashion to industrial components, making it globally popular. Whether you're talking about high-tech applications or everyday items, nylon's got it covered. Here's why it's a superstar in various industries:

- Textiles and clothing fibers: From durable raincoats to delicate lingerie.

- Industrial materials: Used in everything from construction to injection molding.

- Automotive parts: Essential for components that demand strength and flexibility.

- 3D printing filaments: A go-to material for precision and reliability.

- Fishing industry: Crucial for strong, durable fishing nets and lines.

This widespread use isn't just about variety; it's about delivering performance across the board. That's what makes nylon truly indispensable.

Wide Geographic Reach

Nylon's global fame stretches far and wide, cherished for its robustness and adaptability in various sectors. It's not just about how tough it is, but also about how it meets the needs across the globe. From the clothes we wear to the cars we drive, nylon's in there, making things better.

Here's a quick look at how far its reach goes:

| Sector | Application |

|---|---|

| Textiles | Clothing, gear |

| Industrial | Machine parts, tools |

| Consumer Goods | Fishing lines, etc. |

Nylon's wide geographic reach isn't just impressive, it's essential. It's not often you find a material that's so versatile, impacting everything from high fashion to high-tech industries. This stuff's everywhere, and for good reason!

Diverse Industrial Applications

Diving into its diverse industrial applications, nylon's global popularity is undeniable, used in everything from textiles to automotive parts. This synthetic marvel stretches its utility across various sectors:

- Textiles and carpets provide durability and aesthetic versatility.

- Automotive parts benefit from its high tensile strength and wear resistance.

- Construction materials capitalize on nylon's chemical resistance.

- 3D printing filaments exploit its adaptability and strength.

- Fishing lines rely on its toughness and minimal water absorption.

Nylon's ability to meet the demands of these diverse industries not only spotlights its indispensability but also cements its status as a frontrunner in the global materials market. It's the go-to for anyone looking for reliability in an unpredictable world.

Future Prospects

As we look to the future, nylon's potential for innovation and sustainability continues to expand. DuPont's nylon has long set the standard, but now we're seeing a significant shift towards more sustainable production methods in material science. These advancements aren't just pie-in-the-sky; they're real changes designed to minimize environmental impact. There's a buzz around bio-based nylons, which promise to be a game-changer by offering a greener alternative without sacrificing the quality and durability we've come to expect.

Emerging technologies are fine-tuning nylon's properties, enhancing its performance across a variety of applications. From automotive to fashion, the enhanced characteristics of next-gen nylon are pushing boundaries on what this versatile material can do. Moreover, collaborations between academic researchers and industry giants are turbocharging these developments, ensuring that nylon remains at the forefront of both innovation and sustainability.

It's an exciting time to be involved with nylon. The focus isn't just on making it stronger or more flexible—though that's certainly part of it—but also on making it right. Right for the environment, right for consumers, and right for a future where sustainability is no longer optional but essential.

Frequently Asked Questions

Why Is Nylon so Popular?

Nylon's popularity stems from its durability, versatility, and resistance to wear and tear. It's ideal for various applications, from clothing to industrial products, due to its strength and easy maintenance.

Why Did Nylon Become Popular?

Nylon became popular because it's strong, elastic, and lightweight. It revolutionized fashion, especially in women's hosiery, and was invaluable during WWII. Its versatility across industries from automotive to textiles solidified its widespread use.

What Makes Nylon Special?

Nylon's special because it's incredibly strong, abrasion-resistant, and flexible. It's also lightweight, chemically resistant, and can be molded into various shapes, making it versatile for many industrial and textile applications.

When Was Nylon Most Popular?

Nylon peaked in popularity during the late 1930s and 1940s, especially during World War II when it was essential for military supplies and became a coveted item in consumer fashion.

- Why Is Red Velvet Not Red? - April 25, 2024

- How Do You Describe Velvet Fabric? - April 25, 2024

- How Strong Is Velvet? - April 25, 2024