When it comes to choosing between dyeing and printing for your fabric, the decision can be quite the conundrum. Both methods have their own set of advantages and considerations that you'll need to weigh carefully.

In this comparison, we'll delve into the key factors to consider, from color fastness to environmental impact, to help you make an informed choice.

Whether you're seeking vibrant, long-lasting colors, or aiming for intricate design details, understanding the differences between dyeing and printing will empower you to make the best decision for your specific needs.

Key Takeaways

- Dyeing creates a uniform and long-lasting color effect, while printing allows for more intricate and detailed designs.

- Dyeing often results in more vibrant and long-lasting colors compared to printing, as dye permeates fabric fibers while printed colors sit on the fabric surface.

- Dyeing generates significant amounts of wastewater and chemical waste, while printing produces minimal waste due to precise ink application.

- Printing offers greater design flexibility and detail, allowing for intricate patterns, fine lines, and a wider range of vibrant and intense colors.

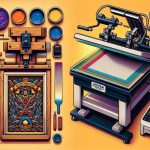

The Basics of Dyeing and Printing

When you're considering the basics of dyeing and printing, it's important to understand the fundamental differences between these two processes.

The dyeing process involves the penetration of color into the fabric, resulting in a permanent change to the material. This is achieved by immersing the fabric in a dye bath, allowing the dye to be absorbed into the fibers.

On the other hand, printing techniques involve the application of color to the surface of the fabric. This can be done through various methods such as screen printing, block printing, or digital printing. Unlike dyeing, where the color becomes a part of the fabric, printing sits on top of the fabric.

Understanding these processes is crucial in determining the most suitable method for achieving the desired results. Dyeing is ideal for creating a uniform and long-lasting color effect, as it permeates the fabric completely.

On the other hand, printing allows for more intricate and detailed designs, as the color is applied only to the surface of the fabric. Both techniques have their unique advantages and can be chosen based on the specific requirements of the project.

Comparison of Color Fastness

You should compare the color fastness of dyeing and printing to determine which method better maintains vibrant colors over time.

Color fastness refers to how well a fabric resists fading or running when exposed to various conditions such as washing, light, and friction.

Here's what you should consider when comparing the color fastness of dyeing and printing:

- Color Vibrancy: Dyeing often results in more vibrant and long-lasting colors compared to printing. This is because the dye penetrates the fabric fibers, becoming a part of the fabric itself. On the other hand, printed colors sit on the surface of the fabric and may fade or wash out more easily over time.

- Fabric Compatibility: Different fabrics may react differently to dyeing and printing processes. For instance, certain fabrics may be more compatible with dyes, allowing for better color penetration and retention. Understanding how each method interacts with specific fabric types can help you determine the best option for maintaining color vibrancy over time.

- Environmental Factors: Consider the environmental impact of each method. Dyeing often requires more water and energy, whereas advancements in digital printing have reduced water usage and waste. This consideration is essential for those seeking sustainable and eco-friendly color retention options.

Environmental Impact Considerations

Considering the environmental impact of dyeing and printing processes, it is crucial to evaluate their sustainability and resource utilization. Additionally, advancements in digital printing have reduced water usage and waste, offering a more eco-friendly alternative to traditional dyeing methods.

When it comes to environmental impact, waste management and energy consumption are key factors to consider. Here's a comparison between dyeing and printing processes in terms of their environmental impact:

| Environmental Factors | Dyeing Process | Printing Process |

|---|---|---|

| Waste Management | Generates significant amounts of wastewater and chemical waste. | Produces minimal waste due to precise ink application without the need for excess dyes. |

| Energy Consumption | High energy consumption, especially in the heating and drying stages. | Lower energy consumption, as digital printing requires less heat and shorter processing times. |

As seen in the comparison, digital printing has an edge over traditional dyeing processes in terms of waste management and energy consumption. This makes it a more sustainable and environmentally friendly option for textile coloring.

Design Flexibility and Detail

The printing process offers greater design flexibility and detail compared to dyeing. When it comes to design precision, printing allows for intricate and complex patterns, fine lines, and precise detailing that may be challenging to achieve through dyeing. This is particularly advantageous for creating intricate, detailed designs in textiles or other printed materials.

In terms of color vibrancy, printing allows for a wider range of vibrant and intense colors. The color application in printing can achieve a higher level of color saturation and brightness, resulting in more vivid and eye-catching designs. This is especially beneficial when working with designs that require a rich and diverse color palette.

Additionally, printing technology enables the incorporation of various special effects such as metallic finishes, embossing, and texture detailing, enhancing the overall visual appeal and tactile experience of the design. These effects can add a unique and luxurious dimension to the printed designs, offering a level of sophistication and intricacy that may be challenging to replicate through dyeing methods.

Cost and Production Efficiency

In terms of cost and production efficiency, printing offers advantages over dyeing in terms of speed, consistency, and overall resource utilization.

When it comes to cost efficiency, printing often requires less labor and time compared to dyeing processes. With printing, the color is applied directly to the fabric, reducing the need for multiple dyeing and washing steps. This not only saves time but also reduces the consumption of water and energy, making it a more environmentally friendly option.

Moreover, production speed is a significant advantage of printing over dyeing. Printing machines can rapidly apply intricate designs to fabric, allowing for high throughput and quick turnaround times. This speed is particularly beneficial in meeting tight production deadlines and responding promptly to market demands. Additionally, the consistency achieved in printing processes ensures uniformity across batches, reducing the need for rework and minimizing material wastage.

Frequently Asked Questions

Can Dyeing or Printing Be Used to Create Different Textures on Fabric?

Yes, both dyeing and printing can be used to create tactile variations and manipulate fabric. Dyeing involves coloring the entire fabric, while printing adds designs to specific areas. Both methods offer unique textures and styles.

How Do Dyeing and Printing Processes Affect the Breathability of the Fabric?

When comparing dyeing and printing, consider how each process affects fabric breathability. Dyeing saturates the fibers, potentially impacting breathability, while printing adds minimal additional layers, maintaining better breathability. Consider these factors when choosing a fabric treatment.

Are There Any Cultural or Historical Factors That Influence the Choice Between Dyeing and Printing?

Cultural influences and historical factors play a significant role in the choice between dyeing and printing. Understanding the traditions and societal norms of a particular culture can greatly impact the decision-making process in textile production.

Can Dyeing or Printing Be Used to Create Special Effects Such as Tie-Dye or Ombre?

You can achieve tie-dye techniques and ombre effects through fabric manipulation, color blending, and surface embellishment using both dyeing and printing methods. Each offers unique ways to create special effects on your fabrics.

How Do Dyeing and Printing Processes Affect the Durability of the Fabric in Terms of Wear and Tear?

When it comes to durability, dyeing and printing both play a role. Dyeing penetrates the fabric, offering long-lasting color vibrancy, while printing may require more maintenance as it can lead to color fading with wear and tear.

- What Is Ringspun Cotton? the Ultimate Guide to Softer, Stronger Fabric - June 23, 2025

- What Does ’56 Pick Polycotton’ Mean? A Guide to Fabric Quality - June 23, 2025

- A Look at Polycotton Sarees: Comfort, Drape, and Maintenance - June 23, 2025