I've always found it fascinating how versatile and eco-friendly rayon is, considering it's made from plant-based cellulose. You'd find it surprising that this fiber comes from wood pulp, bamboo, and even soy. The magic happens when these natural materials undergo a chemical transformation, turning into the soft, absorbent fabric we often wear. But, there's a bit more to the story, especially regarding its sustainability and how it stacks up against other fibers. If you're curious about the nitty-gritty of this process and its impact, I think you'll find the journey from plant to fabric quite intriguing.

Key Takeaways

- Rayon is primarily made from plant-based cellulose, sourced from wood pulp, bamboo, and cotton.

- The cellulose used in rayon production often comes from trees like eucalyptus, beech, and pine.

- To produce rayon, cellulose is extracted using chemicals such as carbon disulfide and sodium hydroxide.

- The manufacturing process transforms cellulose into a viscous solution, which is then spun into fibers to create rayon.

- Varieties such as Modal and Lyocell are specific types of rayon made using slightly different processes and raw materials for enhanced sustainability.

Rayon's Origins

French scientists first whipped up rayon as a cheaper silk substitute, tapping into plant-based cellulose to get the job done. They were on a mission to create a synthetic silk alternative that wouldn't break the bank but still had that luxurious feel. And guess what? They nailed it. By diving into the world of regenerated cellulose, sourced from stuff like wood pulp, they laid the groundwork for what we now know as rayon.

This wasn't just about finding a budget-friendly silk swap. It was about innovation, about pushing the boundaries of what we could make from the world around us. The production process they developed was pretty clever, too. They found a way to dissolve cellulose in chemicals, extrude it into fibers, and then spin it into yarns. That's the viscose method, a cornerstone of rayon production that's still in use.

The Invention of Rayon

So, we're hitting the story of how rayon came to be.

It's pretty cool how some French scientists thought up this synthetic silk substitute in the early 20th century.

Now, I'm gonna talk about how it went from a neat idea to something you can actually wear.

Rayon's Early Development

In the late 19th century, scientists in France came up with rayon, aiming to create a cheaper and more versatile silk alternative. They nailed it, sparking a revolution in the textile industry. Suddenly, we had a synthetic silk replacement that was both cost-effective and adaptable. This wasn't just about fashion; it was about opening doors to sustainable fiber options and innovative textile solutions. Here's a quick look at why rayon's such a big deal:

| Aspect | Impact on Industry | Contribution |

|---|---|---|

| Cost-Effectiveness | Reduced production costs | Made fashion more accessible |

| Versatility | Expanded design possibilities | Encouraged creative freedom |

| Sustainability | Pushed for eco-friendly alternatives | Led to more sustainable practices |

| Innovation | Paved the way for future textiles | Inspired continuous improvement |

French scientists didn't just invent a fabric; they redefined what the textile industry could achieve, making rayon a cornerstone for those chasing both style and sustainability.

Key Inventors Identified

Let's dive into the brains behind rayon, the chemists whose invention changed the textile game forever. These were French scientists, genius French chemists, to be exact.

They crafted rayon as a synthetic silk alternative, and boy, did they hit the mark. Their creation wasn't just another fabric; it revolutionized the textile industry. Suddenly, there was a more affordable option compared to silk, especially crucial during silk shortages.

And when were those shortages most biting? During World War I and II, of course. These times tested the world's resourcefulness, and rayon stood out as a shining example of innovation.

Thanks to these French chemists, the textile world was never the same again.

Evolution Into Commercial Use

Following its invention by French chemists, rayon quickly made its mark as a commercial success, transforming the textile industry with its silk-like qualities. Initially pitched as a silk replacement, it became a go-to for affordability and versatility.

I've seen how it's not just about fashion; during both World Wars, rayon stepped up as a critical resource when silk was scarce, proving its worth beyond just clothes. The evolution didn't stop there.

With China leading the charge, the global rayon market has exploded, showcasing the fiber's adaptability in clothing, home goods, and even industrial uses. Thanks to ever-evolving production methods, this synthetic fiber has firmly established itself as a cornerstone of commercial use in the textile world.

Raw Materials Used

So, we've talked about how rayon came to be, but what's it actually made from?

It starts with plant fibers like wood pulp or bamboo, which then go through a bunch of chemical steps to become the soft, versatile fabric we know.

This process, from sourcing the raw materials to spinning them into fibers, really shapes the kind of rayon we end up with.

Source Plant Fibers

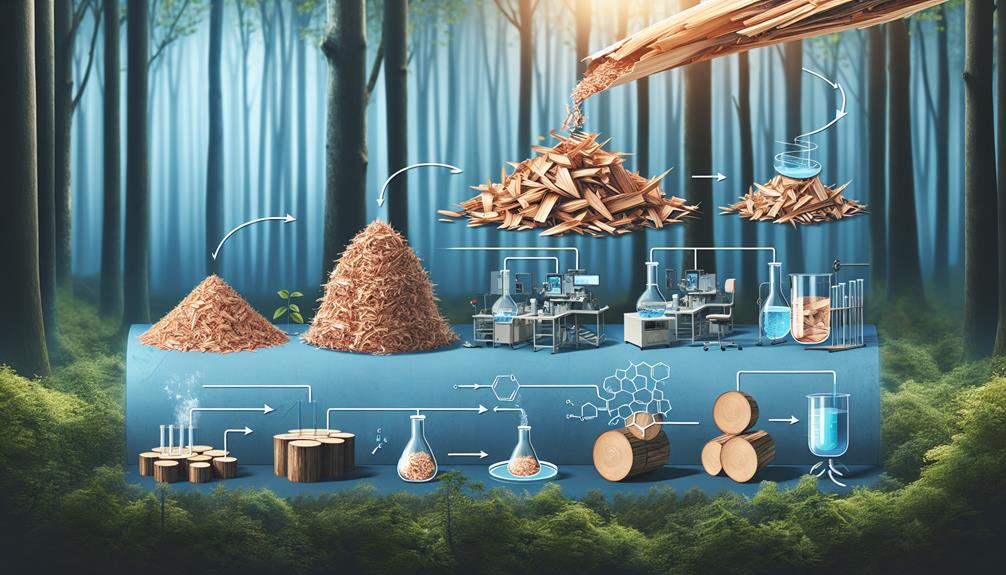

Rayon's journey begins with extracting cellulose from plant sources like wood pulp and bamboo, which are then transformed into soft, versatile fibers. This process taps into a mix of plant fibers, including those from trees like eucalyptus, as well as soy and cotton.

These materials offer a palette for sustainable sourcing, crucial for the eco-conscious out there. The cellulose snagged from these plants is key. It's what gets regenerated into that viscose solution, laying the groundwork for rayon's creation.

Different rayon types, think modal and lyocell, pick from these plant bases to tweak properties, making the choice of raw materials a big deal. It's not just about texture or wear; it's about minimizing our footprint and pushing for quality that respects our planet.

Chemical Processing Steps

Let's dive into how we turn plant stuff into rayon using a bunch of chemicals. The star of the show is cellulose, yanked from trees like eucalyptus and bamboo. Chemical processing kicks in when solvents like carbon disulfide and sodium hydroxide step up, breaking down the cellulose into a gooey, viscous solution. This stuff is then extruded, meaning it's squeezed through tiny holes, to spin out the rayon fibers we use in textile production. It's a bit like magic, transforming wood into wearable fabrics.

| Step | Chemical Used | Outcome |

|---|---|---|

| Dissolution | Sodium Hydroxide | Cellulose becomes soluble |

| Sulfurization | Carbon Disulfide | Cellulose turns into viscous solution |

| Extrusion | – | Solution is extruded into fibers |

| Coagulation | Sulfuric Acid | Fibers solidify |

| Washing | Water | Removes excess chemicals |

This table breaks down the chemical ballet turning cellulose into the rayon fibers essential for our clothes.

Chemical Processing

Diving into how rayon is made, the process starts with chemically treating cellulose fibers, usually from wood pulp. It's a bit of a complex dance that turns those natural fibers into something entirely different. Essentially, we're turning trees into a soft, wearable fabric through a series of chemical reactions.

Here's a quick snapshot to paint the picture:

- The cellulose gets dissolved in some pretty harsh solvents, like carbon disulfide, creating a thick, viscous solution.

- This gooey substance is then extruded through spinnerets, think of them as tiny showerheads, shaping the solution into fine fibers.

- Lastly, these fibers are solidified, forming the basis of what we know as rayon. But it's not all smooth sailing.

The use of toxic chemicals, such as sulfuric acid and sodium hydroxide, raises some big red flags. We're talking about serious environmental concerns and potential risks to human health. It's a bit of a double-edged sword; on one hand, we've got this versatile, affordable material, and on the other, there's a significant environmental and health cost. It's something I'm keeping an eye on, especially as we talk more about sustainability and safer alternatives in the textile industry.

Types of Rayon

So, let's get into the different types of rayon we've got out there.

I've learned that viscose is the go-to for most folks because it's super soft and lets your skin breathe.

Then you've got modal and lyocell, which aren't just comfy but also have their own cool perks, like being eco-friendly and shrink-resistant.

Viscose Rayon Production

Viscose rayon's journey begins with transforming cellulose pulp into a silky, versatile fabric through a chemical process. Delving into its production process reveals a fascinating blend of science and artistry, turning cellulose fibers into something truly wearable.

- Chemical Bath: The magic starts when cellulose pulp meets a chemical concoction, morphing into a viscous solution ready for transformation.

- Spinnerets Galore: Picture tiny showerheads extruding this solution into fine threads, which then solidify in another chemical bath.

- Eco-Friendly Twist: The process doesn't have to be a villain to our planet. Innovations aim for a more sustainable fiber, highlighting environmentally friendly manufacturing processes and the dream of a closed-loop system.

Viscose rayon isn't just fabric; it's a testament to human ingenuity, balancing affordability with a nod to sustainability.

Modal and Lyocell Varieties

After exploring how viscose rayon is made, let's check out Modal and Lyocell, two types of rayon that kick the eco-friendliness up a notch.

So, Modal, right? It's this awesome fabric derived from beech trees, and it's super soft. Plus, it doesn't shrink much, which is a huge bonus.

Then there's Lyocell, another cool kid on the block, made from wood pulp. But the real kicker? It uses a closed-loop process, which means it's way kinder to our planet. Big brands like Lenzing Tencel are all over Lyocell because of its sustainable production and eco-friendly creds.

Both Modal and Lyocell aren't just eco-friendly; they're biodegradable too. Talk about giving traditional viscose rayon a run for its money in the sustainability stakes.

Manufacturing Techniques

To dive into how rayon's made, we need to look at its manufacturing techniques, which start with turning plant-based cellulose into a smooth, versatile fiber. The journey from raw material to the rayon you find in everything from shirts to sheets is fascinating and complex.

- Dissolving Cellulose: Imagine huge vats where cellulose from bamboo, soy, or cotton is dissolved in a cocktail of chemicals. This step transforms solid cellulose into a viscous solution, setting the stage for fiber creation.

- Fiber Extrusion: This solution is then extruded through tiny holes into a chemical bath, where it solidifies into fine strands. Think of a high-tech version of making spaghetti, where each strand is a potential thread in your future clothes.

- Washing and Treating: The newly formed fibers undergo washing and treating processes to remove any lingering chemicals. This stage ensures the fibers aren't only safe but also possess the desired softness and strength.

The manufacturing process, from viscose to modal and lyocell, each comes with its own set of environmental risks and sustainability considerations. It's a balancing act between creating regenerated cellulose fibers efficiently and minimizing our footprint. As we explore these techniques, it's clear that the pursuit of sustainability is reshaping how rayon is produced.

Environmental Impact

While exploring how rayon is made, it's important to also look at the environmental toll it takes. The fabric, though popular for its silk-like feel, comes with a hefty price for our planet. We're talking massive deforestation, harmful chemicals, and effluents that wreak havoc on our environment.

| Aspect | Concern | Impact |

|---|---|---|

| Deforestation | Thousands of hectares of ancient forests cut down annually | Loss of biodiversity, CO2 increase |

| Chemicals | Use of carbon disulfide, sulfuric acid | Health risks, environmental damage |

| Effluents | Viscose production releases harmful effluents | Water and air pollution |

In countries where rayon's produced, there's limited monitoring and accountability. This lack of oversight means these environmental risks often go unchecked. Sure, rayon's biodegradability is a plus, but it doesn't offset the sourcing concerns and the chemical processes involved. We've got to weigh the environmental costs against the benefits. And right now, it seems like our planet's paying a steep price for our fashion choices.

Rayon Vs. Other Fibers

Comparing rayon to other fibers shows it's both eco-friendlier than synthetics and more affordable than natural options like silk and wool. Let me break it down for you. Rayon, essentially an artificial silk spun from plant cellulose, hits a sweet spot in the textile industry. It's like getting the luxury of silk without emptying your wallet or hurting the planet too much.

- Rayon's smooth and soft texture rivals that of silk, yet it doesn't demand the high price or intensive labor silk production entails.

- Being biodegradable, rayon stands out against synthetics like polyester, which can take centuries to break down. It's comforting to know your fashion choices won't linger in landfills forever.

- The viscose process, used to produce rayon, transforms plant cellulose into this versatile fiber. This process highlights rayon's role as a bridge between fully synthetic and natural fibers, offering a more sustainable choice.

In the world of fibers, where the battle lines are often drawn between natural and synthetic, rayon offers a middle ground. It's kind on the environment, gentle on your skin, and easy on your budget.

Uses in Fashion

Rayon's become a go-to fabric in the fashion world, thanks to its silk-like feel and versatility in crafting flowy, elegant garments. It's the secret sauce for designers aiming to create that luxurious vibe without the hefty price tag of real silk. The fabric's softness and elegant drape mean it's perfect for women's clothing where comfort and style need to go hand in hand.

What really sets rayon apart are its silk-like properties. We're talking about that smooth, comfortable feel against the skin, making it a staple for everything from blouses and dresses to scarves. Its versatility shines, allowing for the creation of ethereal, fluttery clothing styles that seem to float around the body, adding an air of sophistication and ease.

And then there's Modal and Tencel, the upgraded versions of rayon, if you will. These types bring an enhanced shine and even better drape, pushing the boundaries of what rayon can achieve in the fashion industry. They're proof of how rayon isn't just a substitute for silk but a formidable fabric in its own right, offering endless possibilities for designers to experiment with soft, flowy garments that resonate with elegance and comfort.

Sustainability Concerns

Despite its popularity in fashion, rayon's environmental footprint raises serious concerns. Diving into the thick of it, the process to make what's hanging in our closets isn't as pretty as the end product. We're talking about a material that, if not produced mindfully, can do more harm than good.

Here's a snapshot:

- Massive deforestation for rayon production strips our planet of ancient forests, wiping out thousands of hectares annually.

- The chemicals thrown into the mix, like carbon disulfide and sulfuric acid, aren't just harsh; they're environmental nightmares causing significant risks.

- Lastly, the aftermath of viscose production isn't any prettier, with effluents contributing to severe water pollution.

Yet, there's a silver lining. The push for sustainable rayon is on the rise, focusing on sourcing from sustainably harvested forests and implementing eco-friendly bleaching methods. This shift towards sustainable practices and collaboration among stakeholders aims to lessen the environmental impact and promote a more sustainable future for fashion. So, while the road ahead is challenging, advancements in sustainable rayon and viscose production show a promising path toward reconciling our fashion desires with the well-being of our planet.

Frequently Asked Questions

Is Rayon Synthetic or Natural?

I'd say rayon isn't purely natural or synthetic; it's semi-synthetic. It starts from natural wood pulp but undergoes heavy chemical processing. So, it's really a mix, blending both natural and synthetic fiber traits.

Is Rayon Better Than Cotton?

I think rayon's better than cotton for certain styles because it's silkier and drapes better. Although cotton's great for breathability, rayon's luxurious feel and versatility in elegant clothing give it an edge for me.

Is Rayon Is a Good Fabric?

I think rayon's a great fabric because it's soft, breathable, and drapes nicely, much like silk. It's also affordable, which is a big plus. However, it's not the best for moisture-wicking or high-performance wear.

Is Rayon Better Than Polyester?

I believe rayon's better than polyester because it's more eco-friendly, biodegradable, and made from plants. It feels softer and is more breathable, making it a superior choice for comfort and environmental impact.