Cotton is mainly made of cellulose, proteins, waxes, and minerals, with cellulose making up 88% to 96%. It gives cotton its strength, softness, and breathability. There are also proteins, waxes, and minerals that enhance its quality. The genetic makeup of cotton affects its fiber properties. Harvesting and processing involve careful techniques to maintain quality. Spinning and weaving further enhance strength and cohesion. Cotton fabric is known for its comfort, durability, and versatility. If you want to understand more about the composition and production of cotton, there's a lot more to discover about this fascinating natural fiber.

Key Takeaways

- Cotton fibers are primarily composed of cellulose, proteins, waxes, and minerals.

- Cellulose content in cotton fibers ranges from 88% to 96%.

- Cellulose provides strength, flexibility, softness, and breathability.

- Other components include hemicellulose, pectin, wax, proteins, and mineral salts.

- Genetic makeup influences fiber quality, traits, and characteristics.

Cotton Plant Structure

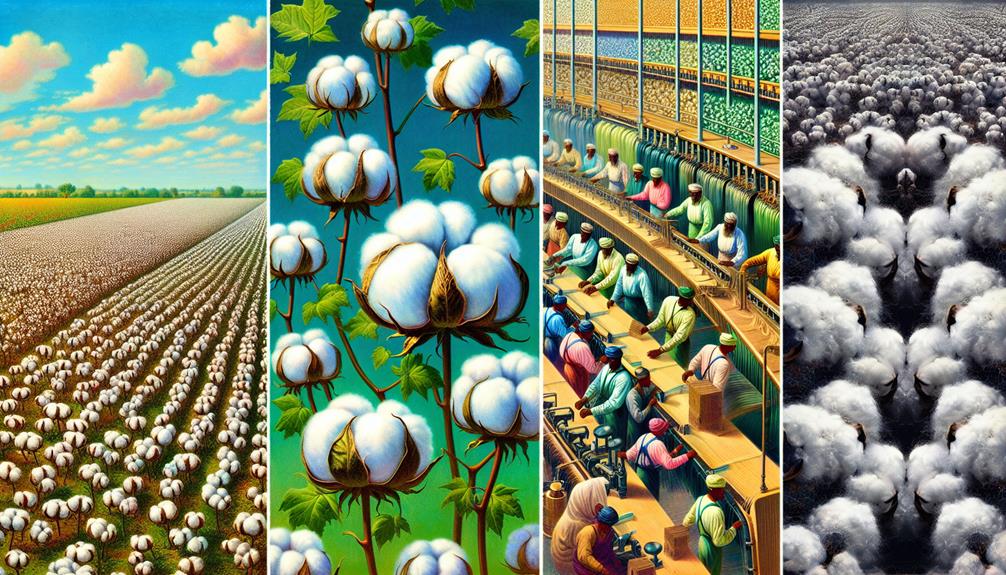

Cotton fibers, essential for producing cotton fabric, stem from the seed coat of cotton plants. These fibers, known for their strength and versatility, can grow up to 2 inches in length. Comprised mainly of cellulose, a carbohydrate derived from glucose, cotton fibers are a product of the photosynthesis process. The lifecycle of cotton plants involves various stages, including the growth from flower buds to flowers, developing seed pods, and finally, the formation of mature cotton fibers.

Understanding the structure of cotton plants is vital in appreciating the quality of cotton fabric. The fibers are intricately intertwined and spun together to form threads used in weaving. This process highlights the innate robustness and longevity inherent in cotton. By grasping the origins of cotton fibers within the seed pods of cotton plants, one can truly comprehend the natural durability and resilience that cotton fabric offers.

Composition of Cotton Fibers

Exploring the makeup of cotton fibers reveals a fascinating blend of cellulose, proteins, waxes, and minerals. Cotton fibers are primarily composed of cellulose, a carbohydrate derived from glucose. This cellulose content can vary from 88% to 96% in cotton fibers.

Alongside cellulose, cotton fibers also contain small amounts of proteins, waxes, and minerals, which contribute to their overall properties. The cellulose molecules within cotton fibers are structured linearly, providing them with both strength and flexibility.

This unique composition is what makes cotton fibers soft, breathable, and highly absorbent, making them ideal for various textile applications. Understanding the composition of cotton fibers sheds light on why cotton is a popular choice in the textile industry.

The intricate combination of cellulose, proteins, waxes, and minerals gives cotton its distinctive characteristics and versatility, making it a sought-after material for a wide range of products.

Cellulose in Cotton Fibers

In delving into the composition of cotton fibers, one can't overlook the significant role played by cellulose. Derived from glucose, cellulose is a complex carbohydrate that forms the backbone of cotton fibers. These cellulose molecules are intricately linked together in long, linear chains, constituting a significant portion of the fiber composition, typically ranging from 88% to 96%.

Cellulose is essential for the strength and durability of cotton fibers, making them highly suitable for textile production. The unique arrangement of cellulose molecules in cotton fibers not only imparts strength but also contributes to their characteristic softness and breathability. This combination of strength and comfort is what makes cotton fibers a popular choice in the textile industry.

Understanding the importance of cellulose in cotton fibers sheds light on why cotton is favored for a wide range of applications, from clothing to household textiles, due to its excellent balance of strength, durability, and comfort.

Other Components in Cotton Fibers

So, let's talk about the other components that make up cotton fibers.

Apart from cellulose, cotton fibers also contain hemicellulose, pectin, and wax.

These components play a role in enhancing the strength, flexibility, and absorbency of cotton fibers.

Fiber Structure

Cotton fibers, beyond their cellulose composition, incorporate a variety of other components such as proteins, waxes, and mineral salts. These additional elements play an important role in the fiber structure and overall characteristics of cotton textiles.

Proteins provide strength and flexibility, waxes contribute to water resistance, and mineral salts help regulate various biological processes within the fibers.

Understanding the diverse composition of cotton fibers, including pectin, hemicelluloses, and lignin, is essential for enhancing fiber quality and performance in different applications.

Natural Characteristics

Comprising various components beyond cellulose, cotton fibers exhibit a complex composition that influences their structural and functional characteristics. Besides cellulose, cotton fibers contain DNA and genes that play an important role in regulating the fiber formation process. These genes, responsible for housekeeping proteins and fiber-specific enzymes, are activated at different stages of cotton fiber growth. The variations in genes among different cotton strains lead to the development of unique characteristics in the fibers produced. Understanding the genetic makeup of cotton fibers is essential for enhancing the quality and properties of cotton products.

| Component | Function | Influence on Fibers |

|---|---|---|

| Cellulose | Provides strength and rigidity | Main structural component |

| DNA | Contains genetic information | Regulates fiber formation |

| Genes | Control protein production | Influence unique traits |

Genetic Makeup of Cotton

Let's talk about the genetic makeup of cotton.

Cotton's DNA structure and gene expression play vital roles in determining fiber quality and characteristics.

Understanding these genetic aspects helps us enhance cotton crops for better productivity and improved fiber features.

Cotton DNA Structure

Within the intricate genetic blueprint of cotton fibers, DNA orchestrates the formation and growth of these essential components of the cotton plant. The genetic makeup of cotton fibers involves a complex interplay of genes and molecular processes, shaping the characteristics of this versatile plant material.

Here are some key points to ponder regarding the cotton DNA structure:

- Cotton fibers contain DNA and genes that control fiber formation.

- Specific genes are activated at different stages of cotton fiber growth.

- Genes for housekeeping proteins and fiber-specific enzymes play roles in cotton fiber cells.

- Different cotton strains exhibit unique characteristics due to genetic variations.

- Understanding gene variations helps in enhancing cotton fiber quality and properties.

Cotton Gene Expression

In understanding the genetic makeup of cotton, the expression of cotton genes plays an essential role in shaping the characteristics and properties of cotton fibers. Cotton fibers, primarily composed of cellulose, derive their unique attributes from genes that control fiber formation.

Variations in gene expression at different growth stages contribute to the diverse characteristics seen in various cotton strains. By studying gene variations, researchers can enhance fiber quality and properties through targeted breeding programs.

Specific genes, including those encoding housekeeping proteins and fiber-specific enzymes, are vital in regulating the development and properties of cotton fibers. This understanding of cotton gene expression is pivotal in advancing the genetic modifications necessary for improving cotton crops and ensuring high-quality fiber production.

Factors Influencing Cotton Characteristics

Factors influencing cotton characteristics are primarily rooted in the genetic makeup of the plant and the activation of specific genes throughout its growth stages. The interplay of genes and environmental factors shapes the development of plant fibers, determining the final fiber characteristics. Here are key points to take into account:

- Genetic Variations: Different cotton strains possess varying gene expressions, leading to diverse fiber qualities.

- Cellulose Production: Genes control the synthesis of cellulose, the main component of cotton fibers.

- Fiber-Specific Genes: Activation of genes for fiber-specific enzymes influences the development of cotton fibers.

- Housekeeping Proteins: Genes responsible for maintaining cellular functions also impact fiber development.

- Quality Improvement: Understanding gene variations in cotton aids in enhancing fiber strength, length, and overall quality.

Harvesting Cotton Fibers

I'll start by talking about how cotton fibers are harvested from the seed pods of cotton plants.

Whether it's using mechanical pickers or hand harvesting methods, the goal is to collect mature cotton bolls during the fall season when they're fully developed.

Proper harvesting techniques are key to ensuring we get high-quality cotton fibers for textile production.

Cotton Plant Growth

Growing cotton involves nurturing delicate flowers that eventually transform into the fluffy bolls containing the coveted fibers. As the cotton plant matures, it goes through several stages before the fibers are ready for harvesting:

- The cotton plant starts to bloom with beautiful white or yellow flowers.

- These flowers then give way to green, spiky seed pods, which later mature into the familiar cotton bolls.

- Inside these bolls, the cotton fibers develop and grow.

- Over approximately 5 months, the bolls expand and fill out with the fluffy fibers.

- Once fully developed, the bolls are carefully harvested to gather the valuable cotton fibers for further processing.

Fiber Extraction Process

In the intricate process of cotton production, the extraction of cotton fibers from the bolls marks a pivotal stage that impacts the quality of the final fabric. Cotton fibers are obtained from the cotton bolls, which are the seed pods of the cotton plant. This extraction can be done manually or through mechanical harvesting methods.

The next step involves ginning, where the fibers are separated from seeds and other plant debris. Subsequently, the fibers are cleaned, straightened, and processed to create yarn for fabric production. The characteristics of the extracted cotton fibers, including their length, strength, and fineness, play an essential role in determining the quality of the final fabric produced.

Harvesting Techniques

When harvesting cotton fibers, whether manually or with mechanical pickers, the objective is to carefully collect the mature cotton bolls to preserve the quality of the fibers. Hand harvesting involves meticulous methods to minimize fiber damage, while mechanical pickers expedite the process but may result in more damage. Harvesting takes place when the cotton bolls are fully ripe and primed for fiber extraction. The precision of the harvesting techniques directly impacts the quality and integrity of the cotton fibers essential for textile production.

- Hand harvesting: Labor-intensive, gentle picking by hand

- Mechanical pickers: Faster harvesting, potential for increased fiber damage

- Ripe cotton bolls: Harvested when fully mature

- Proper techniques: Vital for maintaining fiber quality

- Integrity preservation: Essential for textile production

Processing Cotton Fibers

During the processing of cotton fibers, we carefully manipulate and intertwine individual fibers to create versatile threads for various textile applications. Cotton fibers, composed mainly of cellulose derived from glucose, undergo a complex fiber formation process. This process involves overlapping and twisting individual fibers to create threads suitable for fabric production.

Within these fibers, DNA and specific genes play vital roles in controlling fiber growth and characteristics. The genetic makeup of different cotton strains varies, leading to unique properties in their fibers. By understanding the gene variations in cotton, researchers can enhance fiber quality and properties, ensuring better end products.

This intricate processing stage highlights the importance of genetic factors in determining the quality and attributes of cotton fibers, ultimately impacting the textiles created from them.

Spinning Cotton Fibers Into Yarn

As we spin cotton fibers into yarn, we align and twist individual fibers together to create strong and continuous strands for various textile applications. This process is vital in transforming raw cotton fibers into usable yarn with enhanced strength and durability. Here is a glimpse into the fascinating world of spinning cotton fibers into yarn:

- Alignment: The fibers are carefully aligned to make sure they run parallel to each other, creating a cohesive structure.

- Twisting: Through twisting, the individual fibers interlock, enhancing the yarn's strength and cohesion.

- Strength Enhancement: By twisting the fibers together, the resulting yarn becomes more robust and better suited for weaving and knitting.

- Variety of Techniques: Different spinning techniques can produce a range of yarn thicknesses and textures, offering versatility in textile design.

- Fabric Production: Spinning cotton fibers into yarn is a fundamental step in the production of various fabrics, from soft garments to sturdy textiles.

Spinning cotton fibers into yarn is a skillful process that plays a pivotal role in the textile industry, ensuring the creation of high-quality and versatile materials.

Weaving Cotton Yarn Into Fabric

I intricately weave cotton yarn into fabric using a loom to create essential and versatile textiles for various applications. The process involves carefully interlacing the cotton threads together to form a cohesive fabric structure. Different weaving techniques such as plain, twill, and satin can be utilized to produce unique textures and patterns in the cotton fabric.

By skillfully operating the loom, I guarantee that the cotton yarn is aligned and intertwined correctly, resulting in a strong and resilient final product. Once the weaving is complete, the cotton fabric can undergo additional finishing treatments like washing, drying, and other processes to enhance its properties and appearance further.

Weaving cotton yarn into fabric is a critical step in the production of a wide range of products, including clothing, home textiles, and industrial materials. The versatility of cotton as a material, combined with the various weaving techniques and finishing treatments available, allows for the creation of high-quality textiles suited for different purposes.

Properties of Cotton Fabric

With its breathability and versatility, cotton fabric offers a comfortable and practical choice for a wide array of clothing and textile applications. Cotton fabric's properties make it a preferred option for many due to its exceptional qualities:

- Breathability: Cotton fabric allows air to circulate freely, making it ideal for warm weather clothing as it helps in keeping the body cool and comfortable.

- Moisture-wicking: The moisture-wicking properties of cotton fabric draw sweat away from the skin, keeping the body dry and reducing the risk of skin irritation.

- Comfort: Known for its softness and comfort, cotton fabric is gentle on the skin and suitable for all-day wear.

- Durability: Cotton fabric is strong and durable, making it a long-lasting choice for clothing and home textiles that withstand regular use and washing.

- Versatility: Cotton can be blended with other materials to enhance its properties, making it adaptable for various garment types and styles.

Common Uses of Cotton

In a variety of everyday products, cotton finds widespread use due to its exceptional qualities and versatile nature. Cotton fibers, being soft and breathable, make it a popular choice for clothing items like shirts, pants, dresses, and undergarments. Its durability and comfort also extend its application to home textiles such as sheets, towels, and curtains.

Beyond fabric production, cotton is utilized in non-apparel products like medical supplies and industrial thread, showcasing its versatility across various industries. Additionally, cottonseed oil extraction for cooking and cosmetics highlights the multiple uses of cotton.

The natural, affordable, and easy-care properties of cotton make it a preferred material for a wide range of consumer and industrial textile needs. Its adaptability and sustainability further enhance its appeal, solidifying cotton as a go-to option for a broad array of products.

Frequently Asked Questions

What Is 100% Cotton Made Of?

Cotton, a natural fabric, is made from plant fibers found in cotton seeds. These fibers are mostly cellulose, a plant-produced carbohydrate. Its softness and breathability come from cellulose. We weave cotton into various textiles.

What Is Cotton Material Made Of?

Cotton material consists of cellulose fibers twisted together, offering a soft and breathable feel. Cotton plants' genes regulate fiber development, affecting quality. These fibers, up to 2 inches long, provide durability. Understanding cotton's genetics enhances fabric properties.

How Cotton Is Produced?

Producing cotton involves cultivating cotton plants that yield fibers from the seed coat. Over time, these fibers develop, primarily containing cellulose. Once harvested, the fibers are twisted into threads for fabric. This process transforms plants into versatile textiles.

What Elements Make up Cotton?

In cotton, cellulose and genetic components determine its quality. Genes regulate fiber formation and characteristics. Understanding these elements aids in enhancing cotton's strength and properties. Fibers are woven into threads for fabric production.