Lyocell's not perfect, and I've noticed some issues. First off, it's pretty expensive to produce. The sustainable processes and eco-friendly solvents hike up the costs significantly. There's also a bunch of special care needed to keep lyocell clothes in good shape—think cold washes and avoiding the dryer. Environmentally, although it's better than some alternatives, the manufacturing still requires a lot of energy and uses chemicals that can be harmful if not managed properly. Plus, the solvents used can be a problem if they're not recycled effectively in a closed-loop system. Curious about how these problems might impact lyocell's future? Stick around and you'll see what unfolds.

Table of Contents

Key Takeaways

- Lyocell production involves intense energy use and potentially harmful chemical processes.

- Special care requirements, such as cold washing and air-drying, complicate maintenance.

- The fabric is prone to wear quickly, reducing its overall durability.

- Lyocell is susceptible to water damage, which can distort its shape.

- Frequent pilling issues can affect the fabric's texture and appearance.

High Production Costs

Lyocell's higher production costs stem from its sustainable manufacturing methods, requiring pricier eco-friendly solvents and advanced technology. Unlike traditional fibers, where costs are cut at the expense of the environment, lyocell uses a closed-loop system that recycles solvents. This is great for the planet, but it sure doesn't come cheap.

The heart of the matter is the initial investments needed for this technology. Setting up a plant that adheres to these ethical practices involves some serious cash upfront. We're talking about sophisticated equipment that can handle and reuse these eco-friendly solvents without releasing harmful substances into the environment.

Plus, sourcing sustainable raw materials isn't like picking up conventional cotton. It's a meticulous process that often comes with a higher price tag due to its lower environmental impact.

Special Care Requirements

Maintaining lyocell clothing requires some special steps to keep it looking its best. Lyocell fabric, while known for its softness and strength, demands delicate care to maintain these qualities. It's important to opt for cold washing or even hand washing to prevent damage that can come from more vigorous laundry methods. This approach helps preserve the integrity and appearance of the fabric over time.

You'll also want to avoid putting lyocell garments in the dryer. High heat can wreak havoc on the fibers, leading to shrinkage and weakening. Instead, air-drying is the way to go, ensuring that the fabric retains its shape and texture. Be mindful of ironing lyocell too. Excessive heat from an iron can be just as damaging as a hot dryer. A gentle steam or a low heat setting on your iron should suffice if you need to smooth out any wrinkles.

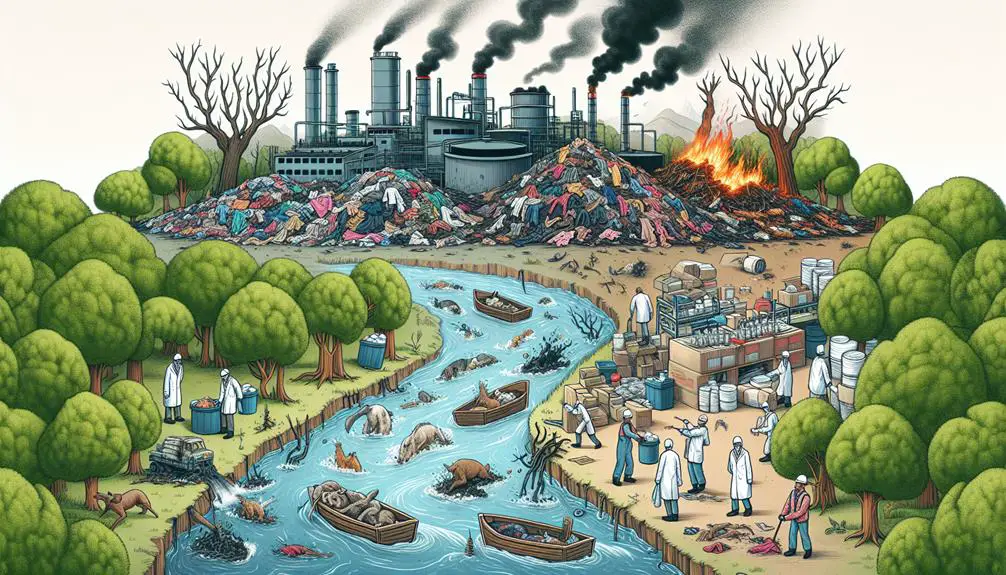

Environmental Impact Concerns

Despite its green reputation, lyocell's production process can still pose significant environmental challenges. While it's often praised for its eco-friendly properties, there are several aspects of its production that raise concerns about its overall environmental impacts.

Here's a breakdown of the main issues:

- Deforestation: If the wood pulp used to make lyocell isn't sourced from sustainable forests, the manufacturing of this fabric could contribute to deforestation. This not only destroys habitats but also increases carbon emissions.

- Chemical Processing: The process to turn wood pulp into lyocell fibers involves various chemicals. Even though these are usually reused in a closed-loop process, there's still a risk of spillage and environmental contamination.

- Carbon Emissions: Transporting the raw materials needed for lyocell can lead to significant carbon emissions, especially if these materials are shipped over long distances.

- Overconsumption: Despite lyocell's sustainable tag, the potential overconsumption of these products can negate its environmental benefits. The increased demand can lead to higher production rates, which in turn may amplify issues like energy use, greenhouse gas emissions, and further deforestation.

Balancing these concerns with the benefits of lyocell is key to truly advancing sustainable fashion.

Energy Consumption

The production of lyocell uses a lot of energy at several stages, from extracting wood pulp to weaving the final fabric. It's not just about chopping down trees and turning them into comfy clothes; each step, including the spinning of fibers and fabric weaving, gobbles up power. This intense energy consumption raises some serious environmental concerns.

Despite lyocell's sustainable properties, the energy used can leave a hefty carbon footprint. It's a bit of a paradox, really. You've got this eco-friendly material that, in its making, could be harming the planet. But it's not all doom and gloom. There's a silver lining if manufacturers stick to energy-efficient practices and lean more into renewable energy sources.

Chemical Use in Production

While lyocell is celebrated for its eco-friendliness, we can't ignore the chemical concerns it brings to the table. Specifically, we need to look at the toxic solvents involved, how effectively we can recycle these chemicals, and the overall environmental impact.

Let's see how these issues stack up in the bigger picture of sustainable fashion.

Toxic Solvent Concerns

One major concern in lyocell production is the use of N-Methylmorpholine-N-oxide (NMMO), a solvent that poses potential environmental risks.

Environmental Impact: Even though NMMO is less harmful than many solvents, it still carries risks that need careful monitoring to avoid damaging ecosystems.

Disposal Challenges: Safe disposal of NMMO is crucial. Improper handling can lead to chemical waste that negatively affects the environment.

Need for Continuous Research: Ongoing research is necessary to fully understand and mitigate the long-term effects of NMMO usage.

Monitoring: Regular monitoring ensures that any potential leaks or spills are caught early and addressed promptly, reducing the risk of environmental harm.

Chemical Recycling Efficiency

Moving on, let's talk about how lyocell's chemical recycling efficiency shapes its production process. The use of N-Methylmorpholine-N-Oxide (NMMO) solvent, which is notably non-toxic, plays a pivotal role here. What's really impressive is the closed-loop process that allows for over 99% solvent recycling. This isn't just good for cutting down waste; it also means we're not constantly needing fresh chemicals, which is a win for sustainable manufacturing.

This efficient chemical use is crucial. It ensures that the production of lyocell aligns with eco-friendly practices, minimizing the environmental impact significantly. By reusing the same solvents, lyocell production sets a benchmark in sustainable textile manufacturing, proving that high efficiency in chemical use can go hand in hand with environmental care.

Environmental Impact Assessment

Let's dive into how the chemical use in lyocell production impacts the environment. Understanding the environmental impact assessment for these processes is crucial for mastering the sustainability of textiles.

- Amine Oxide Usage: This chemical, crucial for dissolving wood pulp into fibers, can be hazardous if not handled correctly.

- Closed-Loop Process: This system helps minimize chemical waste by recapturing and reusing solvents, significantly lowering environmental risk.

- Recycling Solvents: Efforts to recycle solvents in lyocell production reduce the overall chemical footprint, making the process more sustainable.

- Monitoring and Regulating: Ongoing oversight ensures that the chemicals used don't escape into the environment, maintaining a balance between industrial needs and ecological health.

Potential for Greenwashing

Greenwashing risks in lyocell production often involve brands making misleading claims about how eco-friendly their products are. It's a common issue where companies tout their goods as sustainable, yet their practices don't match up. This lack of transparency can seriously mislead us as consumers.

We've got to watch out for these deceptive tactics. Some brands are all talk when it comes to environmental friendliness, but a peek behind the curtain reveals a different story. They might say their lyocell is the greenest thing since sliced bread, but without strict adherence to environmental standards, it's just hot air. It's frustrating because you want to make the right choices for the planet, right?

Limited Durability

When it comes to lyocell, I've noticed it tends to wear out pretty quickly, which can be a real downside.

It's also not great with water; too much of it during washing and the fabric just doesn't hold up well.

Plus, it starts pilling easily, which can make your clothes look old faster than you'd expect.

Prone to Wear Quickly

Lyocell often wears out quicker than many other fabrics, reducing its overall durability. This limited durability can be a real bummer if you're looking for something that lasts. Here's why it's prone to wear quickly:

- Fiber Structure: The very structure of lyocell fibers can break down easier under stress.

- High Heat Drying: If you're blasting your lyocell clothes in the dryer on high, you're accelerating the wear process.

- Rough Handling: Lyocell doesn't take kindly to rough treatment. It needs a gentle touch.

- Care Instructions: Not following the right care instructions? That'll cut its life short too.

Susceptible to Water Damage

I've noticed that despite its benefits, lyocell is quite prone to water damage, which can seriously limit its durability. This fabric, while celebrated for its moisture-wicking properties, doesn't handle prolonged moisture well. It can lose its shape or distort if exposed to water too much. It's a bit of a paradox, really.

To keep lyocell in top shape, careful maintenance is crucial. Avoid excessive washing and drying. Opt for gentle methods that minimize the risk of water damage. Understanding and following the care instructions are key to extending the life of your lyocell garments. It's all about balancing its use with proper care to prevent shape distortion and maintain durability.

Frequent Pilling Issues

Besides its susceptibility to water damage, another challenge with lyocell is its tendency to pill, affecting both its texture and overall durability. When I've worn lyocell garments, I've noticed that frequent pilling really hurts their look and feel.

Here's what I've learned about dealing with this:

- Avoid Friction: Since pilling is caused by abrasion of fibers, especially in areas of friction, I try to minimize rubbing and contact with rough surfaces.

- Follow Care Instructions: I stick closely to the recommended care instructions to avoid damaging the fibers during washing.

- Use Fabric Shavers: Regularly removing pills with a fabric shaver helps maintain the appearance of my lyocell items.

- Choose Quality Blends: Opting for high-quality lyocell blends can diminish durability issues and extend the fabric's life.

Sourcing and Availability Challenges

Sourcing lyocell presents significant challenges due to the limited availability of sustainably managed forests. This issue isn't just about finding enough trees; it's about ensuring that the forests we use are managed in a way that supports environmental health and sustainability. The specialized production processes required to transform wood into lyocell also contribute to its scarcity and higher costs. These complex methods aren't widely implemented, which further limits how much lyocell can actually hit the market.

Ensuring responsible sourcing practices is another big hurdle. It's not enough to just find a forest and start using its resources. We need to consider the broader impact, like potential deforestation and habitat disruption. This careful consideration can slow down production and decrease the availability of raw materials. Plus, there's often a lack of transparency in these supply chains. Without clear information, it's tough for consumers to trust that the lyocell products they buy are truly sustainable.

All of these factors create significant availability challenges for lyocell. While it's a fantastic material with many environmental benefits, these sourcing and production hurdles need to be addressed to fully realize its sustainability potential.

Market Price Variability

The market price of lyocell can swing widely due to several influencing factors. It's a bit of a rollercoaster, really, influenced by everything from the cost of wood pulp to the whims of fashion enthusiasts.

Here's a breakdown:

- Production Costs and Raw Materials: The price of wood pulp, which is crucial for making lyocell, can fluctuate significantly. When it goes up, so do the production costs. Energy costs and advancements in processing technologies also play a big part.

- Global Demand and Competition: As sustainable fashion gains traction, the global demand for lyocell rises. This demand pushes prices up, but it's also tempered by competition among lyocell manufacturers. Each tries to outdo the others with smarter pricing strategies and better brand positioning.

- Economic and Policy Changes: Global economic shifts, trade policies, and currency fluctuations can all toss the market price around. These are often unpredictable and can change the game overnight.

- Consumer Preferences and Trends: Lastly, consumer preferences, especially the growing trend towards sustainable fashion, guide the market. If consumers lean towards eco-friendly products, lyocell prices can soar, influenced as well by how brands market these trends.

Navigating this pricing landscape requires a keen eye on multiple moving parts – it's never just about the tag.

Frequently Asked Questions

What Are the Downsides of Lyocell?

I've found that lyocell's downsides include its potential blend with non-biodegradable fibers, complicating recycling. Additionally, its production can be energy-intensive and may lead to habitat destruction, challenging its sustainability claims.

Is Lyocell Toxic to Wear?

I've researched whether Lyocell is toxic to wear and found it's actually safe. It's made using non-toxic, sustainable processes and doesn't release harmful chemicals, making it a healthy choice for clothing.

Does Lyocell Get Smelly?

I've found that Lyocell doesn't really get smelly because it's moisture-wicking and breathable, which prevents bacteria from building up. So, it stays fresher longer, especially compared to synthetic fabrics.

Is Lyocell Better Than Cotton?

I'd say lyocell is better than cotton. It uses less water, occupies less land, offers great moisture-wicking, and is eco-friendly with a minimal environmental impact due to its closed-loop manufacturing process.

- Care Instructions for Nonwoven Fabrics: Washing and Drying - July 11, 2025

- The Difference Between Woven and Nonwoven Wallpaper Explained - July 11, 2025

- Why Choose Woven Over Nonwoven (And Vice Versa) - July 11, 2025