As you consider the convenience and versatility of poly tricot fabrics, have you ever wondered about the environmental costs of producing them? You're not alone – many of us are unaware of the significant ecological footprint left behind by this common textile. From the extraction of non-renewable resources to the highly energy-intensive production process, the environmental impacts of poly tricot production are multifaceted and concerning. But what exactly are these impacts, and how do they affect our planet? To understand the full scope of the issue, it's essential to examine the entire production process – from start to finish.

Table of Contents

Resource Depletion and Extraction

Poly tricot production relies heavily on the extraction of non-renewable resources, such as petroleum and natural gas, which significantly contributes to resource depletion. These resources are used to produce the raw materials needed for poly tricot production, including polyester and nylon.

The extraction process not only depletes these resources but also leads to environmental degradation, such as habitat destruction and water pollution.

The extraction of these resources often occurs in areas with lax environmental regulations, exacerbating the environmental impacts. The transportation of these resources to manufacturing facilities contributes to additional environmental degradation.

The extraction of non-renewable resources for poly tricot production also has social implications, such as displacement of communities and human rights violations.

It's essential to consider these environmental and social impacts when navigating the world of poly tricot production. By understanding the resource depletion and extraction process, you can make more informed decisions about the products you choose to support.

Energy Consumption and Emissions

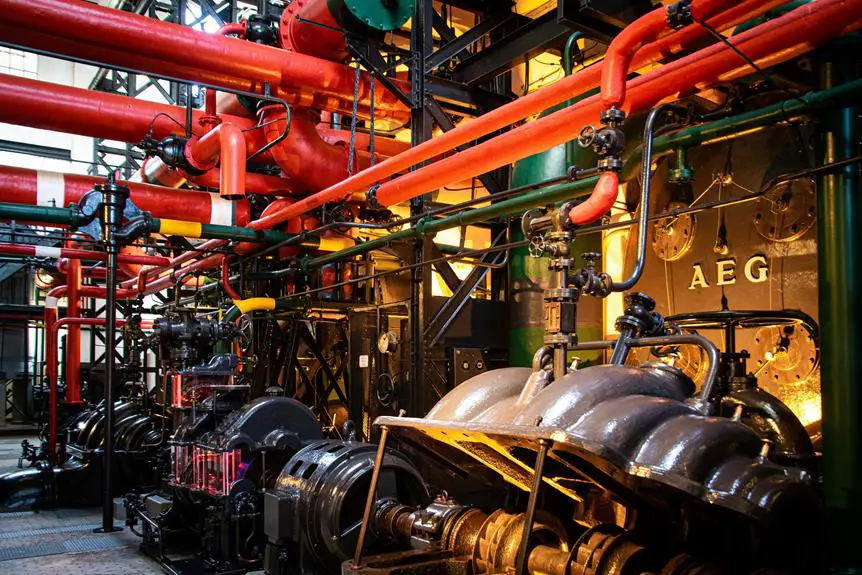

The production of poly tricot fabric is a highly energy-intensive process, with manufacturing facilities relying heavily on fossil fuels to power their operations and generate heat. As you consider the environmental impacts of poly tricot production, it's essential to understand the significant role energy consumption plays.

The extraction, processing, and transportation of fossil fuels require massive amounts of energy, which contributes to greenhouse gas emissions and climate change. When you factor in the energy needed to power manufacturing equipment, heat treatments, and drying processes, the overall energy consumption of poly tricot production becomes substantial.

According to estimates, the textile industry accounts for around 10% of global energy consumption, with a significant portion attributed to synthetic fabric production like poly tricot.

As you look at the emissions side of the equation, it's clear that poly tricot production has a considerable carbon footprint. The burning of fossil fuels releases carbon dioxide, methane, and other potent greenhouse gases into the atmosphere, accelerating climate change.

Water Pollution and Waste

The production process of poly tricot manufacturing requires significant amounts of water, which can lead to water pollution and waste if not managed properly.

The production process involves various stages, from dyeing and printing to finishing treatments, all of which consume large quantities of water. If not treated and discharged responsibly, this wastewater can harm aquatic ecosystems and contaminate water sources.

- Untreated wastewater discharge: If not treated, wastewater from poly tricot production can contain pollutants like dyes, chemicals, and heavy metals that can harm aquatic life.

- Water scarcity: The textile industry's high water demands can strain local water resources, particularly in areas where water is already scarce.

- Dyeing and printing pollution: The dyeing and printing processes used in poly tricot production can release large amounts of pollutants into waterways if not managed properly.

- Waste generation: Poly tricot production generates significant amounts of waste, including fabric scraps, packaging materials, and other non-recyclable materials that can end up in landfills or oceans.

It's essential to address these concerns to minimize the environmental impacts of poly tricot production.

Chemical Use and Toxicity

Poly tricot production relies heavily on chemicals, many of which can be toxic to humans and the environment, and it's crucial to understand the types and amounts used in the manufacturing process. You'll find that chemicals like dyes, finishers, and coatings are commonly used to enhance the fabric's appearance, durability, and performance.

However, these chemicals can have devastating effects on the ecosystem and human health.

When you look at the production process, you'll see that chemicals are used in various stages, from fiber production to fabric finishing. For instance, dyes and pigments are used to color the fabric, while finishers like softeners and wrinkle resistors are applied to improve its texture and appearance.

Unfortunately, many of these chemicals aren't biodegradable and can contaminate waterways, soil, and air. Moreover, workers in poly tricot production facilities are often exposed to these toxic substances, putting their health at risk.

It's essential to recognize the potential harm caused by chemical use in poly tricot production and explore alternative, eco-friendly methods to mitigate these impacts.

Microplastic Release and Impact

As you consider the environmental impacts of poly tricot production, you're likely wondering how microplastics are released into the environment.

It all starts with the polymer breakdown process, where poly tricot fabrics degrade over time.

Polymer Breakdown Process

Breaking down into smaller pieces, microplastics from poly tricot production are released into the environment, where they can persist for centuries and have devastating effects on ecosystems and human health.

As you consider the impact of poly tricot production, it's essential to understand the polymer breakdown process. When poly tricot fabrics are washed or exposed to sunlight, they release microplastics into the environment. These microplastics can come from the fabric itself or from the additives used in the manufacturing process.

Microplastic fragmentation occurs when microplastics break down into even smaller pieces, known as nanoplastics, which can be ingested by small organisms and work their way up the food chain.

Chemical leaching is another process that occurs as microplastics break down, releasing chemicals like bisphenol A (BPA) and phthalates, which have been linked to human health problems.

UV degradation is caused by exposure to sunlight, which can cause microplastics to break down into smaller pieces, increasing their surface area and potential for environmental harm.

Biodegradation is the process by which microplastics are broken down by microorganisms, but this process can take centuries, and the resulting fragments can still harm the environment.

Microfiber Shedding Rates

When you wear or wash clothing made from poly tricot, microfibers are released into the environment at varying rates, depending on factors like fabric type, washing method, and detergent used. You might be surprised to learn that a single wash cycle can release hundreds of thousands of microfibers into the water system. These microplastics can then enter the food chain, harming marine life and potentially even human health.

Research has shown that poly tricot fabrics tend to shed more microfibers than other synthetic fabrics. You can reduce the shedding rate by choosing gentler washing cycles and using a laundry bag to catch loose fibers. However, even with these precautions, some microfiber release is inevitable.

It's essential to consider the long-term environmental implications of your clothing choices. As you wear and wash poly tricot clothing, you're contributing to the growing problem of microplastic pollution. By understanding the microfiber shedding rates, you can make informed decisions about your wardrobe and help mitigate the environmental impacts of poly tricot production.

Landfill Waste and Disposal

Millions of tons of poly tricot waste end up in landfills each year, where it takes hundreds of years to decompose and contributes to the growing problem of landfill waste.

As you consider the environmental impacts of poly tricot production, it's essential to think about what happens to this waste after it's discarded. You might be surprised to learn that poly tricot waste isn't biodegradable, and it doesn't break down in landfills like organic materials do. Instead, it persists for centuries, taking up valuable space and contributing to the environmental problems associated with landfills.

- It's a significant contributor to landfill waste: Poly tricot waste makes up a substantial portion of the synthetic materials in landfills, and it's not going away anytime soon.

- It can leach chemicals into the environment: As poly tricot waste breaks down, it can release chemicals into the soil and groundwater, posing a risk to local ecosystems.

- It's not recyclable: Unlike some other synthetic materials, poly tricot waste isn't recyclable, making it a significant problem for waste management systems.

- It's a waste management challenge: The persistence of poly tricot waste in landfills poses a challenge for waste management systems, which must find ways to manage and dispose of this waste responsibly.

Carbon Footprint and Climate Change

As you consider the long-term effects of poly tricot waste in landfills, it's clear that the environmental impacts of poly tricot production extend far beyond waste management, and you're likely wondering how this fabric contributes to the growing problem of climate change.

The production process of poly tricot involves the extraction and processing of petroleum, which releases massive amounts of greenhouse gases, such as carbon dioxide and methane, into the atmosphere.

These gases trap heat and contribute to global warming, which has severe consequences on ecosystems and human societies. Furthermore, the transportation of poly tricot materials and products also generates significant emissions, adding to the fabric's overall carbon footprint.

You might be surprised to learn that the production of synthetic fibers like poly tricot accounts for around 10% of global greenhouse gas emissions.

As consumers, you have the power to make a difference. By choosing sustainable fabrics, buying second-hand clothing, and supporting eco-friendly brands, you can reduce your carbon footprint and help mitigate the environmental impacts of poly tricot production.

Every small action counts, and collective efforts can lead to significant positive change.

Frequently Asked Questions

Can Poly Tricot Be Recycled or Upcycled Effectively?

You're looking to reduce waste, and poly tricot's recyclability is a concern. Fortunately, poly tricot can be recycled or upcycled into new products, like rags or insulation. You can also repurpose it as cleaning cloths or stuffing for DIY projects.

Are There Biodegradable Alternatives to Poly Tricot?

You're looking for biodegradable alternatives to poly tricot. Luckily, you can opt for sustainable fabrics like organic cotton, hemp, or Tencel, which are not only eco-friendly but also offer similar softness and durability to poly tricot.

How Does Poly Tricot Production Affect Human Health?

You're exposed to toxic chemicals when producing poly tricot, as the fabric's manufacturing process involves harsh dyes and treatments that can cause respiratory issues, skin irritation, and other health problems if proper safety measures aren't taken.

Can Poly Tricot Be Replaced With Natural Fibers?

You're considering replacing poly tricot with natural fibers, which is a great idea. Natural fibers like cotton, hemp, and bamboo are biodegradable and require less processing, making them a more sustainable choice for your textile needs instantly.

Are There Regulations on Poly Tricot Production Worldwide?

You're wondering about regulations on poly tricot production worldwide. Currently, you'll find varying levels of regulations across countries, with some nations implementing stricter standards than others to minimize environmental harm and ensure worker safety.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024