As we tuck ourselves into bed, the soft embrace of microfiber sheets can feel like a gentle hug after a long day.

But have you ever wondered what exactly these cozy sheets are made of?

The mystery behind microfiber sheets lies in the composition of their synthetic fibers, which hold the key to their comfort and durability.

Let's unravel the secrets of what truly makes microfiber sheets a favorite among bedding enthusiasts.

Table of Contents

Key Takeaways

- Microfiber sheets are composed of synthetic fibers like polyester, nylon polymers, or wood pulp.

- They are crafted with thin fibers for a soft, silky texture and enhanced durability.

- These sheets offer practical benefits like moisture-wicking properties and temperature regulation.

- Their production techniques ensure quality, durability, and resistance to shrinking and wrinkling.

Definition of Microfiber Sheets

What exactly makes microfiber sheets stand out from traditional bedding options?

Microfiber sheets are crafted from synthetic fibers such as polyester, nylon polymers, or wood pulp. These materials are intricately woven to produce an exceptionally soft and smooth texture that sets them apart from conventional bedding choices.

One of the key distinguishing features of microfiber sheets is their impressive durability, making them resistant to wear and tear over time. Additionally, these sheets boast remarkable wrinkle resistance, ensuring a neat and tidy appearance on the bed.

Moreover, microfiber sheets are renowned for their moisture-wicking properties, which help regulate body temperature and keep you comfortable throughout the night. When selecting microfiber sheets, factors like GSM rating play a significant role in determining the quality and feel of the fabric.

Composition of Microfiber Sheets

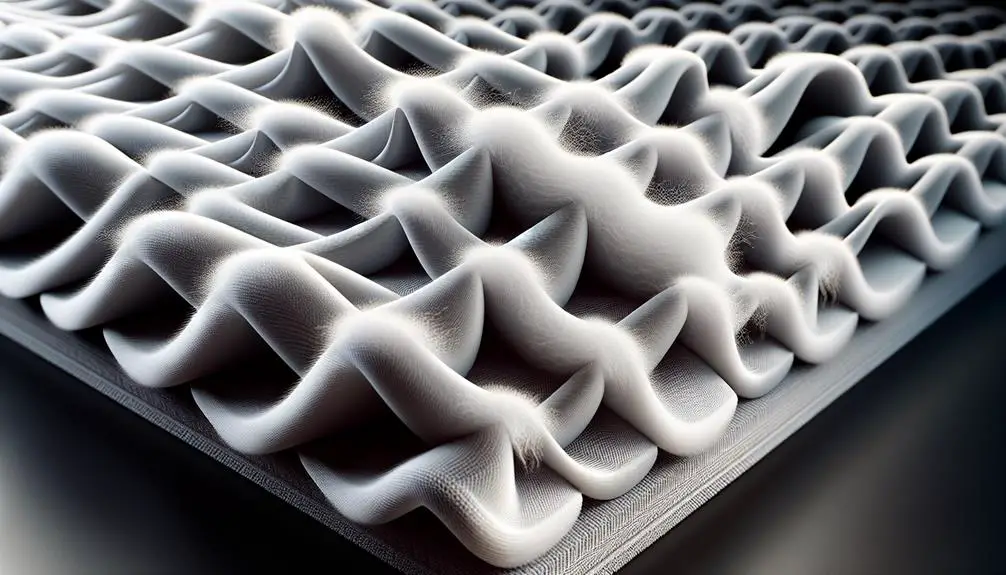

Comprising synthetic materials like polyester, nylon polymers, or wood pulp, microfiber sheets are known for their exceptional softness and durability.

The fibers in microfiber sheets are incredibly thin, contributing to their soft and silky texture, making them a favorite for a comfortable night's sleep. These sheets are highly durable, resistant to shrinking and wrinkling, and require low maintenance, offering a practical bedding option.

Additionally, microfiber sheets are lightweight, further enhancing their comfort and breathability. They're available in different quality options based on factors like GSM rating and brushing techniques, allowing for a variety of choices to suit individual preferences.

With their blend of synthetic materials and unique composition, microfiber sheets provide a luxurious feel while being easy to care for, making them a popular bedding choice for many seeking a combination of softness and durability.

Materials Used in Microfiber Sheets

I'll start by shedding light on the materials used in crafting microfiber sheets. These sheets are typically constructed from synthetic fibers such as polyester, nylon polymers, and even wood pulp.

The intricate weaving of these super-thin fibers results in a strong, soft fabric that resists common issues like shrinking and wrinkling.

Fabric Composition

Crafted from a blend of synthetic fibers like polyester, nylon polymers, or wood pulp, microfiber sheets boast a fabric composition that combines durability with a luxurious softness. This unique blend of materials offers several key benefits:

- Tightly Woven Structure: The fibers are intricately woven together to create a smooth fabric that's both durable and long-lasting.

- Moisture-Wicking Properties: The composition of microfiber allows it to wick away moisture, keeping you cool and comfortable throughout the night.

- Stain Resistance: Thanks to the specific blend of materials, microfiber sheets are resistant to stains, making them easy to maintain and ensuring they look fresh for longer.

Production Techniques

Moving from the fabric composition of microfiber sheets to their production techniques, the materials utilized in creating these linens play a crucial role in their quality and performance. Synthetic materials such as polyester, nylon polymers, and wood pulp are commonly used in the production of microfiber sheets.

The fibers within microfiber sheets are exceptionally thin, providing a luxuriously soft and smooth texture. Polyester is favored in microfiber sheets for its durability and resistance to wrinkles, ensuring longevity. Some variations may incorporate nylon fibers to enhance strength and resilience. Additionally, wood pulp may be blended into certain microfiber sheets to boost absorbency and moisture-wicking capabilities.

Understanding Microfiber Sheet Construction

I'll start by explaining the material composition of microfiber sheets, highlighting the use of synthetic materials like polyester or nylon polymers.

Next, I'll discuss the importance of thread count in determining the quality of microfiber sheets, emphasizing how it influences their softness and durability.

Understanding these key aspects of microfiber sheet construction can help you make informed decisions when selecting the best sheets for your needs.

Material Composition

In the intricate construction of microfiber sheets, the material composition plays a crucial role in determining their characteristics and performance. Microfiber sheets are typically crafted from synthetic materials such as polyester, nylon polymers, or wood pulp. These fibers are incredibly thin, contributing to the sheets' softness and lightweight nature.

The use of synthetic materials like polyester and nylon polymers enhances the sheets' durability and resistance to shrinking and wrinkling, making them a long-lasting bedding option. Additionally, the affordability of microfiber sheets makes them a practical choice for many consumers, offering a balance between quality and price.

The blend of these materials and fibers, along with considerations like GSM rating, influences the overall feel and performance of microfiber sheets.

Thread Count Importance

The composition of microfiber sheets sets the foundation for their quality and feel, with thread count playing a crucial role in understanding their construction. Unlike cotton sheets that are often measured by thread count, microfiber sheets are not. This is because microfiber sheets are made from synthetic materials like polyester or nylon polymers, not natural fibers like cotton.

High thread counts aren't as relevant for microfiber sheets due to their tightly woven construction. While microfiber sheets are durable and resistant to damage from washing machines, they're prone to trapping body heat, which may not be ideal for warmer climates. Additionally, microfiber sheets are breathable and suitable for individuals prone to night sweats, but they can be more susceptible to wrinkling compared to cotton sheets.

Origins of Microfiber Sheets

Frequently overlooked in discussions about bedding materials, the origins of microfiber sheets trace back to the innovative development of synthetic fibers. These synthetic materials, such as polyester, nylon polymers, and wood pulp, undergo a specialized process to create ultra-thin fibers, which are then woven to form the soft and durable microfiber fabric. The use of synthetic components in microfiber sheets contributes to their exceptional softness, impressive durability, and remarkable wrinkle resistance, making them a popular choice for bedding.

- Innovative Development: The creation of microfiber sheets stemmed from advancements in synthetic materials like polyester and nylon polymers.

- Specialized Processing: The transformation of these materials into ultra-thin fibers is a key step in producing the luxurious texture of microfiber sheets.

- Beneficial Properties: The synthetic composition not only enhances the softness and durability of microfiber sheets but also provides excellent wrinkle resistance, meeting the demands of quality bedding.

Key Components in Microfiber Sheets

When it comes to microfiber sheets, understanding the key components is essential.

The material composition, production process, and quality characteristics play crucial roles in determining the overall performance and feel of these sheets.

Let's explore how these elements come together to create the comfortable and durable bedding options that many people enjoy.

Material Composition

Crafted from a blend of synthetic materials like polyester, nylon polymers, or wood pulp, microfiber sheets boast a unique composition that sets them apart in the world of bedding. The key components in microfiber sheets include:

- Super-thin fibers: Processed from synthetic materials, these fibers create a soft and smooth fabric that's gentle on the skin.

- Moisture-wicking: The composition of microfiber enables it to wick away moisture, keeping you cool and comfortable throughout the night.

- Affordable: Due to the synthetic nature of microfiber, these sheets are cost-effective while offering a luxurious feel and durability.

This innovative combination of materials results in bedding that isn't only practical but also stylish and accessible to a wide range of consumers.

Production Process

Moving from the discussion on the material composition of microfiber sheets, the production process of these innovative bedding options involves intricate steps to create their unique properties.

Microfiber sheets are crafted using synthetic materials such as polyester, nylon polymers, and sometimes wood pulp. These materials are processed to create super-thin fibers that give microfiber sheets their soft texture and excellent durability.

Through specialized techniques, manufacturers ensure that microfiber sheets exhibit remarkable resistance to shrinking and wrinkling, making them a popular choice for those seeking low-maintenance bedding solutions.

The combination of these synthetic components results in bedding that isn't only comfortable but also long-lasting, providing consumers with a reliable and affordable option for quality sleep.

Quality Characteristics

Utilizing advanced weaving techniques, microfiber sheets incorporate key components that contribute to their exceptional quality and performance.

- Synthetic Fibers: Microfiber sheets are made of synthetic fibers such as polyester, nylon polymers, or wood pulp, which are finely woven to create a soft and durable fabric.

- Moisture-Wicking Properties: The composition of microfiber allows for moisture-wicking, making these sheets suitable for individuals who sweat during sleep.

- Tight Weave: The tight weave of microfiber sheets enhances their strength and durability, surpassing natural fibers like cotton in longevity and resistance to wear and tear.

The Science Behind Microfiber Sheets

The construction of microfiber sheets involves intricate weaving techniques that result in a fabric known for its exceptional qualities. Microfiber sheets are crafted from synthetic materials such as polyester, nylon polymers, or wood pulp. These synthetic fibers undergo a specialized process to create ultra-fine strands that are then woven into the microfiber fabric.

The unique composition of microfiber contributes to its remarkable softness, durability, and resistance to shrinking and wrinkling. Compared to natural fibers like cotton, microfiber allows for a tighter weave, enhancing its strength and longevity. Additionally, the quality of microfiber sheets can vary based on factors such as GSM rating, which indicates the weight and density of the fabric, and brushing techniques that can affect the texture and appearance of the sheets.

This scientific approach to microfiber sheet production ensures a luxurious and long-lasting bedding option with a host of desirable qualities.

Fibers in Microfiber Sheets

Crafted from ultra-thin synthetic fibers like polyester, nylon polymers, or wood pulp, microfiber sheets boast a reputation for their exceptional softness and durability. These fibers are meticulously woven to create a fabric that offers remarkable qualities:

- Moisture-Wicking: Microfiber sheets excel at wicking away moisture, making them ideal for those who tend to sweat during sleep.

- Resistance: Microfiber sheets are resistant to shrinking and wrinkling, ensuring they maintain their shape and smooth appearance wash after wash.

- Lightweight Comfort: The composition of microfiber allows for a lightweight feel, providing a comfortable sleeping experience without compromising on durability.

The combination of these fibers not only contributes to the luxurious softness of microfiber sheets but also enhances their performance in terms of moisture management and longevity. This makes them a popular choice for those seeking bedding that's both cozy and low-maintenance.

Characteristics of Microfiber Sheets

With their exceptional softness and durability, microfiber sheets stand out for their unique characteristics that cater to both comfort and longevity. Composed of synthetic fibers such as polyester, nylon polymers, or wood pulp, microfiber sheets undergo a specialized process to create ultra-fine fibers that contribute to their remarkable qualities.

The tight weave of these sheets not only enhances their lightweight feel but also makes them resistant to shrinking and wrinkles, ensuring a crisp and neat appearance on the bed.

Moreover, the incorporation of synthetic materials allows for a level of durability that surpasses traditional sheets. This durability, combined with the softness inherent in microfiber, offers a luxurious sleeping experience that withstands the test of time.

Manufacturers often brush or treat microfiber sheets to further amplify their softness, providing a cozy haven for resting. Whether it's the resistance to shrinking, the wrinkle-resistant nature, or the overall tight weave, microfiber sheets embody a harmonious blend of comfort and practicality.

Key Elements of Microfiber Sheets

Crafting microfiber sheets involves weaving ultra-fine synthetic fibers to create a luxurious and durable bedding option. When considering the key elements of microfiber sheets, it's essential to understand the composition and qualities that make them stand out:

- Synthetic Materials: Microfiber sheets are predominantly made from synthetic materials like polyester, nylon polymers, or wood pulp, which are processed into super-thin fibers for a soft and smooth texture.

- Durability: One of the standout features of microfiber sheets is their durability. The tight weave of these sheets enhances their strength, making them long-lasting and resistant to wear and tear.

- Wrinkle Resistance: Microfiber sheets are known for their wrinkle resistance, maintaining a smooth and neat appearance even after multiple washes. This quality ensures that your bedding always looks crisp and fresh, adding to the overall appeal of microfiber sheets.

Components of High-Quality Microfiber Sheets

High-quality microfiber sheets boast a composition of synthetic materials like polyester, nylon polymers, or wood pulp, woven together to create a luxurious and durable bedding option. These synthetic fibers are meticulously crafted to offer a silky-satin feel while maintaining an affordable price point compared to natural fiber alternatives like cotton. The quality of microfiber sheets is often determined by factors such as GSM rating (grams per square meter) and the techniques used during the brushing process. By combining these synthetic materials with advanced weaving methods, manufacturers can produce sheets that are not only soft and smooth but also resistant to shrinking and wrinkling, providing a comfortable sleeping experience. The versatility of microfiber sheets lies in their ability to offer a balance between luxury and affordability, making them a popular choice for those seeking high-quality bedding options.

| Component | Description | Benefits |

|---|---|---|

| Synthetic Materials | Polyester, nylon polymers, wood pulp | Softness and durability |

| GSM Rating | Grams per square meter | Indicates fabric density |

| Brushing Techniques | Advanced methods during production | Enhances softness |

Secrets of Microfiber Sheet Manufacturing

As we explore the intricate process of microfiber sheet manufacturing, the secrets behind creating these luxurious bedding essentials come to light.

- Synthetic Fibers: Microfiber sheets are crafted from synthetic fibers such as polyester, nylon polymers, or wood pulp. These materials are chosen for their durability and ability to create a soft, smooth texture in the sheets.

- Enhanced Durability: During the manufacturing process, microfiber sheets are tightly woven to enhance their durability and resistance to wrinkling. This meticulous weaving process ensures that the sheets maintain their quality even after multiple washes.

- Moisture-Wicking Properties: A key secret to manufacturing microfiber sheets lies in their moisture-wicking properties. The synthetic nature of microfiber allows for efficient moisture absorption, making these sheets ideal for regulating body temperature and providing a comfortable night's sleep.

Understanding these manufacturing secrets sheds light on why microfiber sheets are highly regarded for their luxurious feel, durability, and practical benefits.

Frequently Asked Questions

What Are the Disadvantages of Microfiber Sheets?

Disadvantages of microfiber sheets include limited breathability, potential heat retention, post-wash static, and moisture absorption in certain designs. They are durable but may not suit those with allergies. Stain-resistant yet not ideal for all climates.

Are Microfiber Sheets Healthy to Sleep On?

Sleeping on microfiber sheets may not be the healthiest option for everyone. While they are soft and durable, some prefer natural fibers like cotton for a better sleep experience due to potential skin sensitivity issues.

Do Microfiber Sheets Have a Thread Count?

Yes, microfiber sheets do not have a thread count like cotton sheets. Instead, their quality is often measured by the GSM rating, which indicates softness and durability. Higher GSM ratings result in a more luxurious feel.

Are Microfiber Sheets Made of Polyester?

Yes, microfiber sheets are made of polyester, nylon polymers, or wood pulp fibers. Polyester's durability, softness, and affordability are key reasons for its common use in microfiber sheets. The tight weave creates a smooth, silky texture.

- Is Chenille a Woven or Nonwoven Fabric? - July 11, 2025

- How to Tell if Fabric Is Woven or Nonwoven - July 10, 2025

- The Complete Guide to Nonwoven Materials - July 10, 2025