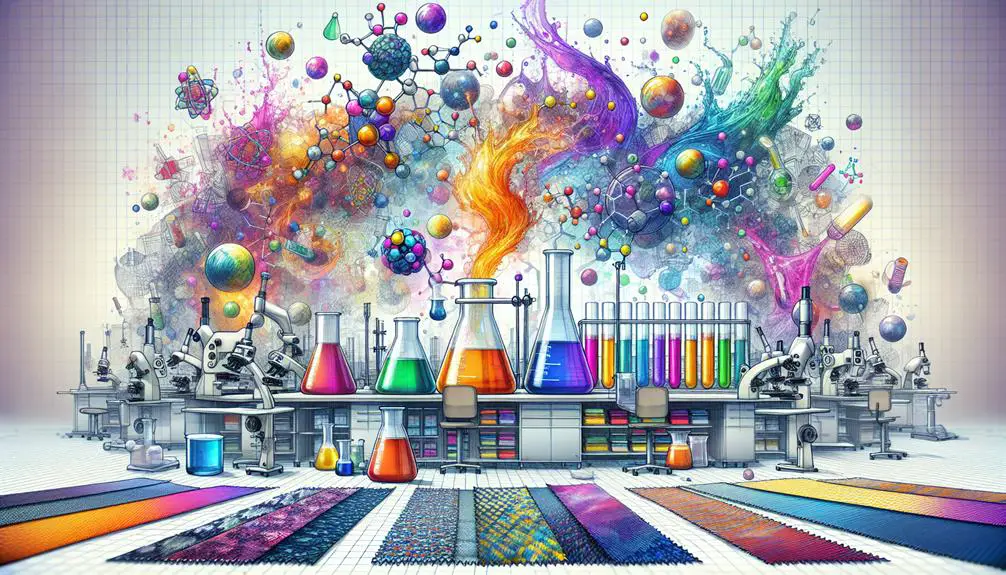

When you think about textile production, you might not immediately think about the significant role that chemistry plays. From the synthesis of fibers to the finishing treatments, every stage involves precise chemical processes. Imagine how polymerization techniques create the fabric threads or how dye chemistry gives textiles their vibrant colors. You also have to think about the importance of eco-friendly innovations and chemical safety measures. These aspects don't just improve the durability and comfort of fabrics; they safeguard the well-being of everyone involved. Curious about how these complex processes come together to shape the clothes you wear every day?

Table of Contents

Key Takeaways

- Chemistry drives fiber synthesis through polymerization, creating strong, durable, and sustainable fibers.

- Dye chemistry ensures vibrant, long-lasting colors via reactive, vat, disperse, and natural dyes.

- Textile finishing techniques enhance fabric durability and aesthetics using chemical treatments.

- Surface embellishments, like embroidery and printing, rely on chemical processes for unique textures and appearances.

- Eco-friendly innovations in chemistry reduce water usage and environmental impact in textile production.

Fiber Synthesis

When you're exploring fiber synthesis, you'll find that it involves creating fibers from raw chemical substances through various polymerization processes. This field is constantly evolving with a keen focus on sustainable fibers.

As you investigate further, you'll appreciate how these fibers can be crafted to meet diverse needs—from everyday clothing to advanced functional textiles.

Understanding biodegradable polymers is critical. These materials break down naturally, reducing environmental impact. You'll see that their use in fiber synthesis isn't just a trend but a necessity for a sustainable future.

By utilizing biodegradable polymers, you contribute to the creation of textiles that decompose without harming the ecosystem.

Nanofiber technology is another groundbreaking area. It enables the production of extremely fine fibers with unique properties. These fibers can enhance the functionality of textiles, offering benefits like improved filtration, increased strength, and even medical applications.

Mastering nanofiber technology will set you apart in the field, allowing you to innovate with precision.

Polymerization Techniques

Polymerization techniques play a pivotal role in transforming raw chemicals into versatile fibers. By mastering these techniques, you can precisely manipulate the molecular structure to create fibers with specific properties.

First, catalyst selection is vital; the right catalyst can significantly hasten the reaction, guaranteeing efficient chain formation. You'll need to balance the catalyst to maintain reaction control, preventing unwanted side reactions that could compromise fiber quality.

Next, consider the molecular structure you aim to achieve. Different fibers require different arrangements of monomers. For instance, when creating polyester, you'll want to guarantee a high degree of polymerization for enhanced strength and durability.

Here's where your expertise comes into play:

- Catalyst Precision: Selecting the best catalyst to accelerate the reaction without compromising the molecular integrity.

- Reaction Control: Monitoring temperature and pressure meticulously to guarantee consistent chain formation.

- Molecular Customization: Tailoring the molecular structure to meet the desired fiber characteristics, such as elasticity or tensile strength.

Dye Chemistry

You'll find understanding dye chemistry essential for producing vibrant textiles.

First, explore the various types of dyes and their unique properties.

Then, learn about different dyeing processes that guarantee the color adheres effectively to the fabric.

Types of Dyes

There are various types of dyes in textile production, each designed to bond with specific fibers and achieve vibrant, long-lasting colors. When you explore the world of dye chemistry, you'll encounter a spectrum of options, each with unique properties and applications.

For those interested in sustainable options, natural pigments offer a compelling choice. Derived from plants, minerals, and insects, these dyes not only provide a rich palette but also align with eco-friendly practices.

Understanding dyes means appreciating their color fastness—how well a dye resists fading or washing out. Different dyeing techniques can enhance this property, ensuring your fabrics maintain their brilliance over time.

Here are three types of dyes that evoke a sense of mastery:

- Reactive Dyes: These establish a covalent bond with the fiber, resulting in excellent color fastness.

- Vat Dyes: Known for their vibrant colors and high durability, they undergo a reduction process to become soluble.

- Disperse Dyes: Ideal for synthetic fibers like polyester, they offer exceptional penetration and color retention.

Mastering these dyes will elevate your textile projects, making them not just beautiful, but also enduring and environmentally responsible.

Dyeing Processes

Building on the understanding of different dyes, let's explore the complex processes that guarantee these dyes bond effectively with textiles. Mastery in dyeing processes is essential for achieving color fastness, guaranteeing that textiles retain their vibrant hues over time. You need to take into account factors like dye penetration and water consumption, as both have significant impacts on the final product and the environment.

In the dyeing process, you'll typically encounter batch dyeing, continuous dyeing, and semi-continuous dyeing. Each has its own set of protocols to optimize dye penetration and minimize water consumption. For example, continuous dyeing is efficient for large batches, reducing water usage compared to batch dyeing methods.

Here's a quick comparison of dyeing methods:

| Dyeing Method | Dye Penetration Quality | Water Consumption Level |

|---|---|---|

| Batch Dyeing | High | High |

| Continuous Dyeing | Moderate | Low |

| Semi-continuous Dyeing | Moderate | Moderate |

| Pad-Dry-Cure | High | Low |

| Garment Dyeing | High | High |

Understanding these methods helps you choose the right process to enhance color fastness while taking into consideration the environmental impact. By mastering these techniques, you can ensure that your textiles not only look great but are also produced sustainably.

Textile Finishing

In textile finishing, chemistry plays a crucial role in enhancing fabric durability and achieving the desired aesthetics.

By applying various chemical treatments, the textiles become more resistant to wear and tear.

These processes can also add softness, sheen, or other appealing qualities to the fabric.

Enhancing Fabric Durability

Textile finishing processes are essential for enhancing fabric durability, guaranteeing your garments withstand wear and tear. When it comes to increasing fabric strength, chemistry plays a pivotal role. By forming strong chemical bonds within the fibers, these processes greatly improve the resilience of the textile.

You'll find that fabrics treated with specific chemicals can resist abrasion, tearing, and other forms of damage that typically shorten the lifespan of your clothes.

Imagine the satisfaction of wearing a shirt that remains as good as new even after countless washes. That's what modern textile finishing can offer. Here are three emotional benefits you might experience:

- Confidence: Knowing your clothes won't deteriorate easily boosts your confidence in wearing them frequently.

- Savings: Durable fabrics mean fewer replacements, saving you money in the long run.

- Sustainability: Longer-lasting textiles contribute to reducing waste, making your choices more environmentally friendly.

Incorporating advanced chemical treatments enhances fabric resilience against daily challenges. This expertise in textile finishing guarantees that the garments you love maintain their integrity and functionality, offering you peace of mind and a wardrobe you can rely on.

Achieving Desired Aesthetics

Achieving the perfect appearance for your garments often hinges on advanced textile finishing techniques that enhance color, texture, and overall appearance. When you explore the domain of color matching, you're guaranteeing that each fabric batch maintains a consistent, vibrant hue that meets your exacting standards. It's not just about dyeing the fabric; it's about achieving a seamless blend that remains true under various lighting conditions.

Fabric manipulation goes beyond simple alterations. You can utilize chemical treatments to adjust the hand feel, drape, and elasticity of textiles. By mastering these techniques, you gain the power to transform a basic fabric into something extraordinary, tailored specifically to your design vision.

Surface embellishment is where your creative potential truly shines. Techniques such as embroidery, printing, and beadwork allow you to add intricate details that elevate your garments from ordinary to exceptional. Similarly, texture creation through processes like brushing, calendaring, or embossing can give your fabric a unique tactile quality that sets it apart.

Incorporating these advanced finishing techniques guarantees your textiles not only look stunning but also meet the high standards of craftsmanship and innovation your audience expects.

Fabric Treatments

Fabric treatments are crucial in improving textile performance and longevity. Understanding these treatments is essential in mastering textile production.

Softening agents enhance fabric comfort and texture, while wrinkle resistance treatments maintain a crisp appearance even after extensive wear.

Stain repellent treatments create a protective barrier, making cleaning spills and stains easier. Odor control treatments incorporate antimicrobial agents to prevent odor-causing bacteria growth, ensuring textiles remain fresh and hygienic.

The benefits of fabric treatments include enhanced comfort, improved durability, and long-lasting freshness.

- Comfort: Softness and wrinkle resistance elevate the feel and appearance of clothes.

- Durability: Stain repellency extends textile life by protecting against everyday mishaps.

- Freshness: Odor control maintains garment freshness, even after multiple uses.

Chemical Safety

While fabric treatments greatly enhance textile performance, it's equally important to make sure chemical safety during their application. You must be vigilant about chemical exposure, as it can pose significant health risks to workers and consumers alike. Implementing protective measures, such as providing appropriate personal protective equipment (PPE) and ensuring proper ventilation, is essential to create a safe working environment.

Conducting a thorough toxicity assessment of the chemicals used in textile treatments is paramount. This involves evaluating the potential short-term and long-term health effects of each substance. By understanding the toxicity of these chemicals, you can develop effective risk management strategies. This might include substituting hazardous chemicals with safer alternatives or adjusting processing methods to minimize exposure.

Effective risk management doesn't stop at the factory floor. You should also establish clear protocols for handling, storage, and disposal of chemicals to prevent environmental contamination and make sure worker safety. Regular training sessions can keep your team informed about the latest safety practices and regulatory requirements.

Eco-Friendly Innovations

Incorporating eco-conscious innovations into textile production can greatly lessen environmental impact and promote sustainability. You can adopt numerous sustainable practices and green technologies to revolutionize your textile operations. By doing so, you not only minimize waste and pollution but also contribute to a healthier planet.

Here are three transformative steps you can take:

- Use Organic Fibers: Opt for organic cotton, hemp, or bamboo. These materials are grown without harmful pesticides or synthetic fertilizers, reducing soil and water contamination.

- Adopt Water-Efficient Dyeing Techniques: Traditional dyeing processes consume vast amounts of water and release toxic chemicals. Embracing waterless dyeing methods, such as supercritical CO2 dyeing, can significantly reduce water usage and chemical waste.

- Implement Closed-Loop Systems: Recycling and reusing water and chemicals within production processes can drastically lower resource consumption and waste output. Closed-loop systems make sure that nothing is wasted and everything is repurposed.

Performance Enhancement

Building on eco-friendly innovations, you can also enhance textile performance by incorporating advanced chemical treatments and finishing techniques. Chemistry applications in textiles have revolutionized the industry, allowing you to create fabrics that aren't only sustainable but also high-performing.

To achieve water and stain resistance, for instance, you can apply fluorocarbon or silicone-based treatments. These chemicals form a protective layer over the fabric, repelling water and oils, so your textiles remain clean and dry.

For enhanced durability, you might consider cross-linking agents that improve fiber strength and elasticity, making garments more resilient to wear and tear.

When it comes to comfort, moisture-wicking chemicals can be integrated into the fabric to guarantee it draws sweat away from the skin, keeping wearers dry and comfortable.

Antimicrobial treatments are another key area of textile innovation. By incorporating silver nanoparticles or other antimicrobial agents, you can produce textiles that prevent bacterial growth, reducing odor and extending the lifespan of the garment.

Incorporating these advanced chemistry applications allows you to create textiles that not only meet but surpass performance expectations. By leveraging these innovations, you can offer products that are at the forefront of textile technology, guaranteeing superior quality and functionality.

Frequently Asked Questions

How Does Chemistry Contribute to Textile Recycling Processes?

You won't believe the magic chemistry works in textile recycling! Through advanced chemical reactions, it breaks down old fabrics and regenerates fibers, transforming waste into new, high-quality materials, almost like turning lead into gold.

What Are the Challenges in Developing Biodegradable Textiles?

You face challenges in developing biodegradable textiles, such as ensuring the sustainable fibers maintain durability and performance. Balancing these qualities with minimizing environmental impact requires advanced research and innovation in material science and production techniques.

How Do Chemical Processes Affect the Durability of Textiles?

You'll find that chemical bonding greatly enhances fabric strength. When you understand these processes, you can manipulate them to create textiles that resist wear and tear, ensuring they maintain their durability over time.

What Role Do Chemical Additives Play in Textile Comfort?

Chemical additives enhance textile comfort by increasing fabric softness and optimizing moisture absorption. You'll find that softer fabrics feel luxurious, while efficient moisture absorption keeps you dry and comfortable throughout the day.

How Is Nanotechnology Utilized in Modern Textile Chemistry?

In modern textile chemistry, you'll find nanotechnology applications enhancing textile functionality. You can create fabrics that are stain-resistant, antimicrobial, and UV-protective. These advancements guarantee your textiles are both innovative and high-performing.

- A Review of Top Ten Fabrics & Tailors in Dhaka - June 20, 2025

- The Role and Responsibilities of a Fabric Sourcing Manager in Bangladesh - June 20, 2025

- Current Chiffon Fabric Price in Bangladesh for Designers - June 20, 2025