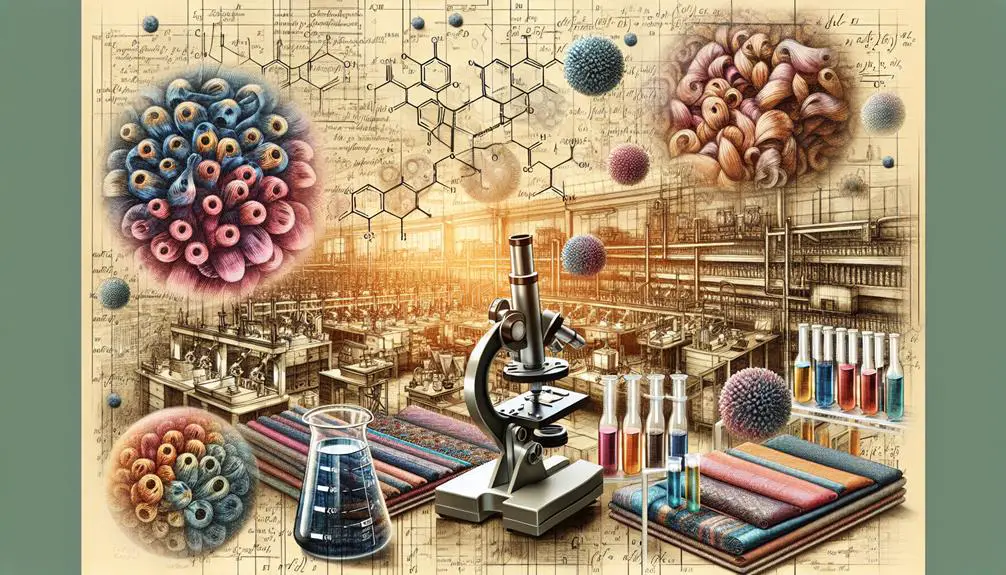

You might not realize it, but chemistry is at the heart of every piece of fabric you encounter. From the synthetic fibers in your activewear to the vibrant dyes in your favorite shirt, chemical processes shape their properties and performance. Think about how those clothes feel, how long they last, and even their environmental impact—chemistry plays a key role in all of these aspects. But how exactly do these chemical interactions work to produce such diverse and functional textiles? Let's explore the fascinating intricacies behind fabric production and discover the science that touches your everyday life.

Table of Contents

Key Takeaways

- Chemistry transforms raw materials like petroleum into polymers, forming the foundation of synthetic fabrics.

- Polymerization creates long chains that determine the strength, flexibility, and overall properties of the fabric.

- Dyeing techniques involve chemical treatments to enable vibrant, long-lasting colors in synthetic fibers.

- Finishing treatments, such as softeners and stain repellents, chemically enhance fabric softness, wrinkle resistance, and longevity.

- Eco-friendly alternatives utilize sustainable materials and non-toxic processes, reducing environmental impact and supporting closed-loop production systems.

Synthetic Fiber Creation

Creating synthetic fibers involves chemically transforming raw materials such as petroleum into versatile and durable fabrics. You'll start with polymer synthesis, which is the cornerstone of this process. By reacting monomers like ethylene, you can create long polymer chains through polymerization. This step is essential because it determines the fundamental properties of your fabric, from strength to elasticity.

Once you've synthesized the polymer, it's time for fiber spinning. This involves extruding the liquid polymer through tiny holes called spinnerets. Imagine this as pushing dough through a pasta maker, but on a microscopic scale. As the polymer exits the spinneret, it solidifies into fine strands. You can control the diameter and structure of these fibers by adjusting the spinning speed and the type of spinneret used.

After spinning, you'll often stretch these fibers to align the polymer molecules, enhancing the tensile strength and flexibility of your material. It's fascinating how you can tweak various parameters—like temperature and stretching speed—to engineer fibers with specific characteristics.

Mastering these techniques allows you to produce high-performance fabrics tailored for everything from sportswear to industrial applications.

Dyeing Techniques

Dyeing techniques are vital for adding vibrant colors and patterns to your synthetic fabrics, transforming them into eye-catching textiles. Mastering these techniques involves understanding the chemistry behind dye penetration and ensuring color fastness.

While synthetic dyes are commonly used for their consistency and range, natural pigments have been utilized for centuries through traditional methods. These natural dyes, extracted from plants, minerals, and insects, offer rich, earthy hues and a sustainable option for those seeking eco-friendly solutions.

To achieve best dye penetration, you need to take into account the molecular interaction between the dye and the fabric. Synthetic fibers often require specific chemical treatments to open up their structure, allowing the dye to bond effectively. This step is important for ensuring that the color is evenly distributed and deeply embedded within the fibers.

Color fastness is another important factor. It measures how well the dye resists fading or washing out over time. Techniques like mordanting, which involves treating the fabric with substances that fix the dye, can greatly enhance color fastness.

Finishing Treatments

After achieving vibrant colors through various dyeing techniques, finishing treatments guarantee your fabric maintains its quality and aesthetics. These treatments are essential for enhancing the softness, wrinkle resistance, and longevity of your textiles. By applying specific chemical processes, you can transform an ordinary fabric into one that's both luxurious and practical.

Softness improvement is a primary goal in finishing treatments. Special softeners are applied to create a pleasant tactile experience. Wrinkle resistance is another vital focus. Chemicals like resins are used to ensure that fabrics maintain a smooth appearance even after multiple washes.

Additionally, stain repellent and water repellent treatments are crucial. By incorporating these treatments, you're able to protect fabrics from everyday mishaps. Stain repellents prevent liquids from penetrating the fibers, while water repellents guarantee that water beads off the fabric surface.

| Treatment Type | Benefits |

|---|---|

| Softness enhancement | Enhanced tactile experience |

| Wrinkle resistance | Maintained smooth appearance |

| Stain repellent | Protection from liquid stains |

| Water repellent | Prevention of water absorption |

| Combined treatments | Thorough fabric care |

Mastering these finishing treatments allows you to produce high-quality fabrics that not only look good but also stand up to the demands of daily use.

Enhancing Durability

Improving resilience in fabrics involves integrating specific chemical treatments that guarantee your textiles withstand wear and tear over time. By delving into the intricacies of chemical bonding, you can greatly enhance the lifespan of your materials. Chemical bonding strengthens the fibers at a molecular level, creating a resilient and robust fabric structure. This guarantees that your textiles can endure daily stress without compromising their integrity.

Incorporating strength additives is another crucial strategy. These compounds are designed to enhance the inherent properties of the fabric, providing additional resistance against abrasion, tearing, and stretching. When applied correctly, strength additives can transform a standard piece of cloth into a powerhouse of durability. You'll find that these treatments don't just make the fabric tougher but also maintain its flexibility and comfort.

Adopting these advanced chemical techniques allows you to produce textiles that aren't only long-lasting but also maintain their aesthetic appeal. Imagine fabrics that retain their vibrancy and texture even after multiple washes and continuous use. By mastering these methods, you ensure your textiles are always in peak condition, offering superior performance and longevity.

Essentially, these chemical enhancements are crucial for producing high-quality, durable fabrics.

Eco-friendly Alternatives

Incorporating eco-friendly alternatives into fabric production not only reduces environmental impact but also meets growing consumer demand for sustainable products. By choosing sustainable materials like organic cotton, bamboo, and recycled polyester, you can significantly lower the carbon footprint of your textiles. These materials are grown or produced using methods that require fewer chemicals and less water, which helps preserve our natural resources.

Adopting ethical practices in your production process is equally important. This means ensuring fair labor conditions, reducing waste, and minimizing energy consumption. You can achieve this by implementing closed-loop systems, where waste products are reused within the production cycle. Additionally, using non-toxic dyes and water-based inks can further decrease the environmental harm associated with fabric production.

Understanding the chemistry behind these eco-friendly alternatives enables you to make informed decisions that align with both environmental and consumer needs. By integrating these sustainable materials and ethical practices, you not only enhance the quality and appeal of your fabrics but also contribute to a more sustainable future.

Frequently Asked Questions

How Do Natural Fibers Differ Chemically From Synthetic Ones?

Like night and day, natural fibers have a complex chemical composition and properties, while synthetic ones are simpler. Natural fibers offer better environmental impacts and sustainability, whereas synthetics often contribute to pollution and waste.

What Chemical Processes Are Involved in Fiber Spinning?

You engage in fiber spinning by initiating polymer formation, where monomers link to form polymers. Next, solvent evaporation solidifies the fibers. Mastering these processes guarantees your fibers have the desired strength and flexibility.

How Does Chemistry Influence Fabric Texture and Feel?

Imagine running your hand over a luxurious fabric. Chemistry's behind that sensational feel. Chemical composition directly influences fabric properties, dictating softness, elasticity, and durability. Master these concepts, and you'll reveal the secrets to perfect textiles.

What Are the Chemical Reactions in Fabric Softening Agents?

You'll find that fabric softening involves chemical reactions between cationic surfactants and fabric fibers. Analyzing the ingredients reveals how these compounds reduce static, increase softness, and enhance the overall feel of the fabric.

How Is Chemical Safety Managed in Fabric Production?

You manage chemical safety in fabric production by following strict chemical regulations and implementing thorough workplace safety protocols. Regular training guarantees you understand potential hazards and use protective equipment, minimizing risks effectively.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024