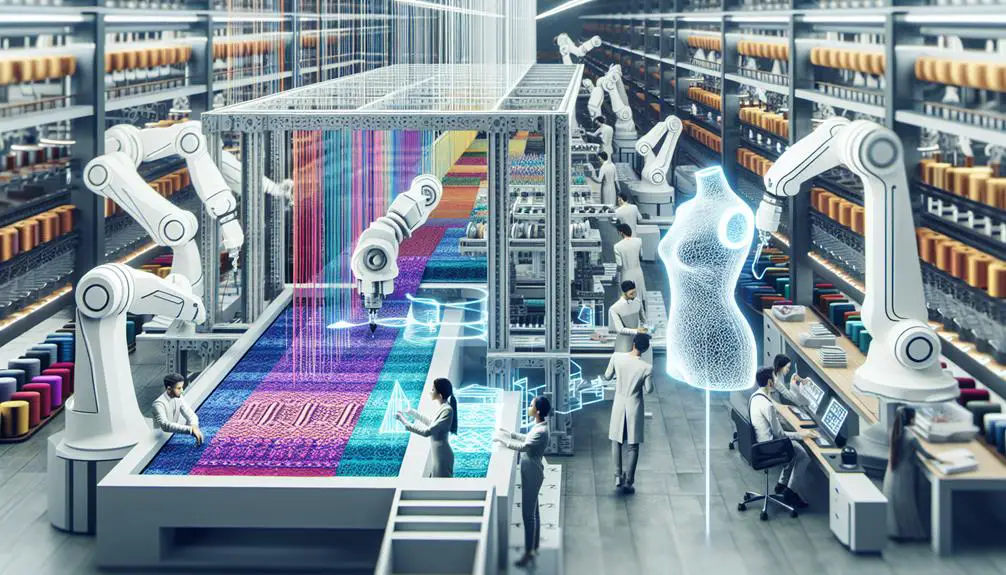

Imagine a world where every piece of clothing you own is custom-made to fit you perfectly, down to the last thread. 3D printing in textile manufacturing isn't just a futuristic fantasy—it's reshaping how we think about fashion, efficiency, and sustainability. You might wonder how this technology manages to streamline production while offering endless design possibilities and reducing waste. As you explore the transformative impact of 3D printing, you'll discover how it's not only changing the fashion landscape but also addressing pressing environmental concerns in the industry.

Table of Contents

Key Takeaways

- 3D printing enables unparalleled customization and efficiency, allowing for tailored clothing designs with a perfect fit.

- It significantly reduces waste through targeted production and use of eco-friendly materials, promoting sustainability.

- The technology offers infinite design flexibility, enabling intricate patterns and unique fabric textures.

- 3D printing disrupts traditional supply chains by streamlining production processes and reducing the need for large inventories.

- It fosters innovation in medical textiles, producing functional products like tailored bandages and smart fabrics with embedded sensors.

Evolution of Textile Manufacturing

From handlooms to fully automated machines, textile manufacturing has seen remarkable advancements over the centuries. You can trace the journey from painstakingly slow hand-weaving methods to today's lightning-fast automated processes. Automation efficiency has fundamentally transformed the textile industry. With automation, what once took days can now be completed in mere hours, allowing for mass production without compromising on quality.

Understanding this evolution is pivotal for anyone serious about mastering the textile field. Early textile workers had to adapt to each technological leap, and the industry itself has shown a remarkable ability to evolve. The introduction of power looms in the 18th century marked one of the first significant shifts, drastically improving productivity.

Fast forward to the 21st century, and you'll find sophisticated machines capable of producing intricate patterns and textures with minimal human intervention.

Textile industry adaptation has been a key driver in this progress. As new technologies emerged, the industry didn't just survive; it thrived, continually improving upon existing methods. Mastering the history of these advancements equips you with a deeper understanding of where the industry is headed, preparing you to embrace future innovations with confidence.

Benefits of 3D Printing

3D printing revolutionizes textile manufacturing by offering unparalleled customization and efficiency. You can streamline production processes, eliminating the need for multiple, time-consuming steps. The result? Remarkable production efficiency that saves both time and resources.

With 3D printing, you're no longer bound by traditional design constraints. You can explore infinite design flexibility, allowing for the creation of intricate and innovative patterns that were previously unimaginable.

One of the most significant impacts of 3D printing is the disruption of the traditional supply chain. You're able to produce textiles on-demand, reducing the need for large inventories and minimizing waste. This shift not only optimizes operations but also contributes to a more sustainable manufacturing process.

Additionally, material innovation becomes a tangible reality. You can experiment with new types of materials that offer unique properties, such as enhanced durability, flexibility, or even environmental benefits.

Customization and Personalization

With 3D printing, you can easily create tailored clothing designs that fit like a dream. Imagine wearing unique fabric patterns no one else has, or sporting individualized fashion accessories that reflect your personal style.

This technology empowers you to bring your creative vision to life in ways traditional methods simply can't match.

Tailored Clothing Designs

Imagine possessing a closet filled with clothing tailored perfectly to your unique measurements and style preferences, all thanks to 3D printing technology. You're no longer bound by off-the-rack limitations. Instead, you can engage in creative collaborations with designers, resulting in fashion-forward pieces that reflect your individuality. This cutting-edge tailoring technology empowers you to customize every aspect of your clothing, from fit to fabric, guaranteeing that each item is a true representation of your personal style.

3D printing in textile manufacturing offers sustainable solutions by minimizing fabric waste and reducing the carbon footprint associated with traditional tailoring methods. When you choose 3D printed garments, you contribute to a more environmentally conscious approach to fashion. This technology allows you to select eco-friendly materials, further enhancing the sustainability of your wardrobe.

Moreover, the precision of 3D printing ensures that your clothes fit flawlessly, enhancing comfort and confidence. You'll experience a new level of personalization, where your clothing isn't just made for anyone but specifically for you.

Unique Fabric Patterns

Now that your clothes fit perfectly, let's explore how you can create unique fabric patterns that truly reflect your personality through customization and personalization. With 3D printing, you're no longer limited to conventional designs. Instead, you can immerse into artistic expression and unleash endless creative possibilities.

Imagine fabric that embodies unique textures and intricate details, unlike anything found in stores. 3D printing technology allows you to craft patterns that are not only visually stunning but also tactilely intriguing. Your wardrobe can now be a canvas for showcasing your personal style and creativity.

| Feature | Benefits | Examples |

|---|---|---|

| Artistic Expression | Showcase your individuality | Custom prints, bespoke designs |

| Unique Textures | Add depth and dimension | Raised patterns, tactile designs |

| Intricate Details | Achieve precision in patterns | Micro-patterns, filigree work |

| Customization | Tailor designs to your liking | Color choice, pattern variation |

| Personalization | Reflect your personal style | Monograms, thematic designs |

Individualized Fashion Accessories

Elevate your fashion game by customizing accessories that reflect your unique style through the power of 3D printing. Imagine walking into a room, wearing custom jewelry that no one else has, pieces that showcase your individuality and taste.

With 3D printing, you can bring your creative visions to life, crafting intricate designs that traditional manufacturing can't achieve. This technology allows you to experiment with various materials and finishes, ensuring your accessories are truly one-of-a-kind.

Bespoke handbags are another area where 3D printing shines. Instead of settling for mass-produced options, you can design a handbag tailored to your exact specifications. From the shape and size to the texture and color, every detail can be customized to meet your needs and preferences.

The result is a handbag that not only serves its functional purpose but also acts as a statement piece, highlighting your fashion-forward mindset.

Waste Reduction and Sustainability

3D printing in textile manufacturing frequently reduces waste by producing only the necessary amount of material for each piece. This targeted production method greatly minimizes the environmental impact, as it eliminates excess material that would otherwise become waste. By utilizing precise amounts of raw materials, you're not just conserving resources, but also ensuring that the textiles produced are more sustainable.

You can see a notable difference in resource conservation when comparing traditional textile methods to 3D printing. Conventional methods often involve cutting large swathes of fabric, resulting in leftover scraps. These scraps contribute to landfill waste and require additional resources to manage. In contrast, 3D printing uses advanced software to create items layer by layer, making sure no extra material is wasted.

Moreover, 3D printing allows for the use of eco-friendly materials, further enhancing sustainability. You can opt for biodegradable or recyclable materials, thereby reducing the long-term environmental footprint.

Challenges in Implementation

You'll face several hurdles when implementing 3D printing in textile manufacturing.

The need for specialized technical skills, high equipment costs, and material limitations can all pose significant challenges.

Understanding these obstacles is vital to successfully integrating this technology.

Technical Skill Requirements

Implementing 3D printing in textile manufacturing demands specialized technical skills that many current workers don't yet possess. To bridge this gap, you need robust training programs focused on skill development.

It's essential to design courses that cover the intricacies of 3D printing technology, software proficiency, and material science. These programs should be hands-on and all-encompassing, ensuring that your team not only understands the theory but can also apply it practically.

Meeting workforce requirements involves more than just basic training. You need employees with specialized knowledge in areas like CAD design, machine operation, and quality control. This means investing in advanced education and continuous learning opportunities.

Encourage your team to stay updated with the latest advancements in 3D printing techniques and materials through workshops and industry conferences.

Cost of Equipment

Purchasing the specialized equipment for 3D printing in textile manufacturing can be a significant financial challenge. The initial investment in 3D printers, which can range from thousands to hundreds of thousands of dollars, is just the start. You also need to budget for equipment maintenance, which guarantees your machines operate efficiently and have a longer lifespan. Don't forget, training programs for your team are essential to maximize the potential of this technology.

To help you understand the costs better, here's a breakdown:

| Expense | Estimated Cost | Frequency |

|---|---|---|

| 3D Printer Purchase | $10,000 – $200,000+ | One-time |

| Equipment Maintenance | $1,000 – $5,000 | Annually |

| Training Programs | $500 – $2,000 | Per employee |

| Software Licenses | $1,000 – $3,000 | Annually |

Forming industry partnerships can alleviate some of these financial burdens. Collaborating with established firms can lead to shared resources and reduced costs. Additionally, consider seeking financial investments from stakeholders who believe in the transformative potential of 3D printing in textiles. While the upfront costs are high, the long-term benefits and innovations can yield significant returns, making the initial financial hurdle worthwhile.

Material Limitations

Managing the material restrictions in 3D printing for textile manufacturing presents a pivotal challenge. You may find that while 3D printing offers remarkable design flexibility and production efficiency, the range of materials available can be limiting. Traditional textiles often exhibit properties like breathability, softness, and elasticity, which are challenging to replicate with current 3D printing materials. This limitation can hinder the overall quality and functionality of the final product.

Moreover, achieving the desired surface texture remains a complex task. You might struggle to produce textiles with the smoothness or intricate textures that traditional methods easily provide. This can affect not only the aesthetic appeal but also the tactile experience of the fabric, which is vital for consumer satisfaction.

Color options in 3D printing are another area where you face limitations. While traditional textile manufacturing offers a vast array of vibrant and consistent colors, 3D printing materials often lack this variety. This limitation can stifle creativity and restrict your ability to meet specific design preferences.

Addressing these material restrictions is essential for fully realizing the potential of 3D printing in textile manufacturing, ensuring that the technology can match the high standards set by conventional methods.

Innovative Applications

Harnessing 3D printing technology, textile manufacturers are exploring groundbreaking applications that revolutionize fabric design and production. In the fashion industry, you're witnessing a surge of artistic collaborations where designers and technologists merge their expertise to craft avant-garde garments. These creations often feature intricate patterns and structures previously unattainable with traditional methods. Imagine dresses that incorporate geometric shapes or shoes printed to fit your foot perfectly.

Such innovations not only push creative boundaries but also set new standards in customization and sustainability.

Medical textiles are another area where 3D printing shines. Functional innovations are transforming how medical professionals approach patient care. Picture bandages that conform precisely to a wound's contours or surgical meshes tailored for specific procedures. You can even look forward to smart fabrics embedded with sensors that monitor essential signs in real-time.

These advancements promise enhanced comfort, better outcomes, and reduced recovery times.

Future Trends and Predictions

Looking ahead, you'll see 3D printing poised to redefine the textile industry with innovations that merge functionality and fashion. As technology advancements accelerate, expect market growth driven by increased consumer demand for personalized, sustainable, and high-performance textiles.

This emerging technology will allow designers to explore new design possibilities, creating intricate patterns and custom fits that were once unimaginable.

Imagine a world where your clothes aren't only tailored to your exact measurements but also designed to meet specific functional needs, such as moisture-wicking or temperature regulation. You'll witness a surge in smart textiles that integrate sensors and electronics, offering unprecedented interactivity and convenience. This shift will catalyze a paradigm change in how we perceive and use clothing.

Moreover, the environmental benefits can't be overstated. 3D printing minimizes waste by using only the necessary material, aligning perfectly with the growing consumer demand for sustainable practices.

You'll see brands adopting this technology to reduce their carbon footprint and meet the increasing consumer expectations for eco-friendly products.

Frequently Asked Questions

How Does 3D Printing Impact Textile Worker Employment Rates?

Investigate the truth: 3D printing can cause job displacement but also offers retraining opportunities. The economic impact varies; however, workforce adaptation is essential. You'll need to stay agile and embrace new skills to thrive.

What Materials Are Commonly Used in 3d-Printed Textiles?

You'll find that PLA, TPU, and PETG are common for 3D-printed textiles. These materials offer excellent design flexibility and material properties while addressing environmental impact and sustainability concerns, making them ideal for innovative textile applications.

Are 3d-Printed Textiles as Durable as Traditional Ones?

Imagine a bridge between tradition and innovation. When it comes to durability comparison, 3D-printed textiles can rival traditional ones. However, sustainability concerns arise, requiring you to weigh the environmental impact against the benefits of cutting-edge technology.

How Do 3d-Printed Textiles Affect Production Costs?

3D-printed textiles can reduce production costs by streamlining the supply chain and allowing for more customization options. You'll also appreciate the innovative designs and reduced environmental impact, making your production process more efficient and eco-friendly.

What Safety Regulations Apply to 3d-Printed Textiles?

You need to adhere to safety standards for 3D-printed textiles, including material toxicity and flammability. Assess the environmental impact, ensuring compliance with regulations on waste and emissions. Mastery requires staying updated on industry guidelines and innovations.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024