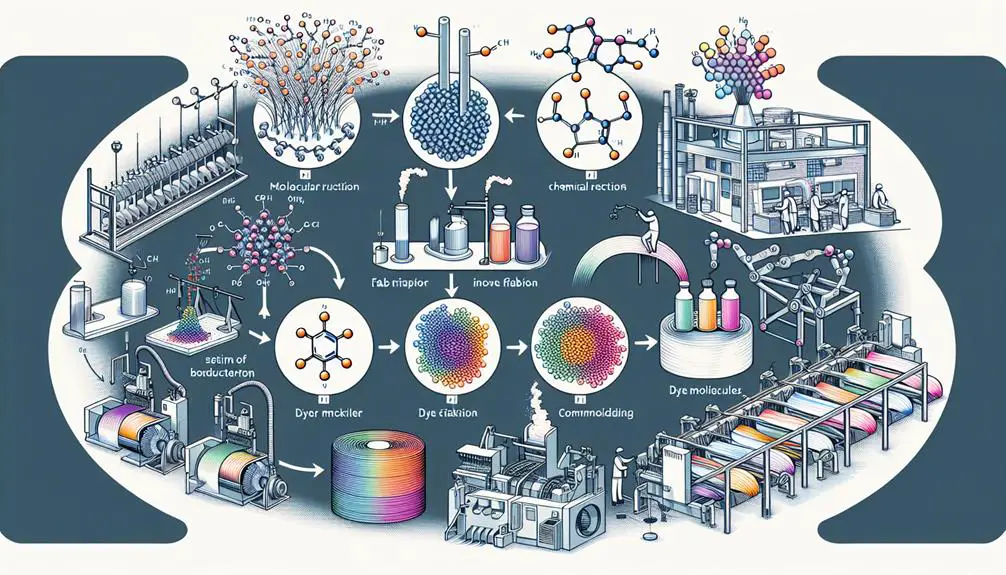

When you think about fabric, you might not consider the intricate chemistry behind its production. From the initial fiber extraction to the final finishing processes, each stage involves precise chemical reactions that determine the fabric's quality and functionality. You'll find that polymerization, where monomers form long chains, is just the beginning. Spinning techniques convert these polymers into fibers, which are then woven into fabric. But it doesn't stop there; chemical treatments enhance durability and texture, while dyeing and printing methods guarantee vibrant, long-lasting colors. What exactly makes each step so essential?

Table of Contents

Key Takeaways

- Chemical extraction methods are used to produce synthetic fibers like nylon and polyester, tailored for specific fabric properties.

- Monomer selection in the polymerization process critically influences fabric strength, flexibility, and durability.

- Chemical treatments such as mercerization and flame retardancy enhance the properties and performance of natural and synthetic fabrics.

- Dyeing methods, including immersion and fiber-reactive dyes, impact fabric coloration and environmental sustainability.

- Quality control using automated inspection ensures fabric consistency and defect minimization throughout the production process.

Fiber Extraction

To understand fabric production, you first need to know how fibers are extracted from their natural or synthetic sources. Natural fibers like cotton, wool, and silk come directly from plants or animals. You'll often use mechanical extraction methods, such as ginning for cotton or shearing for wool, to separate these fibers from their raw materials. Mechanical extraction is straightforward but requires precision to maintain fiber quality.

On the other hand, synthetic fibers like nylon and polyester are man-made. They're derived from petrochemicals and require chemical extraction. This process involves breaking down larger molecules into smaller ones through chemical reactions. For example, you might use solvents to dissolve the raw materials, then precipitate the fibers out. Chemical extraction allows for greater control over the fiber's properties, enabling you to tailor them for specific applications.

Mastering these extraction techniques is essential.

Natural fibers offer biodegradability and comfort, whereas synthetic fibers provide durability and versatility. Understanding how to efficiently extract these fibers guarantees you're set up for success in subsequent steps of fabric production.

This foundational knowledge paves the way for mastering more advanced processes.

Polymerization Process

In the polymerization process, you need to evaluate the criteria for selecting the right monomers, as they directly impact the quality of the final fabric.

Understanding the chain reaction mechanism is essential because it determines the polymer structure and properties.

Additionally, you should focus on factors that influence process efficiency to optimize production.

Monomer Selection Criteria

Selecting the correct monomers is vital for ensuring the desired properties and performance of the final polymer in fabric production. When you're choosing monomers, you need to take into account how they'll affect the polymer structure and chemical properties.

The polymer structure determines the arrangement of the monomer units, influencing the fabric's strength, flexibility, and durability. For instance, monomers that form linear polymers can produce fibers with high tensile strength, perfect for applications requiring robust materials.

You also have to take into consideration the chemical properties of the monomers. This includes factors like polarity, reactivity, and thermal stability. Monomers with high thermal stability are important for fabrics exposed to high temperatures, while those with specific reactive groups can be tailored for dyeing and finishing processes.

Understanding these properties lets you fine-tune the performance characteristics of the fabric, ensuring it meets the specific needs of its intended use.

In addition, the selection process should consider potential environmental impacts and costs. Opting for sustainable monomers can minimize ecological footprints, aligning with modern industry standards.

Chain Reaction Mechanism

Understanding the chain reaction mechanism in the polymerization process is necessary for producing high-quality fabrics. You'll find that this complex series of chemical reactions directly influences the molecular structure of the polymers, which determines the fabric properties.

Initiating the chain reaction involves a catalyst that breaks double bonds in monomers, creating reactive sites. These reactive sites then link up with other monomers, forming long polymer chains.

In this process, controlling the reaction conditions is vital. Temperature, pressure, and the type of catalyst used can all impact the molecular structure of the resulting polymer. A well-controlled polymerization process ensures uniformity in the fabric, leading to consistent strength, elasticity, and durability—key fabric properties sought in textile innovation.

As you dive deeper, you'll recognize that mastering these chemical reactions allows for the creation of specialized fabrics. For instance, altering the polymer chain length can produce materials with varied flexibility or rigidity. This capability paves the way for advanced textile innovation, such as moisture-wicking athletic wear or ultra-soft, durable fabrics for everyday use.

Process Efficiency Factors

Maximizing the efficiency of the polymerization process hinges on fine-tuning reaction conditions such as temperature, pressure, and catalyst type. You need to understand that adjusting these parameters not only enhances reaction rates but also greatly impacts energy consumption. Lowering energy usage without compromising product quality is essential for sustainable manufacturing.

You'll find that waste reduction is another critical factor. By selecting the right catalysts and maintaining ideal reaction conditions, you can minimize by-products and unreacted monomers. This not only cuts down on waste but also improves the overall yield of the desired polymer.

Process automation plays a key role in productivity optimization. Automated systems allow you to maintain precise control over reaction parameters, ensuring consistent quality and reducing human error. Real-time monitoring and adjustments can lead to a more stable process, thereby increasing throughput and efficiency.

Incorporating advanced analytical techniques can further enhance your control over the polymerization process. Techniques such as real-time spectroscopy can provide invaluable insights into reaction kinetics and help you make data-driven decisions to fine-tune the process.

Spinning Techniques

Spinning techniques play an essential role in transforming raw fibers into yarn, which is necessary for fabric production. When you understand the intricacies of yarn formation, you'll appreciate how fiber properties influence the final product. The type of fiber—whether natural or synthetic—determines its tensile strength, flexibility, and durability. These properties directly impact the spinning process and the quality of the yarn produced.

To achieve a strong yarn, various twisting methods are employed. The twist binds the fibers together, enhancing yarn strength and stability. You'll find that the degree of twist varies depending on the desired texture and application of the yarn. For instance, a higher twist results in a firmer yarn, suitable for durable textiles.

Consider the following crucial elements in spinning techniques:

- Drafting: The process of drawing out fibers to align them before twisting.

- Roving: Intermediate stage where fibers are slightly twisted, preparing them for final spinning.

- Ring Spinning: A traditional method providing high-quality, consistent yarn.

Mastering these techniques requires a keen understanding of fiber behavior and the mechanical principles of spinning. With precise control over these factors, you can produce yarns with specific characteristics tailored to various fabric needs.

Fabric Weaving

When you explore fabric weaving, you'll encounter various weaving patterns like plain, twill, and satin. Each pattern requires specific materials and can benefit from chemical treatments to enhance durability and texture.

Understanding these elements helps you appreciate the intricate process behind creating woven fabrics.

Types of Weaving Patterns

Understanding the various types of weaving patterns is fundamental for anyone looking to master fabric production. You'll encounter an array of intricate designs, each bringing its own unique texture and strength to the fabric.

Among the most popular are twill patterns and Jacquard designs. Twill patterns are known for their diagonal lines, which give the fabric durability and flexibility, making them perfect for heavy-duty applications like jeans and workwear.

On the other hand, Jacquard designs offer complex and decorative patterns that are ideal for high-end textiles such as upholstery and fashion garments.

To achieve these sophisticated patterns, you'll need to familiarize yourself with advanced loom technology and keep abreast of textile innovations. Modern looms can be computer-controlled, allowing for precise and intricate designs that were once impossible to create by hand.

Mastering these weaving patterns requires dedication and a deep understanding of both the technical and artistic aspects of fabric production.

- Twill Patterns: Recognized for diagonal lines, providing strength and flexibility.

- Jacquard Designs: Complex, decorative, and perfect for upscale textiles.

- Loom Technology: From traditional handlooms to modern computer-controlled looms, understanding the technology is essential.

Materials and Chemical Treatments

To create fabrics with both aesthetic appeal and durability, selecting the right materials and employing specific chemical treatments is essential. You need to understand the intricacies of fabric weaving and how different materials respond to chemical reactions.

For instance, cotton fibers might require mercerization, which involves treating them with sodium hydroxide to increase their strength and luster. Wool, on the other hand, benefits from treatments that remove natural oils, making the fibers easier to dye and weave.

When you're dealing with synthetic fibers like polyester or nylon, chemical treatments can enhance properties like stain resistance and durability. These treatments often involve the application of resins or other polymer-based compounds that bond with the fiber at a molecular level. Understanding these chemical interactions allows you to fine-tune the characteristics of the final fabric.

However, it's important to take into account the environmental impact of these chemical treatments. Many traditional methods involve harsh chemicals that can be harmful to both workers and the environment. Opting for eco-friendly alternatives, such as enzyme-based treatments, can minimize this impact while maintaining high-quality fabric production.

Your mastery of these techniques ensures that you can produce superior fabrics responsibly.

Chemical Treatments

Chemical treatments play an essential role in enhancing the properties and durability of fabrics. When you think about the fabrics you use daily, it's not just about the material but also the chemistry behind its performance.

For instance, fabric softening treatments make your clothes feel more comfortable by reducing stiffness. These treatments also help in maintaining color fastness, ensuring that your garments retain their vibrant hues even after multiple washes.

In addition to softening and color preservation, you also benefit from treatments aimed at other properties:

- Wrinkle resistance: You can enjoy fabrics that stay smooth and require less ironing, thanks to specific chemical applications.

- Flame retardant: Safety is enhanced through treatments that decrease the fabric's flammability, making it less likely to catch fire.

- Stain resistance: Spills become less worrisome as certain treatments make fabrics more resistant to absorbing stains.

Dyeing Methods

When it comes to adding color to fabrics, several dyeing methods can achieve vibrant and lasting results. Immersion dyeing, for instance, involves soaking the fabric in a dye bath, allowing for excellent dye penetration and uniform color distribution. This method ensures remarkable color durability, especially when the dye and fabric are chemically compatible.

For those seeking precision, direct application techniques such as hand painting or tie-dyeing offer control over patterns and hues. These methods, though labor-intensive, allow for creative expression while maintaining strong dye penetration. However, the choice of dye is essential here; fiber-reactive dyes are often preferred for their superior color durability and ability to create bold, enduring shades.

When considering the environmental impact of dyeing, you need to be mindful of your dye selection. Natural dyes, derived from plants and minerals, present a more eco-friendly option, though they may require mordants to improve color durability.

Synthetic dyes, while offering a broader color range and greater consistency, can be harmful if not managed properly. Adopting low-impact dyeing processes and using biodegradable dyes can mitigate environmental harm.

Printing Techniques

Printing techniques bring intricate designs and vivid patterns to life on fabric, offering endless possibilities for creativity and customization. Whether you're aiming for bold, eye-catching motifs or subtle, elegant details, understanding the various printing methods can elevate your textile projects to new heights.

To master fabric printing, you need to take into account:

- Color fastness: Ensure your chosen technique maintains its vibrancy through washes and wear.

- Design innovation: Experiment with different styles to push the boundaries of what's possible.

- Sustainable practices: Opt for eco-friendly methods to minimize the environmental impact.

One popular technique is screen printing, known for its durability and high-quality results. You push ink through a mesh screen, creating sharp, consistent designs.

Digital printing, on the other hand, uses advanced technology to apply intricate patterns with precision, making it ideal for complex designs.

Block printing is a traditional method that involves hand-carved wooden blocks dipped in dye, offering a unique, artisanal touch.

Finishing Processes

Finishing processes enhance the final appearance, texture, and functionality of the fabric, ensuring it meets the desired quality standards. These processes are essential in tailoring the fabric to meet specific consumer preferences and align with market trends.

You can apply a variety of treatments, such as softening, water-repellent coatings, and wrinkle resistance, to modify the fabric's attributes to meet these demands.

Incorporating sustainable practices in finishing processes is pivotal. Traditional methods often have a significant environmental impact due to the chemicals and large amounts of water involved. By adopting eco-friendly alternatives like enzyme treatments and low-water finishing techniques, you can reduce this impact while still achieving high-quality results.

Pay close attention to market trends that increasingly favor sustainable and ethically produced textiles. Consumers today are more informed and selective, often prioritizing products with reduced environmental footprints. Offering fabrics that not only meet but exceed these expectations can set you apart in a competitive market.

Ultimately, mastering finishing processes allows you to create fabrics that aren't only aesthetically pleasing and functional but also aligned with the principles of sustainability and current consumer trends.

Quality Control

Maintaining high standards in fabric production doesn't stop at the finishing processes; rigorous quality control is key to guaranteeing that every piece meets the desired specifications. You need to implement a robust system that combines both automated inspection and hands-on testing. These methods safeguard that you catch any defects early and uphold the highest quality.

By incorporating production monitoring, you can track each stage and identify any discrepancies immediately. This proactive approach allows for quick defect analysis, saving both time and resources. Automated inspection systems, equipped with advanced sensors and imaging technologies, can scan vast amounts of fabric quickly, identifying inconsistencies that might be missed by the human eye.

However, don't underestimate the value of manual testing. Skilled technicians can provide a tactile assessment that machines can't replicate, ensuring a thorough evaluation of the fabric's quality.

Here's what you should focus on:

- Production Monitoring: Continuously track and analyze each phase to maintain quality and efficiency.

- Defect Analysis: Quickly identify and rectify any issues to minimize waste.

- Automated Inspection and Hands-On Testing: Combine both methods to ensure meticulous and accurate quality checks.

Frequently Asked Questions

How Do Environmental Regulations Impact Fabric Production?

Have you ever considered how government regulations shape fabric production? They enforce sustainability initiatives, ensuring eco-friendly practices. By adhering to these rules, you contribute to a greener planet and enhance your industry expertise.

What Are the Latest Innovations in Sustainable Fabric Production?

You'll find the latest innovations in sustainable fabric production focus on integrating the circular economy in textiles and utilizing bio-based fibers. Advanced technology guarantees these materials are renewable, reducing waste and promoting environmental responsibility.

How Does Fabric Production Affect Local Economies?

Fabric production's economic impact is substantial. You'll see job creation and stronger local supply chains, which drive community development. Supporting local economies guarantees sustainability, fostering growth and stability for businesses and residents alike.

What Historical Events Have Shaped Modern Fabric Production?

Did you know the Industrial Revolution increased fabric production by over 500%? Historical events like the Industrial Revolution and subsequent technological advancements have shaped modern fabric production, making it more efficient and globally impactful.

How Do Different Climates Affect Fabric Properties?

In different climates, fabric durability and moisture absorption vary. In humid climates, fabrics need better moisture absorption to stay comfortable. In dry climates, focus on fabric properties that resist wear and tear for enhanced durability.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024