If you want to produce high-quality meltblown nonwoven fabrics, you’ll focus on melting polymers like polypropylene, then extruding them through fine nozzles in a specialized die head. Controlling temperature, air velocity, and fiber collection shapes fabric properties critical for filtration and medical uses. You’ll also use equipment like extruders and collector drums while monitoring quality through fiber diameter and filtration tests. Understanding these fundamentals prepares you to explore advanced materials and manufacturing innovations next.

Key Takeaways

- Meltblown nonwovens are made by extruding molten polymer through fine nozzles, forming ultra-fine fibers collected into a fabric web.

- Polypropylene is the most common polymer used, with melt temperature, air velocity, and die-to-collector distance critically affecting fiber quality.

- Fiber diameter directly influences filtration efficiency, with meltblown fibers finer and denser than spunbond fibers for superior barrier properties.

- Additives like antibacterials and flame retardants enhance fabric functionality, while thermal and mechanical properties ensure durability.

- Innovations include biodegradable materials and nanotechnology integration, driving sustainability and automation in meltblown manufacturing processes.

Overview of Meltblown Technology

Although meltblown technology might seem complex, it’s actually a straightforward process that produces fine, nonwoven fabrics.

Meltblown technology transforms polymers into fine, nonwoven fabrics through a simple yet precise process.

You start by melting polymer resins, usually thermoplastics, then extruding them through tiny nozzles. High-velocity hot air streams stretch these molten fibers, making them extremely thin. As the fibers cool, they form a web on a collector belt.

You’ll notice this method creates fabrics with fine fiber diameters, often in the micro or sub-micron range, which gives the material unique filtration and barrier properties. This technique allows you to control fiber size and web density by adjusting air pressure, temperature, and polymer flow rate.

Meltblown fabrics are lightweight yet effective, making them ideal for applications like filtration, medical masks, and insulation.

Selection of Raw Materials for Meltblown Fabrics

When choosing raw materials for meltblown fabrics, you’ll want to take into account the types of polymers available and how they affect the final product.

Additives and enhancers play a key role in improving performance, so selecting the right ones is essential.

Don’t forget to prioritize quality and purity standards to guarantee consistent manufacturing results.

Polymer Types Overview

Since the choice of polymer directly impacts the performance and applications of meltblown fabrics, you need to understand the key types available.

Polypropylene (PP) dominates meltblown production due to its excellent melt flow, chemical resistance, and affordability. You’ll find it ideal for filtration, medical, and hygiene products.

Polyethylene (PE) offers flexibility and softness, making it suitable for wipes and packaging.

Polyester (PET) provides higher strength and thermal stability, useful in industrial applications.

Nylon (polyamide) brings durability and moisture resistance but requires careful processing.

Each polymer’s melting point, viscosity, and molecular weight affect fiber formation and fabric properties, so selecting the right polymer guarantees you meet your fabric’s functional requirements without compromising manufacturability.

Understanding these types lets you tailor meltblown fabrics precisely to your application needs.

Additives and Enhancers

Additives and enhancers play an essential role in tailoring meltblown fabrics to specific performance requirements. When selecting raw materials, you’ll consider additives like antibacterials, which improve hygiene, or flame retardants that boost safety.

You might also incorporate antistatic agents to reduce static buildup or hydrophobic additives to enhance water resistance. These substances integrate directly into the polymer melt, ensuring uniform distribution throughout the fabric.

You need to balance additive concentration carefully; too much can compromise fiber formation or mechanical properties. Additionally, processing aids like lubricants can improve melt flow and prevent equipment wear.

Quality and Purity Standards

Guaranteeing the quality and purity of raw materials directly impacts the performance and reliability of meltblown fabrics. When selecting polymers, you need to prioritize consistency in molecular weight and minimal contamination.

Impurities can cause weak spots or clog your equipment, reducing fabric strength and filtration efficiency. Look for suppliers who provide detailed quality certifications and conduct rigorous testing, including melt flow index and moisture content analysis.

You should also verify that additives meet purity standards and won’t introduce unwanted reactions during processing. By maintaining strict quality and purity standards, you guarantee your meltblown products perform reliably, whether for medical masks or industrial filters.

Polymer Melting and Extrusion Process

Before the polymer can be formed into fine fibers, you need to melt and extrude it carefully to maintain its quality.

Start by feeding the polymer pellets into the hopper, where they’re conveyed to the heated barrel. The temperature must be precisely controlled to fully melt the polymer without degrading it.

As the molten polymer reaches the screw tip, the pressure builds to push it through the die channels. You’ll want to monitor melt viscosity and temperature continuously, ensuring consistent flow.

Proper screw design and speed help maintain uniform melting and avoid polymer burn or unmelted fragments. By controlling these parameters, you set the foundation for producing homogenous fibers with the desired properties, which is critical for the performance of your meltblown nonwoven fabric.

Design and Function of the Meltblown Die Head

The meltblown die head plays an essential role in transforming molten polymer into fine fibers by precisely controlling flow and air distribution.

You’ll find that its design includes a narrow slot where the polymer exits, paired with a series of air nozzles positioned around this slot. These nozzles deliver high-velocity, heated air that attenuates the polymer stream, shaping the fibers before they solidify.

The die head’s internal channels guarantee uniform polymer flow, preventing variations that could affect fiber consistency. By adjusting air pressure and temperature, you control fiber thickness and web properties.

The die head must maintain tight tolerances and withstand high temperatures to guarantee continuous, stable operation. Understanding its design helps you optimize fiber quality and production efficiency in meltblown manufacturing.

Fiber Formation Mechanics in Meltblown Production

When you observe fiber formation in meltblown production, you’ll see that molten polymer is stretched and cooled rapidly to create ultra-fine fibers.

The process starts as the polymer melt exits tiny nozzles in the die head, where high-velocity hot air attenuates the polymer streams. This air flow draws the polymer into thin fibers, reducing their diameter dramatically.

Molten polymer exits tiny nozzles and is stretched by high-velocity hot air into ultra-fine fibers.

As these fibers cool quickly, they solidify into fine filaments. You control fiber diameter by adjusting factors like polymer viscosity, air temperature, and velocity.

If you increase air velocity or decrease polymer flow, fibers get thinner. Conversely, higher polymer viscosity leads to thicker fibers.

Understanding these mechanics helps you optimize fiber uniformity and quality, ensuring the meltblown fabric meets specific application requirements without compromising production efficiency.

Web Formation and Laydown Techniques

Although fiber formation is essential, you’ll find that how these fibers come together on the collector greatly impacts the final meltblown fabric quality.

Proper web formation and laydown techniques guarantee uniform fiber distribution and consistent fabric properties. As you manage the process, focus on:

- Collector Speed: Adjusting the speed affects fiber orientation and web density, influencing strength and filtration efficiency.

- Electrostatic Control: Managing static charges helps fibers spread evenly, preventing clumps and enhancing uniformity.

- Airflow Patterns: Optimizing air jets directs fibers precisely onto the collector, controlling web thickness and laydown consistency.

Bonding Methods for Meltblown Nonwovens

Now that you understand how the web forms, it’s essential to explore bonding methods that give meltblown nonwovens their strength.

You’ll mainly encounter thermal bonding techniques and chemical bonding processes to hold the fibers together.

Let’s look at how each method works and when you’d use them.

Thermal Bonding Techniques

Thermal bonding techniques play an essential role in enhancing the strength and durability of meltblown nonwovens by fusing fibers through controlled heat and pressure.

When you apply thermal bonding, you improve fabric integrity without adding chemicals.

Here are three common methods you’ll encounter:

- Calendar Bonding: You pass the meltblown fabric between heated rollers, which melt and bond fibers at contact points, creating a smooth, strong sheet.

- Ultrasonic Bonding: High-frequency vibrations generate heat at fiber intersections, bonding them instantly without external heat sources.

- Hot Air Bonding: Hot air jets fuse fibers by evenly heating the web, preserving softness while enhancing strength.

Each technique offers unique benefits, so you can select the best fit depending on your product’s flexibility, strength, and texture needs.

Chemical Bonding Processes

While thermal bonding relies on heat and pressure to join fibers, chemical bonding processes use adhesives or binders to enhance the strength and stability of meltblown nonwovens.

You apply liquid binders, often polymer-based, evenly across the fabric to create strong fiber-to-fiber connections once dried or cured. This method lets you customize the fabric’s properties—like flexibility, softness, or water resistance—depending on the binder type and application technique.

You can use spray, dip, or foam application methods, each offering different control levels over binder distribution.

Chemical bonding is especially useful when thermal bonding risks damaging delicate fibers or when you need specific performance attributes.

Key Process Parameters and Their Optimization

Because controlling key process parameters directly impacts the quality and efficiency of meltblown nonwoven manufacturing, you need to understand how each variable influences the final product.

Optimizing these parameters guarantees consistent fiber diameter, strength, and filtration performance. Focus on these critical factors:

- Polymer Melt Temperature – Adjust this to maintain polymer flow without degradation, guaranteeing uniform fiber formation.

- Air Temperature and Velocity – Control air conditions precisely to stretch fibers properly and achieve desired thickness and porosity.

- Die-to-Collector Distance – Set the right gap to allow fibers to cool and solidify correctly, affecting web uniformity and bonding.

Equipment Used in Meltblown Manufacturing Lines

You’ll find several key machinery components that keep meltblown manufacturing lines running smoothly.

Automation and control systems help you maintain consistent product quality and efficiency.

Regular maintenance and upkeep are essential to prevent downtime and extend equipment life.

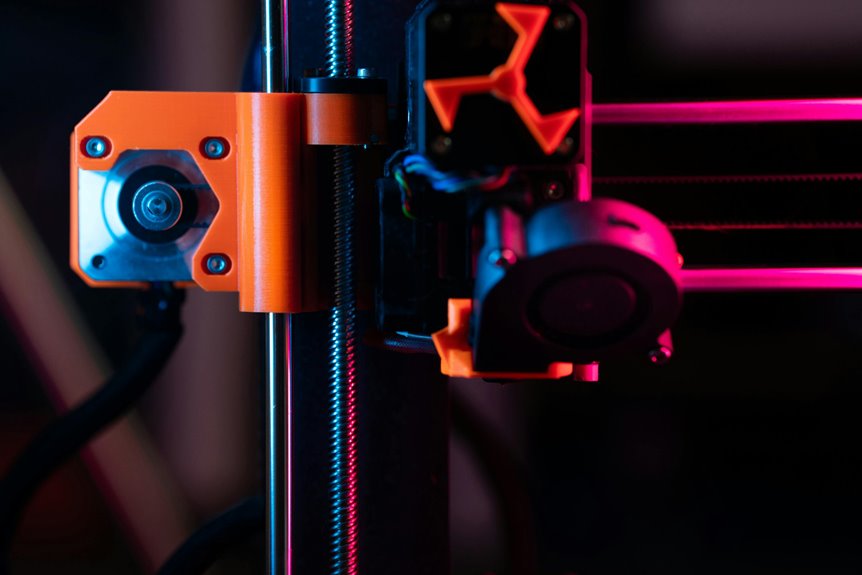

Key Machinery Components

Meltblown manufacturing lines rely on specialized machinery to transform polymer resins into fine, nonwoven fabrics.

To get the best results, you need to understand the key components that make this process possible.

- Extruder – This heats and melts the polymer pellets, pushing the molten material forward at a controlled rate.

- Die Head – Here, the molten polymer is forced through tiny nozzles, creating fine filaments that are immediately blown by high-velocity hot air to form fibers.

- Collector Drum – As fibers form, they’re collected on this rotating drum, which helps lay the fibers uniformly into a web.

Together, these components guarantee the fibers are consistently fine and evenly distributed, giving you high-quality meltblown fabric.

Automation and Controls

Although the core machinery shapes the fabric, automation and controls play an essential role in ensuring consistent quality and efficiency throughout the meltblown manufacturing process.

You’ll rely on advanced control systems to monitor parameters like temperature, air pressure, and polymer flow in real time. Programmable logic controllers (PLCs) adjust these variables instantly to prevent defects.

Automation also helps regulate the speed of the die and collector rolls, maintaining uniform fiber distribution. Sensors track the fabric’s thickness and weight, feeding data to your system for immediate corrections.

Maintenance and Upkeep

Keeping your machinery running smoothly demands regular maintenance and upkeep. Neglecting this can lead to costly downtime and reduced product quality.

Focus on these three key areas to keep your meltblown manufacturing line efficient:

- Routine Inspections: Check critical components like die heads, air blowers, and conveyors for wear or damage. Early detection prevents unexpected failures.

- Cleaning and Lubrication: Regularly clean build-up from nozzles and apply lubricants to moving parts. This guarantees consistent fiber formation and prevents mechanical issues.

- Calibration and Testing: Frequently calibrate temperature controls, pressure gauges, and automation sensors. Proper calibration keeps production parameters within specs, maintaining product consistency.

Quality Control and Testing of Meltblown Fabrics

Because the performance of meltblown fabrics depends heavily on their structural integrity and filtration efficiency, rigorous quality control and testing are essential throughout the manufacturing process.

You should regularly measure fiber diameter, basis weight, and thickness to guarantee uniformity. Filtration efficiency tests, such as particle penetration and airflow resistance, help verify that the fabric meets your required standards.

Mechanical properties like tensile strength and elongation also need assessment to confirm durability. Visual inspections can quickly identify defects like holes or inconsistent fiber distribution.

Common Challenges and Troubleshooting Tips

When you run into issues during meltblown nonwoven production, identifying the root cause quickly can save time and materials.

Common challenges often stem from equipment, material, or process inconsistencies. Here’s how you can troubleshoot effectively:

- Web Uniformity Problems: Check die temperature and air pressure. Variations cause uneven fiber distribution. Adjust settings to stabilize output.

- Clogged Die Tips: Inspect the die for polymer buildup. Regular cleaning prevents blockages that lead to fiber breakage or web defects.

- Poor Bonding Strength: Verify polymer melt temperature and throughput. Insufficient heat or flow disrupts fiber bonding, weakening the fabric.

Applications and Future Trends in Meltblown Materials

Although meltblown nonwoven fabrics have been around for decades, their applications keep expanding rapidly as new industries discover their unique benefits.

You’ll find meltblown materials in filtration systems, medical masks, and hygiene products due to their excellent fine fiber structure and filtration efficiency.

Emerging uses include battery separators and oil spill cleanup, showcasing their versatility.

Meltblown fabrics are proving versatile with innovative uses like battery separators and oil spill cleanup.

As you explore future trends, expect advancements in biodegradable polymers to make meltblown fabrics more eco-friendly.

Additionally, integrating nanofibers and functional additives will enhance performance, opening doors to smart textiles and wearable technology.

By staying updated on these trends, you can leverage meltblown technology to innovate and meet evolving market demands effectively.

Embracing sustainability and multifunctionality will define the next era of meltblown nonwoven manufacturing.

Frequently Asked Questions

How Does Meltblown Fabric Compare to Spunbond in Cost?

You’ll find meltblown fabric costs about 20-30% more than spunbond due to its finer fiber production process. But don’t worry, its superior filtration often justifies the extra expense in many applications you use it for.

What Environmental Impacts Are Associated With Meltblown Production?

You’ll find meltblown production uses significant energy and releases volatile organic compounds. Plus, it relies on petroleum-based polymers, contributing to pollution and waste. So, you should consider sustainable practices to reduce its environmental footprint.

Are Meltblown Nonwovens Recyclable or Biodegradable?

Meltblown nonwovens aren’t typically biodegradable since they’re made from synthetic polymers. Recycling options exist but can be limited due to contamination and material complexity. You should check local recycling programs for proper disposal methods.

What Safety Precautions Are Needed in Meltblown Manufacturing Plants?

You should treat safety like a shield, always wearing protective gear, ensuring proper ventilation, and handling high temperatures carefully. Don’t ignore emergency protocols, and keep machines well-maintained to prevent accidents in the plant.

How Long Does It Take to Set up a Meltblown Production Line?

Setting up a meltblown production line usually takes several weeks to a few months. You’ll need time for equipment installation, calibration, testing, and staff training to guarantee everything runs smoothly and safely.