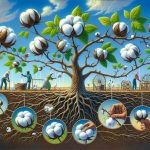

Are you curious about how cotton fabric is made? In this step-by-step guide, we will take you through the entire process.

From planting the cotton seeds to weaving the final fabric, you will learn about each stage of production.

Get ready to dive into the fascinating world of cotton fabric and discover the intricate timeline behind its creation.

Table of Contents

Cotton Seed Planting

To begin the process of cotton fabric production, you’ll need to plant cotton seeds in a well-prepared soil. Cotton seed germination is an essential step in the growth of cotton plants. Before planting, it’s important to treat the cotton seeds to enhance their germination rate. Cotton seed treatment involves the application of fungicides and insecticides to protect the seeds from diseases and pests. This treatment also helps in improving seedling emergence and early plant growth.

Once the seeds are treated, they can be planted in the soil. It’s recommended to plant the seeds at a depth of about half an inch. The soil should be moist but not overly wet to ensure proper germination. After planting, the seeds need to be covered lightly with soil and gently pressed down to ensure good seed-to-soil contact.

Cotton seed germination usually takes around 7 to 10 days, depending on the temperature and moisture conditions. During this time, it’s important to provide adequate water and maintain a consistent temperature to support seed germination. Once the seeds have germinated, they’ll begin to develop into cotton plants, marking the start of the cotton fabric production process.

Harvesting Cotton Bolls

After the cotton plants have fully grown and the cotton bolls have matured, it’s time for you to harvest the cotton. This is a crucial step in the cotton fabric production timeline as it determines the quality and yield of the cotton fibers.

Cotton boll picking techniques play a significant role in ensuring a successful harvest. When picking cotton bolls, it’s important to use gentle hand-picking methods to avoid damaging the fibers. This involves carefully plucking the bolls from the plant, ensuring that the cotton fibers remain intact.

Additionally, it’s crucial to harvest cotton at the right time. Picking the bolls at their peak maturity ensures that the fibers are of optimal quality, length, and strength. Harvesting too early or too late can result in lower quality fibers, affecting the final fabric’s durability and appearance. Therefore, timing is key in achieving the desired cotton fiber characteristics.

Ginning and Separating the Fibers

Start by ginning the harvested cotton bolls to separate the fibers. Ginning is a critical step in the cotton fabric production timeline as it ensures the quality of the cotton fibers.

Here’s a step-by-step breakdown of the ginning process:

-

Step 1: Feeding the Cotton Bolls

-

The cotton bolls are fed into the gin, a machine specifically designed to remove the seeds from the cotton fibers.

-

As the bolls pass through the gin, revolving saws or teeth grip the fibers, pulling them away from the seeds.

-

Step 2: Separating the Fibers

-

Once the fibers are separated from the seeds, they’re collected and formed into a fluffy mass known as lint.

-

The lint is then cleaned to remove any remaining impurities such as dirt, leaves, or other plant matter.

The importance of the ginning process can’t be overstated when it comes to cotton fiber quality. Proper ginning ensures that the fibers aren’t damaged or tangled, resulting in higher quality cotton. It also helps to remove any debris that could affect the fabric’s appearance or functionality.

Spinning Yarn From Cotton Fibers

Begin by spinning the cotton fibers into yarn, a crucial step in the cotton fabric production timeline. Spinning is the process of twisting the cotton fibers together to form a continuous strand of yarn. This step transforms the loose cotton fibers into a strong and durable material that can be used to create various types of cotton fabrics.

To give you a better understanding of the cotton yarn manufacturing process, let’s take a look at the table below which highlights the main steps involved:

| Cotton Fiber Processing Techniques | Description |

|---|---|

| Carding | Aligns the cotton fibers and removes any impurities, creating a thin web of fibers. |

| Drawing | Combines multiple carded strands of cotton fibers to create a single, stronger strand. |

| Roving | Further reduces the thickness of the drawn strand by twisting it and stretching it out. |

| Spinning | Twists the roving to create the final cotton yarn, ready for weaving or knitting into fabric. |

Each of these steps plays a vital role in producing high-quality cotton yarn. From carding to spinning, the cotton fibers undergo various processes to ensure the yarn is consistent, strong, and suitable for different fabric applications.

Weaving the Final Cotton Fabric

To weave the final cotton fabric, you’ll need to operate a loom to interlace the cotton yarns together. This step is crucial in creating a strong and durable fabric.

Here are the cotton fabric weaving techniques and different types of looms used in cotton fabric production:

-

Cotton Fabric Weaving Techniques:

-

Plain Weave: This is the simplest and most common weaving technique, where each weft yarn passes over and under each warp yarn.

-

Twill Weave: This technique creates a diagonal pattern on the fabric, making it more durable and resistant to wrinkles.

-

Different Types of Looms Used in Cotton Fabric Production:

-

Handloom: Traditionally operated by hand, these looms are still used in some regions. They require skilled weavers who manually control the weaving process.

-

Power Loom: These automated machines utilize power sources such as electricity or water to weave fabric at a faster pace. They’re commonly used in large-scale cotton fabric production.

Frequently Asked Questions

How Is Cotton Fabric Dyed or Printed With Patterns and Designs?

To dye or print patterns and designs on cotton fabric, you can use various cotton fabric dyeing techniques and printing methods. These techniques and methods allow you to add color and patterns to the fabric, creating unique and vibrant designs.

What Are Some Common Uses for Cotton Fabric in Everyday Life?

Cotton fabric is commonly used in everyday life for clothing, bedding, and home decor. It has benefits like breathability and softness, but drawbacks include shrinking and wrinkling. Sustainable practices in production help reduce environmental impact.

Are There Any Environmental Concerns Associated With Cotton Fabric Production?

Yes, there are environmental concerns associated with cotton fabric production. It has a significant impact on water usage, pesticide use, and soil degradation. However, sustainable practices like organic farming can help mitigate these effects.

How Does the Quality of Cotton Affect the Final Fabric Product?

The quality of cotton has a direct impact on the durability and texture of the final fabric product. Higher quality cotton results in more durable fabric and a softer, smoother texture.

What Are Some Alternative Materials That Can Be Used to Make Fabric, Besides Cotton?

There are many sustainable fabric options available that can be used as alternative materials for fabric production. These options include hemp, bamboo, linen, and recycled polyester.

- Tetron Fabric for Marine Applications: Durability and Use Cases - June 18, 2025

- Tetron Fabric for Outdoor Furniture: Weather Resistance and Care - June 18, 2025

- Tetron Fabric for Wall Coverings: Style and Application Tips - June 18, 2025