I once compared silkscreen printing to meticulously layering a decadent cake with each color adding depth and richness, while heat press transfers felt more like the precision of a skilled baker applying the final delicate decorations to a masterpiece.

Both methods have their unique strengths and applications, appealing to different needs and preferences in the realm of custom printing.

But which one reigns supreme in the world of garment decoration and branding? Let's unravel the layers of this debate and uncover the best-suited technique for your next project.

Key Takeaways

- Silkscreen printing offers lasting impressions and intricate designs with deep color penetration.

- Heat press excels in replicating complex and colorful designs with efficient design placement.

- Silkscreen is preferred for durability, lasting around 40-50 washes, while heat press transfers offer more design complexity.

- Silkscreen printing is faster in production speed, ideal for high-volume orders, while heat press is efficient for small custom orders.

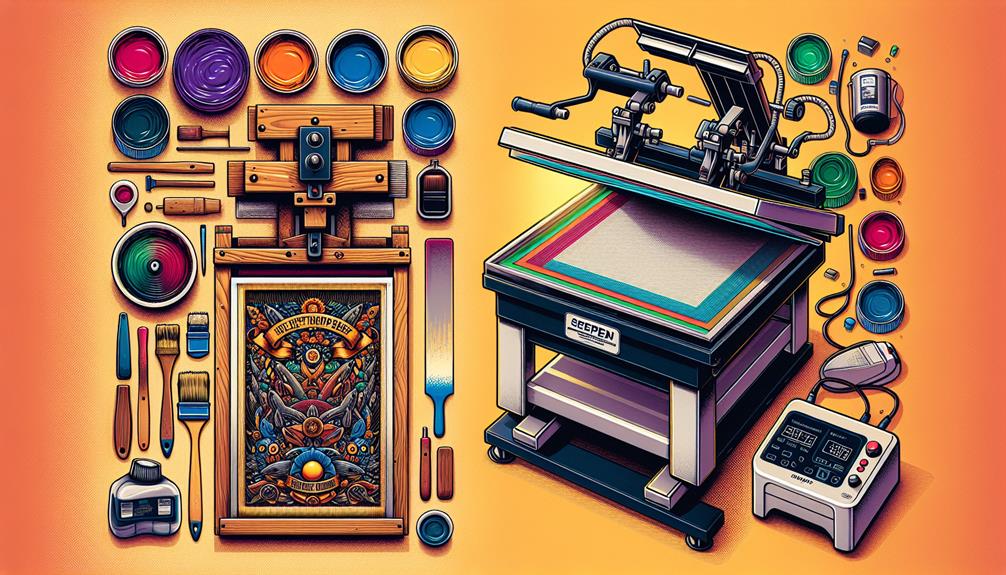

Silkscreening Overview

Silkscreen printing, also known as screen printing, is a versatile and popular method for transferring designs onto fabric with vibrant and long-lasting results. This technique, utilizing silk screening, allows for the creation of intricate multi-colored designs by utilizing different screens for each color.

The process is renowned for its efficiency, making it ideal for large volume orders due to its cost-effectiveness. One of the key advantages of silkscreen printing is its durability; the colors penetrate deeply into the fabric, ensuring that the images remain vibrant and intact for an extended period.

The meticulous nature of silkscreening results in high-quality prints that can withstand the test of time, making it a preferred choice for many seeking a lasting impression. The ability to produce intricate designs with multiple colors efficiently while maintaining durability sets silkscreen printing apart as a reliable and effective method for fabric customization.

Heat Press Basics

When exploring the realm of fabric customization methods, one can't overlook the fundamental technique of heat press application. Heat press involves using heat and pressure to transfer designs onto garments efficiently. It's a versatile method commonly used for applying various types of transfers such as vinyl, screen printing, and digital transfers. One of the key advantages of heat press is its ability to work well on oddly-shaped items like hats and bags, providing flexibility in design placement.

Different types of transfers cater to various design needs, allowing for a wide range of customization options. For example, vinyl transfers are great for single-color designs, while screen printing transfers are ideal for intricate and multi-colored designs. Heat press also offers cost advantages, as discounts often increase with larger order quantities for transfers.

Understanding the basics of heat press is crucial for mastering fabric customization techniques, offering a practical and efficient way to bring designs to life on clothing and accessories.

Cost Considerations

When comparing silkscreen and heat press methods, the cost considerations are crucial. Equipment cost differences and production expense comparisons play pivotal roles in deciding between the two techniques. Understanding these financial aspects is key to making an informed choice for your printing needs.

In addition to the financial aspects, other factors such as the complexity of the design, the type of fabric being used, and the desired durability of the print should also be taken into account. Each method has its own advantages and limitations, so evaluating all these factors will help you determine which method is best suited for your specific project.

Equipment Cost Differences

Considering the initial investment required for equipment, the cost differences between silkscreen and heat press setups can vary significantly.

- Silkscreen equipment costs range from $100 to $1,000, based on quality and features.

- Heat press equipment starts around $200 for basic models and can exceed $1,500 for commercial-grade machines.

Silkscreen requires frames, emulsion, squeegees, and ink, adding to the initial investment.

- Heat press necessitates heat transfer paper, vinyl, or digital transfers, with costs varying by quality and quantity.

Silkscreen equipment costs can be higher upfront due to needing multiple tools and materials for the printing process.

These differences in equipment costs should be carefully considered when choosing between silkscreen and heat press methods for your printing needs.

Production Expense Comparison

To effectively compare the production expenses between screen printing and heat press transfers, we need to delve into the cost considerations associated with each method. Screen printing typically incurs higher initial setup costs due to screen preparation and ink mixing.

On the other hand, heat press transfers are more cost-effective for small custom orders due to their lower setup costs. As volume orders increase, screen printing becomes more economical since setup costs are spread out.

Heat press transfers require less setup time and materials, making them ideal for quick turnarounds. When analyzing production expenses, screen printing may have a higher cost per unit for small orders compared to heat press transfers.

Therefore, understanding the setup costs and order volume is crucial in determining the most cost-efficient method for your printing needs.

Durability and Longevity

In terms of durability and longevity, screen printing stands out for its ability to maintain designs through around 40-50 washes due to the ink deeply penetrating the fabric. Screen printing is known for its lasting power, making it a popular choice for items that will go through regular wear and tear.

Here are some key points to consider:

- Screen printing designs can withstand approximately 40-50 washes.

- The ink in screen printing penetrates deep into the fabric, enhancing durability.

- Longevity is a strong suit of screen printing compared to heat press transfers.

- Heat press transfers may offer more color and design complexity but tend to have a shorter lifespan.

- When it comes to long-lasting images, screen printing is the preferred choice over heat press transfers.

Understanding the durability and longevity aspects of both techniques can help you make an informed decision based on your specific needs and preferences.

Design Complexity

When exploring design complexity in printing techniques, heat press transfers shine for their ability to accurately replicate intricate and colorful designs, making them ideal for detailed artwork. Heat press transfers offer a remarkable advantage over silkscreen printing when it comes to complex designs. With heat press transfers, the intricate details and multiple colors in a design can be faithfully reproduced on fabric. This flexibility allows for a wider range of creative possibilities, making heat press transfers the go-to choice for artists and designers looking to bring elaborate visions to life.

On the other hand, silkscreen printing is better suited for simpler designs with fewer colors. This is because silkscreen printing requires separate screens for each color used in the design, limiting the complexity that can be achieved. Therefore, when it comes to intricate and multicolored designs, heat press transfers outperform silkscreen printing in capturing the nuances and vibrancy of the artwork.

Production Speed

When it comes to production speed in silkscreen versus heat press, there are key points to consider.

Silkscreen may have advantages in certain aspects, but heat press efficiency often stands out in comparison.

Understanding the differences in production time can help determine the best method for each unique printing need.

Silkscreen Speed Advantage

With its ability to swiftly apply ink through efficient screen setups, silkscreen printing outpaces heat press transfers in production speed.

- Setting up screens for different colors in advance boosts efficiency.

- Silkscreen printing is known for its rapid application of ink onto various surfaces.

- Ideal for high-volume orders due to its speedy process.

- The manual nature of silkscreen printing allows for quick turnaround times.

- Quality is maintained even with the high printing speed, making it a top choice for large quantities.

Heat Press Efficiency Comparison

Heat press machines showcase superior efficiency in production speed compared to silkscreen printing. When it comes to heat transfer methods, heat press stands out for its faster production speed, allowing designs to be transferred in a matter of seconds. This rapid processing capability makes heat press an efficient printing solution, especially for businesses needing quick turnaround times or handling small custom orders.

Unlike screen printing, which involves more manual labor and setup time, heat press machines offer rapid processing capabilities ideal for on-demand production. The efficiency of heat press machines caters to businesses that require fast and efficient printing solutions, making them a preferred choice for those looking to optimize their production speed.

Production Time Differences

Moving from discussing the efficiency of heat press machines in the previous subtopic, it's evident that production time differences play a crucial role in comparing silkscreen printing to heat press transfers.

When considering screen printing versus heat press transfers, the following points highlight the key differences in production time:

- Screen printing involves creating screens and applying ink, leading to longer production times.

- Heat press transfers are quicker as they utilize pre-made designs applied with heat and pressure.

- Setup time for screen preparation and alignment is longer in screen printing, impacting overall production speed.

- Heat press transfers excel in quick turnaround times, especially for small custom orders or individual designs.

- For time-sensitive projects or last-minute orders, heat press transfers offer quicker production, making them a preferred choice.

Material Compatibility

When considering material compatibility between silkscreen and heat press methods, various fabrics such as cotton, polyester, and blends are well-suited for screen printing, while heat press transfers excel on materials like polyester, cotton, nylon, and leather. Screen printing is known for its effectiveness on flat surfaces, ensuring consistent ink application, making it a great choice for cotton and polyester garments. On the other hand, heat press transfers offer versatility, allowing designs to be applied on curved or irregular surfaces like nylon and leather. Both methods provide customization options to meet different garment needs. Below is a comparison table showcasing the material compatibility for screen printing and heat press transfers:

| Fabric | Screen Printing Compatibility | Heat Press Transfer Compatibility |

|---|---|---|

| Cotton | ✔ | ✔ |

| Polyester | ✔ | ✔ |

| Blends | ✔ | ✔ |

| Nylon | ✔ | |

| Leather | ✔ |

Environmental Impact

Screen printing's environmental friendliness surpasses that of heat press transfers due to its utilization of water-based inks and minimal waste generation. When considering the environmental impact of these printing methods, it becomes evident that screen printing offers a more sustainable approach. Here are some key points to highlight this fact:

- Screen printing uses water-based inks that are more environmentally friendly compared to the chemicals involved in heat press transfers.

- Heat press transfers can produce more waste from vinyl material and transfer paper, contributing to a higher environmental impact.

- Screen printing allows for sustainable practices such as reusing screens and reducing overall material waste, promoting a greener printing process.

- Heat press transfers may involve chemicals and materials that are less eco-friendly than those used in screen printing methods.

- Choosing screen printing over heat press transfers can play a significant role in lowering the environmental footprint of the printing industry.

Customization Options

When it comes to customization options, both silkscreen and heat press offer unique advantages.

Heat press allows for a wide range of color choices, perfect for intricate and vibrant designs.

On the other hand, silkscreen printing excels in durability and can achieve precise details with simplicity.

Color Choices Available

Curious about the range of color choices available for customization in silkscreen and heat press printing methods? When it comes to color options, both screen printing and heat press transfers offer a variety of choices to suit your design needs. Here are some key points to consider:

- Silkscreen printing allows for precise color matching with custom-mixed inks for each design.

- Heat press transfers offer the flexibility of using a wide range of color options, including vibrant and neon colors.

Silkscreen printing can achieve rich and consistent colors by layering inks, enhancing design customization.

- Heat press transfers can incorporate gradients and shading effects, providing versatile color choices for intricate designs.

- Both silkscreen and heat press methods offer the ability to create multi-colored designs, but heat press transfers excel in detailed color variations.

Durability of Designs

For lasting designs that offer a range of customization options, both screen printing and heat press transfers have distinct advantages. Screen printing boasts superior durability, with designs lasting up to 40-50 washes, ensuring long-lasting quality.

On the other hand, heat press transfers tend to have a shorter lifespan, making them more suitable for short-term use. When it comes to customization options, screen printing allows for intricate designs and multiple colors, providing a high level of personalization.

Heat press transfers, however, offer more flexibility in color choice and design complexity, catering to specific customization needs. In terms of durability and customization options, screen printing excels in long-lasting quality, while heat press transfers offer versatility for various design requirements.

Detail Precision Achievable

With silkscreen printing, achieving intricate detail precision is made possible by utilizing fine mesh screens in the process. This method allows for customization options that cater to fine details and precise artwork reproduction.

When it comes to intricate designs, screen printing excels in providing:

- Ability to capture intricate details accurately

- Precision in replicating complex patterns

- Customization options for each color layer

- High-quality results for detailed customization

- Suitable for precise artwork reproduction

These features make silkscreen printing the preferred choice when aiming for detailed customization and intricate designs on garments. The fine mesh screens used in the process ensure that even the most delicate elements are accurately transferred onto the material.

Maintenance Requirements

To maintain silkscreen equipment effectively, regular cleaning of screens with emulsion remover and proper storage in a cool, dry place are crucial steps for preserving image quality and ensuring longevity. Additionally, inspecting screens for damage or wear is essential to maintain print quality and avoid rework. Utilizing quality screen printing accessories such as squeegees and scoop coaters can also contribute to efficient maintenance practices. Implementing a consistent cleaning schedule and adhering to manufacturer recommendations for emulsion and ink can significantly extend the life of your silkscreen equipment.

| Maintenance Tips | Description | Importance |

|---|---|---|

| Regular Cleaning | Clean screens with emulsion remover to maintain image quality and prevent ink buildup. | Essential |

| Proper Storage | Store screens in a cool, dry place to prevent damage and ensure longevity. | Crucial |

| Quality Accessories | Use squeegees and scoop coaters to enhance maintenance practices and achieve optimal printing results. | Beneficial |

Final Verdict: Choosing the Right Method

When deciding between silkscreen and heat press methods, consider the complexity of your design and the number of colors required. Here are some key points to help you choose the right method:

- Screen Printing for Detailed Designs: Silkscreen printing offers superior quality and durability, making it ideal for intricate and detailed designs.

- Cost-Efficiency for Large Orders: If you have a large order quantity, silkscreen printing is cost-effective due to its efficiency in handling bulk orders.

- Heat Press for Small Custom Orders: Heat press transfers are perfect for small custom orders where flexibility and quick turnaround are essential.

- Challenging Shapes: Heat press methods are suitable for items with challenging shapes like hats and bags, providing a seamless application.

- Quality Consideration: Evaluate the quality needed for your designs; silkscreen is known for its long-lasting and vibrant results, while heat press can be a great option for certain applications.

Considering these factors will help you make an informed decision based on your specific requirements and the desired outcome for your project.

Frequently Asked Questions

Which Is Better Silk Screen or Heat Press?

When deciding between silk screen and heat press, it depends on the goal. Silk screen shines in durable, long-lasting prints. In contrast, heat press excels in intricate, detailed designs that pop. Each method brings its unique strengths to the customization game.

What Are 4 Disadvantages to Silkscreen Printing?

Maintenance of screens, time-consuming setup, limited detail options, and higher costs for small orders are four disadvantages of silkscreen printing. It's crucial to consider these factors when choosing a printing method for designs.

Is Heat Press More Expensive Than Screen Printing?

In my experience, heat press can be pricier than screen printing due to setup costs and materials. However, for small custom orders, the flexibility and speedy results make heat press a worthwhile investment despite the initial expense.

Can You Use a Heat Press for Screen Printing?

Yes, a heat press can be used for screen printing by transferring designs onto fabrics. It's a versatile method for custom orders and smaller items. The process involves applying heat and pressure to create durable, vibrant designs.