Scrim fabric features unique weaves like the strong leno weave, which twists warp threads to provide durability and stability, and the breathable open mesh weave, known for its light, airy structure with larger openings. You’ll find leno weaves great for reinforcement and shade, while open mesh suits ventilation and flexibility needs in sportswear or netting. If you want to explore how these weaves affect your project’s strength, airflow, and cost, there’s plenty more to uncover.

Key Takeaways

- Scrim fabric is a lightweight, loosely woven material allowing air and light to pass through, used for reinforcement and ventilation.

- Leno weave twists adjacent warp threads, creating a strong, stable mesh ideal for durability and controlled openness in applications like shade cloth.

- Open mesh weave features larger, evenly spaced holes, providing excellent breathability, flexibility, and lightweight feel, suitable for sportswear and netting.

- Different scrim weaves vary in strength, openness, and flexibility, influencing their suitability for projects like filtration, protective coverings, or architectural uses.

- Cost and durability depend on weave type; tight weaves like leno offer longevity, while open mesh prioritizes flexibility and ventilation for lightweight uses.

Understanding the Basics of Scrim Fabric

Scrim fabric is a lightweight, loosely woven material that offers strength without bulk. When you work with scrim, you’ll notice it’s often used as a reinforcing layer in various applications, from theatre backdrops to construction.

Its open weave structure allows air and light to pass through, making it versatile for different environments. You’ll find scrim made from materials like cotton, polyester, or fiberglass, each lending unique properties.

Characteristics of Leno Weave in Scrim

One key feature you’ll notice in scrim fabric is the leno weave, which twists adjacent warp threads around each other to create a strong, open mesh.

This twisting technique locks the threads in place, preventing them from shifting and providing excellent stability. You’ll find that leno weave offers durability without sacrificing breathability, making it ideal for applications requiring both strength and airflow.

The open structure also allows light and air to pass through easily, which is why leno weave scrim is popular in construction and decoration.

Its open structure lets light and air flow freely, making leno weave scrim perfect for building and decor.

Additionally, the weave’s resistance to distortion means you can count on consistent performance even under tension or stress.

When working with scrim fabric, understanding leno weave helps you appreciate its balance between openness and toughness.

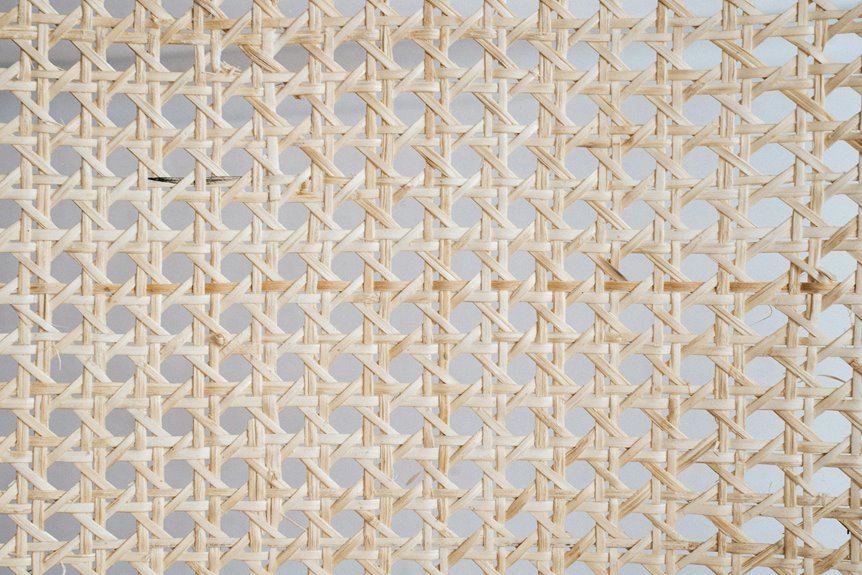

Exploring Open Mesh Weave Structures

Although open mesh weave structures may seem simple, they play an essential role in providing flexibility and ventilation in various fabric applications.

When you work with open mesh fabrics, you’ll notice their distinctive pattern of evenly spaced holes created by the weaving technique. This design allows air and light to pass through freely, making it ideal for uses where breathability is vital, like outdoor gear or protective coverings.

You’ll also appreciate how the open structure gives the fabric a lightweight feel without sacrificing strength. Plus, the weave’s flexibility means it can conform to different shapes easily, enhancing comfort and usability.

Understanding these features helps you select the right open mesh fabric for your specific needs, balancing durability with airflow effectively.

Comparing Leno Weave and Open Mesh Fabrics

You’ll notice that leno weave offers a strong, stable structure by twisting yarns together, which keeps the fabric from shifting.

Open mesh fabrics, on the other hand, provide excellent breathability and flexibility due to their wider gaps.

Understanding these differences helps you choose the right fabric for your needs.

Leno Weave Characteristics

Leno weave stands out for its unique construction, which twists warp yarns around weft yarns to create a strong yet open fabric structure. This twisting technique locks yarns in place, preventing distortion and enhancing durability. When you handle leno weave fabric, you’ll notice it balances breathability with exceptional stability, making it ideal for applications needing both strength and airflow.

Here’s a quick comparison of leno weave characteristics:

| Feature | Leno Weave | Open Mesh |

|---|---|---|

| Strength | High due to twisted yarns | Moderate, less stable |

| Openness | Moderate, controlled gaps | Larger, more porous |

| Durability | Excellent, resists distortion | Lower, can snag easily |

| Use Cases | Shade cloth, curtains | Sportswear, netting |

Open Mesh Advantages

Open mesh fabrics offer distinct advantages that make them a favorite in applications where breathability and flexibility matter most.

Unlike leno weave, open mesh creates larger, more uniform openings, allowing air and moisture to pass through easily. This makes it ideal for sportswear, outdoor gear, and industrial filters where ventilation is essential.

You’ll also appreciate how open mesh stretches and flexes without losing its shape, giving you comfort and durability.

While leno weave locks yarns tightly for strength, open mesh balances strength with lightweight softness.

If you need fabric that promotes airflow and adapts to movement, open mesh stands out. It’s your go-to when flexibility and breathability top your list of priorities, outperforming leno weave in those key areas.

Practical Applications of Different Scrim Weaves

You’ll find different scrim weaves serve specific purposes across industries, from reinforcing materials in construction to enhancing durability in textiles.

Understanding these weaves helps you pick the right fabric for your industrial or architectural project.

Let’s explore how each weave benefits various practical applications.

Industrial Uses

Because scrim fabrics offer strength and breathability, industries rely on them for various practical applications. You’ll find scrim weaves used in reinforcement, filtration, and protective coverings. Their durability guarantees materials hold up under stress, while the open mesh allows airflow and visibility. Here’s a quick look at common industrial uses:

| Application | Scrim Type | Benefit |

|---|---|---|

| Reinforcement | Leno Weave | High tensile strength |

| Filtration | Open Mesh | Allows air and liquid flow |

| Protective Cover | Basket Weave | Durable, abrasion-resistant |

When you choose scrim fabric, consider the weave that best matches your industrial needs for ideal performance.

Architectural Applications

Although scrim fabrics have industrial strengths, their architectural applications truly showcase their versatility.

When you use different scrim weaves, you can enhance buildings both functionally and aesthetically.

Here are four practical ways scrim fabrics contribute to architecture:

- Sun Control: Open mesh scrims reduce glare and heat while allowing natural light.

- Facade Reinforcement: Leno weave scrims add strength and stability to exterior surfaces.

- Acoustic Panels: Dense scrims help absorb sound, improving indoor acoustics.

- Decorative Elements: Various scrim weaves create textured visual effects on walls and ceilings.

Textile Manufacturing Benefits

Beyond architecture, scrim weaves offer significant advantages in textile manufacturing. When you choose scrim fabrics, you benefit from their lightweight yet durable nature, perfect for reinforcing delicate textiles without adding bulk.

The open mesh structure improves breathability, making scrim ideal for sportswear and outdoor gear where ventilation matters. You’ll also find scrim’s strength valuable in composite fabrics, providing stability during production and enhancing the final product’s resilience.

Different weave types, like leno weave, prevent yarn slippage, ensuring consistent fabric quality. Plus, scrim’s flexibility allows you to customize fabric properties for specific applications, from upholstery to industrial filters.

Selecting the Right Weave for Your Project

How do you choose the best scrim fabric weave for your project? Start by evaluating your specific needs—strength, transparency, and flexibility all matter.

Choosing the right scrim fabric weave starts with assessing your project’s strength, transparency, and flexibility needs.

Consider what environment the fabric will face and how much durability you require. Here’s a quick guide to help you decide:

- Strength Needs: Opt for leno weave when you need high tear resistance.

- Visibility: Choose open mesh if you want maximum airflow and visibility.

- Flexibility: Pick a loose weave for projects requiring more stretch.

- Cost Efficiency: Tight weaves often cost more but offer better longevity.

Frequently Asked Questions

How Do Environmental Factors Affect Scrim Fabric Durability?

You’ll find that environmental factors like UV exposure, moisture, and temperature swings weaken scrim fabric over time. They cause fibers to degrade, reducing durability, so you should choose fabrics suited for your specific conditions to guarantee longer life.

Can Scrim Fabric Be Recycled or Reused?

You’re in luck—scrim fabric isn’t just a one-time wonder. You can give it a second life through recycling or creative reuse, turning it into new products or craft materials, helping the planet while saving resources.

What Are the Common Maintenance Practices for Scrim Fabrics?

You should regularly clean scrim fabrics with gentle soap and water, avoid harsh chemicals, and store them dry to prevent mold. Inspect for tears and repair promptly to extend their lifespan and maintain strength.

Are There Any Health Risks Associated With Scrim Fabric Dust?

You wouldn’t want to breathe in scrim fabric dust—it can irritate your lungs and eyes like a thousand tiny needles. Always wear a mask and guarantee good ventilation to keep yourself safe and healthy.

How Does Scrim Fabric Compare to Other Industrial Textiles?

You’ll find scrim fabric offers excellent strength and durability compared to other industrial textiles. It’s lightweight yet tough, often used for reinforcement. Its open weave also provides breathability, which many alternatives lack.