Imagine wearing a jacket that keeps you cool during a heatwave and warm during a cold snap—this is possible with phase-change materials (PCMs) in textiles. These advanced materials absorb and release thermal energy as they change states, effectively managing body heat. You might wonder how exactly a fabric can adjust its properties so dynamically. Understanding the science behind PCMs will not only reveal their fascinating capabilities but also highlight their practical applications in everyday clothing. Let's explore the mechanisms that make this innovative technology work.

Table of Contents

Key Takeaways

- PCMs in textiles absorb and release heat by melting and freezing to manage temperature.

- Microencapsulation and direct fiber embedding are common methods for integrating PCMs into textiles.

- PCM-infused fabrics prevent overheating by absorbing excess heat and releasing it when temperatures drop.

- Organic PCMs like paraffin wax and inorganic PCMs such as salt hydrates are commonly used for their thermal properties.

- PCM-infused clothing enhances thermal comfort and performance in various environmental conditions.

Understanding Phase-Change Materials

Phase-change materials (PCMs) are substances that absorb and release thermal energy during the process of melting and freezing. In the field of fabric technology, these materials are revolutionizing the way we think about heat management.

By incorporating PCMs into textiles, you're not just creating a fabric; you're developing a smart material that can manage temperature dynamically.

Imagine wearing a jacket that adapts to your body heat. When you get too warm, the PCMs embedded in the fabric absorb the excess heat, melting in the process and storing the thermal energy. Conversely, when the temperature drops, these materials solidify and release the stored heat back to you. This cyclical process ensures that your body remains at a stable and comfortable temperature, regardless of external conditions.

Integrating PCMs into textiles involves advanced fabric technology. These materials are either microencapsulated or embedded directly into fibers, creating a seamless integration that doesn't compromise comfort or aesthetics.

The key to mastering this technology is understanding the precise melting and freezing points of the PCMs being used. By doing so, you guarantee optimal heat management, providing superior thermal comfort in a variety of settings.

Thermal Regulation Mechanism

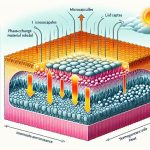

To grasp how textiles with PCMs keep you comfortable, let's explore the intricate thermal regulation mechanism at play. When you're wearing PCM-infused fabrics, these materials actively absorb and store heat from your body when temperatures rise. This process, known as heat storage, prevents overheating and maintains thermal comfort. As temperatures drop, the stored heat is released back to you, providing warmth when you need it most.

This dynamic process hinges on the PCM's ability to change phases. When the surrounding temperature exceeds the PCM's melting point, it transforms from solid to liquid, absorbing heat. Conversely, as temperatures fall below the melting point, the PCM solidifies, releasing the stored heat. This continuous cycle of heat absorption and release ensures that you stay within an ideal temperature range, regardless of external conditions.

Here's a concise table to illustrate the key points:

| Phase | Temperature Condition | Effect |

|---|---|---|

| Solid | Below Melting Point | Releases Stored Heat |

| Liquid | Above Melting Point | Absorbs Excess Heat |

| Solid | Temperature Drops | Provides Warmth |

| Liquid | Temperature Rises | Prevents Overheating |

Types of PCMs in Textiles

You'll find a variety of PCMs in textiles, each tailored to optimize thermal control and enhance comfort. One common type is organic PCMs, such as paraffin wax. These materials are often favored for their reliable phase-change characteristics. They seamlessly integrate into fabrics, improving thermal efficiency without compromising flexibility.

Another option is inorganic PCMs like salt hydrates. Their high thermal conductivity makes them excellent for applications requiring rapid heat absorption and release.

When it comes to fabric integration, microencapsulation stands out as a prevalent method. This technique involves encasing the PCM in tiny capsules before embedding them into the textile fibers. This not only guarantees durability but also enhances the fabric's overall performance.

Another approach is coating, where the textile surface is treated with a PCM layer to directly regulate temperature.

Material selection is vital in the manufacturing process. Choosing the right PCM and integration method can significantly impact the textile's efficacy. Organic PCMs are highly adaptable, while inorganic options offer strong thermal responses. The choice depends on the specific requirements of the end product, ensuring that the final textile delivers ideal thermal comfort and performance enhancement.

Applications in Clothing

Incorporating PCMs into clothing can greatly enhance thermal comfort, making garments more adaptable to varying temperatures. Imagine wearing a jacket that keeps you cool during a brisk walk but warms you up when the wind picks up. This adaptability is achieved through smart fabrics infused with phase-change materials, which absorb, store, and release heat as needed.

In the domain of wearable technology, PCMs are revolutionizing activewear and outdoor gear. You'll find jackets, gloves, and even socks embedded with these materials, ensuring you stay comfortable regardless of external conditions. For athletes, PCMs can be integrated into uniforms to help regulate body temperature during intense physical activity, optimizing performance and endurance.

Everyday clothing also benefits from this innovative technology. Consider business attire that keeps you cool during a hot commute but warms you up in an air-conditioned office. PCMs can be woven into the fabric of shirts, trousers, and even undergarments, making them versatile enough to handle varying indoor and outdoor environments.

Benefits and Challenges

While phase-change materials offer remarkable advantages in clothing, they also present several challenges that must be addressed. One of the primary benefits is their ability to regulate temperature, providing comfort across a range of climates. They absorb excess heat when you're warm and release it when you're cold, making them ideal for outdoor and active wear. This thermoregulation can enhance performance and safety in extreme conditions.

However, limitations exist that you can't overlook. For instance, the durability of phase-change materials can be an issue. Repeated washing and wear might degrade their effectiveness over time. Additionally, integrating these materials into textiles can increase manufacturing costs, making the products more expensive for consumers.

Here are some key points to bear in mind:

- Thermal Regulation: Enhances comfort and performance by maintaining an ideal temperature.

- Durability Concerns: Repeated use and laundering may reduce effectiveness.

- Cost Implications: Higher manufacturing costs can lead to pricier end products.

- Material Integration: Ensuring even distribution within textiles can be technically challenging.

Balancing these advantages and limitations is essential for maximizing the benefits of phase-change materials in your clothing. Understanding these factors will help you make informed decisions about their application and management.

Frequently Asked Questions

How Are Phase-Change Materials Integrated Into Textile Fibers?

Imagine weaving magic into fabric. You integrate phase-change materials into fibers during the manufacturing process. This involves embedding microcapsules within the fibers, ensuring efficient temperature regulation while maintaining comfort and performance in your textiles.

Do Phase-Change Materials Affect the Durability of Textiles?

You're wondering if phase-change materials affect textile durability. They can have a durability impact, but advancements in technology guarantee minimal effect, preserving textile longevity while delivering temperature-regulating benefits. Mastering this balance is key.

Are Phase-Change Materials in Textiles Safe for Skin Contact?

Imagine wrapping yourself in a cloud of comfort! You'll be relieved to know that phase-change materials in textiles are designed with skin safety in mind, minimizing health concerns, and ensuring they're perfect for everyday wear.

How Can Consumers Identify Textiles With Phase-Change Materials?

To identify textiles with phase-change materials, check textile labeling for specific mentions of fabric technology. Boost your consumer awareness by researching brand claims and using reliable identification techniques like product reviews and expert recommendations.

What Are the Environmental Impacts of Using Phase-Change Materials in Textiles?

You'll need to take into account energy consumption during manufacturing processes and the challenges of recycling and end-of-life disposal. These factors can have a substantial impact on the environment, influencing sustainability and waste management. Choose wisely to minimize harm.

- Inflatable Airplane Kevlar Fabric: High-Altitude Applications - June 21, 2025

- Hypalon Kevlar Fabric: Combining Durability and Chemical Resistance - June 21, 2025

- Molding Kevlar Fabric: Techniques for Custom Shapes - June 21, 2025