You might have heard of Phase-Shift Materials (PSMs) in textiles, but do you know how they actually work? These materials absorb and release thermal energy during phase shifts, such as melting and solidifying. When temperatures rise, PSMs absorb heat and melt, storing the energy. When it cools down, they solidify and release this stored heat, helping maintain a stable temperature. This innovative mechanism can enhance comfort and contribute to energy efficiency. But how exactly does this process regulate body temperature, and what types of PSMs are used? Let's explore this fascinating topic further.

Table of Contents

Key Takeaways

- PCMs absorb and release thermal energy during phase transitions to regulate temperature.

- Textiles use PCMs to maintain consistent temperature by absorbing excess heat and releasing stored heat.

- PCMs are integrated into textiles using microencapsulation or coating methods for precise thermal control.

- Different types of PCMs, including organic, inorganic, and bio-based, are tailored for specific applications and temperature ranges.

- PCM textiles enhance comfort and performance by dynamically adapting to body and environmental temperature changes.

What Are Phase-Change Materials?

Phase-change materials (PCMs) are substances that absorb and release thermal energy during the process of melting and freezing. When delving into the complexities of PCMs, understanding their role in thermal regulation is crucial. By absorbing heat when they melt and releasing it when they solidify, PCMs help maintain a consistent temperature, which is crucial for various applications, including textiles.

Incorporating PCMs in textiles leads to superior thermal regulation. Imagine wearing a jacket that adapts to your body temperature, keeping you warm when it's cold and cool when it's hot. This dynamic adjustment is possible because PCMs can store and release thermal energy as needed. As a result, you experience enhanced comfort without the bulk of traditional insulation materials.

Energy efficiency is another critical advantage of using PCMs. By maintaining ideal temperature ranges, PCMs reduce the need for additional heating or cooling, thereby saving energy. For instance, in clothing, this can mean less reliance on external heating sources, making your garments more energy-efficient. In turn, this not only reduces energy consumption but also contributes to sustainability efforts.

Understanding PCMs is your first step toward mastering their benefits in textiles.

The Science Behind PCMs

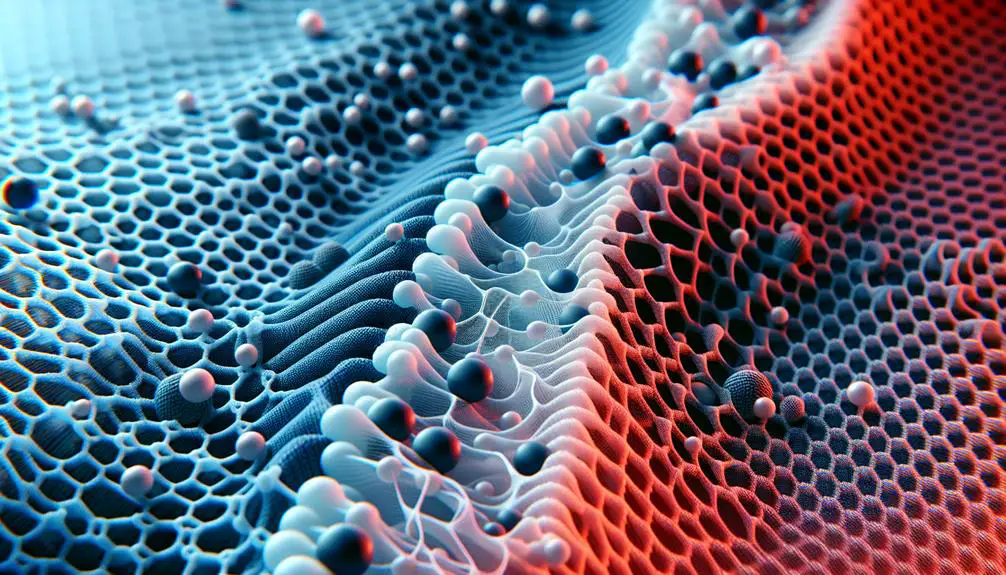

To comprehend how PCMs improve textiles, you need to delve into the underlying science that governs their thermal properties. Phase-change materials (PCMs) are substances that absorb or release significant amounts of latent heat when they alter their physical state, typically between solid and liquid. This state shift happens at specific temperatures, enabling PCMs to function as thermal buffers.

Scientific explanation begins with the concept of latent heat, the energy absorbed or released during a phase shift without changing temperature. When PCMs in textiles encounter temperature variations, they absorb excess heat by melting or release stored heat by solidifying. This procedure stabilizes the temperature, providing efficient thermal regulation.

The molecular structure of PCMs plays a crucial role. During the solid-to-liquid conversion, molecular bonds break, absorbing energy and cooling the surroundings. Conversely, during the liquid-to-solid conversion, bonds reform, releasing energy and warming the environment. This recurring process enables PCMs to uphold a balanced thermal environment.

How PCMs Regulate Temperature

By absorbing and releasing heat during state shifts, PCMs effectively manage temperature fluctuations in textiles. When you wear a garment embedded with phase-change materials, it regulates comfort by absorbing excess body heat as it changes from a solid to a liquid state. Conversely, when the temperature drops, the PCM releases the stored heat, solidifying and maintaining temperature equilibrium. This dynamic process guarantees you remain comfortable regardless of external conditions.

Consider the following table to understand how PCMs operate at different temperatures:

| Temperature Range | PCM State | Heat Exchange |

|---|---|---|

| Below 20°C | Solid | Releases heat |

| 20°C – 30°C | Shifts | Absorbs heat |

| Above 30°C | Liquid | Stores heat |

| Cooling Down | Liquid | Releases heat |

| Warming Up | Solid | Absorbs heat |

This continuous cycle of absorbing and releasing heat is what makes PCMs so effective in maintaining temperature stability. By integrating PCMs into textiles, you can experience an optimized thermal environment that adjusts to your body's needs. This is especially beneficial in varying climates, where maintaining comfort is essential. Whether you're in a cold or hot environment, PCMs work tirelessly to guarantee your body temperature remains within a comfortable range.

Different Types of PCMs

You'll find various types of PCMs, each tailored to different applications and temperature ranges. Understanding these types will help you select the right PCM for your specific needs, ensuring best performance and efficiency.

One of the most commonly used types is organic PCMs. These materials, such as paraffins and fatty acids, boast excellent thermal storage capacity and stability. Their PCM properties make them ideal for applications requiring consistent and reliable temperature regulation.

Another popular type is inorganic PCMs, which include salt hydrates and metallics. These materials offer a higher thermal conductivity compared to organic PCMs, making them suitable for applications where rapid heat transfer is essential. However, they can be more prone to phase separation and supercooling.

Lastly, bio-based PCMs are gaining traction due to their sustainability and eco-friendliness. Derived from natural sources like plant oils and animal fats, these PCMs provide a green alternative without compromising on performance. They're perfect for those seeking environmentally conscious solutions.

- Organic PCMs: Paraffins, fatty acids

- Inorganic PCMs: Salt hydrates, metallics

- Bio-based PCMs: Plant oils, animal fats

Integration in Textiles

Integrating phase-change materials (PCMs) into textiles transforms everyday fabrics into smart textiles capable of dynamic temperature regulation. You start by selecting the right PCMs based on specific material properties like melting point, thermal conductivity, and encapsulation ability. These properties guarantee that the PCMs provide optimal thermal management without compromising the textile's inherent characteristics.

One innovative approach is microencapsulation, where PCMs are enclosed in tiny capsules and then embedded into the textile fibers. This technique allows the PCMs to interact with the environment while maintaining the fabric's flexibility and durability.

Another method is coating, where PCMs are applied as a layer on the textile's surface. This option is simpler but might alter the textile's feel and breathability.

To master textile innovation, you'll need to understand how to balance PCM integration with the textile's functional and aesthetic requirements. For instance, integrating PCMs into sportswear involves guaranteeing the fabric remains lightweight and stretchy.

In contrast, PCM-incorporated bedding demands a soft, breathable finish. By fine-tuning the integration process, you can create advanced textiles that offer superior comfort and functionality, setting you apart in the competitive world of smart fabrics.

Benefits of PCM Textiles

Smart textiles incorporating PCMs offer remarkable advantages, such as improved thermal comfort and energy efficiency, making them a game-changer in various applications. You'll find that these materials notably enhance your clothing's ability to regulate temperature, thereby guaranteeing you're comfortable regardless of external conditions.

This means you'll experience satisfactory performance whether you're outdoors in the heat or in a chilly environment.

One of the primary benefits of PCM textiles is their capability to absorb, store, and release heat. This characteristic allows for sustainable cooling, reducing the need for additional energy consumption to maintain a comfortable temperature. By incorporating PCMs into your textiles, you contribute to a more environmentally friendly environment.

Consider these key advantages of PCM textiles:

- Improved Thermal Regulation: Maintains ideal body temperature by absorbing and releasing heat as needed.

- Energy Efficiency: Decreases the necessity for external heating or cooling systems, leading to reduced energy usage and costs.

- Satisfactory Performance: Ensures you stay comfortable in various conditions, enhancing your overall experience.

Applications in Athletic Wear

Athletic attire incorporating phase-change materials (PCMs) boosts your performance by regulating body temperature during vigorous physical activities. When you're pushing your limits, PCMs absorb excess heat and release it as needed, maintaining an optimal temperature. This dynamic thermal regulation is pivotal for performance enhancement, as it helps prevent overheating and keeps you comfortable.

Sweat absorption is another key benefit of PCM athletic attire. By effectively managing moisture, these textiles guarantee that sweat is quickly wicked away from your skin, reducing the risk of chafing and discomfort. This moisture management is essential for maintaining an ideal environment for your performance, allowing you to focus entirely on your activity rather than worrying about wet, sticky clothing.

Moreover, PCMs excel in heat dissipation. As you generate body heat during exercise, the PCMs in your athletic attire work to dissipate this heat efficiently. This not only helps in cooling your body but also reduces the buildup of heat within the fabric, making it more breathable and comfortable to wear.

PCMs in Bedding

When you incorporate phase-change materials (PCMs) into bedding, you'll experience superior temperature regulation, which leads to enhanced sleep quality. These materials absorb and release heat, maintaining a comfortable sleeping environment.

You'll also find that integrating PCMs into sheets, blankets, and mattress covers is a seamless process, enhancing your overall sleep experience.

Temperature Regulation Benefits

Leveraging phase-change materials (PCMs) in bedding offers a practical solution for maintaining an ideal sleep temperature throughout the night. By integrating PCMs into your bedding, you can achieve unparalleled energy efficiency and comfort. These materials absorb excess heat when you're too warm and release it when you start to cool down, effectively creating a balanced thermal environment. This balance not only enhances your comfort but also reduces the need for additional heating or cooling, making your sleep setup more energy-efficient.

Incorporating PCMs in your bedding also aligns with sustainability goals. By optimizing your body's temperature regulation, you'll minimize reliance on external energy resources, thereby contributing to a more sustainable lifestyle. Additionally, the performance of PCMs ensures that this temperature regulation is both effective and long-lasting, providing continued benefits without frequent replacements.

Here are some compelling reasons to ponder PCMs in your bedding:

- Energy Efficiency: Lower reliance on heating and cooling systems.

- Comfort: Maintains a stable sleep environment, reducing nighttime discomfort.

- Sustainability: Contributes to a reduced carbon footprint by optimizing natural temperature regulation.

Enhanced Sleep Quality

Incorporating phase-change materials into your bedding can greatly enhance sleep quality by maintaining an ideal sleeping temperature. Imagine slipping into bed and finding that your sheets and comforter adapt to your body's needs, ensuring you neither overheat nor get too cold during the night. This advanced technology in textiles actively works to absorb, store, and release heat, creating an environment of improved comfort tailored specifically for you.

You know how restless nights can ruin your day, making you feel sluggish and irritable. With phase-change materials, you'll experience fewer interruptions as your bedding regulates temperature fluctuations, allowing for deeper, more restorative sleep. By stabilizing the microclimate around your body, these materials help you maintain a consistent sleep cycle, which is essential for cognitive function and overall well-being.

This advanced technology isn't just a luxury; it's a practical solution to common sleep disturbances caused by temperature inconsistencies. Picture waking up refreshed, without the discomfort of night sweats or chills. Phase-change materials in your bedding represent the pinnacle of sleep innovation, offering a scientifically-backed way to enhance your nightly rest.

Embrace the future of improved comfort and transform your sleep experience with this cutting-edge approach.

Material Integration Techniques

To achieve the benefits of improved sleep quality, understanding the techniques for integrating phase-change materials (PCMs) into bedding is essential. Integrating PCMs effectively requires a blend of advanced fusion technology and fabric innovation. By mastering these methods, you can create bedding that dynamically adapts to body temperature, guaranteeing a restful night.

Using material bonding methods, PCMs can be encapsulated within microcapsules and embedded directly into fibers. This method ensures that the PCMs are evenly distributed and securely held within the textile structure, enhancing durability and performance.

Textile engineering plays an important role in weaving these advanced materials into bedding fabrics. Engineers focus on creating blends that maximize the thermal regulation properties of PCMs without compromising comfort or breathability.

Here are three innovative techniques for integrating PCMs into bedding:

- Microencapsulation: Encases PCMs in tiny capsules that are then integrated into the fabric, offering precise thermal control.

- Coating: Applies a thin layer of PCM directly onto the fabric surface, providing a simpler method for thermal regulation.

- Fiber Integration: Embeds PCM particles directly into the fibers during the manufacturing process, ensuring longevity and consistent performance.

Mastering these methods allows you to harness the full potential of PCMs, leading to bedding that truly improves sleep quality.

Future of PCM Textiles

The future of PCM textiles holds exciting possibilities for enhancing comfort and performance in everyday clothing. You'll find that innovative designs and sustainability practices are at the forefront of this transformation. Imagine garments that not only adapt to your body temperature but also integrate eco-conscious materials, reducing environmental impact. The fusion of advanced technology with responsible manufacturing can redefine how we experience comfort.

Consider how your clothing could evolve:

| Benefit | Emotion |

|---|---|

| Adaptive Temperature | Comfort and Relief |

| Eco-Conscious Materials | Pride in Sustainability |

| Longer Lifespan | Satisfaction and Value |

| Enhanced Performance | Confidence and Assurance |

Future developments in PCM textiles will likely focus on refining these benefits. Think about adaptive temperature control that's even more precise, keeping you comfortable in any climate. Eco-conscious materials will guarantee you're part of a sustainable future, giving you pride in your choices. Longer-lasting garments mean you get more value and satisfaction from your wardrobe.

As technology advances, PCM textile innovations will continue to offer enhanced performance, boosting your confidence in any activity. Embrace the future of PCM textiles, where cutting-edge comfort meets sustainable living, and your everyday wear becomes an extraordinary experience.

Frequently Asked Questions

Are Phase-Change Materials Safe for Sensitive Skin?

You'll find phase-change materials generally safe for sensitive skin, with minimal allergy risks. Their breathability and comfort levels are high, ensuring you stay comfortable. Always check product specifics to guarantee they meet your personal skin sensitivity requirements.

How Do PCMS Impact the Cost of Textile Products?

You should consider the cost impact of PCMs on textile products. While they can increase expenses, the benefits like enhanced comfort and skin safety often justify the price. Mastery involves balancing cost with these long-term advantages.

Can PCMS Be Used in All Types of Fabrics?

You should know that fabric compatibility is vital when using PCMs. While many fabrics can incorporate PCMs effectively, application limitations exist. Not all fabrics are suitable, so you must carefully consider the material's properties and intended use.

Do PCMS Affect the Weight of the Textile?

Oh, you're worried about weight impact? PCMs won't turn your clothes into lead armor. They balance performance, comfort, and durability without making textiles feel like a medieval outfit. You'll hardly notice the difference!

How Long Do PCM Textiles Maintain Their Temperature-Regulating Properties?

You're wondering how long these textiles maintain their temperature-regulating properties. With proper care, they can retain durability and performance for years. Regular maintenance guarantees their effectiveness, so don't neglect upkeep to maximize longevity.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024