Imagine you're wearing a jacket infused with phase-change materials during a brisk morning jog; as the sun rises, the jacket absorbs your body heat, keeping you cool. Phase-change materials (PCMs) in fabrics work by storing and releasing thermal energy through a process of solid-liquid transformation. This dynamic mechanism guarantees you're comfortable regardless of temperature fluctuations. Curious about how this innovative technology actually integrates into clothing and its potential benefits? You'll soon uncover the fascinating science and practical applications behind PCMs in fabrics.

Table of Contents

Key Takeaways

- Phase-Change Materials (PCMs) absorb and release heat by changing phases, ensuring dynamic thermal regulation in fabrics.

- PCMs in fabrics create a microclimate, enhancing comfort without external temperature control devices.

- Microencapsulation and coating methods evenly distribute PCMs, providing efficient heat absorption and release.

- In PCM-integrated fabrics, microencapsulated particles act as thermal batteries, helping maintain stable body temperature.

- Organic, inorganic, and bio-based PCMs offer tailored thermal properties, making them suitable for various fabric applications.

What Are Phase-Change Materials?

Phase-change materials (PCMs) are substances that absorb and release thermal energy during the process of melting and solidifying. If you're aiming for mastery in understanding PCMs, it's pivotal to start with their definition.

PCMs are compounds that can store and release large amounts of heat due to their ability to change phases—like from solid to liquid and back. This phase change happens at a specific temperature, making them highly effective for thermal regulation.

The properties of PCMs make them unique and incredibly useful. They have a high latent heat capacity, which means they can absorb a lot of heat without a significant rise in temperature. This property is what allows PCMs to maintain a stable temperature for extended periods.

Additionally, they exhibit thermal stability, meaning they won't degrade or lose effectiveness after numerous phase changes. Their thermal conductivity is usually moderate, ensuring a gradual and controlled release of stored energy.

Understanding these properties is essential if you want to harness the full potential of PCMs. By leveraging their ability to manage thermal energy efficiently, you can design fabrics that offer superior comfort and performance, making them ideal for a variety of applications.

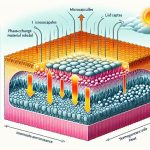

Thermal Energy Storage

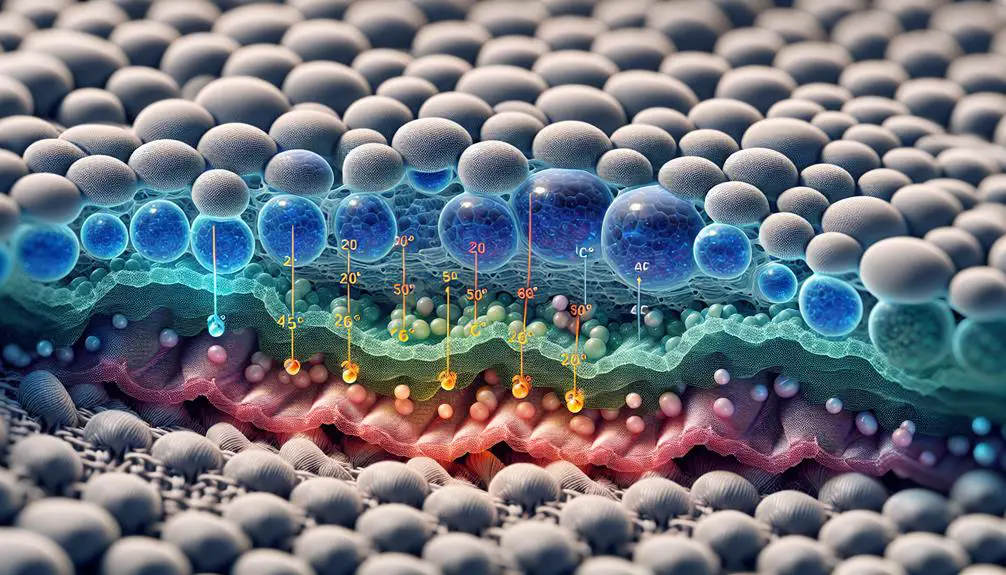

Thermal energy storage in fabrics using PCMs allows for effective temperature regulation by absorbing and releasing heat as needed. You can think of these materials as tiny thermal batteries embedded within the fabric, tirelessly working to keep your body at an ideal temperature.

When the surrounding temperature rises, the PCMs absorb excess heat, which helps cool you down. Conversely, when temperatures drop, they release stored heat to keep you warm. This dynamic process significantly enhances energy efficiency since your body doesn't have to expend as much energy on thermal regulation.

Imagine wearing a jacket that knows when to keep you cool during a brisk walk and warm when you're standing still. That's the magic of PCMs in action. They create a microclimate around your body, maintaining comfort without the need for external heating or cooling devices.

This not only improves your comfort but also contributes to overall energy efficiency. By integrating PCMs into fabrics, you're essentially wearing a smart system that adapts to your thermal needs in real-time, ensuring ideal temperature regulation and enhancing your experience whether you're indoors or outdoors.

Mechanism of Action

Fundamentally, PCMs operate by undergoing a phase change between solid and liquid states, absorbing or releasing heat during this process. When integrated into fabric technology, PCMs can effectively manage thermal energy, keeping you comfortable in varying temperatures.

As the temperature rises, PCMs absorb excess heat, melting from a solid to a liquid state. This phase change process cools you down by absorbing the heat that would otherwise make you feel too warm.

Conversely, when the temperature drops, the PCMs solidify, releasing stored heat and providing warmth. This dynamic thermal regulation is what makes PCMs so valuable in fabric technology. They act as a thermal buffer, maintaining a stable temperature close to your skin.

By embedding PCMs into fabrics, manufacturers can create garments that offer enhanced thermal comfort, making them ideal for both extreme conditions and everyday wear.

You'll find that the phase change process is seamless and continuous, ensuring that the fabric adjusts to your body's needs without any manual intervention. This smart adaptation is a key feature of advanced fabric technology, enabling top-notch performance and comfort in a variety of environments.

Types of PCMs

You'll find that phase-change materials (PCMs) come in various types, each tailored to specific thermal management needs. Organic PCMs, like paraffins and fatty acids, are widely used for their high latent heat and non-corrosive nature. They excel in fabric applications where flexibility and comfort are paramount.

Inorganic PCMs, such as salt hydrates, offer a different set of advantages, including higher thermal conductivity and cost-effectiveness. However, they can be more challenging to work with due to their corrosive properties.

Eutectic PCMs, which are a combination of organic and inorganic materials, offer a balanced approach. They provide a customized melting point, which is particularly useful in high-performance fabric applications.

When selecting materials for your project, consider the specific thermal requirements and the environmental conditions the fabric will face.

Bio-based PCMs are gaining traction for their sustainability. Derived from renewable resources, they align with eco-friendly and sustainable fabric applications, offering a green alternative without compromising on performance.

Material selection is essential; you'll need to balance thermal properties, durability, and environmental impact to achieve the desired outcome. Mastering these types of PCMs allows you to optimize fabric performance for a wide range of applications.

PCM Integration Methods

Integrating phase-change materials (PCMs) into fabrics involves several innovative techniques that enhance thermal regulation and comfort. These integration techniques are designed to maximize the performance enhancement offered by PCMs.

Let's delve into four primary methods:

- Microencapsulation:

This technique involves encasing PCM particles within microscopic capsules, which are then embedded into the fabric. This method ensures the PCMs are well-distributed and protected, providing consistent thermal regulation without compromising the fabric's feel.

- Coating:

In this approach, a PCM-infused coating is applied to the fabric's surface. This technique allows for a uniform layer of PCMs, enhancing the material's ability to absorb, store, and release heat efficiently. Coating is particularly useful for applications requiring high thermal performance.

- Fiber Spinning:

By incorporating PCMs directly into the polymer solution before spinning the fibers, manufacturers create PCM-integrated fibers. This technique guarantees that the thermal regulation properties are intrinsic to the fabric, offering long-lasting performance.

- Lamination:

This method involves layering a PCM-containing film between fabric layers. Lamination provides robust thermal management, making it ideal for high-performance textiles where durability and consistency are critical.

Benefits in Fabrics

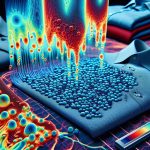

By integrating phase-change materials into fabrics, you gain significant benefits with enhanced thermal regulation, improved comfort, and energy efficiency. These materials absorb, store, and release thermal energy, ensuring your body temperature remains stable.

Imagine the advantage of having cooling technology embedded in your clothing, actively managing heat to prevent overheating and excessive sweating.

Comfort is paramount, and phase-change materials excel in this regard. They react to temperature fluctuations in your environment, providing a consistent and comfortable experience. No more dealing with sudden chills or unbearable heat.

Whether you're an athlete pushing physical limits or someone who values everyday comfort, this technology boosts performance by keeping you in an ideal thermal state.

Energy efficiency isn't just for buildings and vehicles; it extends to your wardrobe. By regulating temperature more effectively, your body expends less energy trying to cool down or warm up. This translates to less fatigue and enhanced endurance.

Plus, phase-change materials contribute to sustainability by reducing the need for additional layers, which can decrease textile waste.

In essence, incorporating phase-change materials into fabrics offers a trifecta of cooling technology, superior comfort, and exceptional performance. You're not just wearing clothes; you're experiencing a revolution in personal thermal management.

Applications in Fashion

Fashion designers are increasingly incorporating phase-change materials into their collections, blending innovative technology with stylish aesthetics. By doing so, they're not just enhancing the visual appeal but also revolutionizing the functionality of clothing.

Imagine garments that can regulate your body temperature, providing comfort and efficiency in various environmental conditions. Phase-change materials in fashion are paving the way for a new era of sustainable fashion and innovative textiles.

Here's how phase-change materials are making their mark in fashion:

- Sustainable Fashion: These materials contribute to energy conservation by reducing the need for external heating or cooling, aligning perfectly with the ethos of sustainable fashion.

- Innovative Textiles: Designers are experimenting with fabrics that offer both style and advanced functionality, creating pieces that aren't only beautiful but also smart.

- Performance Wear: Phase-change materials are being used in performance wear, ensuring athletes and active individuals maintain peak body temperatures during their activities.

- Futuristic Designs: The integration of these materials is leading to futuristic designs that are as functional as they're forward-thinking, pushing the boundaries of what fashion can achieve.

Sportswear Innovations

In the world of sportswear, phase-change materials are revolutionizing athletic gear by enhancing performance and comfort. These materials adapt to your body's temperature, providing ideal temperature regulation, so you can focus on your game, not your gear. When you heat up, the materials absorb excess heat, and when you cool down, they release it back to you. This comfort technology maximizes your time in the zone.

Performance enhancement isn't just about temperature. Moisture control is critical too. Phase-change materials wick away sweat, keeping you dry and reducing the risk of chafing. Imagine running a marathon without the distraction of damp, clingy clothes. These fabrics elevate your athletic experience.

Here's a quick look at how phase-change materials in sportswear deliver:

| Benefit | How It Works | Impact on Performance |

|---|---|---|

| Temperature Regulation | Absorbs and releases heat as needed | Maintains ideal body temp |

| Moisture Control | Wicks sweat away from the skin | Keeps you dry and comfortable |

| Comfort Technology | Adapts to changes in physical activity | Enhances overall comfort |

| Performance Enhancement | Reduces overheating and dehydration risks | Boosts endurance and focus |

Harness the power of phase-change materials in your sportswear and experience unparalleled comfort and performance.

Future of PCM Fabrics

The future of PCM fabrics promises even greater advancements in comfort and performance, transforming how we experience clothing in everyday life and specialized applications. Imagine not just regulating your body temperature but doing so with garments that are lighter, more breathable, and more sustainable.

The next wave of PCM fabrics will bring innovative designs that integrate seamlessly into our wardrobes while minimizing environmental impact.

Here's what you can expect:

- Enhanced Customization: Future PCM textiles will be tailored to specific activities, providing optimal thermal regulation whether you're running a marathon or attending a formal event.

- Sustainable Technology: The textiles industry is moving towards eco-friendly solutions. PCM fabrics will incorporate biodegradable materials and energy-efficient production methods, reducing their carbon footprint.

- Smart Integration: Expect to see PCM fabrics combined with smart technology. Imagine clothing that adapts dynamically to your body's needs, adjusting thermal properties in real-time.

- Durability: Innovative designs will ensure that PCM properties last longer, even after numerous wash cycles, enhancing the longevity and value of your garments.

Frequently Asked Questions

Are Phase-Change Materials Safe for Direct Contact With Skin?

You're wondering if phase-change materials are safe for direct contact with skin. Don't worry; they've been tested for skin safety and show no health concerns, making them suitable for clothing and other applications.

How Do You Care for Garments With Phase-Change Materials?

Wondering how to care for these high-tech garments? Follow washing instructions carefully and store them properly to maintain fabric durability and heat retention. By doing so, you'll guarantee longevity and peak performance of your phase-change clothing.

Can Phase-Change Materials Be Recycled or Reused?

You can explore recycling options for phase-change materials, enhancing their reusability benefits. By properly recycling these materials, you contribute to sustainability and extend the product's lifecycle, aligning with eco-friendly practices and achieving mastery in material management.

What Is the Environmental Impact of Producing Phase-Change Materials?

Oh, you thought producing phase-change materials was a breeze? Think again! Sustainable sourcing and manufacturing require high energy consumption, leading to significant emissions. So, you're saving the planet with a side of pollution.

Are There Any Known Allergies Associated With Phase-Change Materials?

You're probably wondering about allergy risks tied to phase-change materials. Currently, there's no substantial evidence linking them to significant skin irritation or allergic reactions, but always test new materials to confirm personal compatibility.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024