Imagine you're wearing a jacket that keeps you warm in the cold but doesn't make you overheat indoors. That's the magic of phase-change materials (PCMs) in action. PCMs absorb excess heat when you're too warm and release it when you're cold, maintaining a stable temperature. This technology is seamlessly integrated into fabrics through microencapsulation, ensuring efficient and durable temperature control. Curious about how these materials fundamentally alter your comfort level in various conditions? Let's explore the mechanics behind PCMs and their innovative applications in everyday textiles.

Key Takeaways

- PCMs absorb and release thermal energy during melting and freezing, regulating fabric temperature.

- The integration of PCMs in textiles ensures superior thermal regulation by maintaining stable temperatures.

- Microencapsulation of PCMs in fabrics provides secure embedding and efficient temperature control.

- PCMs enhance comfort and adapt to changing temperatures by managing heat absorption and release.

- PCM fabrics contribute to energy savings and sustainability by reducing the need for additional heating or cooling.

What Are Phase-Change Materials?

Phase-change materials (PCMs) are substances that absorb and release thermal energy during the process of melting and freezing. They play a critical role in material science due to their unique ability to regulate temperature. When a PCM melts, it absorbs heat from its surroundings, helping to cool the environment. Conversely, when it freezes, it releases heat, thereby warming the area. This cyclical process makes PCMs exceptionally efficient for thermal regulation.

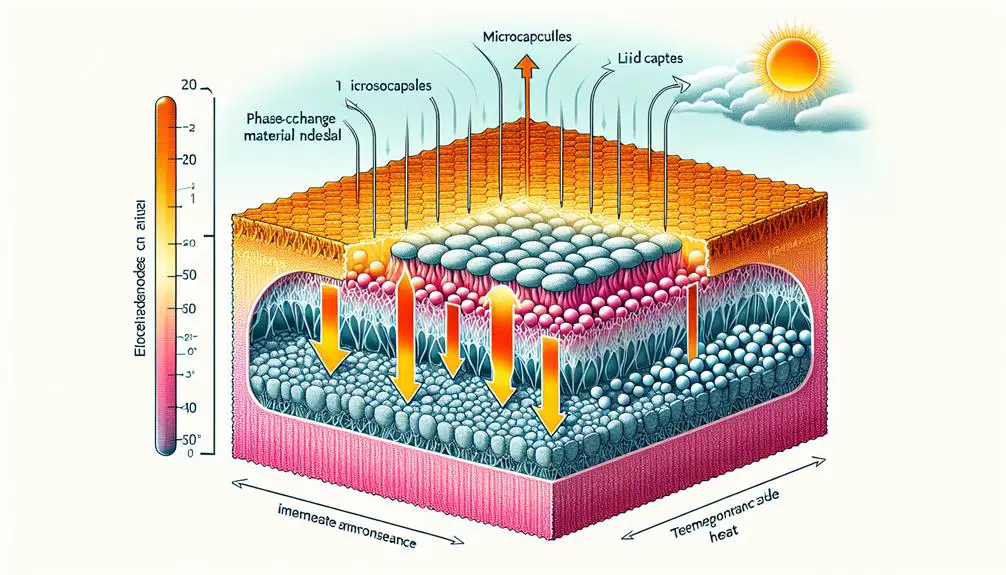

In the field of material science, PCMs are engineered to enhance their effectiveness in various applications, including textiles. By integrating PCMs into fabrics, you can achieve superior thermal regulation, ensuring comfort regardless of external temperature fluctuations. The microscopic capsules of PCMs embedded in the fabric maintain a stable temperature by absorbing excess heat when you're too warm and releasing it when you're cold.

Understanding the principles behind PCMs allows you to appreciate their transformative impact on modern fabrics. Mastering the application of PCMs in textiles involves knowing the precise melting and freezing points required for best performance, ensuring that the materials used will consistently provide the desired thermal regulation.

This knowledge empowers you to make informed decisions when selecting advanced PCM-enhanced fabrics for various uses.

History of PCMs in Textiles

You might be surprised to learn that the journey of phase-change materials (PCMs) in textiles started with early innovations in military and aerospace applications.

Over the years, these materials found their way into commercial use, marking significant milestones in the textile industry.

Now, let's explore how these developments have shaped modern fabric technologies.

Early Textile Innovations

The history of PCMs in textiles dates back to the 1980s when NASA's innovations led to the development of temperature-regulating fabrics for astronaut suits. This groundbreaking technology was a significant leap in textile evolution, merging advanced science with fabric engineering to optimize body temperatures for astronauts in the challenging environment of space.

Before this, ancient techniques like weaving and dyeing were the primary methods of enhancing fabric performance. These methods, while effective in their time, couldn't address the intricate thermal management needs that modern applications demanded. NASA's introduction of phase-change materials (PCMs) into textiles marked a departure from these traditional methods, embedding microcapsules within the fabric to absorb, store, and release heat as necessary.

You can appreciate how this innovation transformed the textile industry, providing a new level of functionality that went beyond mere aesthetics or basic protection. It paved the way for subsequent developments in smart textiles, enabling fabrics to react dynamically to environmental changes.

Understanding this evolution helps you grasp the importance of PCMs in modern textile applications and appreciate the sophisticated engineering that makes today's high-performance fabrics possible.

Commercial Adoption Milestones

After NASA's pioneering work, the commercial adoption of phase-change materials in textiles began to gain traction in the early 1990s, revolutionizing consumer applications from outdoor apparel to bedding. You witnessed the market growth as companies like Outlast Technologies began integrating PCMs into everyday products. This innovation provided consumers with unprecedented thermal comfort.

However, adoption challenges initially slowed progress. Manufacturers had to balance cost, durability, and functionality. Despite these hurdles, technology advancements steadily improved PCM integration, making the materials more accessible and efficient.

By the early 2000s, the industry impact was undeniable. Major brands incorporated PCMs into their product lines, enhancing performance wear, sleep systems, and even medical textiles. This widespread adoption underscored the transformative potential of PCMs in enhancing quality of life.

Here's a snapshot of key milestones in the commercial adoption of PCMs:

| Year | Milestone | Impact |

|---|---|---|

| 1990s | First consumer products launched | Revolutionized thermal comfort |

| 2000s | Major brand partnerships | Enhanced market growth |

| 2010s | Advanced PCM formulations | Improved durability and cost |

| 2020s | Widespread adoption | High industry impact |

| Future | Continued innovation | Ongoing technology advancements |

How PCMs Function

Fundamentally, phase-change materials (PCMs) absorb and release heat to uphold a stable temperature. When integrated into fabric technology, PCMs play a crucial role in thermal regulation. As you wear PCM-infused clothing, the materials dynamically interact with your body heat. When your temperature rises, PCMs absorb excess heat, changing from solid to liquid. This absorption process prevents overheating by storing the heat energy.

Conversely, when your body temperature drops, PCMs release the stored heat by shifting back from liquid to solid. This release process guarantees a consistent warmth, preventing you from feeling cold. The ability of PCMs to alternate between these states allows fabrics to maintain an ideal thermal balance.

Incorporating PCMs into fabrics demands precision, as the microencapsulation process ensures that these materials remain securely embedded within the textile fibers. This seamless integration not only enhances the fabric's functionality but also preserves its comfort and durability.

Types of PCMs

You'll encounter various types of PCMs, each with unique properties tailored for specific thermal regulation needs. These materials are designed with different applications in mind, ensuring best performance in diverse environments.

Here's a closer look at the primary types of PCMs you might come across:

- Organic PCMs: These are often composed of paraffins or fatty acids. They're popular due to their wide range of melting points and excellent thermal stability. Organic PCMs are ideal for applications requiring consistent and reliable thermal regulation.

- Inorganic PCMs: Typically composed of salt hydrates, inorganic PCMs offer high latent heat storage capacity. They're suitable for applications where rapid thermal response is essential. However, they can sometimes suffer from phase separation and supercooling issues.

- Eutectic PCMs: These are mixtures of two or more components that melt and solidify at a single temperature. Eutectics offer precise thermal regulation, making them perfect for applications where maintaining a specific temperature range is crucial.

- Bio-based PCMs: Derived from renewable resources, these PCMs are gaining popularity for their eco-friendly compositions. They're suitable for sustainable fashion and other environmentally conscious applications.

Benefits of PCMs in Fabrics

You'll find that incorporating PCMs in fabrics offers impressive benefits like temperature regulation efficiency and enhanced comfort levels.

These materials help maintain a stable body temperature, making you feel more comfortable in varying climates.

Additionally, they can lead to potential energy savings by reducing the need for external heating or cooling.

Temperature Regulation Efficiency

Incorporating phase-change materials (PCMs) into fabrics can enhance temperature regulation, ensuring the most comfortable experience in varying climates. By storing and releasing heat, PCMs provide exceptional thermal comfort, making your clothing adaptable to changing temperatures.

This adaptability translates to energy efficiency, as you won't need to rely as heavily on external heating or cooling sources.

Here are four key benefits of PCMs in fabrics:

- Thermal Comfort: PCMs absorb excess body heat and release it when temperatures drop, maintaining a consistent thermal environment. This means you'll stay comfortable regardless of external conditions.

- Energy Efficiency: With PCMs in your fabrics, you're less likely to adjust your thermostat frequently. The materials help keep your body at an ideal temperature, reducing the need for additional energy consumption.

- Moisture Management: PCMs naturally manage moisture by absorbing and releasing heat, which helps regulate sweat and keeps you dry. This feature is particularly beneficial for activewear and outdoor clothing.

- Sustainable Textiles: Integrating PCMs into fabrics supports the development of sustainable textiles. By enhancing the performance and longevity of clothing, you're contributing to a more sustainable fashion industry.

Enhanced Comfort Levels

By incorporating phase-change materials into fabrics, the comfort levels of your clothing can greatly increase, adapting seamlessly to your body's temperature needs. These advanced materials absorb, store, and release heat as your body temperature fluctuates, ensuring you stay comfortable whether you're active or at rest. This means your clothing can offer enhanced performance by maintaining an ideal temperature balance, no matter the external conditions.

Phase-change materials (PCMs) don't just improve comfort; they also contribute to sustainable textiles. By moderating temperature, these fabrics reduce the need for additional heating or cooling, lowering your energy consumption and environmental footprint. Imagine having a wardrobe that not only feels great but also supports your eco-friendly lifestyle.

Here's a quick comparison to illustrate the benefits:

| Feature | Traditional Fabrics | Fabrics with PCMs |

|---|---|---|

| Temperature Adaptation | Limited | Dynamic |

| Comfort Level | Variable | Consistently High |

| Performance in Activities | Standard | Enhanced Performance |

| Environmental Impact | Higher | Lower (Sustainable) |

Energy Savings Potential

Leveraging phase-change materials in your clothing not only enhances comfort but also offers substantial energy savings. By regulating temperature, these fabrics reduce the need for external heating or cooling, ultimately lowering your energy bills. Here's how PCMs can make a difference:

- Cost Effectiveness: By maintaining a favorable temperature, PCM-infused fabrics reduce reliance on HVAC systems. This translates to lower energy consumption and significant cost savings over time.

- Environmental Impact: Reduced energy use means fewer carbon emissions. Wearing PCM-enhanced clothing helps you minimize your environmental footprint, contributing to a more sustainable future.

- Innovation: The integration of PCMs in textiles represents a groundbreaking advancement in fabric technology. This innovation offers a dual benefit: improved personal comfort and enhanced energy efficiency.

- Market Adoption: As awareness grows about the benefits of PCMs, their market adoption is increasing. This trend encourages manufacturers to develop more PCM-based products, making them more accessible and affordable.

Applications in Clothing

Phase-change materials in fabrics revolutionize the way clothing adapts to temperature changes, keeping you comfortable in varying climates. Imagine your jacket cooling you down during a strenuous hike and warming you up as the evening chill sets in. That's the power of phase-change materials, seamlessly integrating science and style.

In the fashion industry, designers are leveraging these advanced materials to create garments that do more than just look good. High-end brands are now incorporating phase-change technology into their collections, providing you with outfits that maintain ideal comfort regardless of external conditions. This innovation allows you to wear your favorite pieces year-round, without compromising on style or comfort.

For performance wear, phase-change materials are a game-changer. Whether you're an athlete or an outdoor enthusiast, you need clothing that can keep up with your dynamic lifestyle. These fabrics absorb excess heat when you're active and release it when you're resting, ensuring your body temperature stays regulated. This adaptability reduces the risk of overheating and improves overall performance, making your gear as resilient as you are.

Applications in Bedding

In bedding, these innovative materials ensure you remain comfortable all night by adapting to your body's temperature changes. Phase-change materials (PCMs) used in bedding products offer superior thermal insulation and moisture management, securing a restful sleep environment.

When it comes to bedding, PCMs provide a dynamic response to your body's needs, making them an excellent choice for those seeking advanced comfort solutions.

Here's how PCMs enhance your bedding experience:

- Temperature Regulation: PCMs absorb and release heat as your body temperature fluctuates, maintaining a consistent sleeping temperature. This secures you stay cozy without overheating or feeling too cold.

- Thermal Insulation: By effectively managing heat exchange, PCMs offer superior thermal insulation, reducing the need for heavy blankets and allowing for a lighter, more breathable bedding setup.

- Moisture Management: These materials wick away moisture, keeping you dry and comfortable throughout the night. This feature is particularly beneficial for those who tend to sweat during sleep.

- Enhanced Sleep Quality: The combination of temperature regulation and moisture management leads to better sleep quality, as your body can rest without the disruptions caused by thermal discomfort.

Innovations in PCM Fabrics

Recent innovations in PCM fabrics have revolutionized how we experience comfort and temperature control in everyday clothing. These advancements offer significant sustainability benefits and performance improvements, making your wardrobe smarter and more eco-friendly.

One of the standout features of modern PCM fabrics is their enhanced comfort. They adapt dynamically to your body temperature, ensuring you're neither too hot nor too cold. This adaptability leads to significant energy efficiency, as you'll rely less on external heating and cooling systems.

Moreover, the integration of phase-change materials in textiles has led to impressive performance improvements. These fabrics not only regulate temperature but also enhance moisture management and durability. As a result, you get clothing that's not just comfortable but also long-lasting.

Here's a quick comparison of the benefits and innovations in PCM fabrics:

| Innovation | Benefit |

|---|---|

| Temperature regulation | Comfort enhancement |

| Moisture management | Increased wearability |

| Durability improvements | Longer lifespan |

| Energy efficiency | Reduced environmental impact |

| Smart textiles | Advanced user experience |

These breakthroughs in PCM fabrics are transforming the textile industry, making it possible for you to enjoy clothing that's both high-performing and sustainable. By embracing these innovations, you're not just upgrading your comfort but also contributing to a greener planet.

Future of PCM-Enhanced Textiles

As we look ahead, the future of PCM-enhanced textiles promises even greater advancements in smart clothing technology and sustainability. Imagine fabrics that not only regulate your body temperature but also reduce environmental impact. With PCM technology, the sustainability impact is substantial as it reduces the need for energy-intensive heating and cooling.

You'll notice significant market growth as more industries recognize the benefits of PCM-enhanced textiles. Here's what you can expect:

- Sustainability Impact: PCM fabrics will lessen the carbon footprint by reducing reliance on HVAC systems, leading to lower energy consumption.

- Consumer Adoption: As awareness grows, more consumers will embrace PCM-enhanced clothing for its comfort and energy-saving properties.

- Fashion Integration: Designers will incorporate PCM materials into mainstream fashion, blending functionality with style seamlessly.

- Market Growth: The increasing demand for innovative, eco-friendly textiles will drive market expansion, offering new opportunities for businesses and entrepreneurs.

Frequently Asked Questions

How Do You Care for Clothes With Phase-Change Materials?

You've got to follow specific washing instructions and use gentle drying techniques. For effective stain removal, use mild detergents. Storage tips include keeping them in a cool, dry place to maintain their quality.

Are Phase-Change Materials Safe for Sensitive Skin?

Are you worried about skin irritation or allergies? Don't be. Phase-change materials are generally safe for sensitive skin, boasting excellent fabric compatibility and breathability, ensuring you stay comfortable and irritation-free.

Do Phase-Change Materials Affect the Weight of the Fabric?

Yes, phase-change materials can slightly increase the fabric's weight, but they won't compromise fabric breathability. They enhance thermal regulation, ensuring ideal comfort without making the fabric noticeably heavier, maintaining performance and wearability.

Can PCMS Be Used in All Seasons?

So, you think PCMs are only for summer applications? Think again. They're equally effective as winter alternatives, keeping you cool when it's hot and warm when it's freezing. Versatility at its best, right?

How Long Do the Effects of PCMS Last in Fabrics?

You're wondering about the durability and effectiveness of these materials in fabrics. They maintain effectiveness for years, but longevity depends on proper maintenance. Wash gently and avoid harsh detergents to preserve their performance.