Imagine slipping into a jacket that adapts to your body heat, keeping you perfectly comfortable regardless of the weather. This isn't science fiction; it's the promise of phase-change materials (PCMs) in modern textiles. By absorbing and releasing thermal energy, PCMs regulate temperature, ensuring you stay neither too hot nor too cold. You'll find that these materials not only enhance comfort but also extend the lifespan of your garments and boost energy efficiency. Want to know how these cutting-edge materials are transforming the textile industry and what it means for your wardrobe? There's much more to explore.

Table of Contents

Key Takeaways

- PCMs in fabrics regulate body temperature by absorbing and releasing thermal energy during phase transitions.

- PCM-enhanced textiles reduce the need for additional clothing layers, providing comfort across varying temperatures.

- Microencapsulated PCMs ensure even distribution and consistent thermal management within textile fibers.

- PCM fabrics improve energy efficiency by lowering reliance on external heating and cooling systems.

- PCM integration in sportswear enhances performance by actively managing temperature and wicking moisture.

Understanding Phase-Change Materials

Phase-change materials (PCMs) are substances that absorb and release thermal energy during the process of melting and freezing. By harnessing these unique properties, you can greatly enhance the performance of fabrics across various applications. PCMs are embedded within textiles, creating innovative fabric technology that regulates temperature effectively. Imagine your clothing automatically adjusting to your body heat, keeping you comfortable in varying conditions.

In fabric technology, PCM applications are particularly revolutionary for outdoor gear, activewear, and even bedding. These materials can absorb excess heat when you're active and release it when you're cooling down. This dynamic thermal regulation ensures that you stay comfortable without the need for additional layers.

Moreover, PCM applications extend beyond personal comfort. They improve energy efficiency in buildings by incorporating PCMs into curtains or upholstery, reducing the need for heating and cooling systems. The versatility of PCMs in fabric technology is practically limitless, offering solutions that cater to both individual and environmental needs.

How PCMs Work

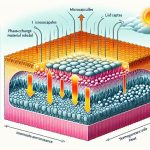

Ever wondered how PCMs manage to regulate temperature so effectively? Phase-change materials (PCMs) work by leveraging their unique ability to absorb and release heat during phase changes. When you wear a fabric embedded with PCMs, you're basically wrapping yourself in a smart thermal management system.

Here's how PCM functionality operates:

- Heat Absorption: When the temperature rises, PCMs absorb excess heat, causing them to change from solid to liquid.

- Heat Release: As temperatures drop, these materials solidify, releasing the stored heat back into your environment.

- Latent Heat: This process of phase change involves latent heat, where energy is stored or released without changing the overall temperature of the material.

- Thermal Buffering: PCMs act as a thermal buffer, smoothing out temperature fluctuations and maintaining a more consistent microclimate.

- Microencapsulation: In fabrics, PCMs are often microencapsulated, meaning they're enclosed in tiny capsules that can be evenly distributed within the textile fibers.

Benefits of PCMs in Fabrics

You'll find that fabrics with PCMs greatly enhance comfort by maintaining a perfect temperature balance. Imagine wearing a jacket that keeps you warm when it's cold and cool when it's hot. That's the magic of phase-change materials (PCMs) embedded in textiles. They absorb, store, and release heat as needed, ensuring you experience ideal thermal comfort throughout the day.

By integrating PCMs into fabrics, you reduce the need for additional layers of clothing or excessive heating and cooling. This adaptability translates to considerable energy savings, both for individuals and for industries reliant on climate control. Think about the reduction in heating costs in winter or cooling expenses in summer—PCMs make this possible.

In addition to personal comfort, incorporating PCMs into fabrics enhances the performance and lifespan of the garments. The materials are engineered to undergo thousands of thermal cycles without degradation, making them a durable choice. Not only do you gain an edge in comfort and efficiency, but you also contribute to a sustainable future by cutting down on energy consumption and waste.

Mastering the use of PCMs in fabrics means embracing a future where comfort and energy efficiency go hand in hand.

Types of PCMs

When exploring the different types of PCMs, understanding how each one uniquely influences fabric performance is essential. You'll find that the right PCM selection can make a significant difference in comfort, temperature regulation, and overall fabric compatibility.

Here are the main types of PCMs to keep in mind:

- Organic PCMs: These include paraffins and fatty acids. They're notable for their high heat storage capacity and stability, making them an excellent choice for various fabrics.

- Inorganic PCMs: Typically composed of salt hydrates, these PCMs are cost-effective and have high latent heat storage but can be less compatible with some textiles due to their corrosive nature.

- Eutectic PCMs: These are mixtures of organic and inorganic compounds designed to achieve a specific melting point, offering a balanced approach to thermal regulation and fabric integration.

- Bio-based PCMs: Derived from natural sources, bio-based PCMs are eco-friendly and sustainable, aligning well with fabrics that prioritize environmental impact.

- Microencapsulated PCMs: These involve encapsulating PCM within a shell material, allowing for better fabric compatibility and easier integration into textiles without compromising their structural integrity.

Understanding these types will guide your PCM selection process, ensuring the best fabric performance and compatibility.

Applications in Sportswear

When it comes to sportswear, phase-change materials (PCMs) offer impressive benefits.

You'll appreciate the enhanced temperature regulation, keeping you comfortable during intense workouts.

Plus, moisture-wicking properties guarantee you stay dry and focused.

Temperature Regulation Benefits

Phase-change materials in sportswear actively manage your body temperature, ensuring comfort during intense physical activities. These advanced fabrics absorb, store, and release heat, which helps maintain a stable body temperature.

By integrating phase-change materials into sportswear, you can up your game in several ways:

- Energy efficiency: These materials reduce the need for external heating or cooling, making your gear more energy-efficient and sustainable.

- Enhanced comfort: Experience consistent comfort regardless of the external temperature, allowing you to focus solely on your performance.

- Improved performance: Maintaining an ideal body temperature means you can train harder and longer without overheating or getting too cold.

- Adaptive response: The materials adjust dynamically to your body's thermal needs, providing a tailored experience that enhances your workout.

- Reduced fatigue: By keeping your body at a stable temperature, you can minimize energy loss and reduce fatigue, giving you an edge in endurance sports.

When you're pushing yourself to the limit, the last thing you want to worry about is temperature regulation. With phase-change materials, your sportswear works as hard as you do, ensuring you stay comfortable and perform at your best while also contributing to sustainability.

Moisture-Wicking Properties

Beyond temperature regulation, moisture-wicking properties in sportswear play a vital role in keeping you dry and comfortable during workouts. When you're pushing your limits, sweat management becomes essential. Advanced materials in sportswear excel at moving sweat away from your skin, promoting evaporation, and ensuring you stay cool and dry.

Phase-change materials (PCMs) integrated into fabrics enhance this moisture-wicking capability. These materials can absorb, store, and release moisture, working seamlessly with your body's natural cooling processes. This dual action of sweat management and temperature regulation sets performance gear apart from ordinary clothing.

Fabric breathability is another notable factor. Breathable fabrics allow air to circulate, preventing overheating and further aiding in moisture evaporation. The combination of moisture-wicking properties and high breathability ensures that your sportswear can handle the most intense activities.

| Feature | Benefit |

|---|---|

| Moisture-Wicking | Keeps skin dry, reduces chafing |

| Fabric Breathability | Enhances comfort, prevents overheating |

| Sweat Management | Improves overall performance |

| Phase-Change Materials | Regulates temperature, manages moisture |

For athletes and fitness enthusiasts aiming for mastery, investing in sportswear with these advanced features can notably impact your performance and comfort.

Medical Textile Innovations

Medical textile innovations are revolutionizing patient care by incorporating phase-change materials to regulate body temperature and enhance comfort. These advanced fabrics aren't only enhancing patient outcomes but also addressing crucial issues in healthcare through a combination of cutting-edge technology and sustainable practices.

By integrating antimicrobial properties, these textiles help decrease infection rates and promote cleaner hospital environments. The sustainability in healthcare is further improved by the use of eco-friendly materials, reducing the environmental impact typically associated with medical fabrics.

Smart textiles and wearable technology are at the forefront of these innovations. Imagine a hospital gown that monitors essential signs or bedding that adjusts its temperature to keep patients comfortable. These advancements are designed to provide:

- Continuous temperature regulation: Ensuring patients don't overheat or become too cold.

- Enhanced comfort: Soft, breathable fabrics that adapt to the body's needs.

- Improved hygiene: Antimicrobial treatments that keep bacteria at bay.

- Sustainable options: Fabrics made from recyclable or biodegradable materials.

- Integrated monitoring: Wearable technology that tracks health metrics in real-time.

PCM Integration Techniques

To achieve these advancements in medical textiles, understanding PCM integration techniques is essential for maximizing fabric performance. You need to focus on embedding phase-change materials (PCMs) effectively to harness their full potential.

One common method is microencapsulation, where PCMs are enclosed in microscopic capsules before being integrated into the fibers. This technique ensures a stable and controlled release of thermal energy, allowing for precise temperature regulation.

Another approach is coating fibers with PCM solutions. This method involves applying a thin layer of PCM directly onto the fabric's surface. It's less intrusive and can be tailored to specific applications, offering flexibility in design and functionality.

Additionally, you can utilize PCM-embedded fibers, where the materials are incorporated during the fiber manufacturing process. This results in an even distribution of PCMs throughout the textile, providing consistent thermal management.

Innovative applications of these techniques include smart wound dressings that maintain ideal healing temperatures and hospital garments that regulate body temperature, enhancing patient comfort and recovery.

Challenges and Limitations

When considering phase-change materials, you'll face several challenges. Issues like inconsistent thermal regulation, reduced durability under stress, and high costs can limit their effectiveness and accessibility.

Understanding these limitations is vital for making informed decisions about integrating these materials into your products.

Thermal Regulation Issues

Despite their promising capabilities, phase-change materials in fabrics often face important challenges in maintaining consistent thermal regulation. While they excel in providing insulation efficiency and integrating advanced comfort technologies, they can struggle to adapt to rapid temperature fluctuations or extreme conditions. This inconsistency can diminish their effectiveness and limit their appeal for applications requiring reliable performance.

You might encounter several issues related to thermal regulation in phase-change materials:

- Response Time: The delay in response to temperature changes can result in discomfort.

- Temperature Range: Their effectiveness is often limited to a narrow temperature range, reducing versatility.

- Integration: Seamlessly incorporating these materials into textiles without compromising other properties can be tricky.

- Wear and Tear: Over time, the materials might lose their thermal-regulating properties due to repeated cycles.

- Energy Savings: Inconsistent thermal regulation can affect the overall energy savings and sustainability of the textiles.

Addressing these challenges is essential for maximizing the potential of phase-change materials. By enhancing their response time and broadening their effective temperature range, you can greatly improve the comfort and energy efficiency of sustainable textiles. Mastering these aspects will enable you to create fabrics that not only perform well but also contribute to a more sustainable future.

Durability Under Stress

Over time, phase-change materials in fabrics often face significant durability challenges under stress. As you subject these materials to repeated use, their ability to maintain structural integrity and performance can diminish. Durability testing becomes vital to confirm these fabrics can withstand everyday wear and tear. Stress resistance is essential; without it, the fabric's effectiveness in thermal regulation may degrade, leading to a less dependable product.

To better understand these challenges, consider the following table summarizing common durability tests and their outcomes:

| Test Type | Method | Outcome |

|---|---|---|

| Tensile Strength | Stretching fabric until it breaks | Measures max stress before failure |

| Abrasion Resistance | Rubbing fabric against rough surface | Assesses wear and tear resilience |

| Pilling Resistance | Simulating fabric-to-fabric contact | Evaluates surface fuzz formation |

| Flexural Endurance | Bending fabric repeatedly | Tests long-term flexibility |

Examining these test results, you can identify areas where phase-change materials need improvement. For instance, poor abrasion resistance might indicate a need for stronger fiber blends. Each test provides insights into how these materials cope under different stressors, confirming they remain effective across various applications. By focusing on enhancing stress resistance, you'll contribute to creating more durable, high-performance fabrics.

Cost and Accessibility

After addressing the durability concerns, let's tackle another significant challenge with phase-change materials: their cost and accessibility. When you delve into cost analysis, you'll notice that phase-change materials (PCMs) often come with a hefty price tag. This can be a barrier for widespread adoption, especially in consumer markets where cost-efficiency is paramount.

Market availability also poses a challenge. Not all regions have equal access to high-quality PCMs, creating disparities in who can leverage these advanced materials. The supply chain complexities further complicate this issue, making it difficult for manufacturers to source PCMs reliably.

Here are some key factors to contemplate:

- High Production Costs: The intricate manufacturing process of PCMs drives up costs.

- Limited Suppliers: Few companies specialize in PCMs, limiting options and driving up prices.

- Regional Disparities: Availability varies by region, affecting global market penetration.

- Scale Economies: Bulk production reduces costs, but only large-scale operations can afford this.

- Import Duties: Tariffs and import taxes can add to the overall expense.

To master the integration of PCMs into your products, you must navigate these financial and logistical hurdles. Conducting a thorough cost analysis and understanding market availability will be essential steps in overcoming these challenges.

Future Trends in PCM Fabrics

As technology continues to advance, PCM fabrics are poised to revolutionize the textile industry with their innovative applications and enhanced performance features. You'll see a surge in sustainability solutions where PCM fabrics can minimize energy consumption by regulating body temperature more efficiently. This fabric innovation isn't just about comfort; it's about creating a more sustainable future.

In the fashion industry, PCM fabrics are driving textile advancements that go beyond traditional boundaries. Imagine clothing that adapts to your body's temperature, keeping you cool in the summer and warm in the winter. This adaptability offers an unparalleled level of comfort and functionality, making PCM fabrics a game-changer in high-performance apparel.

You can expect to see PCM fabrics in everything from everyday wear to specialized sports gear and even luxury fashion lines. They provide a unique blend of style and practicality, making them a highly sought-after material in modern textile design.

Real-World Examples

Take a closer look at how phase-change materials are already transforming various industries with real-world applications. These innovative materials aren't just theoretical marvels; they're making significant impacts through practical applications.

Let's explore some compelling case studies to see how PCMs are enhancing fabric performance across different sectors.

- Outdoor Gear: Think about high-performance jackets that regulate body temperature during extreme weather conditions. Brands like Columbia and Patagonia have integrated PCMs to guarantee comfort and functionality.

- Medical Textiles: Hospital gowns and bedding incorporating PCMs can help maintain a stable body temperature for patients, notably improving comfort and potentially aiding in recovery.

- Sportswear: Athletes benefit from PCM-infused fabrics that keep them cool during intense workouts and warm during rest periods. This technology is already used in brands like Under Armour and Adidas.

- Military Applications: Soldiers' uniforms with PCMs offer better thermal regulation in diverse climates, enhancing both comfort and operational effectiveness.

- Home Textiles: Bedding products such as mattresses and pillows with PCMs ensure a more restful sleep by maintaining an ideal sleeping temperature.

These examples illustrate the tangible benefits of phase-change materials in various real-world contexts, showcasing their versatility and transformative potential.

Frequently Asked Questions

Are Phase-Change Materials Environmentally Friendly and Sustainable?

You're right to question the sustainability and efficiency of phase-change materials. These materials often have a positive environmental impact and longevity, making them a potentially sustainable choice. Always research specific products for the best results.

How Do You Care for Fabrics Containing Pcms?

To maintain fabrics with PCMs, follow specific fabric maintenance guidelines. Use cold water and gentle cycles for washing. Avoid bleach and high heat when drying. Always check the washing instructions on the label for precise care details.

Can PCMS Be Used in Household Textiles Like Bedding?

"Home is where the heart is," and you can definitely use PCMs in household textiles like bedding. They offer comfort benefits and improve sleep quality, making your nights more restful and your days more productive.

What Are the Cost Implications of Pcm-Enhanced Fabrics?

When evaluating the cost implications of PCM-enhanced fabrics, you should consider performance benefits and market demand. While production costs may be higher, the enhanced performance can justify the investment, especially if market demand supports premium pricing.

Do PCMS Affect the Weight or Texture of the Fabric?

Yes, PCMs can affect the weight and texture of the fabric. You'll notice a slight weight impact due to added materials, and texture changes might occur, making the fabric feel different but still comfortable and functional.

- Tetron Fabric for Marine Applications: Durability and Use Cases - June 18, 2025

- Tetron Fabric for Outdoor Furniture: Weather Resistance and Care - June 18, 2025

- Tetron Fabric for Wall Coverings: Style and Application Tips - June 18, 2025