You might not know that medical textiles now use advanced antimicrobial fabrics that can inhibit bacterial and fungal growth even after numerous washes. These innovations aren't just about cleanliness; they're reshaping infection control and patient care. By incorporating nanotechnology and bio-based fibers, these fabrics provide durability, breathability, and non-toxicity. Curious about how this technology works and its real benefits for healthcare? Let's explore the latest advancements and their impact on hygiene standards and overall well-being in medical settings.

Key Takeaways

- Antimicrobial fabrics use silver ions, copper, and other agents to inhibit microbial growth and ensure prolonged protection in healthcare settings.

- Advanced fiber techniques include nanotechnology and microencapsulation for enhanced durability and functionality in medical textiles.

- Smart textiles now feature real-time pathogen detection and health monitoring capabilities for improved infection control.

- Sustainable antimicrobial solutions utilize natural agents, recycled materials, and biodegradable fibers to minimize environmental impact.

- Innovations in surgical gowns offer varying levels of antimicrobial protection, comfort, and durability to meet diverse healthcare needs.

Importance of Medical Textiles

Understanding the importance of medical textiles, you'll see how they play a vital role in infection control and patient care. In hospitals and clinics, the risk of infections spreading is a constant concern. This is where textile innovation steps in, offering advanced solutions to minimize these risks. Medical textiles are designed not just for comfort, but for their ability to prevent infections.

Imagine the fabrics used in surgical gowns, drapes, and bed linens. They're not your everyday textiles. These are crafted with cutting-edge technology that incorporates barriers to pathogens. By hindering microbial growth, these medical textiles act as a frontline defense in infection prevention. You can appreciate how crucial this is, especially in environments where sterility can mean the difference between life and death.

Furthermore, the innovation in these textiles extends to their durability and functionality. They undergo rigorous testing to guarantee they meet high standards of hygiene and safety. This means fewer infections, reduced hospital stays, and overall better patient outcomes.

Mastering the knowledge of medical textiles will give you an edge in understanding how modern healthcare continues to evolve, ensuring safer and more effective patient care.

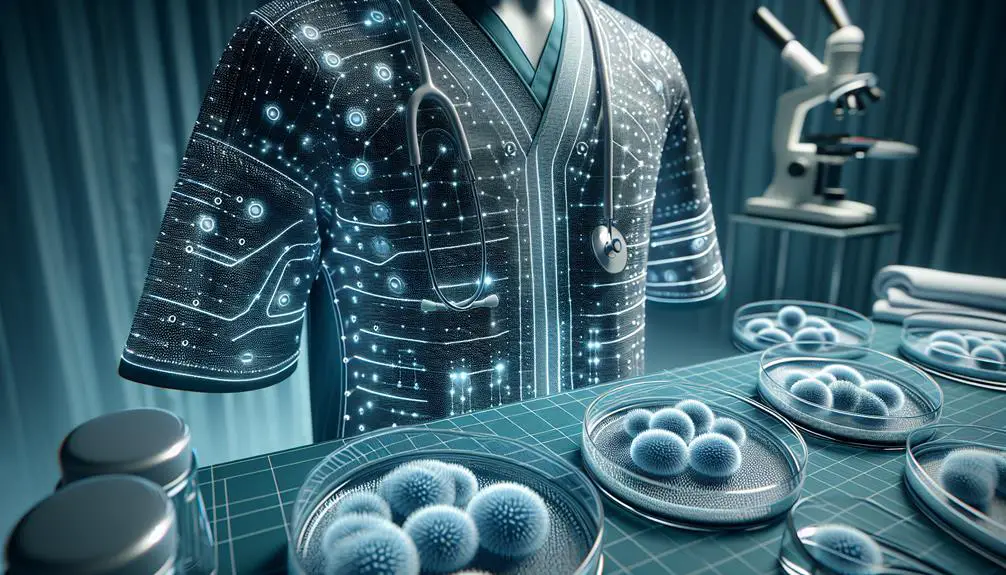

Understanding Antimicrobial Fabrics

Let's explore how antimicrobial fabrics take medical textiles a step further by actively inhibiting the growth of harmful bacteria and fungi. These advanced fabrics incorporate specific properties that not only prevent microbial growth but also enhance the overall hygiene and safety in medical environments.

Key fabric properties contribute to their effectiveness:

- Microbial resistance: The fabrics are designed to resist colonization by bacteria and fungi, reducing the risk of infections.

- Durability: These fabrics maintain their antimicrobial properties even after multiple washes, ensuring long-lasting protection.

- Breathability: Despite their advanced features, they still allow airflow, providing comfort without compromising protective capabilities.

- Non-toxicity: Safe for human contact, these fabrics don't release harmful chemicals, making them ideal for use in healthcare settings.

Types of Antimicrobial Agents

Antimicrobial fabrics utilize various agents such as silver ions, copper, quaternary ammonium compounds, and triclosan to combat harmful microorganisms effectively. Each of these agents has unique properties that make them suitable for different applications.

Silver ions, for instance, are prized for their wide-range antimicrobial activity and durability in textile treatment. They disrupt bacterial cell walls and interfere with crucial cellular functions, making them challenging for microorganisms to develop resistance against.

Copper is another potent agent. It not only kills bacteria but also inactivates viruses and fungi, offering a vital defense.

Quaternary ammonium compounds, or quats, are commonly used in textile manufacturing processes due to their ability to bind to fabric fibers and provide long-lasting antimicrobial properties. They work by disrupting the cell membranes of bacteria, causing cell death.

Triclosan, although effective, has raised concerns about antimicrobial resistance and environmental impact. Despite this, it remains a staple in some applications due to its ability to inhibit bacterial fatty acid synthesis, essential for cell growth.

How Antimicrobial Fabrics Work

These fabrics function by integrating antimicrobial agents directly into the textile fibers, creating a hostile environment for harmful microorganisms. This integration guarantees that the antimicrobial properties aren't just surface-level but embedded throughout the fabric, offering consistent microbial defense.

Key mechanisms include:

- Chemical bonding: Antimicrobial agents are chemically linked to the fibers, ensuring long-lasting protection and enhanced fabric functionality.

- Physical embedding: Agents are physically incorporated into the fibers during the manufacturing process, making the fabric resilient against microbial invasion.

- Slow-release technology: Some textiles use slow-release mechanisms, gradually releasing antimicrobial agents to maintain prolonged effectiveness.

- Electrostatic disruption: Certain agents disrupt the cell walls of bacteria through electrostatic forces, effectively neutralizing them.

Understanding these advanced methods gives you a grasp of textile innovation aimed at health protection. By utilizing such techniques, antimicrobial fabrics guarantee that harmful microorganisms like bacteria, fungi, and viruses can't thrive.

This continuous protection isn't just a reactive measure but a proactive approach to maintaining hygiene and health. You can rely on these fabrics to provide both durability and safety, making them an essential component in medical and everyday applications where hygiene is paramount.

Key Benefits of Antimicrobial Textiles

Building on the innovative mechanisms of antimicrobial fabrics, the key benefits they offer are numerous and impactful for both personal and professional applications.

First and foremost, these fabrics excel in infection prevention. By actively inhibiting the growth of harmful microorganisms, antimicrobial textiles reduce the risk of infections, creating safer environments in various settings. This is particularly crucial in spaces where hygiene is paramount, like fitness centers and public transportation.

Another significant advantage is textile durability. Antimicrobial treatments can extend the lifespan of fabrics by preventing the accumulation of bacteria, mold, and mildew, which can degrade materials over time. This means your garments, linens, and other textiles will maintain their integrity and appearance longer, providing better value and reducing waste.

Moreover, antimicrobial textiles contribute to overall health and well-being. By minimizing microbial presence, they help control odors and reduce the likelihood of skin irritations and allergies. This is especially beneficial for individuals with sensitive skin or pre-existing conditions.

Applications in Healthcare Settings

You'll find antimicrobial fabrics transforming healthcare settings by enhancing hospital bedding, revolutionizing surgical gowns, and improving staff uniforms.

These innovations reduce infection risks and promote a cleaner environment.

Embracing these textiles can make healthcare facilities safer for patients and staff alike.

Hospital Bedding Solutions

Hospitals are increasingly turning to antimicrobial fabrics for bedding to reduce infection rates and enhance patient safety. By integrating antimicrobial properties into hospital bedding, you can notably improve infection control measures. These fabrics inhibit the growth of harmful bacteria, viruses, and fungi, creating a safer environment for patients and healthcare staff.

Utilizing antimicrobial bedding offers several advantages:

- Enhanced Hygiene: Antimicrobial bedding reduces the microbial load, contributing to a cleaner and more sanitary hospital environment.

- Durability: These fabrics are designed to withstand frequent washing and high temperatures, maintaining their antimicrobial properties over time.

- Comfort: Advanced materials ensure that antimicrobial bedding remains soft and comfortable for patients, promoting better rest and recovery.

- Cost-Effectiveness: Although the initial investment might be higher, the long-term benefits include reduced infection-related costs and extended fabric life.

You can't overlook the benefits of incorporating antimicrobial fabrics into hospital bedding. They provide a proactive approach to infection control, ensuring that patient safety and comfort are prioritized. As you aim to master healthcare solutions, embracing these innovative textiles will indisputably enhance the overall quality and efficiency of care in medical settings.

Surgical Gown Innovations

Surgical gown innovations are revolutionizing healthcare settings by enhancing protection, comfort, and functionality for medical professionals. With advancements in surgical gown design and fabric technology, you're now better protected against infections and contaminants. Modern gowns incorporate antimicrobial protection, making them indispensable in surgical settings where sterility is paramount.

In the domain of surgical gown design, fabric technology plays a key role. These gowns are crafted from advanced materials that offer superior breathability and flexibility, guaranteeing you stay comfortable during long procedures. Additionally, the integration of antimicrobial agents directly into the fabric ensures continuous microbial defense, reducing the risk of cross-contamination.

Here's a detailed comparison to help you understand the advancements better:

| Feature | Traditional Gowns | Innovative Surgical Gowns |

|---|---|---|

| Fabric Technology | Basic cotton or polyester | Advanced antimicrobial fabrics |

| Antimicrobial Protection | Low to none | High |

| Comfort and Flexibility | Limited | Enhanced |

| Durability | Moderate | High |

These innovations in surgical gown design and fabric technology are not just about meeting regulatory standards; they're about surpassing them. By embracing these advancements, you're guaranteeing a safer and more efficient surgical environment.

Antimicrobial Uniform Benefits

Expanding beyond surgical environments, antimicrobial uniforms offer significant benefits across various healthcare settings by providing continuous protection against harmful pathogens. These uniforms enhance both the safety and comfort of healthcare professionals, ensuring they can perform their duties with confidence.

You'll appreciate the antimicrobial durability of these fabrics, which maintain their pathogen-fighting properties even after multiple washes. This means less frequent replacements and sustained protection over time, making them a cost-effective choice. Uniform comfort is another critical aspect, as these textiles are designed to be breathable and flexible, allowing for ease of movement during long shifts.

Consider the following advantages:

- Reduced Infection Rates: By actively neutralizing bacteria, antimicrobial uniforms decrease the chances of hospital-acquired infections (HAIs).

- Enhanced Professional Image: Clean, fresh-smelling uniforms contribute to a professional appearance, fostering trust among patients.

- Improved Hygiene Standards: Continuous antimicrobial action helps uphold high hygiene standards in various healthcare settings.

- Cost Efficiency: The long-lasting nature of antimicrobial fabrics reduces the need for frequent uniform replacements.

Innovations in Fabric Technology

You'll find that innovations in fabric technology are revolutionizing antimicrobial textiles.

Advanced fiber techniques, smart textile integration, and sustainable antimicrobial solutions are leading the charge.

These advancements promise to enhance both functionality and eco-friendliness in everyday fabrics.

Advanced Fiber Techniques

How are the latest advancements in fiber technology revolutionizing the development of antimicrobial fabrics?

With fiber innovation at the forefront, the landscape of textile development has experienced remarkable transformations. Today, advanced fiber techniques aren't just enhancing the durability and functionality of fabrics but also embedding antimicrobial properties directly into the fibers themselves. This guarantees a longer-lasting and more effective defense against pathogens.

Consider these cutting-edge advancements:

- Nanotechnology Integration: By incorporating nanoparticles like silver or copper directly into the fibers, you can create fabrics that inhibit bacterial growth at a microscopic level.

- Bio-based Fibers: Utilizing natural antimicrobial agents from plants or other biological sources, these fibers offer sustainable and effective pathogen resistance.

- Microencapsulation: This technique involves embedding antimicrobial agents within tiny capsules that are then bonded to the fibers, releasing the agents slowly over time.

- Electrospinning: Creating ultra-fine fibers through electrospinning allows for a larger surface area and better integration of antimicrobial substances.

Each of these innovations showcases how fiber technology isn't just keeping pace with the demands of modern medical textiles but setting new benchmarks in the industry. By mastering these techniques, you can stay ahead in the rapidly evolving field of antimicrobial fabric development.

Smart Textile Integration

Imagine wearing clothes that can monitor your health and adjust to environmental changes—this is the promise of smart textile integration in fabric technology. By embedding sensors and microprocessors into fabrics, wearable technology is revolutionizing the field. You're not just wearing clothes; you're donning sophisticated systems that can track essential signs, detect pathogens, and even release antimicrobial agents when needed.

Infection control becomes far more efficient with these smart textiles. They can identify bacterial presence and respond in real-time, minimizing the risk of infections. For instance, hospital garments incorporating these smart fabrics can monitor patients' health metrics while simultaneously controlling microbial growth. It's a dual-purpose solution that enhances both safety and convenience.

Moreover, smart textiles offer unparalleled adaptability. They can modify their properties based on external stimuli, such as temperature and humidity, ensuring optimal comfort and function. Imagine a fabric that can regulate its breathability or warmth based on your body's needs.

Sustainable Antimicrobial Solutions

Sustainability in antimicrobial fabric technology relies on the innovative use of eco-friendly materials and processes that minimize environmental impact. You can't ignore the importance of integrating these solutions into your medical textiles.

The latest advancements not only focus on reducing harm but also improving the overall efficiency and effectiveness of antimicrobial fabrics.

To achieve this, consider the following eco-friendly alternatives:

- Natural Antimicrobial Agents: Utilizing plant-based antimicrobials like bamboo and coconut fibers can provide natural resistance to bacteria and fungi.

- Recycled Materials: Incorporating recycled polyester or nylon reduces waste and energy consumption, making the production process more environmentally friendly.

- Waterless Dyeing Techniques: Adopting methods that use little to no water can significantly reduce pollutants and preserve valuable water resources.

- Biodegradable Fibers: Developing fabrics from biodegradable polymers ensures that, at the end of their lifecycle, they break down naturally without causing harm to the environment.

Evaluating Fabric Efficacy

To evaluate the efficacy of antimicrobial fabrics, you need to assess both their laboratory performance and real-world applications. Start with rigorous fabric testing and efficacy analysis to guarantee these textiles meet antimicrobial standards. Testing in controlled environments simulates conditions the fabrics will face, providing a clear picture of their ability to inhibit microbial growth.

Next, look at certification requirements. Certification bodies have strict criteria for antimicrobial efficacy. Meeting these standards not only validates the fabric's performance but also enhances its credibility and marketability.

| Testing Parameter | Importance |

|---|---|

| Microbial Reduction Rate | Measures how efficiently fabric kills or inhibits microbes |

| Durability of Antimicrobial Finish | Assesses how long the antimicrobial properties last after multiple washes |

| Safety and Toxicity | Ensures the fabric is user-friendly |

| Compliance with Standards | Verifies adherence to industry benchmarks and regulations |

In real-world applications, observe how the fabric performs in everyday conditions. Check for any reduction in efficacy over time. Remember, maintaining efficacy in the field is just as vital as achieving it in the lab. Combining robust fabric testing with real-world evaluation assures you're getting a reliable and effective antimicrobial textile.

Future Trends in Medical Textiles

As you look to the future of medical textiles, consider the potential of smart fabric technologies that can monitor patient health in real-time.

You'll also see a growing emphasis on sustainable medical textiles, aiming to reduce environmental impact.

These innovations promise to revolutionize patient care and medical practices.

Smart Fabric Technologies

Embracing cutting-edge innovation, smart fabric technologies are revolutionizing the future of medical textiles. Imagine a hospital environment where fabrics actively monitor patient health through wearable sensors, ensuring infection control is more effective than ever.

These advanced textiles are designed to do more than just cover or protect; they interact with the wearer's body, providing real-time data and feedback.

Here's how smart fabric technologies are transforming medical textiles:

- Wearable Sensors: Integrating sensors into fabrics allows continuous monitoring of crucial signs, such as heart rate and body temperature, helping clinicians make timely decisions.

- Infection Control: Embedded antimicrobial agents in smart fabrics can detect and respond to pathogens, creating an active defense against infections.

- Data Collection: Smart fabrics can collect and transmit data to healthcare providers, facilitating remote monitoring and personalized treatment plans.

- Adaptive Comfort: These textiles can adjust their properties, such as temperature or moisture-wicking capabilities, to enhance patient comfort and recovery.

Sustainable Medical Textiles

Sustainable medical textiles are paving the way for an eco-friendly future in healthcare by using biodegradable materials and reducing waste. You'll find that the shift towards sustainability isn't just a trend; it's a necessity. With eco-friendly production methods, these textiles minimize environmental impact while maintaining high performance standards.

Imagine a hospital gown that not only offers antimicrobial protection but also biodegrades when discarded, leaving no harmful residues behind.

Adopting biodegradable materials like organic cotton, bamboo, and even biopolymers derived from natural sources can drastically cut down on the waste generated by traditional medical textiles. These materials decompose naturally, reducing landfill contributions and the need for incineration.

Moreover, eco-friendly production processes focus on reducing water and energy consumption, and minimizing the use of harmful chemicals. This means you're not just opting for a sustainable product, but also supporting a greener manufacturing ecosystem.

Ultimately, the move towards sustainable medical textiles offers a dual benefit: safeguarding public health while protecting our planet. By choosing these advanced materials, you're contributing to a more sustainable healthcare system that's prepared for the future.

Challenges and Considerations

Understanding the complexities of antimicrobial fabrics requires a deep understanding of both their potential benefits and the inherent challenges. One major hurdle you'll face is manufacturing hurdles. Creating fabrics that maintain their antimicrobial properties through washing and wear isn't simple. The integration of antimicrobial agents must be precise, ensuring they don't compromise the fabric's integrity or comfort.

Another critical aspect is regulatory compliance. The medical textiles industry is heavily regulated, and for good reason. You must guarantee that your products meet strict standards and guidelines, which can vary significantly between regions. This often involves rigorous testing and certification processes that can be both time-consuming and costly.

Additionally, consider the environmental impact. While antimicrobial fabrics offer noteworthy health benefits, the chemicals used can pose environmental risks. Balancing efficacy with eco-friendliness is a delicate act.

Manufacturing hurdles: Ensuring durability and efficacy.

Regulatory compliance: Meeting strict standards and guidelines.

Cost considerations: Balancing quality and affordability.

Environmental impact: Managing the use of chemicals responsibly.

Mastering these challenges isn't easy, but with a strategic approach, you can create antimicrobial fabrics that are both effective and compliant with industry standards.

Frequently Asked Questions

Are Antimicrobial Fabrics Safe for People With Sensitive Skin?

Yes, antimicrobial fabrics are generally safe for people with sensitive skin. However, always check for potential skin reactions or allergies. Guarantee the fabric offers comfort and breathability to minimize any adverse effects.

How Should Antimicrobial Fabrics Be Washed or Maintained?

Treat antimicrobial fabrics like gold. For proper care, follow washing instructions to maintain fabric longevity and prevent skin reactions. Be mindful of expiration concerns and prioritize virus prevention. Consider environmental impact and production sustainability.

Do Antimicrobial Fabrics Have an Expiration Date?

You're wondering if antimicrobial fabrics have an expiration date. They do. Their antimicrobial longevity can vary, affecting fabric safety, especially for sensitive skin. Always check manufacturer guidelines to ensure best protection and skin compatibility.

Can Antimicrobial Fabrics Prevent the Transmission of Viruses?

You're wondering if antimicrobial fabrics can prevent the transmission of viruses. Their effectiveness varies, but they do enhance safety. They're generally safe for sensitive skin, but always check specific claims and test results for assurance.

Are There Any Environmental Concerns With the Production of Antimicrobial Fabrics?

Imagine a double-edged sword: production impact and sustainability are major concerns, along with chemical exposure for workers. You need to weigh the environmental footprint against the benefits of antimicrobial fabrics to truly grasp their full impact.