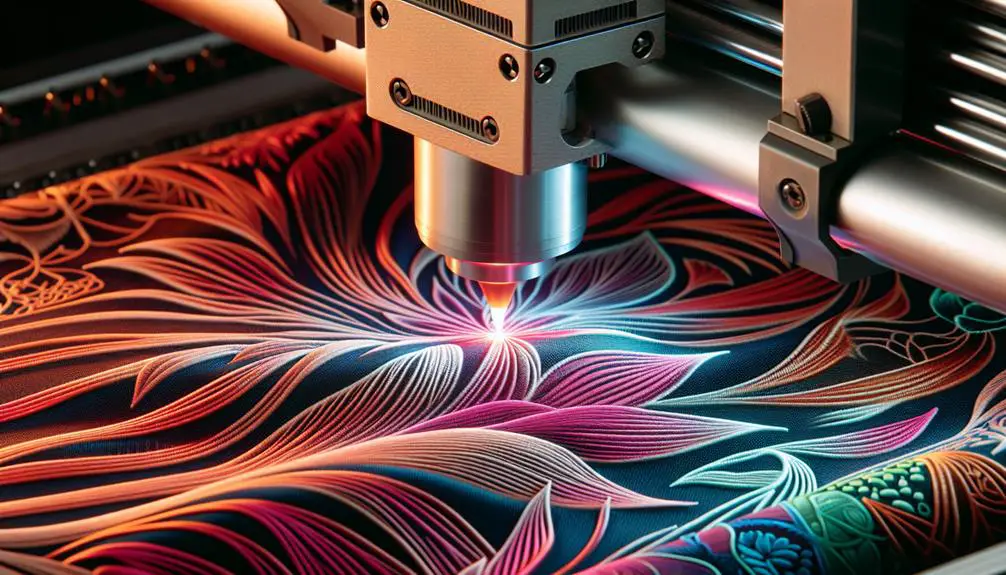

Imagine crafting a masterpiece like Da Vinci, but with textiles and a laser engraver. You'll need to start by selecting the appropriate fabric, as the choice can make or break your project. Cotton and linen, for example, are your closest allies due to their heat resistance. Next, designing your pattern requires some finesse—consider font selection and sizing carefully. Setting up the laser engraver is another crucial step, where precise adjustments guarantee excellent results. With the right techniques, you'll soon master engraving. But what happens after you've finished your design?

Table of Contents

Key Takeaways

- Choose natural fibers like cotton or linen, and avoid synthetic fabrics like polyester that can melt or discolor during laser engraving.

- Prepare your design with clear, sans-serif fonts and adjust the size to fit the textile dimensions, marking placement with fabric chalk.

- Secure the fabric on the engraving bed with clamps or adhesive mats and adjust laser settings to match the textile material.

- Conduct a test engraving on a scrap piece to verify settings, ensuring consistent focus and alignment of the laser beam.

- Post-engraving, brush off residue gently, spot clean with mild detergent, and store the fabric flat with acid-free tissue paper to prevent creasing.

Choosing the Right Textile

When you're selecting the appropriate textile for laser engraving, consider the fabric's composition and how it reacts to heat. Different materials respond uniquely to laser engraving, so understanding these nuances is essential.

For example, natural fibers like cotton and linen generally handle the heat well, providing clean, crisp engravings. Meanwhile, synthetic fabrics such as polyester can melt or discolor if not handled correctly.

Your fabric selection should align with your specific design considerations and the printing methods you plan to use. Certain textiles are better suited for detailed designs, while others might be more forgiving of minor errors.

For instance, fleece mightn't showcase intricate details as well as a tightly woven cotton fabric.

Material compatibility is another crucial factor. Some textiles mightn't be suitable for laser engraving due to their chemical composition. Fabrics treated with fire retardants or other chemicals can produce hazardous fumes when engraved.

Always make sure the material you choose is safe and suitable for laser work.

Preparing Your Design

Successful laser engraving on textiles begins with carefully preparing your design to achieve excellent results. Start by considering the design placement. The position of your engraving on the textile can greatly impact the final appearance. Measure your textile and visualize where the design will look most balanced and aesthetically pleasing. Mark the spot lightly with fabric chalk for reference.

Next, immerse into font selection. The type of font you choose can make or break your design. Opt for fonts that are clear and not overly intricate, as fine details may get lost during the engraving process. Bold, sans-serif fonts often work best for readability and visual impact. Test different fonts on a small piece of fabric to see how they translate when engraved.

Don't forget to adjust the size of your design according to the textile's dimensions. Too large, and it could overwhelm the fabric; too small, and it might look insignificant. Use design software to scale your design precisely, ensuring it fits perfectly within the designated area.

Setting Up the Laser Engraver

Before starting your project, make sure you've properly adjusted the laser engraver to match the specific type of textile you're working with. Laser adjustment is essential for achieving precise and consistent results. Begin by consulting your laser engraver's manual to modify the settings according to the textile material. This step guarantees efficient engraving and prevents damage to both the fabric and the machine.

Next, prioritize safety measures. Always wear safety goggles designed for laser use and verify that your workspace is well-ventilated. Double-check that all safety features on your machine are operational to prevent accidents.

Now, focus on material placement. Secure the textile firmly on the engraving bed to avoid any displacement during the process. Use clamps or adhesive mats specifically designed for laser engraving to keep the fabric taut and in position. This will help in maintaining the integrity of your design.

Lastly, pay close attention to adjusting the laser beam focus. Modify the focal length to match the thickness of the textile. A properly focused laser beam will produce clean and detailed engravings.

Engraving Techniques and Tips

To achieve the best outcomes in laser engraving on textiles, start by selecting the appropriate engraving technique for your specific fabric. Different textiles react uniquely to laser engraving, so understanding material compatibility is essential. For example, natural fibers like cotton and linen generally handle higher engraving depths better than synthetic fabrics, which might melt or warp if the laser is too intense.

Next, adjust your laser engraver's settings to match the fabric's properties. Fine-tuning the power and speed controls guarantees you don't scorch or burn the material. Use a lower power setting for delicate fabrics and a higher one for sturdier textiles. Always conduct a test engraving on a scrap piece to verify your settings.

Pay close attention to the engraving depth. Too shallow, and the design won't be visible; too deep, and you risk damaging the fabric. Typically, a depth of 1-2 millimeters is adequate for most textiles, but this can vary based on the material.

Lastly, maintain a consistent focus and alignment of your laser beam. Any deviation can result in uneven engraving, impacting the final appearance. By mastering these techniques, you'll achieve professional-grade, precise engravings every time.

Post-Engraving Care and Maintenance

After you've completed the laser engraving, it's vital to properly clean and care for your textile to make certain the design remains vibrant and the fabric stays intact.

Start by gently brushing off any loose residue with a soft, dry brush. This initial step prevents debris from embedding into the fabric fibers.

Follow these cleaning instructions to maintain the integrity of your engraved textile:

- Spot Cleaning: Use a gentle detergent diluted in water. Dab the area gently with a clean cloth, avoiding excessive moisture.

- Avoid Harsh Chemicals: Steer clear of bleach or strong solvents, as they can degrade the fabric and fade the engraving.

- Air Drying: Lay the textile flat to dry, keeping it out of direct sunlight to prevent color fading.

Proper storage is equally essential. Make sure your engraved textile is stored in a cool, dry place. Fold it neatly, placing acid-free tissue paper between the folds to prevent creasing and color transfer.

For added protection, use a breathable fabric cover or a cotton storage bag.

Frequently Asked Questions

Can Laser Engraving Be Done on Blended Fabrics?

Yes, you can laser engrave on blended fabrics. Understanding the fabric composition is essential. Blends can expand your design possibilities, allowing for intricate and varied patterns while ensuring the material withstands the engraving process.

How Does Laser Engraving Affect Fabric Durability?

A stitch in time saves nine. Laser engraving, with its precision, can either enhance or diminish fabric longevity depending on technique and material quality. Master the process to guarantee your textiles remain durable and aesthetically pleasing.

Are There Safety Precautions for Laser Engraving on Textiles?

Yes, there are important safety measures. Guarantee proper ventilation to avoid inhaling fumes. Always wear safety goggles and gloves. Regularly inspect your equipment to prevent malfunctions. Master these precautions to maintain a safe engraving environment.

What Are the Environmental Impacts of Laser Engraving on Textiles?

You should consider environmental concerns when laser engraving textiles. Promote sustainability practices by choosing eco-friendly materials and proper ventilation. This reduces harmful emissions and promotes a more sustainable approach to textile customization.

Can You Laser Engrave on Pre-Dyed or Printed Fabrics?

Absolutely, you can laser engrave on pre-dyed or printed fabrics. While you might worry about fabric compatibility, most textiles handle it well. Plus, laser engraving does a great job of preserving the fabric's original colors.

- The Science Behind Spunlace (Hydroentanglement) Nonwoven Fabric - July 11, 2025

- A Buyer’s Guide to Nonwoven Geotextile Fabric - July 11, 2025

- Where to Find Melt Blown Nonwoven Fabric for Filters - July 11, 2025