If you've ever held a feather in your hand, you know how light it feels. But is carbon fiber fabric really light?

In this brief exploration, we'll delve into the science behind this innovative material to understand its weight and strength characteristics. Understanding the weight-to-strength ratio of carbon fiber, as well as the factors that can affect its weight, will shed light on its lightweight properties.

By comparing carbon fiber to traditional materials, we can gain insight into its relative lightness. Finally, we'll examine real-world applications and offer tips for working with this remarkably light and strong fabric.

Key Takeaways

- Carbon fiber fabric has a high strength-to-weight ratio and excellent stiffness.

- It provides exceptional structural integrity while remaining lightweight, surpassing steel or aluminum.

- The manufacturing process of carbon fiber fabric involves polymerization, thermal treatment, and layering with resin infusion.

- Carbon fiber fabric is extensively used in aerospace, automotive, and sports equipment industries for its lightweight and strong properties.

What Is Carbon Fiber Fabric

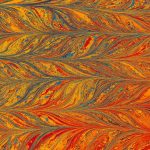

You may frequently encounter carbon fiber fabric in high-performance applications such as aerospace, automotive, and sports equipment. Carbon fiber production involves spinning and weaving carbon fibers into a fabric.

The raw material used in carbon fiber production is a precursor material that undergoes a series of heating and stretching processes to create the final carbon fiber. The properties of carbon fiber fabric make it desirable for various applications. It's known for its high strength-to-weight ratio, making it incredibly strong while remaining lightweight. Additionally, carbon fiber fabric exhibits excellent stiffness, chemical resistance, and temperature tolerance.

These properties make it an ideal choice for industries where high performance and durability are crucial. The weaving process of carbon fibers into fabric allows for tailored designs and orientations of the fibers, resulting in specific mechanical properties. This level of customization makes carbon fiber fabric highly versatile and suitable for a wide range of uses.

Understanding the production process and the properties of carbon fiber fabric is essential for harnessing its full potential in various high-performance applications.

The Science Behind Lightweight Materials

Exploring the science behind lightweight materials, carbon fiber fabric is engineered to provide exceptional strength while maintaining a remarkably low weight. Through careful production techniques and precise material composition, the fabric achieves an impressive balance of properties, making it highly sought after in a variety of high-performance industries.

| Material Properties | Manufacturing Process | Application |

|---|---|---|

| High strength-to-weight ratio | Polymerization of precursor fibers | Aerospace industry |

| Low density | Thermal treatment in controlled environments | Automotive sector |

| Stiffness | Layering and resin infusion | Sports equipment |

Carbon fiber fabric's material properties are a result of its high strength-to-weight ratio, low density, and stiffness. The manufacturing process involves polymerization of precursor fibers followed by thermal treatment in controlled environments and layering with resin infusion. These properties and manufacturing techniques make the fabric ideal for various applications such as the aerospace industry, automotive sector, and sports equipment. Understanding the science behind lightweight materials like carbon fiber fabric is crucial for optimizing its utilization in diverse high-performance fields.

Weight-to-Strength Ratio of Carbon Fiber

When evaluating the weight-to-strength ratio of carbon fiber, it's important to consider the significant advantage it offers in terms of strength-to-weight.

This means that carbon fiber can provide exceptional structural integrity while remaining lightweight, making it a valuable material in various applications.

Understanding the weight-to-strength ratio of carbon fiber is crucial for realizing its potential benefits in creating lightweight yet strong products.

Strength-To-Weight Advantage

With a remarkable weight-to-strength ratio, carbon fiber fabric offers an exceptional strength-to-weight advantage. The material composition of carbon fiber, which consists of thin strands of carbon atoms bonded together, contributes to its outstanding strength-to-weight ratio.

During the production process, these carbon atoms are aligned parallel to the long axis of the fiber and then bonded together with a polymer matrix, resulting in a material that's incredibly strong yet lightweight. This unique composition and production process give carbon fiber fabric a significant strength-to-weight advantage compared to traditional materials like steel or aluminum.

As a result, products made with carbon fiber, such as aircraft components and sports equipment, exhibit exceptional strength and durability while being significantly lighter in weight.

Structural Integrity Benefits

You can understand the structural integrity benefits of carbon fiber fabric by considering its impressive weight-to-strength ratio, which surpasses that of traditional materials like steel or aluminum. This superior weight-to-strength ratio is what makes carbon fiber fabric stand out in terms of structural integrity and weight distribution. The table below compares the weight-to-strength ratio of carbon fiber with steel and aluminum:

| Material | Weight-to-Strength Ratio |

|---|---|

| Carbon Fiber | High |

| Steel | Moderate |

| Aluminum | Moderate |

As shown in the table, carbon fiber has a high weight-to-strength ratio, indicating its ability to provide exceptional strength while maintaining a lightweight structure. This characteristic makes carbon fiber fabric an ideal choice for applications where structural integrity and weight distribution are crucial.

Lightweight Material Applications

To fully understand the practical applications of carbon fiber fabric's weight-to-strength ratio, consider its unmatched performance in lightweight structures. The weight-to-strength ratio of carbon fiber makes it an ideal choice for various applications, especially in aerospace engineering.

Here are some key areas where carbon fiber's lightweight design and exceptional strength are invaluable:

- Aerospace applications: Carbon fiber is extensively used in the aerospace industry for manufacturing aircraft and spacecraft components due to its high strength and low weight.

- Automotive industry: Carbon fiber composites are increasingly being used in the automotive sector to reduce vehicle weight, improve fuel efficiency, and enhance performance.

- Sports equipment: Carbon fiber's exceptional weight-to-strength ratio makes it a popular choice for manufacturing lightweight and durable sports equipment such as bicycles, tennis rackets, and fishing rods.

Factors Affecting Carbon Fiber's Weight

When manufacturing carbon fiber fabric, attention to detail during the layup process significantly impacts its weight. The material composition of carbon fiber fabric plays a crucial role in determining its weight. The type and quality of carbon fibers used, along with the resin matrix, directly affect the final weight of the fabric. Different carbon fibers have varying densities, tensile strengths, and stiffness, which influence the overall weight of the fabric. Similarly, the resin matrix, which holds the carbon fibers together, contributes to the fabric's weight based on its density and the amount used during the manufacturing process.

The manufacturing process also has a profound impact on the weight of carbon fiber fabric. Factors such as the method of layup, the pressure applied during curing, and the temperature control during the curing process can all affect the final weight of the fabric. Properly controlled manufacturing processes can result in a lighter fabric, as any deviations in the process can lead to inconsistencies in the material, potentially adding unnecessary weight.

Therefore, meticulous attention to both material composition and manufacturing processes is essential for achieving the desired lightweight properties of carbon fiber fabric.

Comparing Carbon Fiber to Traditional Materials

Comparing carbon fiber to traditional materials involves considering various factors that affect performance and weight. When looking at the weight comparison between aluminum and carbon fiber, it's important to note that carbon fiber is significantly lighter than aluminum, making it an attractive option for industries where weight reduction is critical. Additionally, when comparing carbon fiber to steel, carbon fiber is about 70% lighter, yet still possesses outstanding strength and stiffness. This makes it a preferred choice for applications where high strength and low weight are paramount.

- Carbon fiber vs. Aluminum: Carbon fiber is significantly lighter than aluminum, making it ideal for weight-sensitive applications.

- Carbon fiber vs. Steel: Carbon fiber is approximately 70% lighter than steel while maintaining exceptional strength and stiffness.

- Weight reduction: Carbon fiber offers a substantial reduction in weight compared to traditional materials, making it an advantageous choice for various industries.

When considering the weight comparison between carbon fiber and traditional materials, it becomes evident that carbon fiber's lightweight nature provides a competitive edge in various applications, making it an appealing choice for industries seeking to optimize performance while minimizing weight.

Real-World Applications of Lightweight Carbon Fiber

You can find lightweight carbon fiber used in a diverse range of real-world applications, from aerospace components to high-performance sports equipment.

In the aerospace industry, carbon fiber is extensively utilized in aircraft components such as wings, fuselage panels, and interior structures. Its high strength-to-weight ratio and durability make it an ideal material for enhancing fuel efficiency and overall performance. The Boeing 787 Dreamliner, for example, incorporates a significant amount of carbon fiber-reinforced polymer composites in its construction, reducing the aircraft's weight and fuel consumption. Moreover, carbon fiber is also employed in the manufacturing of satellite components due to its ability to withstand the harsh conditions of space while remaining lightweight.

Beyond aerospace, carbon fiber finds its way into various sporting goods like tennis rackets, bicycle frames, and golf clubs, where its lightweight properties contribute to improved maneuverability and performance. Additionally, automotive manufacturers increasingly use carbon fiber in car bodies and components to enhance fuel efficiency and overall vehicle performance.

As technology and manufacturing processes continue to advance, we can expect to see even more innovative real-world applications for lightweight carbon fiber.

Tips for Working With Lightweight Carbon Fiber

Working with lightweight carbon fiber requires precision and attention to detail to ensure optimal results. When working with this material, consider the following tips for efficient handling and maintenance:

- Use the right tools: Utilize sharp cutting tools specifically designed for carbon fiber to ensure clean cuts and prevent fraying or splintering of the material.

- Implement proper working techniques: When laying up carbon fiber fabric, ensure that it's cut and positioned accurately to avoid unnecessary waste and ensure the structural integrity of the final product.

- Maintenance considerations: After completing a project, be sure to inspect the carbon fiber components regularly for any signs of wear, delamination, or damage. This proactive approach can help identify and address any issues before they escalate.

Frequently Asked Questions

How Does the Cost of Carbon Fiber Fabric Compare to Traditional Materials Like Steel or Aluminum?

When comparing the cost of carbon fiber fabric to traditional materials like steel or aluminum, the weight advantage is significant. Carbon fiber is generally more expensive, but its superior strength-to-weight ratio can make it cost-effective in certain applications.

Can Carbon Fiber Fabric Be Easily Repaired if It Becomes Damaged?

To repair damaged carbon fiber fabric, start by assessing the extent of the damage. Then, sand down the damaged area, apply epoxy resin, and let it cure. Finally, sand and polish the repaired area for a seamless finish. Maintenance tips can prolong its lifespan.

Are There Any Environmental Concerns Associated With the Production or Disposal of Carbon Fiber Fabric?

When considering the environmental impact of carbon fiber fabric, it's important to note that its production process involves high energy consumption and emissions. However, recycling options are available, making it more sustainable in the long run.

What Are the Limitations of Carbon Fiber Fabric in Terms of Temperature Resistance and Durability?

When considering temperature resistance and durability, carbon fiber fabric has limitations. It may not withstand extreme temperatures and can be prone to delamination. However, its high strength-to-weight ratio and repairability make it advantageous in many applications.

Are There Any Safety Considerations to Keep in Mind When Working With Carbon Fiber Fabric, Such as Potential Health Risks or Special Handling Requirements?

When working with carbon fiber fabric, potential health risks and special handling requirements must be considered. Exposure to carbon fibers can cause skin and respiratory irritation, so proper protective gear and ventilation are essential.

- What Does Polyamide Mean - July 1, 2025

- Polyamide Washing Instructions - July 1, 2025

- Polyamide Vs Wool - July 1, 2025