Are you ready to learn how to serge lace fabric like a pro?

In this article, we will guide you through the step-by-step process of achieving clean and professional-looking edges on your lace fabric.

You’ll discover the secrets to choosing the right lace fabric, preparing your sewing machine, and adjusting the tension settings for flawless results.

So, grab your sewing machine and let’s dive into the world of serging lace fabric!

Table of Contents

Choosing the Right Lace Fabric

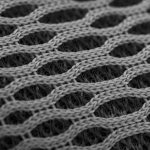

When choosing the right lace fabric, you’ll want to consider the color, pattern, and weight that best suits your project. The first step is to determine the type of lace you need. There are many different lace types available, such as Chantilly, Alençon, and Guipure. Each type has its own unique characteristics and can add a different touch to your project. It’s important to choose a lace type that complements your design and enhances the overall look.

Next, take into account the delicacy of the lace. Some lace fabrics are more delicate than others and require extra care when working with them. Delicate lace should be handled gently to avoid snagging or tearing. It’s also important to use the right tools and techniques when sewing with delicate lace. For example, using a fine needle and thread can help prevent damage to the fabric. Additionally, it’s a good idea to test the lace fabric before starting your project to ensure it can withstand the desired treatment, such as washing or ironing.

Preparing Your Sewing Machine

Before starting, make sure you’ve gathered all the necessary materials for preparing your sewing machine. The first step is choosing the right thread for your project. Consider the weight and color of your fabric when making your selection. For lace fabric, it is best to choose a lightweight thread that matches the color of the fabric or is close to it. This will ensure that your stitches blend seamlessly with the lace.

Next, you need to select the appropriate needle for your sewing machine. For lace fabric, it is recommended to use a fine needle, such as a size 9 or 11. This will help prevent any damage to the delicate fabric. Make sure to check your sewing machine manual for any specific recommendations on needle size for lace fabric.

Once you have your thread and needle ready, it’s time to prepare your sewing machine. Start by ensuring that your machine is clean and free of any dust or debris. Give it a thorough cleaning, especially around the needle area. This will help prevent any thread breakage or skipped stitches.

After cleaning, insert the selected needle into your sewing machine, following the instructions in your manual. Make sure it is securely in place. Finally, thread your machine, referring to the manual for proper threading instructions.

Adjusting the Tension Settings

When working with lace fabric, it’s crucial to find the optimal tension settings on your sewing machine. This will help you achieve clean and even stitches without any puckering or stretching.

If you encounter any tension issues, such as loose or tight stitches, it’s important to troubleshoot and make the necessary adjustments to ensure a successful outcome for your lace project.

Optimal Tension for Lace

To achieve the optimal tension for lace, it’s important to adjust the settings on your serger machine. Lace fabric requires delicate handling to prevent any damage or distortion. Here are some techniques to help you achieve the perfect tension:

-

Start by selecting the appropriate thread and needle for your lace fabric. Using a fine thread and a smaller needle size will ensure smoother stitches without puckering or pulling.

-

Gradually adjust the tension dial on your serger machine. Begin with a lower tension setting and slowly increase it until you achieve the desired result. Remember to test the tension on a scrap piece of lace fabric before working on your actual project.

-

If you encounter any issues with tension, such as skipped stitches or loopy threads, troubleshoot by checking the threading path, needle position, and bobbin tension. Making these adjustments will help you maintain consistent and even stitches on your lace fabric.

Avoiding Puckering or Stretching

Achieving the optimal tension on your serger machine helps you avoid puckering or stretching your delicate lace projects. To maintain the perfect tension, you need to consider a few factors. First, make sure your thread is properly threaded through the tension disks. This helps prevent snagging and ensures smooth stitching. Second, adjust the tension dials according to the fabric type and the desired result. Too much tension can lead to puckering, while too little tension can cause the fabric to stretch. Lastly, always test on a scrap piece of lace before starting your project to ensure the tension is just right. By following these steps, you can avoid any mishaps and achieve flawless serged lace creations.

| Factors to Consider | Tips for Maintaining Thread Tension |

|---|---|

| Proper threading | Ensure thread is correctly threaded through tension disks to avoid snagging. |

| Tension adjustments | Adjust tension dials based on fabric type and desired result. Too much tension can cause puckering, while too little can stretch the fabric. |

| Test on scrap lace | Always test tension on a scrap piece of lace before starting your project to ensure optimal results. |

Troubleshooting Tension Issues

One common issue with thread tension on a serger machine is that it can lead to puckering or stretching. If you’re experiencing common tension problems, such as thread breaks, don’t worry. There are some troubleshooting steps you can take to resolve these issues.

First, check the upper tension dial and make sure it is properly set. If it’s too tight, it can cause the thread to break.

Next, examine the threading path to ensure that the thread is correctly threaded through all the guides and tension discs. Sometimes, a simple rethreading can fix the problem.

Additionally, check the needle threader and make sure it is properly aligned with the needle.

Serging the Edges of the Lace

When serging lace fabric, it’s important to use a narrow zigzag stitch to prevent the edges from fraying. This will help you avoid distortion and secure the delicate edges of the lace. By using a narrow zigzag stitch, you can ensure that the lace fabric remains intact and doesn’t unravel. This stitch creates a secure seam that holds the edges together without causing any damage or distortion to the fabric.

To start, adjust your serger settings to a narrow zigzag stitch. This stitch will allow you to encase the edges of the lace fabric, preventing them from fraying. When serging, guide the fabric through the machine slowly and steadily, making sure that the edges are aligned properly. Take your time to ensure accuracy and precision.

As you serge, keep an eye on the tension of the thread. If the tension is too tight, it can cause the delicate lace fabric to pucker or distort. Adjust the tension dial if necessary to achieve the desired result.

Remember to handle the lace fabric gently and avoid pulling or stretching it while serging. This will help maintain the integrity of the delicate lace and prevent any distortion or damage.

Finishing Touches and Cleaning Up

When it comes to properly serging lace fabric, preventing frayed edges and tidying up loose threads are crucial finishing touches.

You want to ensure that your lace edges are clean and secure, without any fraying or unraveling.

Taking the time to neatly trim any loose threads and secure them with a serger stitch will give your lace project a polished and professional look.

Proper Lace Serging

To create a clean edge, it’s important to use a narrow serger foot when serging lace fabric.

Here are three key tips for properly serging lace fabric to avoid snagging and prevent unraveling:

-

Adjust the tension: Lace fabrics are delicate, so it’s crucial to adjust the tension on your serger to prevent snagging. Lower the tension settings slightly to ensure a smoother feed and reduce the risk of damaging the delicate lace.

-

Use a fine needle: When serging lace, opt for a fine needle with a smaller gauge. This will help prevent the needle from piercing through the delicate threads of the lace, reducing the chance of unraveling.

-

Test on scrap fabric first: Before serging the actual lace fabric, always test your settings and techniques on a scrap piece of lace. This way, you can ensure that the serger foot and stitch length are appropriate, avoiding any potential mishaps on the final product.

Preventing Frayed Edges

Now that you know how to properly serge lace fabric, let’s focus on preventing frayed edges and securing the lace edges. When working with delicate lace, it’s important to take extra precautions to ensure that the edges do not unravel. One effective method is to use a narrow three-thread overlock stitch. This stitch not only prevents fraying but also provides a clean and professional finish. Additionally, you can also apply a fabric adhesive to the edges of the lace before serging. This will help secure the threads and prevent any potential unraveling. By following these steps, you can confidently work with lace fabric and achieve beautiful and durable results.

| Method | Description | Benefits |

|---|---|---|

| Narrow three-thread overlock stitch | Prevents fraying and provides a clean finish | Professional look, durability |

| Applying fabric adhesive | Secures threads and prevents unraveling | Added strength, longevity |

Tidying up Loose Threads

Take a moment to trim any loose threads on the edges of your project to ensure a neat and polished final result. It’s important to prevent unraveling and secure delicate lace fabric to maintain its beauty and longevity.

Here’s what you need to do:

-

Gather your materials: sharp scissors, a seam ripper, and a pair of tweezers.

-

Carefully inspect the edges of your lace fabric for any loose threads.

-

Use your sharp scissors to snip the loose threads close to the fabric, being careful not to cut into the lace itself.

-

If you come across a particularly stubborn thread, gently use the seam ripper or tweezers to remove it without causing any damage.

Troubleshooting Common Issues

If you’re having trouble with skipped stitches while serging lace fabric, try adjusting the tension on your machine. Troubleshooting stitch quality is essential to achieve a professional finish on your lace projects.

Skipped stitches can be frustrating, but there are steps you can take to prevent them.

First, check the tension settings on your serger. The tension controls the tightness of the stitches. If the tension is too loose, the stitches may skip. Gradually increase the tension until the stitches are forming properly. However, be careful not to make the tension too tight, as it may cause the fabric to pucker or break.

Next, examine the condition of your needle. A dull or bent needle can cause skipped stitches. Replace the needle regularly, especially when working with delicate fabrics like lace. Use a needle specifically designed for serging to ensure the best results.

Another factor to consider is the type of thread you’re using. Using a high-quality thread that is appropriate for your fabric can make a significant difference in stitch quality. Cheap or old thread may be more prone to breaking or skipping stitches.

Lastly, take your time when serging lace fabric. It is delicate and requires a gentle touch. Slow down the speed of your machine and guide the fabric carefully to prevent skipped stitches and potential damage to the lace.

Conclusion

In conclusion, serging lace fabric requires careful preparation and attention to detail. By choosing the right lace fabric, preparing your sewing machine, and adjusting the tension settings, you can achieve clean and professional-looking edges.

Serging the edges of the lace is the main step, followed by adding finishing touches and cleaning up any loose threads. If you encounter any issues along the way, troubleshooting common problems will help you overcome them.

With practice and patience, you’ll be able to successfully serge lace fabric and create beautiful finished projects.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024