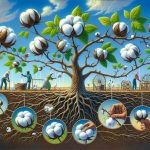

In this how-to guide, you’ll learn the process of producing and dyeing cotton fabric.

First, you’ll discover how to cultivate cotton plants and harvest the bolls.

Then, you’ll see how the cotton fibers are ginned and separated before being spun into yarn.

Next, you’ll explore the weaving or knitting process to create the fabric.

Finally, you’ll be guided through the steps of preparing the cotton fabric for dyeing and using natural or synthetic dyes to add vibrant colors.

Table of Contents

Cultivating Cotton Plants

To cultivate cotton plants, you’ll need to prepare the soil, plant the seeds, and provide proper care throughout the growing season.

Cotton plant growth requires specific conditions and techniques to ensure a successful harvest. First, start by preparing the soil. Cotton plants prefer well-drained soil with a pH level between 5.5 and 7.5. It’s important to remove any weeds or debris from the planting area to prevent competition for nutrients.

Next, plant the cotton seeds. Sow the seeds in rows, spacing them about 1 inch apart and ½ inch deep. Cover the seeds with soil and gently pat it down. Once the seeds have germinated, thin the seedlings to allow for proper spacing.

Throughout the growing season, provide the cotton plants with regular water and fertilizer. Water the plants deeply but be careful not to overwater, as cotton plants are susceptible to root rot. Apply fertilizer according to the instructions on the packaging, ensuring that it contains the necessary nutrients for cotton growth.

Additionally, monitor the plants for pests and diseases, and take appropriate action if any issues arise. By following these cotton cultivation techniques, you can promote healthy plant growth and increase your chances of a successful harvest.

Harvesting Cotton Bolls

Once the cotton plants have reached maturity, it is important for you to carefully harvest the cotton bolls using sharp shears or a cotton picking machine. The cotton bolls are the seed pods of the cotton plant and contain the fibers that will eventually be spun into cotton fabric. Harvesting the cotton bolls at the right time is crucial to ensure the quality of the fibers.

When harvesting cotton bolls, it is essential to handle them with care to prevent damage. Using sharp shears or a cotton picking machine helps to minimize any harm to the bolls. Once the bolls are harvested, they undergo a series of processing steps to separate the seeds from the fibers.

Here is a table outlining the various uses and processing steps of cotton bolls:

| Use | Processing Steps |

|---|---|

| Cotton fabric | Ginning, carding, spinning |

| Cottonseed oil | Extraction, refining, processing |

| Animal feed | Removing lint, crushing, drying |

| Cottonseed meal | Grinding, extracting oil |

| Paper production | Pulping, bleaching, drying |

As you can see, cotton bolls have various uses and go through different processing methods depending on the desired end product. It is important to handle the bolls carefully during harvesting and subsequent processing to ensure the best quality fibers and products.

Ginning and Separating Cotton Fibers

To separate the cotton fibers from the seeds, you’ll need to use a machine called a cotton gin. Cotton ginning is the process of removing the seeds from the cotton fibers, allowing for further processing and use in the textile industry.

The cotton gin is a mechanical device that uses a series of rotating saws and brushes to separate the fibers from the seeds. The cotton is fed into the gin, where the saws grip and pull the fibers away from the seeds. As the fibers are separated, they’re collected and sent to the next stage of processing. The seeds, on the other hand, are collected separately for various purposes, such as producing cottonseed oil or animal feed.

The fiber separation process is crucial in ensuring that only the high-quality cotton fibers are used for making fabric. By removing the seeds, the cotton fibers become more refined and suitable for spinning into yarn and weaving into fabric.

The cotton gin revolutionized the cotton industry, making it easier and more efficient to process cotton on a large scale.

Spinning Cotton Fibers Into Yarn

Now that you have separated the cotton fibers, it’s time to spin them into yarn.

There are various methods to spin cotton fibers, including ring spinning and open-end spinning.

The quality of the fiber plays a crucial role in determining the strength and durability of the yarn produced.

Fiber Preparation Techniques

Start by preparing the cotton fibers for spinning into yarn. This crucial step ensures that the fibers are ready to be transformed into beautiful and versatile fabric.

Here are four fiber preparation techniques that will inspire and excite you:

-

Hand-carding: Feel the satisfaction of combing the fibers with handheld brushes, creating fluffy and even strands for spinning. It’s a mindful and meditative process that allows you to connect with the cotton fibers on a deeper level.

-

Drum carding: Watch as the cotton fibers are fed into a drum carder, which gently aligns and blends them together. The rhythmic hum of the machine creates a sense of anticipation, knowing that soon you’ll have perfectly blended fiber ready for spinning.

-

Hackling: Experience the thrill of pulling the cotton fibers through sharp metal teeth, separating and smoothing them. This technique produces long, silky strands that are ideal for spinning fine yarns. Each pull of the fibers brings a sense of accomplishment and progress.

-

Combing: Enjoy the precision of combing the cotton fibers with a combing tool, creating a smooth and lustrous preparation. The meticulousness required in this technique brings a sense of satisfaction, knowing that the fibers are now ready for the spinning process.

With these fiber preparation techniques, you’ll be able to create yarn that isn’t only functional but also showcases your creativity through decoration techniques and dyeing techniques.

Yarn Spinning Methods

Get ready to spin cotton fibers into yarn using various methods.

Two common spinning methods for cotton fibers are ring spinning and open end spinning.

Ring spinning is a traditional method that produces high-quality yarn with a smooth finish. It involves passing the fibers through a series of machines, including the blow room and carding process, to clean and align the fibers before spinning them into yarn.

On the other hand, open end spinning is a more modern and efficient method that produces a coarser yarn. It skips the blow room and carding process and directly spins the fibers into yarn.

Both methods have their advantages and disadvantages, so it’s important to consider factors like yarn quality and production efficiency when choosing the spinning method for your cotton fabric.

Importance of Fiber Quality

To ensure the production of high-quality yarn, it’s crucial to prioritize fiber quality when spinning cotton fibers into yarn. The impact of fiber quality on fabric durability can’t be overstated. High-quality fibers will result in stronger and more durable yarn, leading to longer-lasting fabrics.

On the other hand, poor fiber quality can result in weak yarn that’s prone to breakage and pilling, reducing the lifespan of the fabric. Additionally, the role of fiber quality in dye absorption is significant. High-quality fibers have better dye affinity, allowing for more vibrant and long-lasting colors.

Poor fiber quality may result in uneven dye absorption, leading to patchy or faded colors. By emphasizing fiber quality, you can create fabrics that aren’t only durable but also visually appealing.

Weaving or Knitting Cotton Fabric

To weave or knit cotton fabric, begin by selecting high-quality cotton yarns that are suitable for the desired fabric construction. Weaving techniques involve interlacing the yarns horizontally and vertically to create a stable and durable fabric. There are various weaving patterns that can be used, such as plain weave, twill weave, and satin weave.

Plain weave is the simplest and most common, with each weft yarn passing over and under each warp yarn in an alternating pattern. Twill weave creates a diagonal pattern and is often used for denim fabric. Satin weave produces a smooth and lustrous fabric with a floating yarn structure.

On the other hand, knitting cotton fabric involves creating loops of yarn and interlocking them together. Knitting patterns can range from basic stockinette stitch to more complex cable and lace patterns. Knitted cotton fabric is known for its stretch and flexibility, making it ideal for garments like t-shirts and sweaters.

Whether you choose to weave or knit cotton fabric, the quality of the yarns and the skillful execution of the techniques will ultimately determine the end result.

Preparing Cotton Fabric for Dyeing

To prepare cotton fabric for dyeing, you’ll need to start by thoroughly washing and scouring the fabric to remove any impurities or finishes that could interfere with the dye absorption process. This step is crucial in achieving vibrant and long-lasting colors.

Here are four reasons why fabric preparation is so important in cotton fabric dyeing techniques:

-

Enhanced dye penetration: By removing impurities and finishes, the fabric becomes more porous, allowing the dye to penetrate evenly and deeply. This results in rich and uniform color saturation.

-

Improved color fastness: Proper fabric preparation ensures that the dye adheres firmly to the fabric fibers, making it less likely to fade or wash out over time. This increases the longevity of the dyed fabric.

-

Even dye distribution: By eliminating any surface treatments or coatings, fabric preparation creates an even surface for dye application. This prevents blotchiness or uneven color distribution, resulting in a professional-looking finish.

-

Minimized color bleeding: When fabric isn’t properly prepared, excess dye can leach out during washing or wearing, leading to color bleeding and staining. Thorough washing and scouring help to remove any residual dye, reducing the risk of color transfer.

Dyeing Cotton Fabric With Natural or Synthetic Dyes

To achieve vibrant and long-lasting colors when dyeing cotton fabric, you’ll need to use a specific quantifier determiner for natural or synthetic dyes. When it comes to dyeing cotton fabric, you have the option to choose between natural or synthetic dyes. Both have their pros and cons, so it’s important to consider your preferences and needs.

Natural dyes are derived from plants, insects, and other natural sources. They offer a wide range of colors and are environmentally friendly. One of the advantages of natural dyes is that they create unique and subtle shades, giving your cotton fabric a more organic and natural look. However, natural dyes can be more time-consuming and require special techniques to achieve vibrant colors. Techniques such as mordanting, which involves using fixatives to enhance color fastness, can help achieve brighter and more long-lasting results with natural dyes.

On the other hand, synthetic dyes are created using chemicals and offer a wider range of bright and intense colors. Synthetic dyes are easier to use and require less time and effort compared to natural dyes. They also provide excellent color fastness, ensuring that your cotton fabric retains its vibrant hues for a longer period. However, synthetic dyes aren’t as environmentally friendly as natural dyes and may contain harmful chemicals.

Ultimately, the choice between natural and synthetic dyes depends on your preferences, the desired color outcome, and the environmental impact you’re willing to accept. Experimenting with both types of dyes can help you determine the best option for your specific projects.

Frequently Asked Questions

How Long Does It Take for Cotton Plants to Grow and Be Ready for Harvest?

It takes about 120 to 180 days for cotton plants to grow and be ready for harvest. You can determine cotton plant maturity by checking the bolls for fullness and the leaves for yellowing.

What Are Some Common Pests and Diseases That Affect Cotton Plants, and How Can They Be Controlled?

Common pests and diseases like boll weevils and bacterial blight affect cotton plants. To control them, you can use organic solutions such as neem oil and handpicking. Don’t worry, these methods are effective!

Are There Any Specific Environmental Conditions Required for Cultivating Cotton Plants?

To successfully cultivate cotton plants, you need specific environmental conditions. Factors such as temperature, sunlight, soil type, and moisture levels play a crucial role in the growth and development of cotton plants.

What Is the Average Yield of Cotton per Acre or Hectare?

To maximize your cotton yield per acre or hectare, use proper cultivation techniques. Factors like soil fertility, irrigation, pest control, and crop rotation can impact the average yield.

Can Cotton Fabric Be Dyed Using Different Techniques, Such as Tie-Dye or Batik?

Yes, cotton fabric can be dyed using different techniques like tie-dye and batik. These methods involve creating unique patterns and designs on the fabric using various dyeing techniques.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024