Wondering how many bales of cotton are packed into a round bale? While it may seem like a single bale, there's actually a lot more to it. Understanding the process of baling and the factors that affect the quantity of bales in a round bale is essential for maximizing your cotton yield.

In this guide, you'll explore the intricacies of round bale formation, the baling process, and how to calculate the number of bales per round bale. By the end, you'll have a comprehensive understanding of how to optimize your cotton production from round bales.

Let's dive in and unravel the mystery behind the number of bales in a round bale.

Key Takeaways

- Round bale density is determined by factors such as moisture content and compression force, which affect the amount of cotton packed into a bale.

- Harvesting techniques and practices have a significant impact on bale quantity and yield, with efficient methods minimizing leaf loss and maintaining fiber integrity.

- Round bales offer advantages in handling and outdoor storage, as their cylindrical shape sheds water effectively and they require less labor during baling and handling.

- Calculating the number of bales per round bale is important for yield management, storage planning, transportation logistics, and overall efficiency in cotton production.

Understanding Round Bale Formation

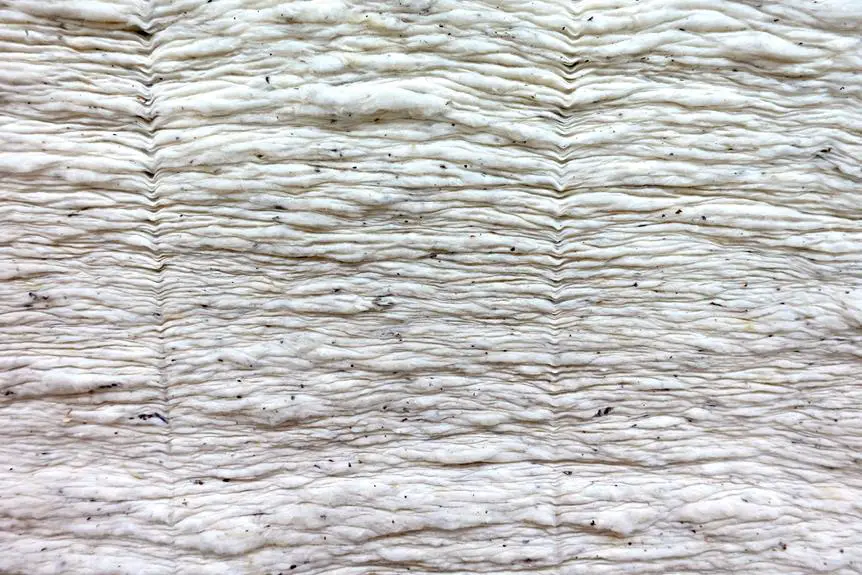

To understand round bale formation, you need to consider the mechanics of how cotton is compressed and wrapped into a cylindrical shape. Round bale density and bale size play crucial roles in this process. Bale density refers to the amount of cotton packed into a bale, while bale size determines the dimensions of the final cylindrical shape.

The compression phase involves gathering the loose cotton and using mechanical force to compact it into a dense, cohesive form suitable for baling.

Once the cotton is compressed, bale wrapping begins. This step involves the use of twine or netting to securely bind the cotton and maintain its cylindrical shape. The wrapping not only holds the bale together but also protects it from environmental elements and physical damage during handling and transportation.

Efficient bale handling is essential to ensure the integrity of the round bale. Proper equipment and techniques must be employed to lift, transport, and store the bales without causing deformation or compromising their structural integrity.

Understanding the intricate process of round bale formation is crucial for achieving consistently high-quality bales and optimizing efficiency in cotton harvesting and processing.

Factors Affecting Bale Quantity

When compressing cotton into a round bale, you should consider the density and size of the bale, as these factors significantly impact the quantity of bales produced.

The density of the bale is influenced by factors such as the moisture content of the cotton and the compression force applied during baling. Higher density bales generally result in a higher yield per bale.

Additionally, the size of the bale plays a crucial role in determining the number of bales produced. Larger bales will naturally contain more cotton, leading to a lower bale count compared to smaller bales.

Harvesting techniques also influence bale quantity. Efficient harvesting methods that minimize leaf loss and maintain the integrity of the cotton fibers can lead to higher yields and, consequently, fewer bales. Conversely, poor harvesting practices can result in lower bale yields.

The Baling Process Demystified

Let's demystify the baling process and explore the techniques involved in cotton baling.

You'll discover the advantages of round bales and how they've revolutionized the cotton baling industry.

We'll also take a look at the latest innovations in baling equipment that have streamlined the process and improved efficiency.

Cotton Baling Techniques

Mastering the art of cotton baling involves precision, efficiency, and attention to detail. Cotton compression is a critical aspect of the baling process. To achieve optimal bale density, the cotton must be compressed effectively. This is usually done using a mechanical baler that exerts pressure to compact the cotton into dense bales.

Understanding the ideal bale density for different cotton varieties is essential for producing high-quality bales. Factors such as moisture content, fiber length, and variety impact the optimal density. It's crucial to monitor and adjust the compression settings to ensure consistent bale density throughout the entire baling process.

Round Bale Advantages

To achieve optimal bale density for your cotton, it's essential to understand the advantages of round baling and demystify the baling process.

Round bales offer several advantages over traditional square bales. They're more efficient to handle, requiring less labor during both the baling and handling processes. Additionally, round bales are less prone to spoilage, as their cylindrical shape sheds water more effectively, making them suitable for outdoor storage.

When it comes to handling techniques, round bales can be easily moved with specially designed bale spears or forks. Moreover, their rounded shape allows for easy rolling during transport, simplifying loading and unloading.

In terms of round bale storage, these bales can be stored in the field without the need for immediate cover, reducing the urgency and cost of storage solutions. For transport, round bales can be stacked more efficiently, maximizing space during shipping.

Baling Equipment Innovations

When baling cotton, you'll achieve optimal results by utilizing the latest baling equipment innovations to demystify and streamline the baling process.

Baling technology advancements have led to significant efficiency improvements, making the process faster and more cost-effective. Innovations such as automatic knotting systems, adjustable bale densities, and improved moisture monitoring have revolutionized the way cotton is baled.

These advancements not only enhance productivity but also contribute to reducing the environmental impact of the baling process. Sustainability considerations are now a key focus in baling equipment innovations, with manufacturers developing solutions that minimize waste and energy consumption.

Calculating Bales per Round Bale

You can calculate the number of bales per round bale by dividing the weight of the round bale by the weight of a single bale. By doing this, you can determine the efficiency of bale storage and transportation, as well as improve yield management.

Here's an example table to illustrate this calculation:

| Round Bale Weight (lbs) | Single Bale Weight (lbs) | Bales per Round Bale |

|---|---|---|

| 1000 | 20 | 50 |

| 1500 | 25 | 60 |

| 2000 | 30 | 66 |

| 2500 | 35 | 71 |

In the table, the first column represents the weight of the round bale, the second column represents the weight of a single bale, and the third column represents the calculated bales per round bale. This calculation is crucial for farmers and agricultural professionals to maximize their bale storage, transportation, and overall efficiency in managing yields. By understanding the number of bales per round bale, farmers can optimize their operations and make informed decisions regarding equipment, storage, and transportation logistics.

Variations in Bale Production

Variations in bale production can significantly impact the efficiency of your cotton storage and transportation processes. Understanding the variation in bale density and bale weight fluctuations is crucial for effective management of your cotton bales.

The density of cotton bales can fluctuate due to factors such as the type of cotton, compression methods, and storage conditions. These variations can affect the number of bales that can be stored or transported in a given space, impacting logistical planning and costs.

Moreover, fluctuations in bale weight can impact the overall yield and quality of cotton produced. It's essential to monitor and manage these variations to optimize storage space, transportation efficiency, and overall profitability.

Utilizing Round Bales Effectively

To maximize efficiency when utilizing round bales of cotton, understanding the factors influencing bale density and weight fluctuations is crucial for effective management.

When it comes to storage solutions, consider using tarps or storing bales indoors to protect them from the elements and minimize deterioration.

Proper bale handling is also essential. Ensure that equipment used for moving and stacking bales is in good condition to prevent damage or loss of product. Additionally, regularly inspect and maintain the equipment to guarantee smooth operations.

When handling round bales, be mindful of their weight fluctuations, as this can impact transportation and storage. It's important to plan for these variations by adjusting handling equipment and storage facilities accordingly.

By understanding the factors influencing bale density and weight fluctuations, you can implement strategies to optimize storage and handling, ultimately maximizing the efficiency of utilizing round bales of cotton.

This proactive approach won't only streamline operations but also minimize waste and potential losses.

Maximizing Cotton Yield From Round Bales

Maximize cotton yield from round bales by carefully monitoring and adjusting handling equipment and storage facilities to account for fluctuations in bale density and weight. Balancing moisture content is crucial for optimizing density and ensuring maximum cotton yield. Properly maintained equipment and facilities are essential for achieving this. The table below provides a quick reference for factors affecting cotton yield from round bales.

| Factors Affecting Cotton Yield | Description | Importance |

|---|---|---|

| Moisture content | Balancing moisture is crucial | High |

| Bale density | Optimizing density is key | High |

| Equipment maintenance | Properly maintained equipment | Medium |

Frequently Asked Questions

Can Round Bales of Cotton Be Used for Anything Other Than Textile Production?

You can explore alternative uses for round bales of cotton beyond textile production. This can contribute to sustainability practices by repurposing cotton bales for insulation, compost, or even as a building material in eco-friendly construction projects.

What Are the Environmental Impacts of Using Round Bales for Cotton Production?

Using round bales for cotton production can have significant environmental impacts. However, by implementing sustainable practices such as reducing water usage, minimizing chemical inputs, and promoting biodiversity, you can mitigate these effects and contribute to a more eco-friendly industry.

Are There Any Special Storage Considerations for Round Bales of Cotton?

When handling round bales of cotton, specialized handling techniques are crucial for effective moisture control. Proper storage considerations, such as protecting the bales from excess moisture, are essential to maintain the quality of the cotton.

What Are the Potential Challenges in Transporting Round Bales of Cotton?

Transporting round bales of cotton presents unique challenges. Their size and weight require careful logistics and handling. Securing and protecting them during transportation is crucial to prevent damage and ensure safe delivery.

How Do Different Types of Cotton Plants Affect the Quantity of Cotton in a Round Bale?

Different types of cotton plants can impact the cotton yield in a round bale due to variations in plant genetics. Understanding these differences can help you optimize your cotton production for better bale quantities.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024