You start making scrim fabric by choosing quality natural or synthetic fibers based on strength and purpose. After cleaning and aligning the fibers, you spin them into yarn using techniques that affect durability. Then, you design an open-weave pattern and set up a loom, carefully maintaining tension during weaving to form the strong mesh. Once woven, you finish and inspect the fabric for quality before packaging it. Exploring further reveals details on each essential step.

Key Takeaways

- Select and prepare raw fibers by cleaning, carding, and aligning for uniformity, choosing natural or synthetic types based on scrim use.

- Spin fibers into yarn using methods like ring or open-end spinning, controlling twist direction to enhance yarn strength and texture.

- Design open-weave patterns such as plain or leno weave, then set up the loom with even tension to ensure consistent mesh density.

- Weave fabric and apply finishing treatments like heat-setting or coatings to improve durability, moisture resistance, and UV protection.

- Inspect fabric quality for uniform weave and strength, then package securely on tubes or wrapped bundles with clear labeling for shipment.

Choosing the Right Raw Fibers

Before you begin weaving scrim fabric, you need to choose the right raw fibers carefully. The quality and type of fiber directly affect the strength, durability, and appearance of your final scrim.

Natural fibers like cotton or linen offer breathability and softness, while synthetic options such as polyester or nylon provide enhanced strength and resistance to moisture.

Natural fibers bring softness and breathability; synthetics add strength and moisture resistance to your scrim fabric.

You should consider the intended use of the scrim—whether for reinforcement, decoration, or insulation—to guide your fiber selection.

Also, check the fiber’s length and fineness; longer, finer fibers typically produce smoother, stronger threads.

Preparing Fibers for Processing

Once you’ve selected the right fibers, you need to prepare them properly to guarantee smooth processing. Start by cleaning the fibers to remove dirt, grease, and impurities that could affect quality. You’ll typically use washing or scouring methods suited to the fiber type.

After cleaning, the fibers must be aligned and disentangled through carding, which separates and straightens them into a loose web. This step confirms uniformity and prevents clumps.

Next, combing may follow to remove shorter fibers and further align the longer ones, enhancing strength and smoothness. Proper moisture control is also essential; you’ll condition the fibers to the right humidity level to avoid static or brittleness.

These steps set the foundation for efficient handling in the subsequent spinning stage.

Spinning Fibers Into Yarn

Now that you’ve prepared the fibers, it’s time to choose the right fiber types for your yarn.

You’ll use specific spinning techniques to twist these fibers into strong, consistent yarn.

Understanding these choices helps you create scrim fabric with the strength and texture you want.

Fiber Types Selection

Although scrim fabric can be made from various materials, selecting the right fiber type is essential because it directly affects the strength, texture, and durability of the yarn you’ll spin.

You need to evaluate the fiber’s properties to guarantee the scrim performs well in its intended application. Natural fibers offer breathability and a soft touch, while synthetic fibers provide enhanced strength and resistance to wear.

When choosing fibers, keep these in mind:

- Cotton: Soft and breathable, ideal for lightweight scrims.

- Polyester: Strong and resistant to moisture, perfect for outdoor use.

- Glass fibers: Extremely durable and heat-resistant, used in industrial scrims.

Picking the right fiber sets the foundation for quality scrim fabric.

Yarn Spinning Techniques

Choosing the right fibers is just the beginning; turning them into yarn involves careful spinning techniques that affect the fabric’s final strength and texture.

When you spin fibers, you draw them out and twist them together, which binds them into a continuous thread. You can choose between ring spinning, which produces smooth, strong yarn with a tight twist, or open-end spinning, which is faster and creates thicker, bulkier yarn.

The twist direction—either S-twist or Z-twist—also influences the yarn’s durability and how it behaves during weaving. By controlling tension and twist, you guarantee the yarn resists breakage and maintains uniform thickness.

These spinning choices directly impact scrim fabric’s open weave, making it both sturdy and flexible for its various applications.

Designing the Open-Weave Pattern

When you design the open-weave pattern, you’ll need to master key weaving techniques that shape scrim’s unique texture.

Choosing the right yarn affects both strength and flexibility, so make your selection carefully.

Keep in mind that maintaining pattern consistency can be tricky but is essential for quality fabric.

Weaving Techniques Overview

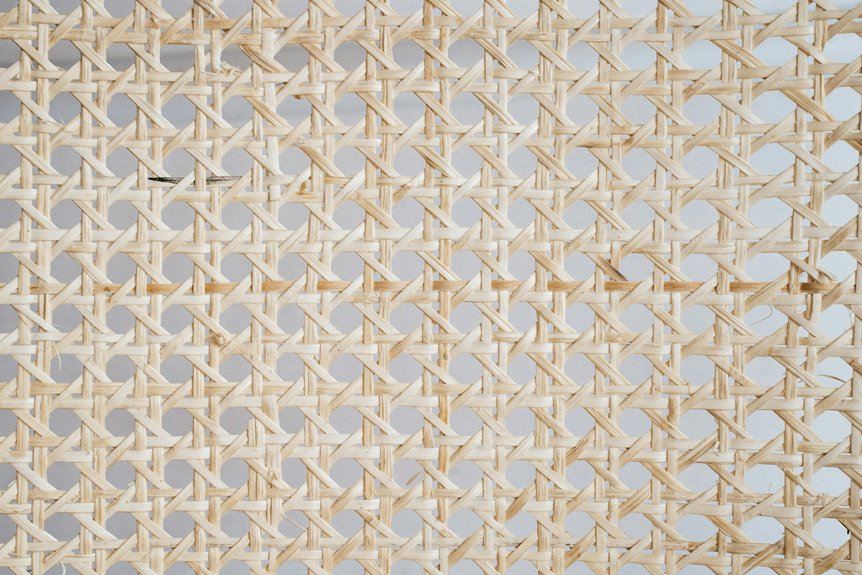

Since scrim fabric is defined by its open-weave structure, understanding the weaving techniques behind it’s crucial.

You’ll find that the weaving process directly impacts the fabric’s strength, flexibility, and transparency. When creating scrim, you use specialized looms to interlace warp and weft threads in a controlled pattern that guarantees uniform gaps.

Here are key weaving techniques you’ll encounter:

- Plain Weave: The simplest, alternating threads over and under, creating even mesh openings.

- Leno Weave: Twisting warp threads around the weft to lock fibers in place, enhancing durability.

- Huckaback Weave: Produces a textured surface with open spaces, balancing strength and breathability.

Yarn Selection Impact

Anyone working with scrim fabric knows that yarn selection plays a crucial role in defining the open-weave pattern‘s performance and appearance.

When you choose yarns, you’re not just picking materials; you’re influencing strength, flexibility, and translucency. Thicker yarns create a bolder, more robust mesh, while finer yarns offer delicate transparency.

The fiber type matters too—natural fibers like cotton provide softness but may lack durability, whereas synthetic yarns such as polyester add resilience and resistance to moisture.

You’ll also want to take into account yarn twist and texture, as these affect how the yarns interlock and the fabric’s stability.

Pattern Consistency Challenges

Choosing the right yarn sets the stage, but maintaining pattern consistency in scrim fabric presents its own set of challenges.

When designing the open-weave pattern, you need to guarantee that every loop and intersection aligns perfectly to maintain strength and appearance. Variations can cause weak spots or uneven textures, which compromise the fabric’s function.

You’ll face challenges like:

- Tension control: Keeping yarn tension uniform prevents irregular gaps.

- Machine calibration: Precise adjustments avoid pattern distortions during weaving.

- Environmental factors: Humidity and temperature can affect yarn elasticity and consistency.

Setting Up the Loom for Scrim

Before you start weaving scrim fabric, you need to prepare the loom carefully to make sure the threads align correctly. Begin by threading the warp yarns through the heddles and reed, guaranteeing even tension across all strands. This step prevents uneven gaps or distortions in the mesh. Adjust the loom settings to match the desired scrim density and mesh size. Double-check the alignment to avoid tangling during weaving.

| Step | Description |

|---|---|

| 1. Warp Preparation | Measure and arrange yarns |

| 2. Threading Heddles | Insert warp yarns precisely |

| 3. Reed Setup | Position reed for correct spacing |

| 4. Tension Adjustment | Make sure uniform yarn tightness |

| 5. Final Check | Confirm alignment and spacing |

Setting up the loom with care makes sure your scrim fabric will have a consistent, open weave.

Weaving the Scrim Fabric

Start weaving the scrim fabric by carefully interlacing the weft threads through the prepared warp yarns. This process creates the open-weave mesh that defines scrim fabric’s unique look and strength.

As you weave, maintaining even tension guarantees the fabric stays uniform and durable. You’ll notice the grid-like pattern forming as the threads cross over and under each other.

To weave effectively, focus on:

- Consistent thread spacing to maintain the mesh’s openness

- Smooth shuttle movements for efficient weft insertion

- Monitoring tension to prevent warping or bunching

Finishing Treatments and Quality Checks

Once the scrim fabric has taken shape through weaving, it moves on to finishing treatments that enhance its durability and performance.

You’ll find the fabric undergoes processes like heat-setting to stabilize its dimensions and coatings to improve resistance to moisture, UV rays, or abrasion. These treatments guarantee the scrim meets specific industry standards and functions well in its intended applications.

After finishing, you’ll conduct thorough quality checks, inspecting for uniformity in weave, strength, and absence of defects such as holes or weak spots.

Testing tensile strength and dimensional stability is essential to confirm the fabric performs reliably.

Packaging and Distribution of Scrim Fabric

Although the scrim fabric has passed all quality checks, you still need to package it carefully to protect its integrity during transport and storage. Proper packaging guarantees the fabric stays clean, wrinkle-free, and undamaged.

Even after quality checks, careful packaging is essential to keep scrim fabric pristine during transport and storage.

You usually roll the fabric onto sturdy cardboard tubes or fold it neatly, then wrap it in protective plastic to guard against moisture and dust. Clear labeling helps with easy identification and inventory management.

When preparing scrim fabric for shipment, focus on:

- Securing rolls or bundles tightly to prevent shifting

- Using moisture-resistant materials for wrapping

- Including detailed labels with fabric type, batch number, and dimensions

Frequently Asked Questions

What Are Common Uses for Scrim Fabric in Construction?

Think of scrim fabric as the skeleton in construction’s body; you’ll use it to reinforce drywall, stabilize plaster, and support roofing materials. It’s lightweight yet strong, keeping structures sturdy and cracks at bay.

How Does Scrim Fabric Differ From Mesh or Netting?

You’ll notice scrim fabric is tightly woven for strength, unlike mesh or netting, which have larger, looser openings. Scrim provides reinforcement, while mesh or netting focus on ventilation or filtration purposes.

Can Scrim Fabric Be Recycled or Reused?

You can recycle or reuse scrim fabric, especially if it’s made from synthetic fibers like polyester. Reusing it in crafts or as reinforcement helps reduce waste, and specialized recycling programs handle scrim for sustainable disposal.

What Environmental Impacts Are Associated With Scrim Production?

You’ll find scrim production uses energy and water, releasing emissions that impact the environment. Choosing recycled fibers and eco-friendly processes can reduce waste and pollution, helping you minimize your ecological footprint during scrim fabric manufacturing.

Are There Safety Precautions When Handling Scrim Fabric?

Better safe than sorry—when handling scrim fabric, you should wear gloves to avoid irritation and cut-resistant gloves if it’s stiff or coarse. Also, use eye protection, as loose fibers might cause discomfort or injury.