You start by creating Kevlar’s strong polymer through a chemical reaction between specific monomers under controlled conditions. Then, the polymer solution is spun into fine fibers and solidified. These fibers are stretched and heated to align molecules, boosting strength. Next, the fibers are woven into fabric using precise tension and weave patterns for durability. You’ll find this process guarantees Kevlar’s toughness and light weight. Keep exploring to uncover the detailed steps behind this remarkable manufacturing journey.

Key Takeaways

- Kevlar monomers, para-phenylenediamine and terephthaloyl chloride, are prepared with strict temperature and purity controls for polymerization.

- Polymerization links monomers into long chains, producing a viscous polymer dope under controlled temperature and pressure.

- The polymer solution is extruded through spinnerets, then solidified in a coagulation bath to form strong, flexible fibers.

- Fibers are drawn and stretched while heated to align molecular chains, enhancing tensile strength and durability.

- Kevlar yarns are woven on looms with precise tension control into fabric using specific weave patterns for desired applications.

The Chemistry Behind Kevlar

Although you mightn’t see it, the chemistry behind Kevlar plays an essential role in its strength and durability.

You’re dealing with a polymer made from repeating units of aromatic polyamides, specifically para-aramid fibers. These molecules line up in rigid, rod-like chains, which stack tightly due to strong hydrogen bonds between the amide groups.

This tight packing creates a crystalline structure that resists stretching and breaking. When you handle Kevlar, its exceptional strength comes from these molecular interactions, not just the physical fibers.

The alignment and bonding at the chemical level give Kevlar its lightweight yet incredibly tough nature, allowing it to absorb and disperse energy efficiently.

Kevlar’s chemical bonds create a lightweight, tough fabric that efficiently absorbs and disperses energy.

Understanding this chemistry helps you appreciate why Kevlar outperforms many other materials in protective applications.

Polymerization Process

You start by preparing the monomers carefully to guarantee purity and proper reaction.

Then, these monomers link together to form long polymer chains through a controlled process.

This polymerization step is essential for giving Kevlar its incredible strength and durability.

Monomer Preparation

Before Kevlar fabric takes shape, the monomer preparation stage kicks off the polymerization process, where the building blocks of the fiber are carefully synthesized.

You start by combining specific raw chemicals—primarily para-phenylenediamine and terephthaloyl chloride—in a controlled environment. These ingredients react to form the monomers, the essential units that will link together later.

During this step, you’ll maintain strict temperature and purity controls to guarantee the monomers’ quality and reactivity remain ideal. Any impurities or deviations can compromise the final fiber’s strength and durability.

Polymer Chain Formation

Once the high-purity monomer solution is ready, it undergoes polymerization, a critical step where individual monomers link to form long, strong polymer chains.

You initiate this process by mixing the monomers under controlled temperature and pressure conditions, often in a solvent that facilitates the reaction. As the monomers react, they form rigid, rod-like polymer chains through a condensation reaction, releasing small molecules like hydrochloric acid.

You carefully control the reaction time to guarantee the chains grow to the desired length, which directly impacts Kevlar’s strength and durability.

After polymerization, the solution contains a viscous liquid called the polymer dope, rich in these extended chains. This polymer dope then moves on to the spinning stage, where it transforms into the solid Kevlar fibers you’re familiar with.

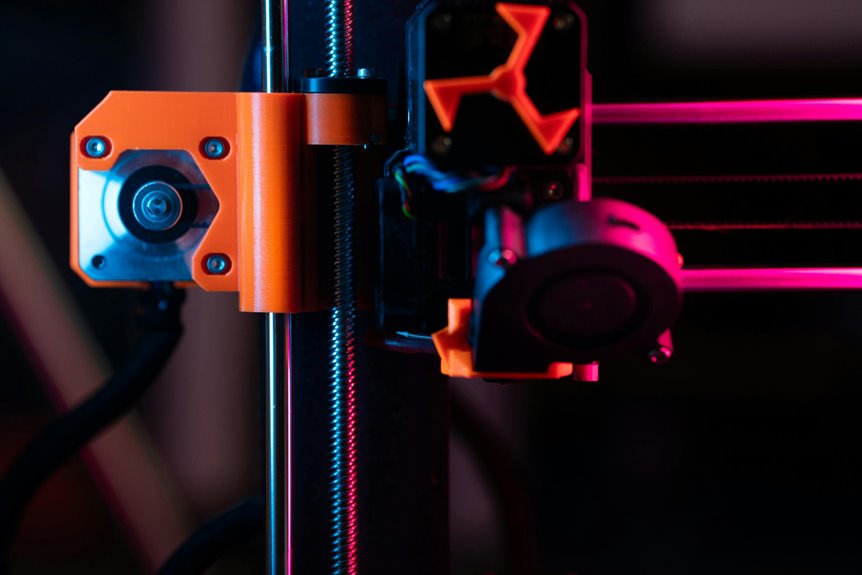

Spinning Kevlar Fibers

Although the chemical process forms the foundation, spinning Kevlar fibers transforms the liquid polymer solution into strong, continuous filaments.

You start by extruding the polymer solution through tiny holes in a spinneret, creating multiple fine strands simultaneously. As these strands emerge, they solidify instantly because they enter a coagulation bath, which removes the solvent and causes the fibers to harden.

You carefully control the temperature and composition of this bath to guarantee the fibers form uniformly without defects. This spinning step is essential—it converts the viscous liquid into solid fibers that retain the polymer’s strength and flexibility.

Once spun, the fibers are collected onto spools, ready for the next stage. By managing this process precisely, you set the stage for Kevlar’s impressive durability in its final fabric form.

Drawing and Stretching Fibers

You draw and stretch the Kevlar fibers to align their molecular chains, boosting their strength and stiffness. This step is essential because it enhances the fiber’s mechanical properties, making it suitable for high-performance applications.

When you stretch the fibers, the polymer chains become more orderly, increasing tensile strength.

Here’s what you do during this stage:

- Heat the fibers to soften them slightly without melting

- Pull the fibers at a controlled speed and tension

- Monitor fiber diameter to verify consistency

- Repeat stretching to achieve desired molecular alignment

- Cool the fibers to lock in the improved structure

Weaving Kevlar Fabric

After enhancing the strength and alignment of Kevlar fibers through drawing and stretching, the next step is weaving them into fabric.

You’ll start by arranging the strong Kevlar yarns on a loom, setting warp threads lengthwise. Then, you’ll insert weft threads crosswise, interlacing them carefully with the warp. This process creates a tight, durable weave that maintains Kevlar’s exceptional tensile strength.

Depending on your specific application, you might choose different weave patterns, like plain or twill, to balance flexibility and protection. You’ll need to control tension precisely during weaving to avoid damaging the fibers.

The result is a robust fabric ready for various uses, from body armor to industrial materials. Weaving transforms individual fibers into a functional textile without compromising Kevlar’s unique properties.

Quality Control and Finishing

Because even the strongest Kevlar fabric can have flaws, quality control plays a crucial role in manufacturing. You’ll want to inspect the fabric thoroughly, checking for inconsistencies or defects that could compromise strength.

Thorough inspection ensures Kevlar fabric’s strength by identifying flaws that could compromise its performance.

Testing includes:

- Visual inspections for weaving errors or damage

- Tensile strength tests to verify durability

- Thickness and weight measurements for uniformity

- Chemical resistance checks to confirm protective properties

- Dimensional stability tests to prevent shrinkage or distortion

After passing quality checks, the fabric undergoes finishing processes. You’ll apply treatments to enhance durability, water repellency, or fire resistance, depending on the intended use.

Finally, the Kevlar fabric is carefully rolled and packaged to maintain integrity during shipping. This meticulous quality control and finishing guarantee you receive top-grade Kevlar fabric ready for demanding applications.

Frequently Asked Questions

What Are Common Uses of Kevlar Fabric?

You’ll find Kevlar fabric used in bulletproof vests, motorcycle gear, and helmets because it’s incredibly strong and lightweight. It also protects racing sails, ropes, and even in sports equipment to keep you safe and secure.

How Does Kevlar Compare to Other Protective Materials?

Think of Kevlar as the superhero among protective materials—it’s lighter than steel but just as tough. You’ll find it offers superior strength and flexibility, making you safer without weighing you down like traditional options do.

Is Kevlar Fabric Recyclable or Biodegradable?

Kevlar fabric isn’t biodegradable because it’s a synthetic polymer, and recycling it’s challenging due to its strong molecular structure. You’ll find limited recycling options, so proper disposal or repurposing is usually the best approach for Kevlar products.

What Safety Precautions Are Needed During Kevlar Production?

You should wear protective gloves, goggles, and masks to avoid skin irritation and inhaling fibers. Make sure your workspace is well-ventilated and follow proper handling procedures to prevent accidents and contamination during Kevlar production.

How Long Does Kevlar Fabric Typically Last in Use?

You trust Kevlar to protect, you rely on Kevlar to endure. Typically, Kevlar fabric lasts 5 to 10 years in use, depending on exposure, wear, and care. You should inspect it regularly to maintain safety.