I'll guide you through how cotton cloth is made. First, cotton bolls are harvested and processed to extract lint fibers. We transport these fibers to textile mills, clean out impurities, and align fibers for spinning. Next, we twist these fibers into yarn, weave them into fabric with intricate patterns, and perform additional processes like dyeing and printing for unique designs. Finally, embellishments and finishing treatments enhance fabric characteristics. This summary reveals the intricate steps involved in creating cotton cloth from scratch.

Key Takeaways

- Harvest cotton bolls and gin to separate lint from seeds.

- Clean fibers by removing impurities like dirt and seeds.

- Spin fibers into yarn using spinning frames.

- Weave yarn into fabric on looms with intricate patterns.

- Enhance fabric through dyeing, printing, embroidery, and finishing treatments.

Harvesting and Ginning Process

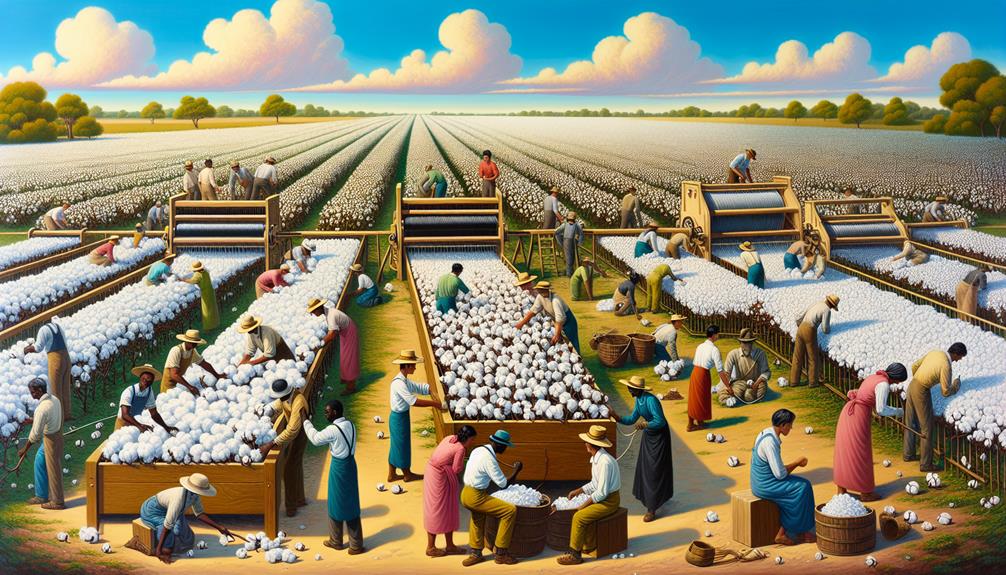

When it comes to making cotton cloth, the initial essential step is the harvesting and ginning process. Cotton harvesting involves picking cotton bolls from plants either by hand or using mechanical pickers. Once the cotton bolls are collected, they undergo the ginning process, where machines are employed to separate the fibers (known as lint) from the seeds and other debris effectively. This process is pivotal in guaranteeing that the cotton fibers are clean and suitable for further processing. The separated lint is then compressed into bales weighing approximately 500 pounds each for transportation to textile mills.

The ginning process plays a significant role in the cotton production chain as it determines the quality of the fibers that will be used in producing textiles. By efficiently separating the lint from the seeds, ginning ensures that only the best fibers are sent to the textile mills for further processing into various cotton products.

Transportation to Textile Mills

I'll start by highlighting the importance of transportation logistics in the supply chain management process when moving cotton bales from gins to textile mills. Efficient transportation plays a critical role in ensuring the timely delivery of the raw material for fabric production.

Careful handling of the cotton bales during transport is essential to protect the valuable lint fibers and maintain the quality of the final cotton cloth.

Transportation Logistics

Cotton bales weighing approximately 500 pounds are efficiently transported from gin facilities to textile mills for further processing using specialized methods such as trucks and trains. During the journey, the cotton bales are carefully handled to prevent damage to the delicate fibers inside, ensuring the quality of the raw material. Textile mills strategically plan incoming cotton deliveries to optimize production schedules, meeting the demand for fabric production. This meticulous planning helps in maintaining a seamless flow of raw cotton to the textile mills, supporting continuous fabric manufacturing.

Cotton bales are loaded onto sturdy trucks, ready to begin on their journey to the textile mills.

Trains chug along the tracks, carrying vast quantities of cotton bales to their destination.

The cotton bales are stacked neatly, awaiting their turn to undergo the transformation into textiles.

Supply Chain Management

Effectively managing the transportation of cotton bales from gin facilities to textile mills is vital for ensuring timely delivery and maintaining the quality of raw materials. Cotton bales, each weighing around 500 pounds, are carefully transported to guarantee the integrity of the raw material.

A well-organized transportation network is essential for textile mills to receive the cotton bales promptly for fabric production. Supply chain management in cotton involves intricate logistics planning to optimize transportation routes and minimize costs.

Opening, Cleaning, and Carding

After opening the compressed cotton bales, the next essential steps involve thoroughly cleaning the fibers and carding them to prepare for spinning. The cleaning process removes impurities such as dirt, seeds, and leaves from the cotton fibers, ensuring the purity of the final fabric. Here's what happens during this critical stage:

- Removing Impurities: Dirt, seeds, and other unwanted particles are separated from the cotton fibers, leaving behind clean and pure material.

- Aligning Fibers: Carding machines meticulously align the cotton fibers in a parallel orientation, facilitating the spinning process and enhancing the fabric's strength and quality.

- Creating a Sheet: The carding machines produce a sheet-shaped lap of cotton fibers, ready to be spun into yarn for further fabric production.

These steps are essential for achieving soft, clean, and durable cotton fabrics by eliminating tangles, ensuring uniformity, and enhancing the overall quality of the fibers.

Spinning Cotton Into Yarn

So, when it comes to spinning cotton into yarn, it's all about transforming those fibers into the thread we need.

We'll look at the spinning process and the techniques that make it happen.

Let's unravel the magic of turning cotton into the versatile yarn we use for making cloth.

Yarn Spinning Process

In the yarn spinning process for making cotton cloth, cotton fibers are carefully aligned and twisted to create the essential yarn needed for weaving. This process involves utilizing spinning frames and spinning mules to convert carded sliver into yarn, ensuring the fibers are strong and cohesive.

The spinning action adds durability and resilience to the cotton fibers, enhancing the overall quality of the yarn produced. Different spinning techniques are employed to meet specific fabric requirements, allowing for a variety of yarn types to be created for weaving.

The precision and expertise involved in spinning cotton fibers into yarn are vital in ensuring the final fabric meets the desired standards of strength and quality.

Techniques for Spinning

When spinning cotton fibers into yarn, various techniques are employed to ensure the resulting yarn meets specific fabric requirements and standards of strength and quality. Spinning machines play a vital role in aligning and twisting the cotton fibers to create durable yarn suitable for weaving into fabric.

Different spinning techniques like ring spinning, open-end spinning, and air jet spinning are utilized to produce various types of cotton yarn tailored for different applications. The spinning process is pivotal in determining the quality and characteristics of the final cotton yarn, impacting its strength, texture, and appearance.

Weaving the Fabric

Weaving cotton fabric involves skillfully interlacing warp threads and weft yarn in a specific pattern on a loom. This process is essential for creating the intricate fabric structures that we enjoy in our garments and household textiles. As the weaver, I meticulously align the yarns and set up the loom to begin the weaving process.

Here are three key steps involved in weaving cotton fabric:

- Aligning the Warp Threads: Before weaving can commence, the warp threads are carefully arranged on the loom, ensuring they're evenly spaced and under proper tension.

- Interlacing with Precision: Using the shuttle, I pass the weft yarn through the warp threads, following a specific pattern to create the desired fabric design.

- Adjusting Loom Motions: Throughout the weaving process, I adjust the loom's motions to create various fabric structures, such as plain weave, twill, or satin weaves, giving the fabric its unique characteristics.

Additional Fabric Processes

As I progress through the cotton fabric production process, various additional fabric processes play an essential role in enhancing the quality and characteristics of the final product.

Roving machines are important as they elongate drawn sliver during the winding process. Twisting fibers is another key step to obtain green yarn in the cotton fabric production process.

The green yarn, after twisting, is then wound onto bobbins for further processing. The spinning process is where the green yarn is finely elongated to achieve the desired thickness for cotton fabric production.

Finally, the finished yarn is carefully wound onto bobbins, shaping it into cheese or cone forms in the winding process. These additional fabric processes are crucial in ensuring that the cotton fabric produced meets the desired standards with respect to strength, texture, and overall quality.

Each step adds value and contributes to the creation of a high-quality cotton fabric.

Achieving the Desired Look

To achieve the desired look in cotton cloth, we employ various techniques such as dyeing, printing, embroidery, and finishing treatments. When working with cotton fabric, the following methods are essential in achieving the perfect aesthetic:

- Dyeing Techniques: Utilizing methods like direct, discharge, resist, and tie-dye to infuse vibrant colors and intricate patterns into the fabric.

- Printing: Employing techniques such as screen printing, block printing, or digital printing to add detailed designs and motifs to the cotton cloth.

- Embroidery: Enhancing the fabric with decorative elements through hand or machine embroidery, creating unique textures and visual interest.

Frequently Asked Questions

How Is Cotton Made Into Fabric Step by Step With Pictures?

Sure, let's dissect it step by step. I'll guide you through how cotton is transformed into fabric from start to finish, with images to aid understanding. Let's explore this fascinating process together!

How Is Cotton Turned Into Thread?

I turn cotton into thread through processes like ginning, cleaning, carding, and spinning. Ginning separates fibers from seeds and debris, cleaning removes impurities, carding aligns fibers, and spinning twists them into yarn for weaving fabric.

How Are Cotton Produced?

Cotton is produced through planting, monitoring growth, and harvesting in warm regions like India and Egypt. Sustainable practices such as organic cultivation and water conservation are crucial to reduce environmental impact in cotton production.

What Is the Difference Between Cotton and Cotton Cloth?

Cotton is the raw fiber from cotton plants, while cotton cloth is the woven or knitted fabric made from cotton yarn. Understanding this difference is essential for appreciating the intricate manufacturing process involved in creating cotton cloth.