Classifying cotton involves evaluating fiber length, strength, micronaire, color, and extraneous matter. This assessment helps determine quality and market value.

Key Takeaways

- Cotton is classified based on staple length, strength, micronaire, color, and extraneous matter.

- USDA classing facilities use precision instruments for rigorous testing and analysis.

- Classification ensures uniform quality standards for fair market value.

- High Volume Instrument (HVI) measures fiber properties accurately.

- Classification impacts pricing, market competitiveness, and buyer preferences.

Cotton Classification Process

When classifying cotton, we start by taking samples after the ginning and cleaning process. These samples are then sent to USDA classing facilities where they undergo equalization to guarantee fair classification. Once at the classing facility, the samples are subjected to rigorous testing using precision instruments to measure various quality parameters. The use of these advanced instruments guarantees accurate and consistent results.

At the testing stations, the cotton samples are analyzed for fiber length, strength, micronaire, color, and other essential characteristics that determine the quality of the cotton. The results obtained from these tests are promptly imported into the system and shared with customers to provide transparency in the classification process.

Moreover, the PBI system plays an important role in tracking the cotton from the gin to the classing office. This system ensures traceability and efficient data management throughout the classification process, enabling better quality control and consistency.

Fiber Quality Assessment

Evaluating fiber quality in cotton involves examining various characteristics such as staple length, strength, micronaire, color grade, reflectance, yellowness, and trash percent area. Staple length, which is the average length of cotton fibers, is vital as it impacts yarn quality and spinnability. Additionally, color grade plays a significant role in determining the market value and quality of cotton, with grades ranging from white to yellow. The color of the fiber can affect the dye absorption and overall aesthetics of the end product.

When appraising fiber quality, it's essential to take into account these aspects collectively to determine the overall grade and suitability of the cotton for various purposes. Understanding the fiber characteristics such as staple length and color grade allows for better decision-making in processing and utilizing the cotton. By evaluating these factors meticulously, one can guarantee the production of high-quality cotton products that meet industry standards and consumer expectations.

Length Measurement Methods

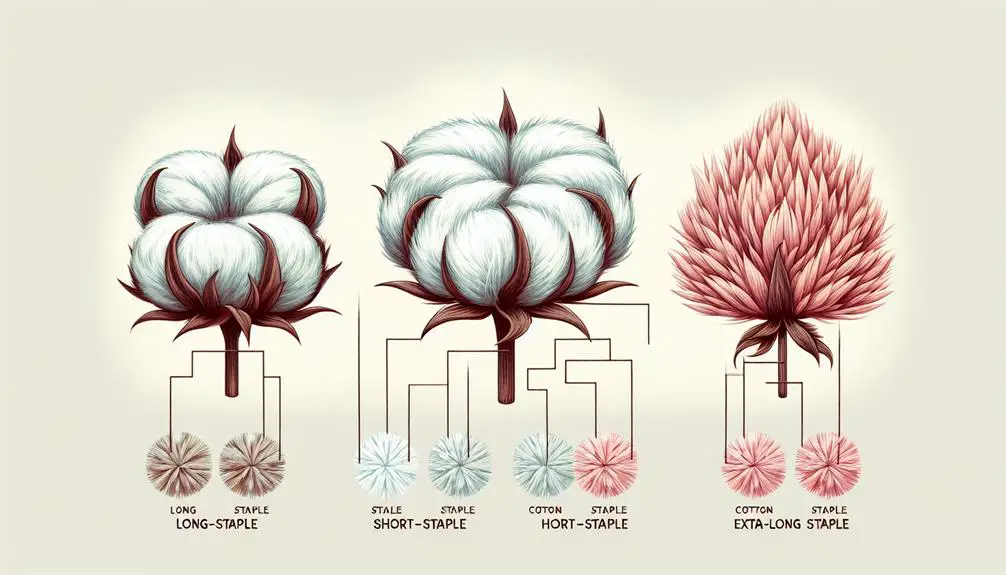

To accurately measure cotton length, various methods are utilized to determine the staple length of the fibers. Staple length is important in evaluating fiber quality and impacts the spinnability and strength of yarns. Longer staple lengths generally lead to improved yarn quality and strength compared to shorter staple lengths.

The USDA plays a significant role in standardizing staple lengths, categorizing them into groups like very short and extra-long to classify cotton based on fiber length. Short staple fibers often result in irregular yarns of lower quality, while longer staple fibers enhance spinnability and overall yarn quality.

Understanding staple length is crucial in cotton classification as it directly influences the quality and market value of cotton products. By adhering to USDA standards and accurately measuring staple lengths, producers and buyers can guarantee consistency and quality in the cotton industry.

Strength Evaluation Techniques

Strength evaluation techniques are essential for gauging the fiber's ability to withstand stress during processing and use. One prominent instrument used for this purpose is the High Volume Instrument (HVI), known for its accurate and objective measurement of cotton fiber strength.

Fiber strength is a critical factor in determining the quality and durability of cotton products such as textiles and yarns. By employing strength evaluation techniques, industry standards for strength and performance can be met, ensuring that cotton products are of high quality.

Understanding the strength of cotton fibers is an integral part of the USDA's classification process, providing valuable information to buyers and manufacturers. Understanding the strength of cotton fibers is essential as it directly impacts the final products' longevity and performance.

Utilizing tools like the HVI helps in maintaining consistency and reliability in evaluating fiber strength, ultimately contributing to the production of durable and high-quality cotton goods.

Extraneous Matter Detection

Moving from understanding cotton fiber strength to another critical aspect of cotton classification, the detection of extraneous matter plays a significant role in determining the quality and market value of cotton products. Extraneous matter includes foreign materials such as seeds, stems, leaf particles, and even plastic, which can impact the quality of cotton. High Volume Instrument (HVI) technology is employed to scan cotton samples, quantify, and classify the extraneous matter content accurately. This technology aids in maintaining quality consistency by adhering to USDA standards that specify acceptable levels of extraneous matter in cotton bales. Detecting extraneous matter is crucial as it influences processing efficiency, end-product performance, and overall market value. Below is a table illustrating the importance of extraneous matter detection in cotton classification:

| Aspect | Importance |

|---|---|

| Quality Consistency | Ensures consistent quality standards are met |

| Processing Efficiency | Affects the efficiency of cotton processing |

| Market Value | Influences the market value of cotton products |

| Meeting Buyer Requirements | Essential for meeting buyer demands and specifications |

USDA Classing Offices

So, let's talk about the USDA classing offices.

These facilities play a crucial role in the cotton classification process, ensuring that cotton quality is accurately assessed and standardized.

Understanding the operations at these USDA classing offices gives insight into the meticulous process that guarantees consistency in cotton classification.

Classing Process Overview

Upon receiving sample cotton bales, USDA classing offices utilize the High Volume Instrument (HVI) system to accurately and uniformly classify the fiber quality for farmers seeking this service. The classification process is essential for determining the quality of cotton and providing valuable information to farmers.

Here are some key points to highlight:

- Sample cotton bales are tested and classified by USDA classing offices.

- The High Volume Instrument (HVI) system guarantees uniform and accurate classification.

- Farmers pay for classification services per bale to assess their cotton's quality.

- Results from classification testing are promptly shared with customers for transparency.

- The USDA's classing process ensures that cotton buyers worldwide receive reliable fiber quality information.

Importance of Classification

Why is the classification process conducted by USDA classing offices important for the cotton industry?

The USDA's classification of cotton plays a vital role in determining the quality of cotton based on factors like fiber length, strength, and color. This classification system not only helps in setting market prices by using specific grading criteria but also guarantees transparency and quality in the cotton market.

By utilizing the High Volume Instrument (HVI) system, USDA classing offices maintain a uniform and precise method of categorizing cotton. Additionally, the classification provided by these offices gives U.S. cotton a significant global marketing advantage.

Farmers rely on USDA classing services to showcase the quality of their cotton, ultimately benefiting the entire cotton industry.

HVI System Importance

The importance of the HVI system in cotton classification can't be overstated due to its fundamental role in accurately measuring key fiber properties. The HVI system helps in determining staple length, strength, micronaire, color, trash, leaf, and extraneous matter. It ensures uniformity and consistency in cotton grading for fair market value.

Precision instruments within the HVI system provide reliable data for quality measurements, contributing to the overall accuracy of the grading process. Adopting the HVI system has greatly improved efficiency in cotton classification processes, enabling more precise evaluations and enhancing the overall quality of the graded cotton.

This system plays a fundamental role in the cotton industry by providing standardized measurements that are essential for setting fair prices and ensuring transparency in the market.

Price Setting Mechanisms

So, when it comes to setting prices for cotton, we need to take into account how market fluctuations, supply and demand, and global trade impact the overall pricing mechanism.

These factors play a vital role in determining the value of cotton and how it's priced in the market.

Understanding these dynamics is essential for both buyers and sellers in the cotton industry.

Market Price Fluctuations

Market price fluctuations in the cotton industry are driven by various factors such as supply and demand, weather conditions, global economic trends, and government policies. Understanding these fluctuations is essential for successfully maneuvering the cotton market.

Here are five key points to ponder:

- Futures markets play a significant role in setting cotton prices by enabling stakeholders to hedge against future price movements.

- Geopolitical events, trade agreements, and currency fluctuations can impact cotton prices, leading to market volatility.

- Cotton price indexes like the A Index and USDA Cotton Classing prices act as benchmarks reflecting global market trends.

- Consumer preferences also influence cotton prices, affecting demand and ultimately market dynamics.

- Monitoring these factors is vital for making informed decisions regarding production, trade, and investments in the cotton industry.

Supply and Demand

When considering the dynamics of supply and demand in the cotton industry, one must understand how price setting mechanisms are influenced by cotton classification. Grade standards set by the USDA classification play an important role in determining the value of cotton.

Buyers assess the quality of cotton based on these standards to determine prices. Factors such as fiber length, strength, and micronaire influence price setting mechanisms. Cotton that meets or exceeds these standards commands premiums, while cotton below these standards may face discounts.

The specific attributes required by different market applications further impact price fluctuations. The USDA classification system not only aids in setting fair prices but also provides a competitive edge for cotton producers in the global market.

Global Trade Impact

How does cotton classification impact global trade through its price setting mechanisms?

The standards set by cotton classification play a vital role in determining the quality and price of cotton in the global market. Here are five key points to ponder:

- Cotton classification guarantees uniform quality standards are maintained across different grades.

- The pricing mechanisms based on classification promote transparency and fairness in trade.

- Buyers seek specific quality attributes in classified cotton to meet their market needs.

- Producers are incentivized to deliver high-quality cotton through premiums offered for superior grades.

- Discounts applied to below-grade cotton underscore the importance of maintaining quality standards in the classification process.

Market Application Insights

In my experience, understanding how cotton is classified is essential for tailoring products to meet specific industry quality standards. The classification of cotton is important as it allows buyers to pinpoint the exact fiber characteristics needed for different market applications. Buyers in industries like apparel, household furnishings, and nonwoven products prioritize attributes such as staple length, strength, and color based on their manufacturing requirements.

For instance, nonwoven products have stringent quality needs concerning leaf, micronaire, staple length, and extraneous matter. The USDA's classification system plays a significant role in ensuring transparency and quality for buyers worldwide. This transparency gives U.S. cotton a marketing advantage, as it assures buyers of the quality they're purchasing.

Premiums and Discounts

To incentivize quality production, farmers receive bonuses for above-base grade cotton. This system encourages farmers to excel in their crops. On the flip side, deductions are applied to below-grade cotton, motivating farmers to improve the quality of their produce. This transparent approach in cotton classification guarantees that buyers globally can easily distinguish between various grades, aiding them in making well-informed purchasing decisions. The USDA's classification system plays a vital role in maintaining the overall quality and consistency within the cotton industry.

- Farmers receive bonuses for above-base grade cotton.

- Deductions are given for below-grade cotton.

- Transparency is guaranteed through clear quality distinctions.

- Buyers rely on classification standards for informed decisions.

- The USDA's system maintains quality and consistency.

Value Determination Significance

When it comes to cotton classification, understanding the significance of value determination is essential. Quality assessment methods and economic impact analysis play a critical role in evaluating the worth of cotton in the market.

These factors help buyers and sellers navigate the industry by making informed decisions based on the quality of the cotton being traded.

Quality Assessment Methods

Utilizing advanced technology, the cotton industry employs precise methods to assess quality, directly impacting its market value.

- High Volume Instrument (HVI): USDA uses this since 1991 for accurate classification.

- Parameters Measured: Color grade, reflectance, yellowness, trash percent area guarantee consistency.

- Staple Length Categories: Standardized by USDA, affecting yarn quality and spinnability.

- Cotton Grading: 39 color grades from white to yellow determine pricing and market suitability.

- Fiber Characteristics: Staple length, strength, and micronaire are key factors in classification.

Economic Impact Analysis

Moving from understanding the quality assessment methods to examining the economic impact, the value of cotton bales is greatly influenced by the classification system.

Cotton classification directly impacts the economic value for farmers by guiding buyers in identifying specific fiber characteristics based on market application, which in turn affects pricing. The system encourages the production of higher quality cotton through premiums offered for above-base grade cotton, incentivizing farmers. Conversely, below-grade cotton may incur discounts, reflecting the economic repercussions of lower quality fiber.

This transparent classification system not only benefits buyers globally by ensuring quality assurance but also fosters fair market transactions. Understanding the economic impact of cotton classification is essential for both farmers and buyers in successfully maneuvering the market.

Frequently Asked Questions

What Is the Classification of Cotton?

Classifying cotton involves evaluating fiber characteristics like staple length, strength, color grade, and trash percent area. This examination is essential for determining cotton quality and market value. The USDA's High Volume Instrument (HVI) system guarantees uniform standards since 1991.

What Category Is Cotton In?

Cotton falls into various categories based on its fiber characteristics. The USDA sets standards for classification, including color grades. This classification helps determine cotton quality and market value, influencing pricing and trade negotiations.

What Are the 4 Grades of Cotton?

The four grades of cotton are Strict Low Middling, Low Middling, Strict Middling, and Middling. They determine the quality based on color. This grading system helps buyers and sellers understand cotton quality and value.

What Are the 4 Types of Cotton?

There are four main types of cotton: Upland, American Pima, G. herbaceum, and G. arboreum. Each type has unique fiber properties influencing quality and market value. Upland cotton is versatile, Pima is high-quality, and the others have shorter fibers.