When you think about high-performance fabrics, it's important to contemplate how each component is meticulously chosen to enhance specific qualities. For instance, fiber selection is the foundation, where materials like aramids offer durability and spandex provides elasticity. You might be surprised at how moisture management integrates both hydrophilic and hydrophobic fibers to keep you comfortable. But that's just the beginning. Advancements in weaving techniques, like 3D and nano-weaving, take these fabrics to another level. Curious about how these elements come together to create the ultimate fabric for various needs? There's a lot more to uncover.

Table of Contents

Key Takeaways

- High-performance fabrics utilize advanced fibers like aramids and spandex for enhanced durability, elasticity, and thermal regulation.

- Moisture management is achieved through fabric construction and blending hydrophilic and hydrophobic fibers to balance absorption and repellency.

- Effective thermal control is optimized using phase change materials and hollow fibers for heat management in various conditions.

- Durability is ensured through rigorous testing methods like the Martindale Abrasion Test and Tensile Strength Test to assess wear resistance and tensile strength.

- Ventilation is enhanced by designing fabrics with micro-ventilation structures and strategic perforations to promote airflow and breathability.

Fiber Selection

When selecting fibers for engineered fabrics, you need to take into account their specific properties and how they'll impact the performance of the final product. Fiber selection isn't just about choosing between natural and synthetic fibers; it's a strategic decision that influences durability, elasticity, and thermal regulation.

Each fiber type brings unique advantages. For instance, polyester offers excellent strength and resistance to stretching and shrinking, while nylon is prized for its high tensile strength and abrasion resistance. Cotton, known for its breathability and comfort, may be blended with other fibers to enhance specific qualities.

Textile innovation has led to the development of high-performance fibers like aramids, which provide outstanding heat resistance and strength, making them ideal for protective clothing. Similarly, spandex offers superior elasticity, making it essential for athletic wear.

By understanding these materials' properties, you can tailor fabric performance to meet specific requirements, whether it's for sports, industrial applications, or everyday use.

Incorporating advanced fibers elevates the overall quality of the fabric, ensuring that it meets the rigorous demands of its intended use. Mastery in fiber selection empowers you to create engineered fabrics that excel in performance, comfort, and durability.

Moisture Management

Choosing the correct fibers is essential, but optimizing moisture control guarantees that your engineered fabric improves comfort and performance. Effective moisture control assures that your fabric can handle sweat absorption and water repellency, keeping you dry and comfortable.

By focusing on fabric construction and comfort properties, you can engineer a textile that excels in both athletic and everyday wear.

- Fabric Construction: The weave or knit structure greatly impacts how moisture is managed. Open weaves facilitate airflow, enhancing sweat evaporation, while tight weaves can provide water repellency.

- Sweat Absorption: Fibers like polyester and nylon are hydrophobic, meaning they resist water absorption. However, treatments can be applied to enhance their ability to wick away sweat from the skin, improving overall comfort.

- Water Repellency: Durable Water Repellent (DWR) coatings can be added to fabrics, creating a barrier that prevents external moisture from penetrating while allowing internal moisture to escape.

- Comfort Properties: Blending hydrophilic and hydrophobic fibers can balance sweat absorption and water resistance, ensuring that the fabric remains lightweight and breathable under various conditions.

Mastering moisture control through these techniques doesn't just elevate performance; it guarantees that every activity, from intense workouts to casual strolls, is experienced in utmost comfort.

Thermal Regulation

Effective thermal control in engineered fabrics guarantees you stay warm in cold conditions and cool in the heat, optimizing overall comfort and performance. Mastering this balance requires a deep understanding of material science.

Advanced fabrics utilize technologies like phase change materials (PCM) and hollow fibers to manage heat transfer efficiently. These materials absorb, store, and release heat based on your body's needs, ensuring energy efficiency and comfort.

In cold environments, engineered fabrics trap body heat without adding bulk, allowing you to maintain agility. On the flip side, in hot conditions, these fabrics facilitate moisture evaporation and enhance airflow, keeping you cool. Such dual functionality ensures that you perform at your peak, irrespective of temperature fluctuations.

Sustainability also plays an essential role in thermal regulation. Modern engineered fabrics often incorporate recycled materials, aligning with eco-friendly practices while maintaining high performance. By choosing sustainable options, you contribute to a healthier planet without compromising on comfort or efficiency.

Understanding the intricate balance of thermal control not only enhances your immediate comfort but also optimizes your long-term energy efficiency and performance in various conditions. This mastery of textile technology elevates your experience in both everyday activities and demanding physical endeavors.

Durability Testing

Ensuring the longevity of engineered fabrics requires rigorous durability testing to maintain their performance under various conditions.

You need to understand that durability testing isn't just a checkbox; it's a thorough process designed to evaluate how well a fabric holds up against wear and tear. This involves evaluating various aspects, with fabric abrasion being a significant focus.

By simulating real-world conditions, these tests reveal how a fabric will behave over time.

Consider these four important durability tests:

- Martindale Abrasion Test: Measures fabric's resistance to wear through repeated rubbing, providing essential data on how it withstands friction.

- Tensile Strength Test: Evaluates the fabric's ability to resist breaking under tension, ensuring it can handle significant stress without tearing.

- Pilling Resistance Test: Assesses how likely the fabric is to form small balls of fiber, which can affect both appearance and texture.

- Seam Strength Test: Determines the durability of seams under strain, important for maintaining garment integrity during use.

Stretch and Recovery

Stretch and recovery tests measure how well a fabric can return to its original shape after being stretched, guaranteeing flexibility and resilience in various applications. When you consider fabric elasticity, it's important to understand that not all materials are created equal. High-performance fabrics, especially those used in sportswear and activewear, rely on advanced stretch technology to provide comfort and functionality.

In fabric engineering, the ability to maintain shape and strength after repeated use is essential. Performance recovery is the metric that evaluates this capability. A fabric with excellent stretch and recovery properties won't sag or lose its form, even after extensive wear and washing. This is vital for athletes who demand gear that moves with them and retains its form through rigorous activities.

You should also note how modern stretch technology integrates with various fibers. Blends of spandex, elastane, and other synthetic fibers are engineered to enhance elasticity without compromising durability. This meticulous engineering guarantees that the fabric can stretch to accommodate movement and then recover, maintaining its original structure and fit. Understanding these principles allows you to choose materials that will consistently meet high-performance standards.

Breathability Standards

When you think about breathability standards, consider how moisture-wicking technologies, ventilation design techniques, and fabric permeability testing play an important role.

These factors guarantee that the fabric keeps you comfortable and dry during intense activities.

Let's explore how each of these elements contributes to enhancing fabric performance.

Moisture-Wicking Technologies

How do advanced moisture-wicking technologies ensure that your performance gear keeps you dry and comfortable? By mastering the science of sweat absorption and heat dissipation, these fabrics guarantee you perform at your peak without being weighed down by moisture or overheating.

Here's how:

- Sweat Absorption: High-performance fabrics are crafted to pull moisture away from your skin. This rapid absorption minimizes the discomfort and chafing caused by sweat.

- Heat Dissipation: Effective moisture-wicking fabrics also assist in heat dissipation. By transferring sweat to the fabric's outer layer, they help regulate your body temperature, keeping you cool during vigorous activities.

- Fiber Composition: The selection of fibers in these fabrics, such as polyester or polypropylene, is essential. These synthetic fibers are hydrophobic, meaning they repel water and push it to the surface for quick evaporation.

- Fabric Weave: The fabric's weave pattern enhances its moisture-wicking capability. A tight weave can trap moisture, while a looser weave allows for better airflow and quicker drying times.

Understanding these key elements helps you choose the right gear to stay dry and comfortable, regardless of the intensity of your activity.

Ventilation Design Techniques

Often overlooked but essential, ventilation design techniques ensure your performance gear maintains peak breathability standards. Achieving ideal airflow is vital for high-performance fabrics. You want your gear to manage heat dissipation effectively, keeping you cool when the intensity rises.

Engineers meticulously design these fabrics, focusing on material construction that enhances ventilation. By incorporating micro-ventilation structures and strategic perforations, airflow enhancement is achieved. These design elements allow air to circulate freely, preventing heat buildup and enabling efficient moisture absorption.

The key is in balancing the fabric's strength with its ability to breathe; too dense, and airflow is restricted, too light, and durability suffers. Understanding these principles empowers you to choose the best gear for any activity.

Look for fabrics featuring advanced material construction that prioritize ventilation. Technologies like mesh paneling or laser-cut perforations are excellent indicators of a garment designed with your performance in mind.

You'll notice a tangible difference in comfort and endurance when your gear is engineered to facilitate airflow enhancement and manage heat dissipation. Don't underestimate the significance of ventilation design techniques—they're your secret weapon for maintaining peak performance.

Fabric Permeability Testing

Understanding fabric permeability testing is necessary for ensuring your performance gear meets the highest breathability standards. This type of testing measures how well a fabric allows air and moisture to pass through, an important factor for comfort and performance.

When you engage in rigorous activities, your gear must manage sweat efficiently without compromising on protection.

To master fabric breathability and performance testing, you should focus on the following aspects:

- Water Vapor Transmission Rate (WVTR): This test measures the amount of water vapor that can pass through a fabric over a specific period. It's essential for determining how breathable your waterproof fabric is.

- Air Permeability: This test gauges how easily air flows through the fabric, affecting both ventilation and insulation. High air permeability can enhance comfort during high-energy activities.

- Hydrostatic Head Test: This measures how much water pressure a fabric can withstand before it leaks. It's important for evaluating waterproof fabric and ensuring it meets quality standards.

- Moisture Management Test: This assesses the fabric's ability to wick moisture away from the body and spread it across the surface for quicker evaporation.

UV Protection

Engineered fabrics offer exceptional UV protection, shielding your skin from harmful ultraviolet rays. By enhancing fabric construction and incorporating advanced design elements, these textiles block or reduce UV radiation to a great extent. You'll find that sun protection is no longer just about applying sunscreen; it's woven directly into your clothing options.

High-density weaving techniques and innovative fabric blends enhance UV resistance. For example, tightly woven fabrics create a physical barrier against UV rays, while certain synthetic fibers possess innate UV-blocking properties. Reflective finishes and dark colors can also boost sun protection, ensuring that your clothing choices are as functional as they are fashionable.

Here's a quick comparison of different fabric features:

| Feature | Description |

|---|---|

| High-density weaving | Tight weave offers excellent UV blocking |

| Synthetic fibers | Inherent UV-resistant characteristics |

| Reflective finishes | Reflects UV rays, reducing skin exposure |

Selecting garments with these engineered properties allows you to enjoy outdoor activities without compromising your skin's health. Look for clothing options specifically labeled with a UPF (Ultraviolet Protection Factor) rating to guarantee top-notch protection. By understanding the science behind fabric construction and design elements, you'll master the art of sun protection through intelligent clothing choices.

Antimicrobial Treatments

When exploring antimicrobial treatments in fabrics, you'll find various agents such as silver ions, copper, and triclosan. Understanding how these agents are applied, whether through coatings or integrated into fibers, is essential.

These treatments provide significant benefits for activewear by reducing odor and enhancing hygiene.

Types of Antimicrobial Agents

Antimicrobial treatments in engineered fabrics commonly utilize agents like silver ions, copper, and quaternary ammonium compounds to inhibit bacterial growth. By integrating these agents into fabric finishes, you enhance microbial resistance, ensuring that performance textiles remain fresh and hygienic.

- Silver Ions:

Silver ions are highly effective due to their ability to disrupt bacterial cell membranes. This antimicrobial technology is often embedded in performance textiles, offering long-lasting protection.

- Copper:

Copper works similarly to silver, but it also has antifungal properties. It's a versatile option for fabrics that need to combat a broader range of microbes.

- Quaternary Ammonium Compounds:

These compounds are known for their quick action against bacteria. They disrupt the cell walls of microbes, making them an excellent choice for fabrics requiring frequent cleaning.

- Zinc Pyrithione:

This agent is often used in moisture-wicking fabrics. It provides a durable antimicrobial finish that works well in activewear, where sweat and bacteria are prevalent.

Utilizing these agents in your fabrics' finishes not only boosts microbial resistance but also improves the overall performance of the textiles. Mastering antimicrobial technology is essential for creating advanced performance textiles that meet rigorous hygiene standards.

Application Methods Explained

Applying antimicrobial treatments to performance fabrics involves several methods that ensure the agents are effectively integrated and durable. You'll find that these methods secure the textiles maintain their protective qualities through various activities and washes.

One common method is padding, where the fabric is passed through a bath containing the antimicrobial agent and then squeezed through rollers to remove excess liquid. This technique secures even distribution. Another approach is exhaustion, which uses the principles of chemistry to bind the antimicrobial agents to the fabric fibers. This method is particularly effective for securing long-lasting effects.

Printing techniques have also evolved to incorporate antimicrobial treatments directly into design innovations. Screen printing and digital printing can apply antimicrobial agents in specific patterns, which allows for targeted protection where it's needed most.

Here's a quick overview of the methods:

| Method | Description |

|---|---|

| Padding | Fabric immersed in antimicrobial bath, then squeezed through rollers. |

| Exhaustion | Agents chemically bind to fibers during the dyeing process. |

| Screen Printing | Antimicrobials applied in patterns using a screen stencil. |

| Digital Printing | Precise application of agents using digital printers for targeted areas. |

Benefits for Activewear

These antimicrobial treatments provide significant advantages for activewear, enhancing both performance and hygiene. When you choose activewear with antimicrobial properties, you're not just opting for comfort but also for a fabric that actively works to keep you feeling fresh and dry.

Here's how:

- Odor Control: Antimicrobial treatments prevent the growth of bacteria and fungi, the main culprits behind unpleasant odors. You'll find that your clothes smell fresher for longer, even during intense workouts.

- Quick Drying: These treatments facilitate quicker drying times by reducing the fabric's moisture retention. You'll stay dry and comfortable, even during high-intensity activities.

- Enhanced Durability: By inhibiting microbial growth, these treatments help preserve the fabric's integrity, extending the lifespan of your activewear. Your investment in quality gear pays off over time.

- Hygienic Benefits: Antimicrobial fabrics reduce the risk of skin irritations and infections, providing an extra layer of protection for your skin.

Incorporating antimicrobial treatments in your activewear translates to better performance, longer-lasting gear, and superior hygiene. It's a small addition that makes a huge difference, ensuring you're always at the top of your game.

Eco-Friendly Materials

Eco-friendly materials are transforming the textile industry by decreasing environmental impact and promoting sustainability. You're probably aware that sustainable sourcing and production practices are vital to this transformation. By focusing on renewable resources and minimizing waste, the industry can create high-performance fabrics without depleting the planet's resources. For instance, sourcing organic cotton or recycled polyester greatly reduces water usage and greenhouse gas emissions.

Green certification and standards play an essential role in verifying the eco-friendliness of these materials. Certifications like GOTS (Global Organic Textile Standard) and OEKO-TEX guarantee that fabrics meet strict environmental and social criteria. These standards give you the confidence that the materials you're using are truly sustainable.

Here's a quick comparison of some popular eco-friendly fabrics:

| Fabric Type | Benefits | Common Uses |

|---|---|---|

| Organic Cotton | Reduced water use, no pesticides | T-shirts, jeans, bedding |

| Recycled Polyester | Reduces plastic waste | Activewear, outerwear |

| Hemp | Minimal water, fast-growing | Clothing, accessories |

| Tencel (Lyocell) | Biodegradable, low-impact | Dresses, shirts, home textiles |

| Bamboo | Fast-growing, renewable | Underwear, socks, sportswear |

Innovative Weaving Techniques

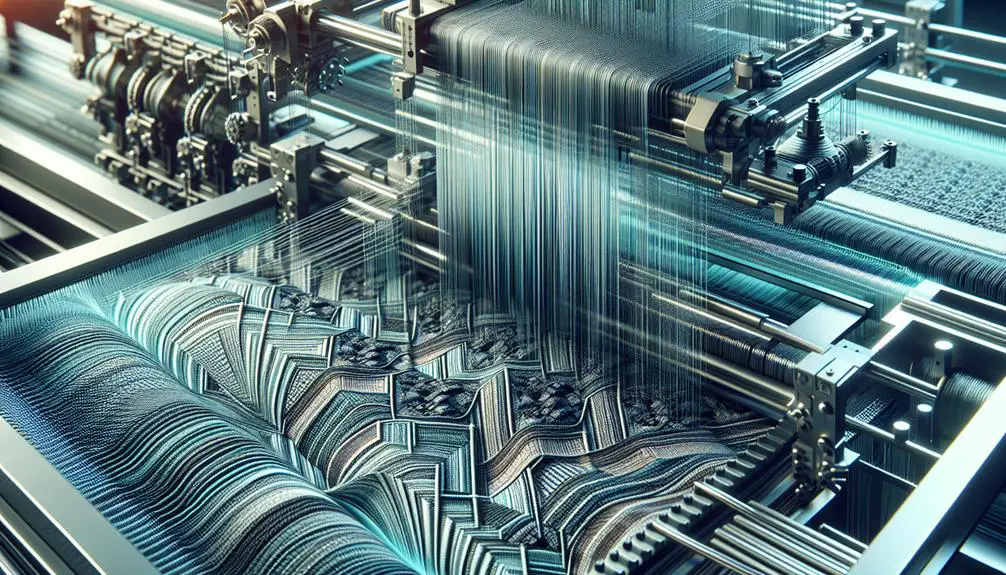

Building on the momentum of eco-friendly materials, innovative weaving techniques are revolutionizing fabric performance and versatility. By merging advanced materials with cutting-edge textile technology, you can create performance fabrics that meet and exceed modern demands.

Here's how these techniques are pushing boundaries:

- 3D Weaving: By weaving fabrics in three dimensions, you're able to create structures with enhanced durability and strength. This technique is ideal for applications requiring high resilience, such as sportswear and aerospace textiles.

- Jacquard Weaving: Leveraging computerized looms, Jacquard weaving allows for intricate, innovative designs without compromising functionality. This method lets you integrate complex patterns directly into the fabric, increasing its aesthetic and performance appeal.

- Nano-Weaving: Incorporating nanotechnology into textile production, nano-weaving enhances the fabric's properties at the molecular level. You can achieve water resistance, improved breathability, and even antimicrobial capabilities, making your fabrics more versatile and high-performing.

- Smart Textiles: Using conductive threads, smart textiles can integrate electronic components directly into the weave. This allows for the creation of fabrics that can monitor essential signs, adjust to temperature changes, or even charge devices.

Frequently Asked Questions

How Do Performance Fabrics Impact Athletic Performance?

Performance fabrics enhance your athletic performance by improving breathability and moisture-wicking, keeping you dry. They offer flexibility for unrestricted movement and durability to withstand intense activities, ensuring you stay comfortable and focused on your goals.

What Are the Costs Associated With High-Performance Fabrics?

When you conduct a cost analysis of high-performance fabrics, you'll find that the performance benefits, fabric durability, and advanced material composition justify the investment, despite higher initial costs. Quality materials offer long-term savings and enhanced results.

Are Performance Fabrics Suitable for Everyday Wear?

Yes, performance fabrics are suitable for everyday wear. You'll enjoy casual comfort and everyday durability, making them perfect for your daily activities. They combine advanced technology with style, ensuring you look and feel great all day.

How Do You Care for Performance Fabrics?

To care for performance fabrics, follow washing instructions closely and take advantage of their stain resistance. Use gentle drying techniques and avoid high heat. Ironing tips include using a low setting or avoiding ironing altogether.

What Are the Leading Brands in Performance Fabric Innovation?

When it comes to leading brands in performance fabric innovation, you've got Patagonia and Nike leading the charge. Their brand collaborations and sustainability efforts are shaping market trends and future developments, paving the way for industry mastery.

- How Does Ring Spun Cotton Affect Garment Fit and Shape Retention? - August 13, 2024

- What Are the Challenges in Producing Ring Spun Cotton? - August 13, 2024

- Is Ring Spun Cotton Suitable for Plus-Size Clothing? - August 13, 2024